Summary of Contents for Allied Vision Prosilica GB Series

- Page 1 GigE V ISION AMERAS Prosilica GB Technical Manual V2.2.6 Allied Vision Technologies GmbH Taschenweg 2a, 07646 Stadtroda, Germany 2019-Jul-08...

-

Page 2: Prosilica Gb At A Glance

Ethernet hardware and cable lengths up to 100 meters. Prosilica GB cameras are GigE Vision V1.2 compliant. Scope of delivery Your Allied Vision camera is delivered with the following components: • Prosilica GB GigE Vision camera • Quickstart Guide • Camera box. -

Page 3: Table Of Contents

Contents Contents Prosilica GB at a glance Scope of delivery ................2 What else do you need? . - Page 4 Contents Notes on specifications..............25 Frame memory .

- Page 5 Contents Out 1 (Opto-isolated)............. . . 59 Out 2 (Non-isolated) .

-

Page 6: Contact Us

Contact us Contact us Connect with Allied Vision by function www.alliedvision.com/en/meta-header/contact Find an Allied Vision office or distributor www.alliedvision.com/en/about-us/where-we-are General inquiries info@alliedvision.com Technical support support@alliedvision.com Sales offices Europe, Middle East, and Africa: +49 36428 677-0 North, Central, and South America: +1 (877) USA-1394... -

Page 7: Document History And Conventions

Document history and conventions This chapter includes: • Document history • Layout styles and symbols used in this manual • Acronyms and abbreviations and used in this manual Prosilica GB Technical Manual V2.2.6 Page 7... -

Page 8: Document History

• Various minor improvements and corrections V2.2.1 2017-Apr-07 • Added cable color to camera I/O connector pin assignment including pin assignment figure and cross reference to the Allied Vision I/O cable data sheet V2.2.0 2016-Dec-01 • Changed the technical manual layout. - Page 9 V2.1.0 2015-Mar-20 • Updated Allied Vision logo • Replaced old links with new Allied Vision website links • Changed file name from ‘GigE Camera and Driver Features’ to ‘GigE Features Reference’ • Changed chapter name from ‘Description of data path’ to ‘Camera data path’...

-

Page 10: Manual Conventions

Document history and conventions Manual conventions To give this manual an easily understood layout and to emphasize important information, the following typographical styles and symbols that are used. Styles Style Function Example Bold Program names, UI elements, highlighting bold important things Italics Publication names, UI non-interactive elements Italics... -

Page 11: Acronyms And Abbreviations

Document history and conventions Practical hint This symbol highlights a practical hint that helps to better understand the camera‘s features and functions, and to make better use of it. Further information available online This symbol highlights URLs for further information. The URL itself is shown in blue. Acronyms and abbreviations The following table provides a list of abbreviations and acronyms used in this document. -

Page 12: Compliance And Intended Use

Compliance and intended use § This chapter includes: • Compliance notifications for the following areas: - Europe • Information about application and intended use of the camera • Copyright and trademark statement Prosilica GB Technical Manual V2.2.6 Page 12... -

Page 13: Compliance Notifications

Compliance and intended use Compliance notifications For customers in Europe Allied Vision has demonstrated the fulfillment of the requirements relating to the Prosilica GB camera family: • Directive 2011/65/EU, including amendment 2015/863/EU (RoHS) Board level cameras Board level models are designed for integration and are delivered without housing on customer's request. -

Page 14: Use In Medical Devices

• The camera-supporting software can be obtained and installed separately from the camera. Usage of the software is solely the responsibility of the user. • The camera must not be opened. For all repair tasks, contact Allied Vision or one of Allied Vision's authorized representatives. -

Page 15: Installation And Hardware

Installation and hardware This chapter describes the components required for your vision system including configuring the host computer, NIC settings, and connecting your Prosilica GB camera. Prosilica GB Technical Manual V2.2.6... -

Page 16: Precautions

Installation and hardware Precautions Electrical connections NOTICE ESD is dangerous for electronic devices, especially when tools or hands get in contact with connectors. We recommend measures to avoid damage by ESD: • Unpacking: Remove the camera from its anti-static packaging only when your body is grounded. -

Page 17: Optical Components

See instructions on optics cleaning in this document. We can clean your camera as a service for you, if necessary. For more information, contact Allied Vision support. NOTICE Provide the following conditions to keep dirt and droplets out of the optical system of camera and lens: •... -

