Summary of Contents for Wilden Pro-Flo P2

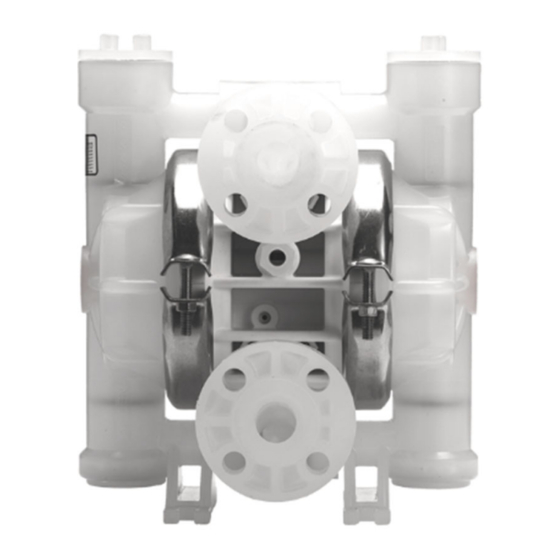

- Page 1 ENGINEERING OPERATION & MAINTENANCE MANUAL P2 Clamped Plastic Pump Where Innovation Flows WIL-10150--E-12...

- Page 2 Warranty Each and every product manufactured by Wilden is built to meet the highest standards of quality. Every pump is functionally tested to ensure integrity of operation. Wilden warrants that pumps, accessories and parts manufactured or supplied by it to be free from defects in material and workmanship for a period of five (5) years from date of installation or six (6) years from date of manufacture, whichever comes first.

-

Page 3: Table Of Contents

P2 Clamped Plastic CONTENTS SECTION 1: Precautions – Read First! ..................... 4 SECTION 2: Wilden Pump Designation System ..................5 SECTION 3: How It Works .......................... 6 SECTION 4: Dimensional Drawings ......................7 SECTION 5: Performance ........................... 8 P2 Plastic Rubber-Fitted ........................... 8 P2 Plastic TPE-Fitted .......................... -

Page 4: Section 1: Precautions - Read First

*4°C to 149°C (40°F to 300°F) - 13 mm (1/2") and 25 mm (1") models Torque Specifications”). only. NOTE: Not all materials are available for all models. See “Wilden NOTE: Some PTFE-fitted pumps come standard from the Pump Designation System” material options for your pump. -

Page 5: Section 2: Wilden Pump Designation System

P2 Clamped Plastic SECTION 2 WILDEN PUMP DESIGNATION SYSTEM P2 PLASTIC LEGEND / X X X / X X / X X X / X X X X 25 mm (1") Pump O-RING Maximum Flow Rate: MODEL VALVE SEAT SPECIALTY... -

Page 6: Section 3: How It Works

HOW IT WORKS – AIR-OPERATED DOUBLE-DIAPHRAGM PUMP The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke. -

Page 7: Section 4: Dimensional Drawings

P2 Clamped Plastic SECTION 4 DIMENSIONAL DRAWING P2 PLASTIC DIMENSIONS METRIC STANDARD ITEM (mm) (inch) 10.9 13.1 11.5 84 DIA. 3.3 DIA. 114 DIA. 4.5 DIA. 15 DIA. 0.6 DIA. ANSI 79 DIA. 3.1 DIA. 109 DIA. 4.3 DIA. 15 DIA. 0.6 DIA. -

Page 8: Section 5: Performance

P2 Clamped Plastic SECTION 5 DIMENSIONAL DRAWING PERFORMANCE P2 PLASTIC RUBBER-FITTED Ship Weights……...Polypropylene 8 kg (75 lb) PVDF 10 kg (23 lb) Air Inlet……………………..……….6 mm (1/4") Inlet…...…………………...…………25 mm (1") Outlet………………...………………25 mm (1") Suction Lift……………………...5.5 m Dry (28') 8.8 m Wet (29') Disp. -

Page 9: P2 Plastic Reduced-Stroke Ptfe-Fitted

P2 Clamped Plastic PERFORMANCE P2 PLASTIC REDUCED-STROKE PTFE-FITTED Ship Weights……...Polypropylene 8 kg (75 lb) PVDF 10 kg (23 lb) Air Inlet……………………..……….6 mm (1/4") Inlet…...…………………...…………25 mm (1") Outlet………………...………………25 mm (1") Suction Lift……………………...3.4 m Dry (11') 8.8 m Wet (29') Disp. per Stroke ……...…..0.23 L (0.061 gal) Max. -

Page 10: Suction Lift Capability

P2 Clamped Plastic SECTION 5 SUCTION LIFT CAPABILITY P2 PLASTIC SUCTION- LIFT CAPABILITY Suction-lift curves are calibrated for pumps operating at 305 m (1,000') above sea level. This chart is meant to be a guide only. There are many variables that can affect your pump's operating characteristics. -

Page 11: Section 6: Suggested Installation, Operation, Maintenance, And Troubleshooting

The suction pipe size should be at least equal to or larger than the elbows, bends and fittings should be avoided. Pipe sizes should diameter size of the suction inlet on your Wilden pump. The suction be selected to keep friction losses within practical limits. All piping hose must be a non-collapsible, reinforced type because these should be supported independently of the pump. - Page 12 Frequency of use, line pressure, viscosity and abrasiveness of process fluid all affect the parts life of a Wilden Operation pump. Periodic inspections have been found to offer the best means The Pro-Flo pumps are pre-lubricated and do not require in- line for preventing unscheduled pump downtime.

