Summary of Contents for Lister Petter GW3

- Page 1 GAMMA SERIES GW3, GWT3, GW4, GWT4, GWT6-1A GWT6-2A, GWTA6 ENGINEs OpErATOrs' HANdbOOk ORIGINAL INSTRUCTIONS P027-08199...

- Page 2 This Company does not guarantee that the same results will be obtained elsewhere under different conditions. Parts that have not been approved by the Lister Petter Power Systems organisation cannot be relied upon for correct material, dimensions or finish. The Company cannot therefore be held responsible for any damage arising from the use of such parts, and the guarantee will be invalidated.

-

Page 3: Table Of Contents

CONTENTS INTRODUCTION ....................6 Engine Identification Engine lifting Care of your engine Service literature Training 1. SAFETY INFORMATION AND PRECAUTIONS ..........8 1.1 Personal Safety 1.2 General Precautions 1.3 Care with Lubricating Oil 1.4 Precautions with Diesel Fuel 1.5 Precautions with Coolant 1.6 Precautions with Batteries Battery Charge Alternator 1.7 Care with Electrical Systems... - Page 4 3.4 Running-In 3.5 Altitude 4. ENGINE FLUIDS ..................20 4.1 Fuel Specification 4.1.1 Low Temperature Fuels 4.2 Lubricating Oil Specification 4.3 Coolant Specification 5. ROUTINE MAINTENANCE ................23 5.1 Maintenance Schedule 5.2 Draining the Cooling System 5.3 Checking the Drive Belts 5.3.1 Adjusting the Belt Tension 5.4 Cleaning the Fuel Lift Pump 5.5 Checking the Fuel Pre-Filter...

- Page 5 GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.13 Checking Valve Clearances 5.13.1 Three Cylinder Engines 5.13.2 Four Cylinder Engines 5.13.3 Six Cylinder Engines 5.13.4 Valve Positions 6. FAULT DIAGNOSIS ..................41 6.1 Problems and Possible Causes 6.2 Code List of Possible Causes 7.

-

Page 6: Introduction

Ensure that all adjustments and repairs are done by properly trained personnel. Your Lister Petter Power Systems distributor can assist in this matter and will also supply the genuine Lister Petter Power Systems parts needed for your engine. -

Page 7: Engine Lifting

If faults do occur they can usually be diagnosed and corrected using the information in section 6. In case of queries about your engine or its installation contact your Lister Petter Power Systems distributor. Your distributor can undertake repairs and will ensure that only the correct parts are fitted and the work is done correctly. -

Page 8: Safety Information And Precautions

Follow all safety instructions accurately. 1. Safety Symbols This fi gure identifi es the ISO 8999 symbols currently used by Lister Petter 1. This figure identifies the ISO 8999 symbols currently used by Lister Petter Power Systems. -

Page 9: Personal Safety

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 1.1 pERSONAl SAfETY • Ensure that you have access to fire extinguishers and have knowledge of emergency procedures. • Identify a location from which calls to the emergency services can be made if necessary. • Ensure that someone knows where you are working and is informed when you leave the working area. - Page 10 GAMMA SERIES ENGINES OpERATORS' hANdbOOk • Use these engines only in the type of application for which they have been designed. • Ensure the engine is securely mounted. • Ensure that the area around the engine is well ventilated. WARNING LACK OF VENTILATION CAN RESULT IN THE BUILD-UP OF TOxIC, AND POTENTIALLY FATAL, EMISSIONS.