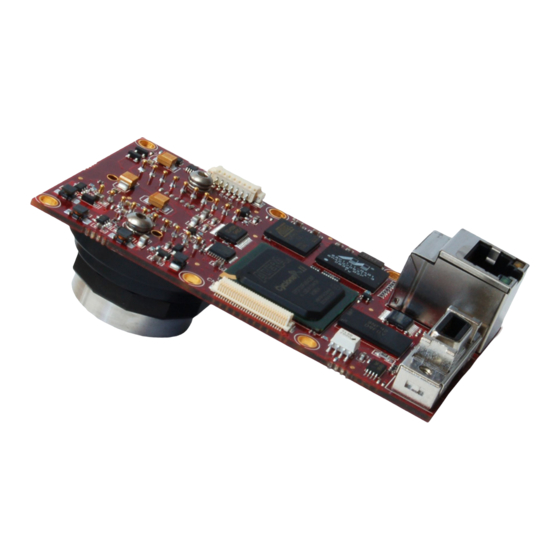

Page 18: Board Level Cameras

Installation and hardware Board level cameras NOTICE Board level cameras • Board level cameras are delivered without housing. Handle the sensor board and main board with care. Do not bend the boards. Do not touch the components or contacts on a board. Hold a board by its edges. •... -

Page 19: Configuring The Host Computer

If your host computer has an available Ethernet port, this can be used with Allied Vision GigE cameras. Allied Vision recommends that your camera system uses a dedicated Ethernet port not shared with Internet or local area networks. If more ports are needed, or your existing NIC is unable to operate at Gigabit Ethernet speeds, installing additional hardware may be required. -

Page 20: Optional: Modifying Nic Ip Address

Installation and hardware Optional: Modifying NIC IP address After initial NIC hardware installation, connect the NIC directly to the camera. The default configuration assigns an IP address automatically using the Link-Local Address range of 169.254.xxx.xxx or an address defined by the DHCP server, if present. -

Page 21: Enabling Jumbo Packets

Optics Allied Vision Prosilica GB cameras offer various mechanical interfaces for installing a lens. Lenses can be purchased directly from Allied Vision or from an Allied Vision distributor. Users need to select the desired focal length and appropriate optical format for the target camera model. -

Page 22: Accessories

Installation and hardware Accessories Allied Vision offers a wide range of accessories for the use of Allied Vision GigE cameras and the easy integration in already existing applications including: • Gigabit Ethernet accessories including standard GigE components. • Lenses for corresponding sensor sizes and resolutions. -

Page 23: Connecting To Host Application

Connecting to host application Once you have installed the Vimba Viewer or third-party application to your host computer, you can connect your Allied Vision GigE camera via an Ethernet cable and connect the 3M Mini D cable to power the camera. -

Page 24: Specifications

Specifications This chapter provides: • Applied standard • Technical specifications • Absolute QE plots • Spectral sensitivity plots • ROI frame rate Prosilica GB Technical Manual V2.2.6 Page 24... -

Page 25: Applied Standards

The GenICam standard consists of multiple modules that specify tasks to be solved. Allied Vision cameras and software make use of these modules, like the SFNC that standardizes feature names and types via an XML file or the transport layer interface (GenTL) that is used to grab images. -

Page 26: Frame Memory

Specifications Frame memory Normally, an image is captured and transported in consecutive steps. The image is taken, read out from the sensor, digitized and sent over the GigE network. Prosilica GB cameras are equipped with an image buffer. The memory operates according to the FIFO principle. -

Page 27: Absolute Qe Plots

Specifications Absolute QE plots Important notice before reading the QE plots All measurements were done without protection glass or IR cut filter. With protection glass or filters, QE decreases by approximately 10 percent. The uncertainty in measurement of the QE values is 10 percent. This is mainly due to uncertainties in the measuring apparatus itself (Ulbricht sphere, optometer). -

Page 28: Specifications Common To All Models

Specifications Specifications common to all models Feature Specification Shutter type Global Default lens mount C-Mount (adjustable) Default optical filter • Monochrome models: No filter • Color models: IRC30 (IR cut filter) Image buffer 16MB TTL I/Os 1 input, 1 output Opto-isolated I/Os 1 input, 1 output RS232... -

