Summary of Contents for Wilden P800

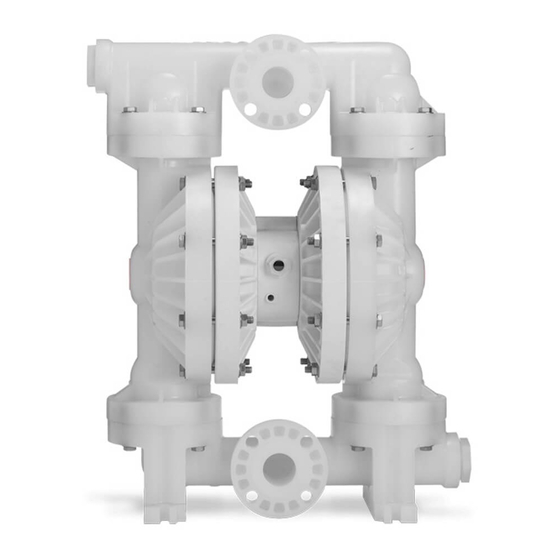

- Page 1 ENGINEERING OPERATION & MAINTENANCE P800 Bolted Plastic Pump Where Innovation Flows WIL-11251-E-02...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works —Pump & Air Distribution System Section 4: Dimensional Drawings P8 00 P ol ypro py len e Cen te r - Por te d... - Page 3 Warranty Each and every product manufactured by Wilden is built to meet the highest standards of quality. Every pump is functionally tested to insure integrity of operation. Wilden warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

-

Page 4: Section 1: Precautions - Read First

WARNING : Prevent static sparking— If static sparking occurs, fire or explosion could result. Pump, valves, and containers must be grounded to a proper grounding point when handling flammable fluids and whenever discharge of static electricity is a hazard. ® Wilden WIL-11251-E-02... -

Page 5: Section 2: Wilden Pump Designation System

W I L D E N P U M P D E S I G N A T I O N S Y S T E M P800 PLASTIC LEGEND P800 / X X X X X / XXX / XX / X XX / XXXX O-RINGS... -

Page 6: Section 3: How It Works -Pump & Air Distribution System

Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 7: Section 4: Dimensional Drawings

Section 4 DIMENSIONAL DRAWING P800 Polypropylene Center-Ported DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.0 15.6 27.1 30.1 13.9 20.0 15.7 16.7 14.2 12.1 10.0 DIN / ANSI COMBO 121 DIA. 4.8 DIA. 152 DIA. 6.0 DIA. 21 DIA. 0.8 DIA. -

Page 8: P800 Polypropylene Side-Ported

DIMENSIONAL DRAWING P800 Polypropylene Side-Ported DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.8 28.7 16.0 31.5 31.8 13.9 20.0 16.0 16.7 14.2 DIN FLANGE 121 DIA. 4.9 DIA. 165 DIA. 6.5 DIA. 18 DIA. 0.7 DIA. ANSI FLANGE 121 DIA. 4.8 DIA. -

Page 9: Section 5: Performance

Section 5 PERFORMANCE P800 PLASTIC RUBBER-FITTED Ship Weight ..Polypropylene 32 kg (70 lb) PVDF 45 kg (99 lb) Air Inlet........13 mm (1⁄2") Inlet ........51 mm (2") Outlet ........51 mm (2") Suction Lift ....6.23 m Dry (20.4') 8.65 m Wet (28.4') -

Page 10: P800 Plastic Reduced- Stroke Ptfe-Fitted

PERFORMANCE P800 PLASTIC REDUCED- STROKE PTFE-FITTED Ship Weight ..Polypropylene 32 kg (70 lb) PVDF 45 kg (99 lb) Air Inlet........13 mm (1⁄2") Inlet ......... 51 mm (2") Outlet .........51 mm (2") Suction Lift ....4.15 m Dry (13.62') 8.65 m Wet (28.4') -

Page 11: P800 Plastic Ultra-Flex™-Fitted

PERFORMANCE P800 PLASTIC ULTRA-FLEX™-FITTED Ship Weight ..Polypropylene 32 kg (70 lb) PVDF 45 kg (99 lb) Air Inlet........13 mm (1⁄2") Inlet ......... 51 mm (2") Outlet .........51 mm (2") Suction Lift ....4.84 m Dry (15.89') 8.65 m Wet (28.4') Disp. -

Page 12: Su Ct Ion - Li Ft Cur Ve S

S U C T I O N L I F T C U R V E S P800 PLASTIC SUCTION - LIFT CAPABILITY Suction-lift curves are calibrated for pumps operating at 305 m (1,000') above sea level. This chart is meant to be a guide only. -

Page 13: Section 6: Suggested Installation, Operation

The suction-pipe size should be at least the equivalent or larger than the diameter size of the suction inlet on your Wilden pump. The suction The best choice possible will be a site involving the shortest and hose must be non-collapsible, reinforced type as these pumps are straightest hook-up of suction and discharge piping. - Page 14 Frequency of use, line pressure, viscosity and abrasiveness of The P800 pumps are pre-lubricated and do not require in-line process fluid all affect the parts life of a Wilden pump. Periodic inspections lubrication. Additional lubrication will not damage the pump,...

