Summary of Contents for Wilden P1500

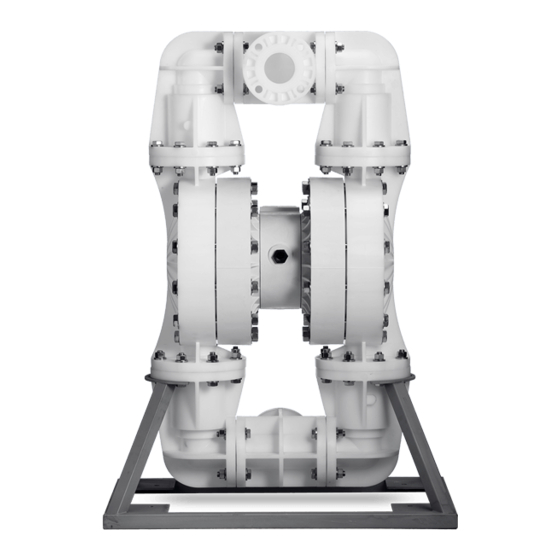

- Page 1 ENGINEERING OPERATION & MAINTENANCE P1500 Bolted Plastic Pump Where Innovation Flows WIL-11160-E-09...

-

Page 2: Table Of Contents

Contents Section 1: Precautions - Read First! Section 2: Wilden Pump Designation System Section 3: How It Works —Pump & Air Distribution System Section 4: Dimensional Drawings P1 500 Pol ypr op yle ne P1 500 PV DF Section 5: Performance... - Page 3 Warranty Each and every product manufactured by Wilden is built to meet the highest standards of quality. Every pump is functionally tested to insure integrity of operation. Wilden warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

-

Page 4: Section 1: Precautions - Read First

If diaphragm rupture occurs, material being fitting for draining the pump during maintenance. pumped may be forced out air exhaust. CAUTION: The P1500 pump is not submersible. WARNING: Prevention of static sparking — If static sparking occurs, fire or explosion could result. Pump,... -

Page 5: Section 2: Wilden Pump Designation System

W I L D E N P U M P D E S I G N A T I O N S Y S T E M P1500 ADVANCED™ LEGEND P1500 / X X X X X / XXX / XX / X XX / XXXX O-RINGS... -

Page 6: Section 3: How It Works -Pump & Air Distribution System

Section 3 The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show the flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 7: Section 4: Dimensional Drawings

DIMENSIONAL DRAWING P1500 Polypropylene DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 36.0 27.2 1280 50.4 12.0 1181 46.5 27.3 23.0 26.8 13.2 15 DIA. 0.6 DIA. FLANGES DIN (mm) ANSI (inch) 160 DIA. 6.0 DIA. 191 DIA. 7.5 DIA. 18 DIA. -

Page 8: Section 5: Performance

For optimum life and performance, pumps should be specified so that daily operation parameters will fall in the center of the pump’s performance curve. Caution: Do not exceed 6.9 bar (100 psig) air supply pressure on P1500 polypropylene pumps. Caution: Do not exceed 8.6 bar (125 psig) air supply pressure on PVDF pumps. -

Page 9: Su Ct Ion - Li Ft Cur Ve S

S U C T I O N L I F T C U R V E S P1500 PLASTIC SUCTION - LIFT CAPABILITY Suction-lift curves are calibrated for pumps operating at 305 m (1,000’) above sea level. This chart is meant to be a guide only. -

Page 10: Section 6: Suggested Installation, Operation

Suggested Installation, Operation, Maintenance and Troubleshooting • Muffler: Sound levels are reduced below OSHA specifications The P1500 plastic pump has a 76 mm (3") inlet and 76 mm (3") outlet and is using the standard Wilden muffler. Other mufflers can be used to designed for flows to 784 lpm (207 gpm). - Page 11 Frequency of use, line pressure, viscosity and abrasiveness of The P1500 is pre-lubricated, and does not require in-line process fluid all affect the parts life of a Wilden pump. Periodic inspections lubrication. Additional lubrication will not damage the pump,...