Page 29: Prosilica Gb650 Series

Specifications Prosilica GB650 series The following table provides model series specifications. The values are valid for Prosilica GB650 and GB650C models. For specifications common to all models, see Specifications common to all models. Specification Feature Prosilica GB650 Prosilica GB650C Sensor model Sony ICX424AL with HAD CCD™... -

Page 30: Absolute Qe

Specifications Absolute QE Figure 1: Prosilica GB650 (Sony ICX424) absolute QE Spectral response Red Response Green Response Blue Response Monochrome Response 0.2000 Sony ICX424 spectral response 0.1000 0.0000 1000 Wavelength [nm] Figure 2: Prosilica GB650 (Sony ICX424) spectral response Prosilica GB Technical Manual V2.2.6 Page 30... -

Page 31: Roi Frame Rate

Specifications ROI frame rate Frame rate ------------------------------------------------------------------------ - 14.39 μs Height 1114.28 μs Height [pixels] Figure 3: Prosilica GB650 frame rate as a function of ROI height Height Frame rate (fps) Height Frame rate (fps) 121.6 304.9 131.8 390.4 145.2 547.2 162.6... -

Page 32: Prosilica Gb660 Series

Specifications Prosilica GB660 series The following table provides model series specifications. The values are valid for Prosilica GB660 and GB660C models. For specifications common to all models, see Specifications common to all models. Specification Feature Prosilica GB660 Prosilica GB660C Sensor model Sony ICX618AL with EXview HAD Sony ICX618AQ with EXview HAD CCD™... -

Page 33: Absolute Qe

Specifications Absolute QE Figure 4: Prosilica GB660 (Sony ICX618) absolute QE Spectral response Red Response Green Response Blue Response Monochrome QE 0.4000 Sony ICX618 spectral response 0.3000 0.2000 0.1000 0.0000 1000 Wavelength [nm] Figure 5: Prosilica GB660 (Sony ICX618) spectral response Prosilica GB Technical Manual V2.2.6 Page 33... -

Page 34: Roi Frame Rate

Specifications ROI frame rate Frame rate ------------------------------------------------------------------------ - 13.26 μs Height 1844.78 μs Height [pixels] Figure 6: Prosilica GB660 frame rate as a function of ROI height Height Frame rate (fps) Height Frame rate (fps) 119.1 261.0 128.0 315.5 139.9 398.0 154.3... -

Page 35: Prosilica Gb1380 Series

Specifications Prosilica GB1380 series The following table provides model series specifications. The values are valid for Prosilica GB1380 and GB1380C models. For specifications common to all models, Specifications common to all models. Specification Feature Prosilica GB1380 Prosilica GB1380C Sensor model Sony ICX285AL with EXview HAD Sony ICX285AQ with EXview HAD CCD™... -

Page 36: Absolute Qe

Specifications Absolute QE Figure 7: Prosilica GB1380 (Sony ICX285) absolute QE Spectral response Red Response Green Response Blue Response Monochrome Response 0.3000 Sony ICX285 spectral response 0.2000 0.1000 0.0000 1000 Wavelength [nm] Figure 8: Prosilica GB1380 (Sony ICX285) spectral response Prosilica GB Technical Manual V2.2.6 Page 36... -

Page 37: Roi Frame Rate

Specifications ROI frame rate Frame rate ------------------------------------------------------------------------ - 27.79 μs Height 4881.40 μs 1050 Height [pixels] Figure 9: Prosilica GB1380 frame rate as a function of ROI height Height Frame rate (fps) Height Frame rate (fps) 1024 30.0 95.8 1000 30.6 130.6... -

Page 38: Prosilica Gb2450 Series

Specifications Prosilica GB2450 series The following table provides model series specifications. The values are valid for Prosilica GB2450 and GB2450C models. For specifications common to all models, Specifications common to all models. Specification Feature Prosilica GB2450 Prosilica GB2450C Sensor model Sony ICX625AL with Super HAD Sony ICX625AQ with Super HAD CCD™... -

Page 39: Absolute Qe

Specifications Absolute QE Figure 10: Prosilica GB2450 (Sony ICX625) absolute QE Spectral response Red Response Green Response Blue Response Monochrome Response 0.3000 Sony ICX625 spectral response 0.2000 0.1000 0.0000 1000 Wavelength [nm] Figure 11: Prosilica GB2450 (Sony ICX625) spectral response Prosilica GB Technical Manual V2.2.6 Page 39... -

