Advertisement

NorthStar

™

brand

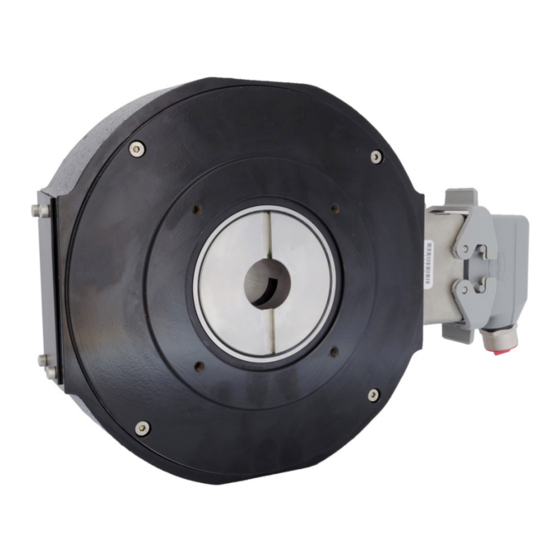

NexGen RIM Tach HT85 Encoder

Key Features

• Hollowshaft Design Mounts Easily to Large Motor

Shafts, up to 4.50" in Diameter

• New Sensor Provides up to 0.075" of Air Gap,

Over 50% More Than Competitive Models

• Expanded Resolution up to 2400PPR

• Redesigned Circuitry for On-Board Diagnostics with

LED and Alarm Output

• Multiple Bore Sizes Available, Including Tapered Shafts

• Stainless Steel and Ductile Cast Iron Construction

SPECIFICATIONS

STANDARD OPERATING CHARACTERISTICS

Code: Incremental, Magnetic

Pulses per Revolution: 60-2400 PPR

Phasing Sense: A leads B for Counter-Clockwise

rotation (CCW) viewing encoder-mounted end

Quadrature Phasing: 90° ± 45°

Symmetry: 50% ±15%

Number of Output Modules: Single or Dual

ELECTRICAL

Input Power Requirements: 5-26VDC, 95mA

typical per sensor module, plus line driver load

Output Signals: IC-WE Differential Line Driver:

150mA, sink or source

Frequency Response: 0 - 180kHz Data & Index

Noise Immunity: Tested to EN61326-1

Electrical Immunity: Reverse polarity and short

circuit protected

ELECTRICAL CONNECTIONS

Signal

Connector Pin

Common

B

A

Z*

Alarm †

Vcc (5-26 VDC)

_

B

_

A

_

Z*

Shield

* Index (Z) optional. See Ordering Information

† Alarm not available with Pigtail cable. See Ordering Information

Encoder Installation Manual

ELECTRICAL (Cont.)

Connector: 10 pin industrial duty latching, sealed

NEMA 4 &12, IP65. Optional MS3102 10 pin,

Pigtail Cable, or Latching connector on cable

extension

MECHANICAL

Bore Diameter: 1" to 4-1/2", straight or tapered

Mounting Configuration: Hollow Shaft mount

with Anti-Rotation Tether

Shaft Speed: 3,600 RPM

Shaft Length Required: 2.5" min

Acceleration Rate: 3,600 rpm/sec max

Allowable Shaft End-Play: 0.25" (Subject to

RPM Limitation)

Allowable Shaft Runout: 0.010" TIR (Subject to

RPM Limitation)

Housing Material: Cast Iron/Stainless Steel

Weight: 30 lbs

Pigtail Cable

1

Black

2

Green

3

Blue

4

Violet

5

N/A

6

Red

7

Yellow

8

Gray

9

Orange

10

Braid

MS 3102E18-IT#

A

E

D

C

F

B

H

G

I

J

ENVIRONMENTAL

Operating Temperature Range: -40°C to +85°C

Storage Temperature Range: -40°C to +120°C

Shock (Sensor Module): 30 G's Min

Vibration: 18 G's @ 5-2000 Hz spectrum

Humidity: Up to 98% (non-condensing)

CONTENTS

Specifications ........................Pg 1

Important ................................Pg 2

Mechanical Installation .........Pg 4

Sensor Module Installation ...Pg 5

Electrical Installation .............Pg 6

Dimensions ............................Pg 7

Ordering Information .............Pg 7

EN 61326-1

Page 1

Advertisement

Table of Contents

Summary of Contents for DYNAPAR NorthStar NexGen RIM Tach HT85

-

Page 1: Table Of Contents

NorthStar ™ Encoder Installation Manual brand NexGen RIM Tach HT85 Encoder Key Features • Hollowshaft Design Mounts Easily to Large Motor Shafts, up to 4.50” in Diameter • New Sensor Provides up to 0.075” of Air Gap, Over 50% More Than Competitive Models •... -

Page 2: Important

Cable - The use of shielded cable is recommended coder and should be free of induced transients. Com- for all encoder installations. When a Dynapar brand mon (also referred to as Com, supply common, and encoder is ordered, the type of termination is gener-... - Page 3 IMPORTANT INSTALLATION INFORMATION FEATURES (cont.) LED STATUS LIGHT: When encoders have a differential line driver, there A multicolor LED Status light will indicate to the user are two signals for each of the outputs. Each signal the overall condition of the encoder. The LED is built (A, B and Z) has a compliment or inverse (A, B and Z into the encoder and does not require any additional referred to as A not, B not, and Z not).

-

Page 4: Mechanical Installation

INSTALLATION 1.0 MECHANICAL INSTALLATION 4. Tighten the clamping ring segment as follows (see The RIM Tach® HT85 is shipped partially assembled. Figure 2): There are no field gap checks, axial alignment, or 1) Look inside the access plate hole and rotate run out checks required. -

Page 5: Sensor Module Installation

1.1 SENSOR MODULE INSTALLATION To install the Sensor Module, perform the following steps. See Figure 4. 1. Remove sensor module and mating connector from packaging. 2. Separate mating connector from sensor module by releasing the two latches. Figure 3: Anti-Rotation Arm Orientation 3. -

Page 6: Electrical Installation

1.2 ELECTRICAL INSTALLATION 4. Mate connector into place on sensor mount and IT IS VERY IMPORTANT that the mating connector snap the two latches into place. If only one sensor is and the encoder body be isolated from electrical being installed, ensure cover plate is installed over ground in the wiring and conduit to prevent motor or other sensor hole. -

Page 7: Dimensions

Fax: +1.847.662.4150 Fax: +1.847.662.4150 Uhlandstrasse 49, 78554 Aldingen WWW.DYNAPAR.COM custserv@dynapar.com northstar.techsupport@dynapar.com www.hengstler.com Headquarters: 1675 Delany Road • Gurnee, IL 60031-1282 • USA NorthStar™ brand is a trademark of DYNAPAR. All rights reserved. Document No. 703284-0001, Rev. A ©2020 DYNAPAR Page 7...

Need help?

Do you have a question about the NorthStar NexGen RIM Tach HT85 and is the answer not in the manual?

Questions and answers