Table of Contents

Advertisement

Quick Links

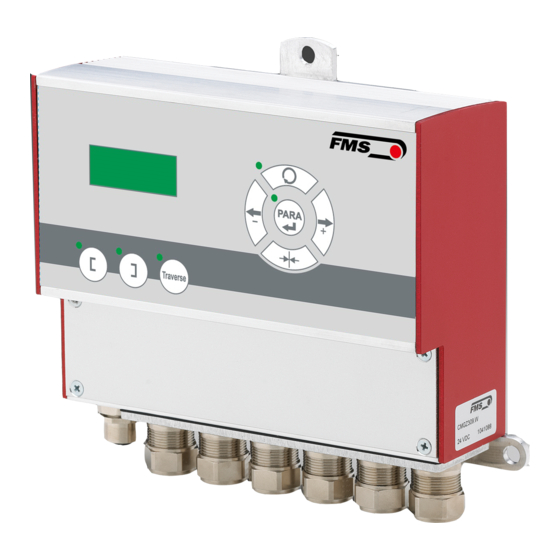

Operating Manual BKS309

Digital Web Guide Controller

Document Version

2.60

07/2019 NS

Firmware Version

V3.00

Diese Bedienungsanleitung ist auch in Deutsch erhältlich.

Bitte kontaktieren Sie Ihren nächstgelegenen FMS Vertreter.

© by FMS Force Measuring Systems AG, CH-8154 Oberglatt – Alle Rechte vorbehalten.

Advertisement

Table of Contents

Summary of Contents for FMS BKS309 Series

- Page 1 Operating Manual BKS309 Digital Web Guide Controller Document Version 2.60 07/2019 NS Firmware Version V3.00 Diese Bedienungsanleitung ist auch in Deutsch erhältlich. Bitte kontaktieren Sie Ihren nächstgelegenen FMS Vertreter. © by FMS Force Measuring Systems AG, CH-8154 Oberglatt – Alle Rechte vorbehalten.

-

Page 2: Table Of Contents

Material sensors ..........................6 QUICK INSTALLATION GUIDE ........................ 7 Configuration ............................7 INSTALLATION AND WIRING ........................8 Installation of a steering frame of the FMS-webMASTER series ............8 5.1.1 Installation of the material sensor ....................8 5.1.2 Alignment of the material sensors ....................9 ELECTRICAL CONNECTION ........................ -

Page 3: Safety Instructions

Operating Manual Web Guide Controller BKS309 2 Safety instructions All safety related regulations, local codes and instructions that appear in the manual or on equipment must be observed to ensure personal safety and to prevent damage to the equipment connected to it. If equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. -

Page 4: Product Information

Operating Manual Web Guide Controller BKS309 3 Product information 3.1 Functional Description The sensors measure the position of the web edge and send this information as an analogue signal to the electronic control unit. In our case a BKS309 web guide controller. -

Page 5: Order Code And Variations Of The Web Guide Controller Bks309

(see operating manual BKS309.EIP) To control one or two motorized traverses (see operating manual BKS309.W.M) To control Chase-and-Follow applications (see operating manual BKS309.W.MS) To control actuators with DC motor, FMS-winderGLIDE BKS.D.7 .ACV Power supply 110 bis 240VAC Table 2: overview variations 23.07.2019... -

Page 6: Steering Frames, Steering Rollers Or Actuators

Table 3: BKS309 variations and options 3.4 Steering frames, steering rollers or actuators Steering frames of the FMS-webMASTER series consist of a fixed lower and a moveable upper frame that supports the rollers. The upper frame is activated by a motor. The rollers are manufactured and balanced according to customer specification. -

Page 7: Quick Installation Guide

Operating Manual Web Guide Controller BKS309 4 Quick Installation Guide The set-up of the BKS309 web guide controller and corresponding web guide is limited to only mounting the devices on the machine frame, wiring and powering up system. 4.1 Configuration Read the operating manual of your web guide or actuator system. -

Page 8: Installation And Wiring

Operating Manual Web Guide Controller BKS309 5 Installation and wiring 5.1 Installation of a steering frame of the FMS-webMASTER series The mounting orientation of the steering frame (indicated by an arrow), must correspond with the direction of the moving web. The lower frame is mounted with four M8 screws to the machine frame. -