- Page 15 1. Check for pump cavitation; slow pump speed down to allow 2. Check tightness of outer pistons to shaft. thick material to flow into liquid chambers. 2. Verify that vacuum required to lift liquid is not greater than the vapor pressure of the material being pumped (cavitation). ® Wilden WIL-11251-E-02...

-

Page 16: Section 7: Disassembly / Reassembly

Models with rubber diaphragms, balls and seats (such as plywood, plastic or are the same except where noted. other suitable material) NOTE: Replace worn parts with genuine Wilden parts for reliable performance. Step 1 Step 2 Step 3 Please note alignment marks on liquid Using a 3/4"... - Page 17 Remove the liquid chamber to expose the Using two adjustable wrenches, or rotating chamber fasteners that secure the liquid diaphragm and outer piston. both diaphragms by hand (counterclockwise), chamber to the center section. remove the diaphragm assembly from the center section assembly. ® Wilden WIL-11251-E-02...

- Page 18 The outer piston, diaphragm and inner piston separate from the shaft, which remains connected to the opposite side diaphragm assembly. ® Wilden WIL-11251-E-02...

-

Page 19: Air Valve / Center Section Disassembly

Drain the pump by turning it upside down and allowing any fluid to flow into a suitable container. Be aware of hazardous effects of contact with your process fluid. • Snap Ring Pliers NOTE: Replace worn parts with genuine Wilden parts for reliable performance. • O-Ring Pick Step 2... - Page 20 During reassembly, never insert the pilot spool into the sleeve with the notched end first, this end incorporates the urethane O-ring and will be damaged as it slides over the ports cut in the sleeve. NOTE: Seals should not be removed from pilot spool. Seals are not sold separately. ® Wilden WIL-11251-E-02...

-

Page 21: Reassembly Hints & Tips

81.3 N•m (60 ft-lb) complete the resizing of the seal. Manifold to Liquid Chamber 44.7 N•m (33 ft-lb) • Perform these steps for the remaining seal. Liquid Chamber to Air Chamber 44.7 N•m (33 ft-lb) Figure A Figure B ® Wilden WIL-11251-E-02... -

Page 22: Section 8: Exploded View And Parts List

Section 8 Exploded View and Parts Listing P800 PLASTIC EXPLODED VIEW FULL - STROKE DIAPHRAGM - FITTED ® Wilden WIL-11251-E-02... -

Page 23: P8 00 P La Sti C Red Uce D - Str Oke D Iap Hrag M - Fi Tte D

Exploded View and Parts List P800/PKPPP P800/KKPPP P800/PKPPP-0502 P800/KKPPP-0502 Part Description Qty. Pro-Flo Air Valve Assembly 04-2000-20-700 04-2000-20-700 04-2000-20-700 04-2000-20-700 ® O-Ring (-225), End Cap (1.859" x .139") 04-2390-52-700 04-2390-52-700 04-2390-52-700 04-2390-52-700 End Cap, Pro-Flo 04-2330-20-700 04-2330-20-700 04-2330-20-700 04-2330-20-700 ®... - Page 24 Exploded View and Parts Listing P800 PLASTIC EXPLODED VIEW REDUCED- STROKE DIAPHRAGM - FITTED ® Wilden WIL-11251-E-02...

- Page 25 Exploded View and Parts List P800/PKPPP P800/KKPPP P800/PKPPP-0502 P800/KKPPP-0502 Part Description Qty. Pro-Flo Air Valve Assembly 04-2000-20-700 04-2000-20-700 04-2000-20-700 04-2000-20-700 ® O-Ring (-225), End Cap (1.859" x .139") 04-2390-52-700 04-2390-52-700 04-2390-52-700 04-2390-52-700 End Cap, Pro-Flo 04-2330-20-700 04-2330-20-700 04-2330-20-700 04-2330-20-700 ®...

-

Page 26: Section 9: Elastomer Options

Section 9 Elastomer Options P800 Plastic Ultra-Flex™ Reduced-Stroke Back- Full-Stroke Back- Material Diaphragms (2) Valve Balls (4) Valve Seat (4) Valve Seat O-Ring (4) Manifold O-Ring Diaphragms Up Diaphragms Up Diaphragms Neoprene 08-1010-51 08-1020-51 08-1060-51 08-1080-51 Buna-N 08-1010-52 08-1020-52 08-1080-52... - Page 27 Notes WIL-11251-E-02 ® Wilden...

- Page 28 Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 WIL-11251-E-02 ® Wilden...

Need help?

Do you have a question about the P800 and is the answer not in the manual?

Questions and answers