-

Page 11: Care With Lubricating Oil

GAMMA SERIES ENGINES OpERATORS' hANdbOOk WARNING Do not expose pressurised containers to heat. Do not incinerate or puncture them. • Fit only genuine Lister Petter Power Systems parts. 1.3 CARE WITh lubRICATING OIl • Wear gloves or barrier cream. •... -

Page 12: Precautions With Batteries

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 1.6 pRECAuTIONS WITh bATTERIES Batteries contain hazardous sulphuric acid. Great care therefore needs to be taken when using them. WARNING BATTERY ACID IS HIGHLY CORROSIVE AND POISONOUS, AND WILL BURN SKIN AND CLOTHING. IT WILL CAUSE PERMANENT DAMAGE, INCLUDING BLINDNESS, IF SPLASHED INTO THE EYES. -

Page 13: Care With Electrical Systems

1.8 lIfTING pRECAuTIONS The engine lifting eyes are suitable for lifting only the engine and accessory assemblies originally fitted by Lister Petter Power Systems. They must not be used to attempt to lift an entire generating set. 1.8 Lifting a Gamma series engine using overhead lifting eyes. -

Page 14: Care With Filters And Elements

GAMMA SERIES ENGINES OpERATORS' hANdbOOk Preparations required before lifting an engine: • Check that the lifting eyes or lugs are not damaged and ensure they are secure. Note: The torque setting for the lifting eyes is 44 Nm (33 ft Ib or 4.5 kgf m). •... -

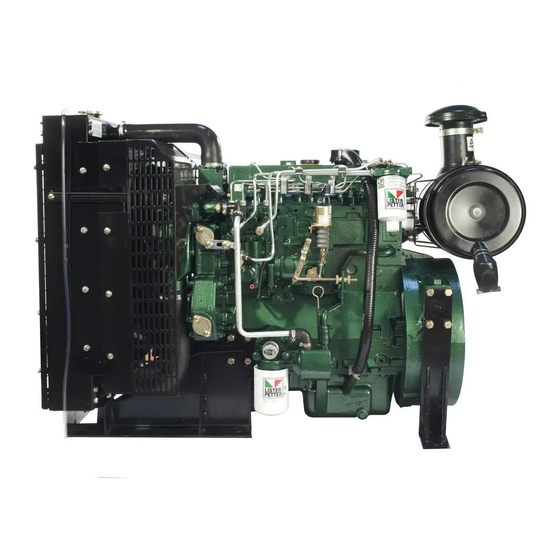

Page 15: Engine Parts And Technical Data

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 2. ENGINE pARTS ANd TEChNICAl dATA Lister Petter Power Systems engines are built for many applications. The views which follow do not necessarily match your engine specification. 2.1 fRONT ANd lEfT SIdE 2.2 REAR ANd RIGhT SIdE 1. - Page 16 TeCHNICAL dATA Engine cycle 4-stroke Cylinder arrangement Inline General Engine Data Anti clockwise viewed from Direction of rotation flywheel end GW3, GW4 Naturally aspirated Induction System GWT3, GWT4, GWT6 Turbocharged GWTA6 Turbocharged and Intercooled Bore (nominal) 100 mm (3.94 in.)

-

Page 17: Operating Instructions

Diesel engines need a cold start aid in very cold conditions. Normally, your vehicle or your machine will be fitted with the correct equipment for your region of operation. Lister Petter Power Systems engines can be equipped with various cold starting systems. For the Gamma engine range these systems are: •... -

Page 18: Starting A Cold Engine With Starting Aids

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 3. Turn the start key to the start position (S) to engage the starter motor (Figure 3.1.2). Allow the key to return to position R when the engine starts. Adjust the speed control to get an even idle speed. 4. -

Page 19: Running-In

Information for turbocharged engines can be obtained from Lister Petter Power Systems. Changes to the settings of the fuel injection pump must be made by a Lister Petter Power Systems distributor or by an approved distributor for the fuel injection pump. -

Page 20: Engine Fluids

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 4. ENGINE fluIdS 4.1 fuEl SpECIfICATION To get the correct power and performance from your engine, use good quality fuel. The recommended fuel specification for Lister Petter Power Systems engines is indicated below. FUeL SPeCIFICATION Factor... -

Page 21: Lubricating Oil Specification

Figure 4.2. For advice on adjustments to an engine setting or to the lubricating oil change periods which may be necessary because of the standard of available fuel, consult you nearest Lister Petter Power Systems distributor. 4.2 Oil viscosity... -