Page 40: Roi Frame Rate

Specifications ROI frame rate Frame rate --------------------------------------------------------------------------- - 26.63 μs Height 12079.91 μs 1200 1500 1800 2100 Height [pixels] Figure 12: Prosilica GB2450 frame rate as a function of ROI height Height Frame rate (fps) Height Frame rate (fps) 2050 15.1 44.2... -

Page 41: Prosilica Gb Model Comparison

Specifications Prosilica GB model comparison Prosilica GB650 Prosilica GB660 Prosilica GB1380 Prosilica GB2450 1000 1200 1500 1800 2100 Height [pixels] Figure 13: Maximum frame rate comparison for select models Prosilica GB Technical Manual V2.2.6 Page 41... -

Page 42: Camera Attribute Highlights

Specifications Camera attribute highlights Allied Vision cameras support a number of standard and extended features. The following table identifies a selection of interesting capabilities of the Prosilica GB camera family. Control Description Gain control Manual and auto Exposure time Manual and auto... -

Page 43: Ir Cut Filter

Specifications IR cut filter All Prosilica GB color models are equipped with an infrared block filter (IR filter). This filter is employed to prevent infrared wavelength photons from passing to the sensor. In the absence of IR filter, images are dominated by red and incapable of being properly color balanced. -

Page 44: Mechanical Dimensions

Mechanical dimensions This chapter includes: • Sensor and connector orientation • CAD drawing and dimensions • Sensor position accuracy • Maximum protrusion distance and filter diameter Prosilica GB Technical Manual V2.2.6 Page 44... - Page 45 Mechanical dimensions The Prosilica GB camera is a board level product which offers several sensor and connector orientation options. The camera variations are described in the following table and detailed dimension drawings are provided in the next section. Sensor orientation Model Description Example...

-

Page 46: Mechanical Drawings

Mechanical dimensions Mechanical drawings Landscape sensor and inline connector Assembly shown is without the camera lens mount. See figure 19 for lens mount dimensions. All measurement values are in millimeters. 50.8 45.7 2 PLCS TYP 6 PLCS TYP 19.1 15.7 M2.5x0.45 ITEM 1: 3M 10214-55G3PC 2 PLCS TYP... -

Page 47: Landscape Sensor And Vertical Connector

Mechanical dimensions Landscape sensor and vertical connector Assembly shown is without the camera lens mount. See figure 19 for lens mount dimensions. All measurement values are in millimeters. 50.8 45.7 2 PLCS TYP 6 PLCS TYP 19.1 13.5 M2.5x0.45 29.5 2 PLCS TYP 23.6 ITEM 1: 3M 10214-6212PC... -

Page 48: Portrait Sensor And Inline Connector

Mechanical dimensions Portrait sensor and inline connector Assembly shown is without the camera lens mount. See figure 19 for lens mount dimensions. All measurement values are in millimeters. 50.8 45.7 6 PLCS TYP 31.2 19.1 2 PLCS TYP 15.7 M2.5x0.45 2 PLCS TYP ITEM 1: 3M 10214-55G3PC ITEM 2: HALO HFJ11-1G16E-L12RL... -

Page 49: Portrait Sensor And Vertical Connector

Mechanical dimensions Portrait sensor and vertical connector Assembly shown is without the camera lens mount. See figure 19 for lens mount dimensions. All measurement values are in millimeters. 50.8 45.7 6 PLCS TYP 31.2 19.1 2 PLCS TYP M2.5x0.45 13.5 2 PLCS TYP 29.5 23.6... -

Page 50: Camera Lens Mount

Mechanical dimensions Camera lens mount 21.3* 16.5 11.4 38.1 26.7 32.5 *Nominal value Add 0.3 mm for color cameras lens mount Figure 19: Prosilica GB Prosilica GB Technical Manual V2.2.6 Page 50... -

Page 51: C-Mount Flange Focal Distance

When the locking ring is loose, unthread the ring a few turns from the camera face. Lens tool - adjustment wrench Contact the Allied Vision Sales team to purchase the hexagonal lens adjustment wrench for Prosilica GB cameras with C-Mount locking ring (order code 02-5003A). Adjusting the lens to infinity Precondition: Use a C-Mount compatible lens that allows an infinity focus. -