- Page 12 1. Check for pump cavitation; slow pump speed down to allow 2. Check tightness of outer pistons to shaft. thick material to flow into liquid chambers. 2. Verify that vacuum required to lift liquid is not greater than the vapor pressure of the material being pumped (cavitation). ® Wilden WIL-11160-E-09...

-

Page 13: Section 7: Disassembly / Reassembly

Be aware of any hazardous effects of contact with your process fluid. • (2 qty.) 5/8" Box Wrench The Wilden P1500 has a 76 mm (3”) inlet and outlet and is designed for flows • (2 qty.) 3/4" Box Wrench up to 878 lpm (232 gpm). - Page 14 . Replace worn parts with genuine Wilden parts for reliable performance. Step 7 Step 8 Step 9...

- Page 15 (Figure 10b). Repeat disassembly instructions for the opposite liquid chamber. Inspect diaphragm assembly and shaft for signs of wear or chemical attack. Replace all worn parts with genuine Wilden parts for reliable performance. Rubber/TPE are not available.

-

Page 16: Air Valve / Center Section Disassembly

A 19 mm (3/4") air inlet ® • Snap-Ring Pliers connects the air supply to the center section. Proprietary composite seals reduce the coefficient of friction and allow the P1500 to run lubefree. Constructed of polypropylene, the Pro-Flo air distribution ® • O-Ring Pick system is designed to perform in on/off, non-freezing, non-stalling, tough duty applications. - Page 17 NOTE: Seals should not be removed from pilot spool. Seals are not sold separately. The end of the pilot spool that has a “center hole” in it should not be fed into the bore first (see TB 1296). ® Wilden WIL-11160-E-09...

-

Page 18: Reassembly Hints & Tips

Slowly insert the center shaft with a rotating motion. This will Elbow/Liquid Chamber 3.4 N•m (32 ft-lb) complete the resizing of the seal. Liquid Chamber/Air Chamber 3.4 N•m (32 ft-lb) • Perform these steps for the remaining seal. Figure B Figure A ® Wilden WIL-11160-E-09... -

Page 19: Section 8: Exploded View And Parts List

Section 8 Exploded View and Parts Listing P1500 PLASTIC EXPLODED VIEW AIR DISTRIBUTION SYSTEM ® Wilden WIL-11160-E-09... - Page 20 Exploded View and Parts List P1500/P... P1500/K... Item No. Description Qty. Part Number Part Number Pro-Flo Air Valve Assembly 15-2010-20 15-2010-20 ® O-Ring (-235), End Cap 71-1280-52 71-1280-52 End Cap, Pro-Flo 15-2332-20 15-2332-20 ® Screw, SHCS, Air Valve (7/16-14 x 5-7/8")

-

Page 21: P1 500 Pla St Ic Li Qu Id P Ath

Exploded View and Parts Listing P1500 PLASTIC EXPLODED VIEW LIQUID PATH ® Wilden WIL-11160-E-09... - Page 22 Exploded View and Parts List Reduced-Stroke Diaphragm-Fitted Full-Stroke Diaphragm-Fitted P1500/PKPPP P1500/KKPPP P1500/PSPPP P1500/KSPPP Item No. Description Qty. Bolt, HHCS, 5/8-11 x 3-1/4 15-6181-03 15-6181-03 15-6181-03 15-6181-03 Washer, 5/8 (.660 x 1.312 x .187) 15-6730-03 15-6730-03 15-6730-03 15-6730-03 Nut, Hex, 5/8-11...

- Page 23 Notes ® Wilden WIL-11160-E-09...

- Page 24 Grand Terrace, CA 92313-5651 USA 1 (909) 422-1730 • F: 1 (909) 783-3440 psgdover.com Where Innovation Flows ® reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document. 05- 2018 ® Wilden WIL-11160-E-09...

Need help?

Do you have a question about the P1500 and is the answer not in the manual?

Questions and answers