Page 22: Coolant Specification

• If possible, use clean soft water in the coolant mix. If an antifreeze mixture other than that recommended by Lister Petter Power Systems is used, it must be ethanediol (ethylene glycol) based with a corrosion inhibitor. It is recommended that the corrosion inhibitor is of the sodium nitrite/ sodium benzoate type. -

Page 23: Routine Maintenance

GAMMA SERIES ENGINES OPERATORS' HANDBOOK GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5. ROUTINE MAINTENANCE 5. ROuTINE MAINTENANCE 5.1 MAINTENANCE SCHEDULE frequent maintenance than those with average running times. The Routine maintenance should 5.1 MAINTENANCE SChEdulE intervals are therefore expressed undertaken regularly at the intervals Routine maintenance should be undertaken regularly at the intervals stated both as running hours and as months. -

Page 24: Draining The Cooling System

GAMMA SERIES ENGINES OpERATORS' hANdbOOk The intervals apply only to engines operating under normal conditions and using fuel and lubricating oil that conform to the specifications given in this handbook. If the engine is running in dusty or otherwise adverse conditions, the maintenance intervals must be more frequent. -

Page 25: Checking The Drive Belts

GAMMA SERIES ENGINES OPERATORS' HAND GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.3 CHECKING THE DRIVE 4. Open the tap or remove the drain plug at the bottom of the radiator in order to BELTS drain the radiator. If the radiator does not have a tap or a plug, disconnect the Always renew a belt if it is worn or hose at the bottom of the radiator. -

Page 26: Cleaning The Fuel Lift Pump

renew a belt if it is worn or GAMMA SERIES ENGINES OpERATORS' hANdbOOk GAMMA SERIES ENGINES OPERATORS' HANDBOOK belts are fitted, they must be d together. ure maximum belt life, it is ECKING THE DRIVE mended that a belt tensioner is used to check the belt renew a belt if it is worn or Fit the gauge (Figure 5.3) at... -

Page 27: Checking The Fuel Pre-Filter

5.6 Fuel filter element types 5.6 Fuel filter element types CAuTION It Is Important that only genuine Lister Petter Power Systems fuel filter elements are used. The wrong element can damage the fuel injection pump. 5.6.1 Renewing a Separate Type fuel filter Element Refer to Figure 5.6.1. -

Page 28: Renewing A Canister Type Fuel Filter Element

engines are fitted with a pre- The filter can have one or two he same main type as the fuel elements. ment (see 5.6 below). This will When twin elements are fitted both y be fitted between the fuel tank GAMMA SERIES ENGINES OpERATORS' hANdbOOk the elements must be renewed at the engine and is connected to the... -

Page 29: Renewing A Quick Release Canister Type Fuel Filter Element

GAMMA SERIES ENGINES OPERATORS' HANDBOOK GAMMA SERIES ENGINES OPERATORS' HANDBOOK the outside surfaces of the fuel 5.6.2 Renewing a canister type fuel filter GAMMA SERIES ENGINES OpERATORS' hANdbOOk n the outside surfaces of the fuel 5.6.2 Renewing a canister type fuel filter element. -

Page 30: Renewing A Fuel Injector

filter head (see arrow). from the fuel injection pump 7.Fit the clamp ring and turn it fully to bend the pipe. If necessary, the right to fasten the canister to the the pipe clamps. filter head. GAMMA SERIES ENGINES OpERATORS' hANdbOOk 3. -

Page 31: Eliminating Air From The Fuel System

GAMMA SERIES ENGINES OpERATORS' hANdbOOk washer. Ensure the fuel leak-off connection is not toward the engine. Fit the flange and engage the flange setscrews. Ensure the injector is not tilted and tighten the flange setscrews evenly and gradually to 12 Nm (9 lbt ft or 1.2 kgfm). CAuTION Do not tighten the nuts of the high-pressure pipes more than the recommended torque. - Page 32 eliminated before the engine can be which is fitted on the top of the fitter (1). started. Air can enter the system if: which is fitted on the top of the fitter (1). started. Air can enter the system if: 2.Operate the priming lever on the fuel •...