Page 52: Lens Protrusion For C-Mount Cameras

Mechanical dimensions 2. Rotate the lens and C-Mount ring until the image is focused. 3. Carefully tighten the locking ring and recheck focus. Lens protrusion for C-Mount cameras Lens protrusion is the distance from outer edge of C-Mount ring to contact point of first surface internal to C-Mount ring. -

Page 53: Camera Interfaces

Camera interfaces This chapter includes: • A general description of the I/Os (including trigger features) • I/O connector pin assignments • I/O block diagrams • A general description of trigger rules including a timing diagram and definitions Prosilica GB Technical Manual V2.2.6 Page 53... -

Page 54: Status Leds

Camera interfaces This chapter provides information on Gigabit Ethernet port, I/Os, and trigger features. GIGABIT ETHERNET PORT I/O PORT: CAMERA POWER EXTERNAL SYNC IO RS232 TX/RX LED2 LED1 Figure 22: Prosilica GB connection ports Status LEDs The color of the LEDs have the following meaning: LED Color Status LED1... -

Page 55: Gigabit Ethernet Port

Gigabit Ethernet over copper. We recommend using Category 6 or higher compatible cabling and connectors for best performance. GigE host controllers A standard PCI GigE host controller card is available for purchase from Allied Vision. Order code: 02-3002A (Intel Pro 1000/GT, PCI, 1 port). Contact the Allied Vision Sales team for additional GigE host controllers. -

Page 56: Camera I/O Connector Pin Assignment

Camera interfaces Camera I/O connector pin assignment The General Purpose I/O port uses a 3M 10214-55G3PC (or 3M 10214-6212PC) connector on the camera side. The mating cable connector is 3M 10114-3000PE or a connector with shielded housing 3M 10314-3210-00X (where X indicates color preference). - Page 57 Cable side connector The cable side connector is available for purchase from Allied Vision. Order code: 02-7003A. Cable color and pin out For cable color and pin out information, see the Allied Vision I/O cable data sheet: www.alliedvision.com/en/support/technical-documentation/accesso- ries-data-sheets.html N.C.

-

Page 58: I/O Definition

12 Volt power adapter A 12 Volt power adapter with 3M Mini D connector is available for purchase from Allied Vision: • Order code: 02-8007C (Power supply, North America, Plug type B) • Order code: 02-8008C (Power supply, Europe, Plug type F) -

Page 59: In 1 (Opto-Isolated)

Camera interfaces In 1 (Opto-isolated) In 1 is optically isolated and can be used in electrically noisy environments to prevent false trigger events. Tie Camera GND to Isolated IO GND to complete the trigger circuit. Compared to the non-isolated trigger, In 1 has a longer propagation time. -

Page 60: Out 2 (Non-Isolated)

Camera interfaces Out 2 (Non-isolated) Out 2 signal is not electrically isolated and can be used when environmental electrical noise is inconsequential and faster trigger response is required. Use Signal GND to complete the external circuit. The output signal is a low voltage TTL, maximum 3.3 Volts. -

Page 61: Camera I/O Opto-Isolated User Circuit Example

Camera interfaces Camera I/O opto-isolated user circuit example Cable Side Out1 Isolated IO GND Camera GND Camera GND Camera Power Camera Power In1(Driver) 3M 10114-3000PE User Power Recommended Values User Power Out1 (Receiver) 12 V 0.7 K 2.7 K 24 V 1.8 K 4.7 K Figure 24: Prosilica GB isolated trigger user circuit... -

Page 62: Camera I/O Non-Isolated User Circuit Example

Camera interfaces Camera I/O non-isolated user circuit example Cable Side Camera GND Camera Power 3M 10114-3000PE In 2 (3.3 V Driver) Out 2 (3.3 V Receiver) Figure 25: Prosilica GB non-isolated trigger user circuit Input: Incoming trigger must be able to source 10 µA, at 3.3 Volts. Input trigger voltage greater than 5.5 Volts will damage the camera. -

Page 63: Video Iris User Circuit Example

Camera interfaces Video iris user circuit example Prosilica GB series cameras provide built-in auto iris controls for controlling video-type auto-iris lenses. These lenses are available from many popular security lens companies including Pentax, Fujinon, Tamron, Schneider and others. Remote iris lens control allows the camera to be more adaptable to changing light conditions. -

Page 64: Trigger Timing Diagram

Camera interfaces Trigger timing diagram The following diagram explains the general trigger concept. Readout me Trigger latency Registered Exposure start delay exposure me User trigger Note: Ji er at the beginning Logic trigger of an exposure has no e ect on the length of exposure. -