Page 9: Alignment Of The Material Sensors

Operating Manual Web Guide Controller BKS309 Description Position Description Web entry side Web exit side Direction of the moving web Material sensor, sensor axis Material sensor, sensor axis left Web edge left Web edge right Material sensor, sensor axis right Integrated web guide controller BKS309.S (optional) Table 4: description Material sensors have to installed on the web exit side... - Page 10 Operating Manual Web Guide Controller BKS309 Description Position Description Web edge Sensor axis Deviation of web edge from sensor axis Detection range of material sensor Center mark of the detection range Figure 5: Material sensors Loosen the clamp Align sensor axis to the web edge Slide the sensor in the new position.

-

Page 11: Electrical Connection

Operating Manual Web Guide Controller BKS309 6 Electrical connection Ground connection Insufficient ground connection may cause electric shock to persons, malfunction of the total system or damage of the control unit! It is vital to ensure that there is a proper and secure earth connection. 6.1 Web guide controller BKS309 Figure 6: electrical connection BKS309_BA_manual.ai... -

Page 12: Material Sensors

Operating Manual Web Guide Controller BKS309 6.2 Material sensors Figure 7: electrical connection material sensors BKS309_BA_manual.ai 6.3 Steering frame BKS020.EE and BKS015.EE with external web guide controller BKS309 Figure 8: electrical connection BKS020.EE and BKS015.EE BKS309_BA_manual.ai 23.07.2019... -

Page 13: Steering Frame Fms-Webmaster Bks030 Or Actuators Fms-Winderglide Bks.d.3 Or Bks

Operating Manual Web Guide Controller BKS309 6.4 Steering frame FMS-webMASTER BKS030 or actuators FMS- winderGLIDE BKS.D.3 or BKS.D.4 Figure 9: electrical connection BKS030, BKS.D.3, BKS.D.4 BKS309_BA_manual.ai 6.5 Actuator FMS-winderGLIDE BKS.D.7 Only in combination with BKS309.R.DC or BKS309.W.DC The use of any other web guide controller will lead to damage or destruction of the components. - Page 14 Operating Manual Web Guide Controller BKS309 Figure 10: electrical connection BKS309.DC (.R and .W) BKS309_BA_manual.ai Figure 11: electrical connection BKS.D.7 BKS309_BA_manual.ai 23.07.2019...

-

Page 15: Operation And Configuration

Operating Manual Web Guide Controller BKS309 7 Operation and configuration Figure 12: Operating panel BKS309_BA_manual.ai Description Position Description LED operating status, on if in automatic mode Center guiding Edge guiding right Edge guiding left Toggle from automatic to manual mode Configuration menu Manually drive right, increase value Manually drive left, decrease value... - Page 16 Operating Manual Web Guide Controller BKS309 Description button Function The sensor is mounted on the left side of the frame and controls the material on the left edge or on the line, if a line sensor is used. One sensor is necessary. The LED indicates the left edge guiding mode. The sensor is mounted on the right side of the frame and controls the material on right edge or on the line, if a line sensor is used.

-

Page 17: Automatic Mode

Operating Manual Web Guide Controller BKS309 Flashing LED with connected line sensor If a digital line sensor is used, it may happen that the web guide controller blocks the steering frame. This protective function is activated when the line is interrupted and impossible to detect anymore. -

Page 18: Approaching And Saving Dedicated Positions

Operating Manual Web Guide Controller BKS309 If key is held, steering frame is moving continuously. These functions can also be carried out via the digital inputs 7.3 Approaching and saving dedicated positions There are two possibilities to alter the values of the Home Position, Middle Position and Maximum Positions of the actuator. -

Page 19: Configuration Via Operating Panel

Operating Manual Web Guide Controller BKS309 8 Configuration via operating panel 8.1 Operating parameters To access the meu for the operating parameters the web guide controller must be in the manual mode. Press the key for longer than 3 sec. The LED will be on and the first parameter will be displayed. - Page 20 Operating Manual Web Guide Controller BKS309 Description Parameter Unit Selection Factory Relay 1 or Relay 1 MidSenso Relay 2 MidSenso Relay 2 MatFound setting Auto&Mat Aut&Miss MatFound Auto Centre Disabled Digital Input 1 Edge→Aut Input 1, 2, Lv→Auto Edge→Aut Input 2 3 or 4 Centre I2=Center...

