Summary of Contents for Wilden P800

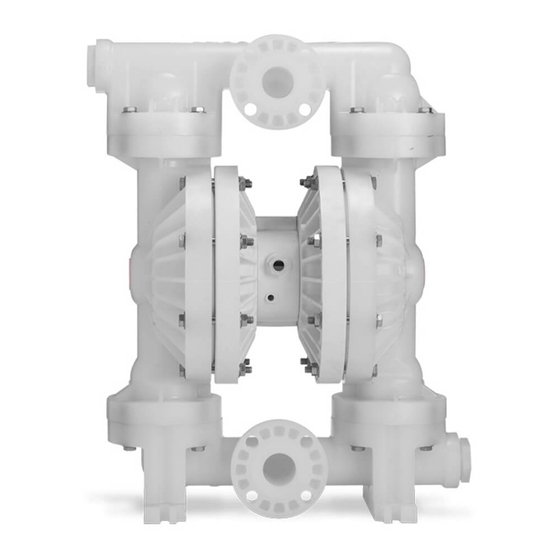

- Page 1 P800/PX800 E n g i n e e r i n g O p e r a t i o n & ™ Advanced Series PLASTIC Pumps M a i n t e n a n c e A d v a n c e y o u r p r o c e s s...

-

Page 2: Table Of Contents

P800 Reduced Stroke-Fitted ........ -

Page 3: Cautions-Read First

CAUTION: The process fl uid and cleaning fl uids must be chemically compatible with all wetted pump components. Consult Chemical Resistance Guide (E4). CAUTION: Do not exceed 82°C (180°F) air inlet temperature for Pro-Flo X™ models. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 4: Wilden Pump Designation System

BACK-UP (White) P = POLYPROPYLENE AIR VALVE TSU = PTFE W/SANIFLEX™ P = POLYPROPYLENE BACK-UP (White) VALVE SEAT & FLANGE O-RING L = ACETAL (P800 only) ® VTS = VITON (White Dot) BN = BUNA-N ® VTU = VITON , ULTRA-FLEX™... -

Page 5: How It Works-Pump & Air Distribution System

H O W I T W O R K S — P U M P The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern through the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke. -

Page 6: Dimensional Drawings

P 80 0 Pla st ic Cen te r- Po rte d DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.0 15.6 27.1 30.1 13.9 20.0 15.7 16.7 14.2 12.1 10.0 DIN / ANSI COMBO 152 DIA. 6.0 DIA. 122 DIA. 4.8 DIA. 20 DIA. 0.8 DIA. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 7 P X80 0 Plas ti c C en ter- Po rte d DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 23.0 15.6 27.1 30.1 14.0 17.8 15.9 16.7 14.2 12.1 10.0 DIN / ANSI COMBO 152 DIA. 6.0 DIA. 122 DIA. 4.8 DIA. 20 DIA. .8 DIA. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 8: Performance

85 Nm /h (50 scfm) air consumption. parameters will fall in the center of the pump performance curve. (See dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 9: Reduced Stroke Ptfe-Fitted

For optimum life and performance, pumps should be specifi ed so that daily operation Caution: Do not exceed 8.6 bar (125 psig) parameters will fall in the center of the pump performance curve. air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 10: Ultra-Flex™-Fitted

85 Nm /h (50 scfm) air consumption. parameters will fall in the center of the pump performance curve. (See dot on chart.) Caution: Do not exceed 8.6 bar (125 psig) air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 11: Suction Lift Curve

S e c t i o n 5 A S U C T I O N L I F T C U R V E P8 0 0 P L AS TI C SU CTIO N L IFT C A PAB ILITY WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 12 N O T E S...

- Page 13 PX800 P X 8 0 0 P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 14: Px800 Performance Curves

fl ow and an even than the fl ow and exhaust is the highest greater decrease in rate, effi ciency porting. fl ow rate setting air consumption. is improved and possible operating costs are reduced. WILDEN PUMP & ENGINEERING, LLC PX800 Performance... -

Page 15: How To Use This Ems Curve

The fl ow rate and air consumption at Setting sect the horizontal discharge pressure line. 2 are found to be 18.2 lpm (4.8 gpm) and 7.9 After locating your EMS points on the EMS /h (4.7 scfm) respectively. PX800 Performance WILDEN PUMP & ENGINEERING, LLC... - Page 16 fl ow rate. optimal EMS setting. For this example the EMS setting is 1.8. WILDEN PUMP & ENGINEERING, LLC PX800 Performance...

- Page 17 (or interpolating) this point on the curve, draw a vertical line downward until reaching the bottom scale on the chart and identify the air X Factor (fi gure 7). For this example the air X Factor is 0.40 PX800 Performance WILDEN PUMP & ENGINEERING, LLC...

-

Page 18: Performance Curves Rubber-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX800 Performance... -

Page 19: Tpe-Fitted

P E R F O R M A N C E PX800 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 20: Reduced Stroke Ptfe-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX800 Performance... -

Page 21: Full Stroke-Fitted

P E R F O R M A N C E PX800 Performance WILDEN PUMP & ENGINEERING, LLC... -

Page 22: Ultra-Flex™-Fitted

P E R F O R M A N C E WILDEN PUMP & ENGINEERING, LLC PX800 Performance... -

Page 23: Suction Lift Curve

S U C T I O N L I F T C U R V E PX8 0 0 PL A S TIC SU CTIO N L IFT C A PAB ILITY Traditional Rubber Diaphragms TPE Diaphragms UltraFlex Diaphragms Reduced Stroke PTFE Diaphragms Full Stroke PTFE Diaphragms PX800 Performance WILDEN PUMP & ENGINEERING, LLC... - Page 24 22069 Van Buren St. • Grand Terrace, CA 92313-5651 92313 5 Tel 909-422-1730 • Fax 909-783-3440 • www.wildenx.com...