-

Page 33: Method Using In-Line Pb Type Injection Pump

5.8.2 Method Using In-Line PB Type at point of maximum cam lift it will not 5.8.2 Method Using In-Line PB Type nt of maximum cam lift it will not be possible to operate the priming Injection Pump ossible to operate the priming lever. -

Page 34: Changing The Lubricating Oil

The canister contains a valve and special tube to ensure that lubricating oil does ure section of the fuel system. not drain from the filter. Therefore, ensure that the correct Lister Petter Power CAUTION k this and rectify if necessary. -

Page 35: Cleaning The Breather System

Therefore, ensure that sposed of in a responsible GAMMA SERIES ENGINES OpERATORS' hANdbOOk the correct Lister Petter canister r and in accordance with local is used. ty guidelines. HANGING THE CATING OIL o Figure 5.9. -

Page 36: Servicing The Air Cleaner

a tray under the filter to collect wash it with clean kerosene. ubricating oil. 3.Wash the breather body with clean ve the filter canister with a strap kerosene. GAMMA SERIES ENGINES OpERATORS' hANdbOOk ch or similar tool. Ensure that 4.lf necessary, renew the O-ring (3). daptor (Figure 5.10) is secure filter head, and then discard anister. -

Page 37: Air Filter

Figure 5.12 A typical wet type air cleaner. GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.12.1 Air Filter Environmental conditions have an 5.12.1 Air filter important effect on the frequency at Environmental conditions have an important effect on the frequency at which the which the air filter needs service Figure 5.12.2 Air filter with dust va air filter needs service. -

Page 38: Restriction Indicator

GAMMA SERIES ENGINES OPERATORS' HANDBOOK GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.13.1 Three Cylinder Engine removed for service 5.12.2 Restriction Indicator After a clean element has been fitted, 1.Remove the cover plate The restriction indicator for these engines must work at a pressure difference of press the rubber bottom (3) of the window of the flywheel hou GAMMA SERIES ENGINES OPERATORS' HANDBOOK... -

Page 39: Four Cylinder Engines

4.Repeat the procedure for the remaining valves following the firing order (3 cylinder engines have firing order 1 - 2 - 3). GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.Replace the rocker cover ensuring 5.12.3 Restriction indicator: (1) that the rocker cover gasket is in window and No.1 piston in the compression stroke (both valves fully closed). -

Page 40: Six Cylinder Engines

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 5.13.3 Six Cylinder Engines The sequence of valves from number 1 cylinder is shown in the table below. Number 1 cylinder is at the front of the engine (fan and gear end). VALVe POSITIONS Cylinder and Valve Number GAMMA SERIES ENGINES OPERATORS' HANDBOOK Valve: I=Inlet;... -

Page 41: Fault Diagnosis

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 6. fAulT dIAGNOSIS 6.1 pROblEMS ANd pOSSIblE CAuSES See table below, in conjunction with 6.2 Code List of Possible Causes opposite. FAULT dIAGNOSIS Possible Cause Problem Checks by Operator Checks by Workshop Personnel The starter motor turns the engine 1, 2, 3, 4 None too slowly... -

Page 42: Code List Of Possible Causes

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 6.2 COdE lIST Of pOSSIblE CAuSES Checks by the Operator Checks by Workshop personnel 1. Battery of low capacity 33. Fault in fuel injection pump 2. Bad electrical connections 34. Broken drive on fuel injection pump 3. -

Page 43: Engine Storage

If the above procedure is carried out correctly, there should be no damage due to corrosion . Lister Petter Power Systems are not responsible for damage which may occur when an engine is in storage after a period of service. -

Page 44: Maintenance Record

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 8. MAINTENANCE RECORd Your Lister Petter Power Systems engine must be properly maintained using the intervals and procedures described in this manual. You must be familiar with the routine tasks set out in 5.Routine Maintenance, and their correct frequency set out in 5.1 Maintenance Schedule. - Page 45 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor / Dealer Stamp Date...