Page 65: Trigger Rules

Camera interfaces Term Definition Exposure start delay Registered exposure time subtracted from the readout time and indicates when the next exposure cycle can begin such that the exposure will end after the current readout. Interline time Time between sensor row readout cycles. Imaging High when the camera image sensor is either exposing and/or reading out data. -

Page 66: Image Data Flow

Image data flow This chapter presents diagrams that illustrate data flow of the image data. Prosilica GB Technical Manual V2.2.6 Page 66... - Page 67 Image data flow The following diagrams illustrate Prosilica GB image data flow. The individual blocks are described in more detail in the GigE Features Reference. Sensor Vertical Binning Vertical ROI Analog Gain Offset Analog Analog Analog Analog Histogram Calculation Bayer Horizontal Horizontal ROI White balance...

-

Page 68: Cleaning Optical Components

Cleaning optical components This chapter describes safety instructions and cautions for cleaning lenses, optical filters, protection glass, or sensors. Prosilica GB Technical Manual V2.2.6... -

Page 69: Keep Optical Components Clean

Read these instructions before you contact Allied Vision or your Allied Vision distribution partner for assistance. Contact Allied Vision or your Allied Vision distribution partner if you are not familiar with the procedures described in this chapter. Keep optical components clean The best way to ensure the camera remains clean is to avoid penetration of foreign substances into the camera. -

Page 70: Materials For Cleaning Optical Components

IR cut filter or protection glass, it is probably on the sensor. NOTICE Removing IR cut filter A pin spanner wrench (Allied Vision order code: 02-5003A) suitable for IR filter removal is available for purchase from Allied Vision for all Prosilica GB cameras. Materials for cleaning optical components Use only these cleaning materials for optical components •... -

Page 71: Cleaning With Compressed Air

If you notice that the camera lens or sensor is not clean after attempting to clean twice, or if you have any questions regarding cleaning your camera, contact your Allied Vision distribution partner. Cleaning with compressed air Allied Vision does not recommend cleaning Prosilica GB cameras with compressed air. NOTICE •... - Page 72 Cleaning optical components If you want to clean your camera with compressed air despite of all the warnings: • Use an optic approved compressed air product or compressor. • Use an anti-static ionizer attachment to reduce the risk of static-caused damage.

-

Page 73: Firmware Update

Firmware update This chapter includes instructions on updating the firmware on your Allied Vision Prosilica GB camera. Prosilica GB Technical Manual V2.2.6... - Page 74 (XML file) to the host computer. NOTICE Do not unplug the GigE cable or camera power supply during the update procedure. To update the firmware on your Allied Vision GigE camera Launch the Allied Vision Firmware Loader. Prosilica GB Technical Manual V2.2.6...

- Page 75 Firmware update Click Next. The Firmware Loader displays a list of firmware included in the package. Click Next. Select your camera model on this page. Recovery Mode Select the Use recovery mode check box if the connected GigE camera is not found by the firmware loader, or if the GigE camera is listed as unavailable.

- Page 76 Firmware update Click Next. Click Upload to start the update. The existing firmware will be erased and the new firmware will be updated to the camera. Prosilica GB Technical Manual V2.2.6...

- Page 77 Firmware update The Firmware Loader displays a success status upon completion. Click Quit to exit the loader. Power cycle after upgrade or downgrade You must always power cycle the camera after a firmware upgrade or downgrade. Prosilica GB Technical Manual V2.2.6...

- Page 78 Index Index Update..........74 Flange focal distance C-Mount..........51 Frame memory.........26 Frame rate ..........26 Adjustment of C-Mount ....... 51 General safety notes .........17 GenICam ..........25 Gigabit Ethernet Cable length ........2 Block diagram Interface..........2 Prosilica GB monochrome cameras..67 GigE Host controller ........55 GigE Vision ..........25 GND for ext.

- Page 79 Index Integrating light ........59 Interline time ........65 Registered exposure time .....64 Output signals Sensor row readout cycles ....65 Out 1 ........56 signal Out 2 .......... 57 exposure start delay ......65 Signal GND ........57 Spectral transmission IRC30 filter.........43 Status LEDs..........54 Power DC ............22 Trigger...

Need help?

Do you have a question about the Prosilica GB Series and is the answer not in the manual?

Questions and answers