-

Page 13: Section 7: Disassembly/Reassembly

P2 Clamped Plastic SUGGESTED INSTALLATION, OPERATION, MAINTENANCE AND TROUBLESHOOTING Troubleshooting Pump air valve freezes. Pump will not run or runs slowly. Check for excessive moisture in the compressed air. Remove plug from pilot spool exhaust. Either install a dryer or a hot air generator for compressed Ensure that the air inlet pressure is at least 0.4 bar (5 psig) air. -

Page 14: Pump Disassembly

NOTE: The model used for these instructions incorporates rubber diaphragms, balls, and seats. Models with PTFE diaphragms, balls and seats are the same except where noted. NOTE: Replace worn parts with genuine Wilden parts for reliable performance. Step 1 Step 2... - Page 15 P2 Clamped Plastic DISASSEMBLY / REASSEMBLY Step 4 Step 5 Step 6 Remove the top liquid retainer and Using a 1/2" socket driver, loosen the Remove the bottom liquid retainer and retainer O-rings, discharge valve balls, bottom retainers. retainer O-rings, discharge valve balls, seats and valve seat O-rings from the seats and valve seat O-rings from the liquid chamber and inspect for nicks,...

- Page 16 Using two 1" sockets, remove diaphragm Inspect diaphragms, outer and inner and inspect O-rings for signs of wear. assembly from center section assembly. pistons and disc spring (not shown) for signs of wear. Replace with genuine Wilden parts if necessary. WIL-10150-E-12...

-

Page 17: Air Valve Disassembly

Be aware of any hazardous effects of contact O-Ring Pick with your process fluid. NOTE: Replace worn parts with genuine Wilden parts for reliable performance. Step 1 Step 2 Step 3 Loosen the air valve bolts utilizing a 3⁄16"... - Page 18 P2 Clamped Plastic DISASSEMBLY / REASSEMBLY Step 4 Step 5 Step 6 Remove air valve end cap to expose air Remove pilot spool sleeve retaining snap Remove pilot spool retaining snap valve spool by simply lifting up on end cap ring on both sides of center section with ring on both sides of center section once air valve bolts are removed.

- Page 19 P2 Clamped Plastic DISASSEMBLY / REASSEMBLY Step 9 Check center section Glyd™ rings for signs of wear. If necessary, remove Glyd™ rings with O-ring pick and replace. NOTE: Seals should not be removed from assembly. Seals are not sold separately. WIL-10150-E-12...

-

Page 20: Reassembly Hints And Tips

P2 Clamped Plastic DISASSEMBLY / REASSEMBLY REASSEMBLY HINTS AND TIPS Upon performing applicable maintenance to the air distribution system, Maximum Torque Specifications the pump can now be reassembled. Please refer to the disassembly instructions for photos and parts placement. Description Torque Air Valve, Pro-Flo®... - Page 21 P2 Clamped Plastic DISASSEMBLY / REASSEMBLY SHAFT SEAL INSTALLATION Pre-Installation Tools After all the old seals have been removed, the inside of the bushing The following tools can be used to aid in the installation of should be cleaned to ensure no debris is left that may cause premature the new seals: damage to the new seals.

-

Page 22: Gasket Kit Installation

P2 Clamped Plastic GASKET KIT INSTALLATION (02-9502-99) Carefully prepare sealing surfaces by removing all debris and foreign matter from diaphragm bead and all mating surfaces. If necessary, smooth or deburr all sealing surfaces. Mating surfaces must be properly aligned in order to ensure positive sealing characteristics. Step 1 Step 2 Step 3... -

Page 23: Section 8: Exploded View And Parts List

P2 Clamped Plastic SECTION 8 EXPLODED VIEW AND PARTS LIST P2 FULL-STROKE DIAPHRAGM-FITTED ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS WIL-10150-E-12... - Page 24 P2 Clamped Plastic EXPLODED VIEW AND PARTS LIST Qty. Per P2/ PKPPP/0400 P2/ PKPPP/0402 P2/ KKPPP/0400 P2/ KKPPP/0402 Item Part Description Pump Pro-Flo Air Valve Assembly 01-2010-20 01-2010-20 01-2010-20 01-2010-20 ® End Cap 01-2332-20 01-2332-20 01-2332-20 01-2332-20 O-Ring, End Cap 01-2395-52 01-2395-52 01-2395-52...

- Page 25 P2 Clamped Plastic EXPLODED VIEW AND PARTS LIST P2 PLASTIC REDUCED-STROKE ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN REPAIR KITS WIL-10150-E-12...

- Page 26 P2 Clamped Plastic EXPLODED VIEW AND PARTS LIST P2/ PKPPP/0400 P2/ PKPPP/0402 P2/ KKPPP/0400 P2/ KKPPP/0402 Item Part Description Qty. Pro-Flo Air Valve Assembly 01-2010-20 01-2010-20 01-2010-20 01-2010-20 ® End Cap 01-2332-20 01-2332-20 01-2332-20 01-2332-20 O-Ring, End Cap 01-2395-52 01-2395-52 01-2395-52 01-2395-52 Gasket, Air Valve...

-

Page 27: Section 9: Elastomer Options

P2 Clamped Plastic SECTION 9 ELASTOMER OPTIONS P2 PLASTIC Reduced - Stroke Bottom Full-Stroke Full-Stroke Backup Valve Seat Tee Section Top Retainer O- Backup Retainer O- Material Diaphragms (2) Valve Balls (4) Diaphragms (2) Diaphragms (2) O-Rings (4) O-Rings (4) Rings (2) Diaphragms (2) Rings (2) - Page 28 22069 Van Buren Street Grand Terrace, CA 92313-5651 USA P: +1 (909) 422 -1730 psgdover.com Where Innovation Flows ® ® Copyright 2021 PSG , a Dover Company ® reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. WIL-10150-E-12...

Need help?

Do you have a question about the Pro-Flo P2 and is the answer not in the manual?

Questions and answers