- Page 46 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor / Dealer Stamp Date...

- Page 47 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor / Dealer Stamp Date...

-

Page 48: Non-Routine Maintenance

GAMMA SERIES ENGINES OpERATORS' hANdbOOk 8.2 NON-ROuTINE MAINTENANCE Hours run Work done by Details of service Distributor / Dealer Stamp Date... - Page 49 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor/Dealer Stamp Date...

- Page 50 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor/Dealer Stamp Date...

- Page 51 GAMMA SERIES ENGINES OpERATORS' hANdbOOk Hours run Work done by Details of service Distributor/Dealer Stamp Date...

-

Page 52: Warranty

• The installation should be in accordance with data supplied by the Lister Petter Power Systems Applications Department. • Long term light load and cold engine running will invalidate the warranty. -

Page 53: Limitations Of Warranty

(see note 1). 9.4 REpAIRS uNdER WARRANTY Lister Petter Power Systems must be contacted and authorisation given before any warrantable work is commenced. 9.4.1 Contact details Head Office... -

Page 54: Appendix: Fuel Pumps And Governors

GAMMA SERIES ENGINES OPERATORS' HANDBOOK GAMMA SERIES ENGINES OpERATORS' hANdbOOk APPENDIX: FUEL PUMPS AND AppENdIx: fuEl puMpS GOVERNORS ANd GOvERNORS PB fuel pumps, RSV governors and PB PUMP electronically controlled governors are PB fuel pumps, RSV governors and electronically controlled governors are applied Characteristics of PB fuel pumps are: applied on certain of the diesel engines on certain of the diesel engines manufactured for the Gamma engine series. -

Page 55: Adjustment And Use Of The Pb Pump

GAMMA SERIES ENGINES OpERATORS' hANdbOOk AdjuSTMENT ANd uSE Of ThE pb puMp 1. Important adjustment of the pump should only be carried out on a special test bench by trained personnel. AdjuSTMENT Of STATIC fuEl SupplY Advanced Angle of Inline pump 1. -

Page 56: Rsv Governor - Pb Pump

GAMMA SERIES ENGINES OPERATORS' HANDBOOK GAMMA SERIES ENGINES OpERATORS' hANdbOOk RSV GOVERNOR - PB PUMP governor lever is equal to the torque RSv GOvERNOR - pb puMp The RSV governor (see figure) is of of the centrifugal force at the specified The RSV governor (see figure) is of the mechanically eccentric type. -

Page 57: Rotary Type Fuel Pumps

GAMMA SERIES ENGINES OpERATORS' hANdbOOk ROTARY TYpE fuEl puMpS Stanadyne rotary pumps DB2 and DB4 are used on certain engine models within the Gamma range. These have mechanical governing (except GWTA6 engines) and incorporate an electrical shut off solenoid. Characteristics of the DB2 / DB4 pump are: 1. -

Page 58: Electronic Governor

GAMMA SERIES ENGINES OPERATORS' HANDBOOK ELECTRONIC GOVERNOR GAMMA SERIES ENGINES OpERATORS' hANdbOOk The figure below gives a basic the high pressure fuel pump rack illustration principle on the engine, thus control ling fuel ElECTRONIC GOvERNOR electronic speed governing. delivery to the engine and hence The figure below gives a basic illustration on the principle of electronic speed solenoid actuator is an actuator of controlling engine speed. - Page 60 GAMMA SeRIeS eNGINeS OPeRATRATORS' HANdbOOk, P027-08199, edITION 4, AUGUST 2020 © LISTER PETTER POWER SYSTEMS Head Office LISTER PETTER POWER SySTEMS LIMITED Unit 14 Estuary Court, Broadmeadow Industrial Estate Teignmouth, TQ14 9FA T: +44 (0) 1285 702211 production facility LISTER PETTER POWER SySTEMS LIMITED...

Need help?

Do you have a question about the GW3 and is the answer not in the manual?

Questions and answers