- Page 21 Operating Manual Web Guide Controller BKS309 Description Parameter Unit Selection Factory Power Power ON Manual Manual Modes Auto Last Set Behavior Auto→Ma Manual Manual when Centre leaving Automatic Mode Home Home Pos 300.0 Position Middle Mid Pos 300.0 62.5 Position Maximal Max Pos 300.0...

-

Page 22: Description Of Operating Parameters

Operating Manual Web Guide Controller BKS309 8.3 Description of operating parameters Adjust Reference Position [Ref Pos] Purpose: The reference position can be adjusted using this parameter. Range: -5.00 to +5.00 Default: 0.00 Increment: 0.01 Unit: [mm] Set Reference Mode [Ref Mode] Purpose: This parameter determinates how the reference position is defined. - Page 23 Operating Manual Web Guide Controller BKS309 Note: The two parameters [RefMode] and [SafeRef] are conditionally dependent on each other. If you require one of both functions, either set [RefMode] to [Auto] or [SafeRef] to [Yes] . Do not activate both functions simultaneously! Dead band [DeadBand] Purpose: This parameter defines the dead band tolerance.

- Page 24 Operating Manual Web Guide Controller BKS309 [Disabled] Setting: Purpose: If [Disabled] is chosen then the relay function is disabled. The relay will never go on. Digital Input 1, 2, 3 or 4 Modes [Input 1…4] These are actually fore parameters one for each digital input Purpose: This parameter determines the functions of the digital inputs.

- Page 25 Operating Manual Web Guide Controller BKS309 Dig. Input Lock, Operation State Automatic and Parameter Auto→Man work in a combinative manner. Their interdependency is described in the following table: Dig. In. Op. State Parameter Function Lock Automatic Auto→Man inactive Centre Move to middle position active irrelevant Automatic operation...

- Page 26 Operating Manual Web Guide Controller BKS309 Password Purpose: The web guide controller can be protected from unauthorized access by means of password. If Password Yes is chosen, the system will request the password to change parameters and other setting. The password itself can’t be changed.

- Page 27 Operating Manual Web Guide Controller BKS309 [Imperial] Setting: Purpose: If [Imperial] is chosen, the controller shows all data in imperial units. Gain Setting [Gain] Purpose: This parameter defines the gain of the feedback value. Range: 0.02 to 2.00 Default: 0.20 Increment: 0.01 Unit:...

- Page 28 Operating Manual Web Guide Controller BKS309 Purpose: The controller stops guiding. Afterwards the motor drive moves to the center. Home Position [Home Pos] Purpose: This parameter determines the position of the actuator spindle in its retracted position. An actuator stops at this position and moves no further backwards.

- Page 29 Operating Manual Web Guide Controller BKS309 Actuator [Actuator] Purpose: The parameter [Actuator] determines the control logic of the web guide controller BKS309. Condition: This parameter appears on the display only if an actuator / winderGLIDE is connected to the controller. The user can choose between two control directions.

-

Page 30: System Parameters

Operating Manual Web Guide Controller BKS309 [Not Set] Action: Purpose: If [Not Set] is chosen, all parameters stay as set by the user. [Yes] Action: Purpose: If [Yes] is chosen, the default parameters are loaded. 8.4 System parameters To access the menu for system parameters, the web guide controller must be in the Manual Mode. -

Page 31: Description Of System Parameters

2) The display shows the unit of measure that was previously selected. 3) Parameter only used in FMS-winderGLIDE series of the sizes BKS.D.3, BKS.D.4 und BKS.D.7. If you are using an actuator of the FMS-winderGLIDE series BKS.D.4 you have to use the system parameters similar to the BKS.D.3... - Page 32 Operating Manual Web Guide Controller BKS309 Offset Centre [Offset><] Purpose: This parameter adjusts the position of a steering frame exactly to the centre. Position Detection [PosDetec] Purpose: This parameter determines what devices that are used to detect the limit positions. The user can choose between three types.