-

Page 25: Suggested Installation, Operation & Troubleshooting

MUFFLER: Sound levels are reduced below OSHA requirements of even the most demanding pumping specifi cations using the standard Wilden muffl er. Other applications. They have been designed and manufactured muffl ers can be used to further reduce sound levels, but to the highest standards and are available in a variety of they usually reduce pump performance. - Page 26 AIR OPERATED PUMPS: To stop the pump from pumping equipment such that it can be reached safely in an emergency situation. operating in an emergency situation, simply close the WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

- Page 27 fl uid discharge pressure and do not require in-line lubrication. Additional or increasing the air inlet pressure. The Wilden P800 lubrication will not damage the pump, however if the and PX800 pumps run solely on compressed air and do not generate heat, therefore your process fl...

-

Page 28: Pump Disassembly

Using a 3/4" wrench, loosen the Remove the discharge manifold to liquid chambers. Use to properly discharge manifold from the liquid expose the valve balls, valve seats align center section with liquid chambers. and valve seat o-rings. chamber. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 29 Using two adjustable wrenches, chamber fasteners that secure the the diaphragm and outer piston. or rotating both diaphragms by liquid chamber to the center section. hand (counterclockwise), remove the diaphragm assembly from the center section assembly. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

- Page 30 2) The outer piston, diaphragm and hand, remove diaphragm assembly inner piston separate from the shaft, from shaft. which remains connected to the opposite side diaphragm assembly. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 31: Pro-Flo

Remove muffl er plate and air valve Lift away valve assembly loosen air valve bolts. bolts from air valve assembly, and remove air valve gasket for exposing muffl er gasket inspection. Replace if necessary. inspection. Replace if necessary. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 32 Use caution when handling air valve spool to prevent damaging seals. Note: Seals should not be removed from assembly. Seals are not sold separately. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

- Page 33 “notched end” fi rst, this end incorporates the urethane o-ring and will be damaged as it slides over the ports cut in the sleeve. Note: Seals should not be removed from pilot spool. Seals are not sold separately. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

- Page 34 Inspect seals for signs of wear and replace entire assembly if necessary. Use caution when handling air valve spool to prevent damaging seals. NOTE: Seals should not be remove from assembly. Seals are not sold separately. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

- Page 35 (2) replace if necessary. for wear. If replacement is necessary, (6) may be removed or replaced if use an o-ring pick to remove the necessary. used Glyd rings then replace with genuine Wilden replacement parts. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 36: Reassembly Hints & Tips

Pro-Flo ® Air Valve Bolts P800 5.1 N•m (45 in-lbs) / PX800 5.1 N•m (45 in-lbs) pliers. This will allow the seal to partially snap back to its Air Chamber to Center Block 27.1 N•m (20 ft-lbs) original shape. - Page 37 E L A S T O M E R K I T S Program Details: • Elastomer & ADS Repair Kits • All Sizes Available • PTFE, Rubber & TPE Elastomers • One Part Number Simplifies Inventory • Eliminates Order Errors •...

-

Page 38: P800 Plastic

F u l l S t r o k e D i a p h r a g m - F i t t e d E X P L O D E D V I E W P800 PLASTIC FULL STROKE PTFE-FITTED CENTER-PORTED 22 23 ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS (see section 9). WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 39: P800 Plastic

08-1065-57 08-1065-57 08-1065-57 *Refer to Elastometer Chart Air Valve Assembly includes items 2 and 3 0502 Specialty Code = PFA-Coated Hardware 0504 Specialty Code = DIN Flange All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... -

Page 40: P800 Reduced Stroke-Fitted

R e d u c e d S t r o k e D i a p h r a g m - F i t t e d E X P L O D E D V I E W P800 PLASTIC CENTER-PORTED ULTRA-FLEX™ WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 41 04-2650-49-700 04-2650-49-700 *Refer to Elastometer Chart Air Valve Assembly includes item numbers 2 and 3 0502 Specialty Code = PFA-Coated Hardware 0504 Specialty Code = DIN Flange All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 42: Px800 Full Stroke-Fitted

F u l l S t r o k e D i a p h r a g m - F i t t e d E X P L O D E D V I E W PX800 PLASTIC FULL STROKE PTFE-FITTED CENTER-PORTED ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS (see section 9). WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 43 Air Valve Assembly includes items 2 and 3. Center Block Assembly includes items 10, 11, 15 and 16. 0502 Specialty Code=PFA-Coated Hardware 0504 Specialty Code=DIN Flange *Refer to Elastometer Chart All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 44: Px800 Reduced Stroke-Fitted

R e d u c e d S t r o k e D i a p h r a g m - F i t t e d E X P L O D E D V I E W PX800 PLASTIC ULTRA-FLEX™ ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS (see section 9). WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03... - Page 45 *Refer to Elastometer Chart Air Valve Assembly includes items 2 and 3. Center Block Assembly includes items 10, 11, 15 and 16. 0502 Specialty Code=PFA-Coated Hardware 0504 Specialty Code=DIN Flange All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11250-E-03...

-

Page 46: Elastomer Options

S e c t i o n 9 E L A S T O M E R O P T I O N S P800 and PX800 Plastic REDUCED STROKE FULL STROKE DIAPHRAGMS ULTRA-FLEX™ BACKUP BACKUP VALVE BALLS VALVE SEAT... - Page 47 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

Need help?

Do you have a question about the P800 and is the answer not in the manual?

Questions and answers