- Page 33 Setting: Purpose: Invers] is chosen when motors are used that turn anticlockwise. If a FMS actuator of the type winderGLIDE is used, the controller sets the drive direction automatically. Actuator Type [winderGL] This parameter determines the used actuator type. The product name Purpose: of FMS actuators is winderGLIDE.

-

Page 34: Reset To Factory Settings

Operating Manual Web Guide Controller BKS309 Setting: 5’000 Default: 80 Increment: unit: [ms] 8.7 Reset to factory settings Factory settings of your BKS309 web guide controller can be reset either via the operating parameter menu. Alternatively, you can follow the procedure below Holding the two buttons while powering–up the controller. -

Page 35: Configuration Via Web Browser

Operating Manual Web Guide Controller BKS309 9 Configuration via web browser The BKSZ309 web guide controller can be embedded in an Ethernet network and the parameter setting can be done over this network by means of a web browser (Internet Explorer 7). - Page 36 Operating Manual Web Guide Controller BKS309 Figure 14: Home Home.jpg The main navigation is on the left-hand side of the window. Figure 15: Remote Control Remote Control 23.07.2019...

- Page 37 Operating Manual Web Guide Controller BKS309 Figure 16: list of operating parameters Figure 17: list of operating parameters for actuators of the FMS-winderGLIDE series 23.07.2019...

- Page 38 Operating Manual Web Guide Controller BKS309 Figure 18:Ethernet Settings Figure 19: Firmware 23.07.2019...

-

Page 39: Peer-To-Peer Connection

Operating Manual Web Guide Controller BKS309 9.1 Peer-to-Peer connection The parameter setting can also be carried out with a desktop or laptop computer directly connected to the BKS309 Controller. Figure 20: Peer-to-peer Before the parameterization of the BKS309 it must be certain that the BKS309 uses an IP address in a static block. - Page 40 Operating Manual Web Guide Controller BKS309 Double click on “Local Area Network”. The dialog box “Status of LAN connection” will open up. Click on Properties On the next dialog box select the network adapter that is used for the connection. In our case “Internet protocol version 4 (TCP/IP)”...

- Page 41 Operating Manual Web Guide Controller BKS309 Select the radio button “Use the following IP address:” Enter the IP address for the computer that could be 192.168.0.1 In the Subnet mask, enter 255 255 255 000, as shown above. Click the “OK” button. Close all windows Start your web browser (Microsoft Internet Explorer, Mozilla Firefox or similar) The default IP address for the BKS309 is 192.168.000.090 as long as it was not...

-

Page 42: Dimensions

Operating Manual Web Guide Controller BKS309 10 Dimensions Figure 21: dimensions BKS309.W – Wall mount BKS309_BA_Manual.ai 23.07.2019... - Page 43 Operating Manual Web Guide Controller BKS309 Figure 22: dimensions BKS309.R - DIN-rail BKS309_BA_Manual.ai 23.07.2019...

- Page 44 Operating Manual Web Guide Controller BKS309 Figure 23: dimensions BKS309.S – panel integrated BKS309_BA_Manual.ai 23.07.2019...

-

Page 45: Technical Data

Operating Manual Web Guide Controller BKS309 11 Technical data Description Cycle time processor Drive of steering frame Stepper motor. Power amplifier 24V integrated in housing Dead band 0 to 2mm, adjustable in 0.1mm steps Position reference ±5mm, adjustable in 0.1mm steps Control modes edge left / edge right / center guiding / line guiding Interface... -

Page 46: Trouble Shooting

No signal; cable Replace cable or send sensor to interruption No signal; sensor defect Send sensor to FMS; use other sensor No response of Wiring not correct Check wiring the interface Display shows... - Page 47 Operating Manual Web Guide Controller BKS309 23.07.2019...

- Page 48 Operating Manual Web Guide Controller BKS309 FMS Force Measuring Systems AG FMS USA, Inc. FMS (UK) FMS (Italy) Aspstrasse 6 2155 Stonington Avenue Suite 119 Aspstrasse 6 Aspstrasse 6 8154 Oberglatt (Switzerland) Hoffman Estates,, IL 60169 (USA) 8154 Oberglatt (Switzerland) 8154 Oberglatt (Switzerland) Tel.

Need help?

Do you have a question about the BKS309 Series and is the answer not in the manual?

Questions and answers