Summary of Contents for Feig Electronic TST FU3E

- Page 1 STARTUP TST FU3E Important ! You must read the function description before operating, connecting or starting up the door controller preliminary public (B) 2007-05-29 FU3E_Inbetriebnahme_7_GB.doc...

- Page 2 Violations will result in liability for damages. All rights reserved in case of patent granting or utility model listing. This Manual is directed especially at persons involved with starting up / commissioning the TST FU3E door controller of FEIG ELECTRONIC GmbH. Starting up the controller must be carried out only by officially trained electrical experts who are familiar with the safety standards of electrical drive and automation technology.

-

Page 3: Table Of Contents

Startup FU3E Contents Safety advisories Technical Data for TST FU3E Installing the Controller Electrical Connection Connecting the supply voltage....................7 Motor connections ........................8 Connecting the safety edge ......................9 Connecting limit switches......................10 4.4.1 Absolute encoder .........................10 4.4.2 Mechanical limit switches......................10 4.4.3 Incremental encoders........................11... -

Page 4: Safety Advisories

A device mark (nameplate with name and address of the manufacturer, serial number, model number, supply voltage and temperature range) must be applied by the user. FEIG ELECTRONIC GmbH Page 4 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 5: Technical Data For Tst Fu3E

Startup FU3E Technical Data for TST FU3E Abmessungen Gehäuse (B x H x T): FU3E: 300x400x120mm (excl. wall bracket) Installation: Vertical using wall bracket on housing bottom Supply voltage through L, N, PE: 400 V ± 10%, 50...60 Hz Permissible range: 200...480V ± 10% / 50...60Hz. -

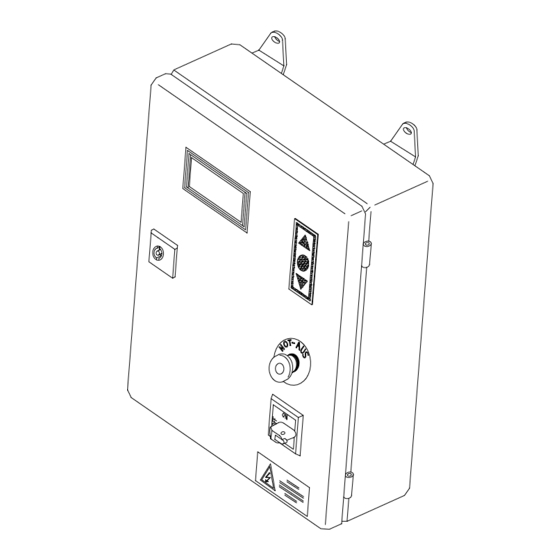

Page 6: Installing The Controller

• The cable entries are not allowed to have to the user. mech. stress. Min. 100mm 50°C -10°C Min. 100mm Fig. 1: Installing the controller Fig. 2: Hole pattern FEIG ELECTRONIC GmbH Page 6 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 7: Electrical Connection

All components connected to the controller must have 4.1 Connecting the supply voltage S1a S2a PE PE PE PE S1b S2b L3´ X17A Sicherung 16A / K-Typ Fig. 3: Connecting the mains cable FEIG ELECTRONIC GmbH Page 7 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 8: Motor Connections

Fig. 4: Motor connections MPORTANT To ensure flawless function of the TST FU3E door controller, a shielded motor cable must be used. In addition, no other wires may be routed except for those connecting the motor. If a motor with electro mechanical break is used you have to observe that the break is noise- suppressed. -

Page 9: Connecting The Safety Edge

• Dynamic optical systems. If one of these safety edges is connected when the TST FU3E door controller is turned on, the edge is automatically detected. IMPORTANT If no safety edge is connected, automatic closing of the door is not possible. -

Page 10: Connecting Limit Switches

FU3E 4.4 Connecting limit switches Three various limit switch systems can be used with the TST FU3E door controller. In the standard setting an absolute encoder is used as the limit switch. In addition, mechanical cam limit switches or incremental encoders may be used. -

Page 11: Incremental Encoders

CLOSE Fig. 12: Connecting incremental encoders 90° 180° Fig 11: Function of an incremental encoder IMPORTANT Recheck the electrical connections before starting up the controller. Improper connections may damage the device. FEIG ELECTRONIC GmbH Page 11 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 12: General Operating Notes For Parameterizing

3 seconds. IMPORTANT After approx. 1h service mode is automatically reset. To return to service mode, you must reset the controller or turn it OFF and then ON again. FEIG ELECTRONIC GmbH Page 12 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 13: Basic Settings

To set the TST FU3E door controller into service, please follow the steps below. 6.1 Automatic querying of the basic data If the TST FU3E door controller has not been preconfigured by the door manufacturer, the following parameters are automatically queried: IMPORTANT For the TST FU3E door controller to automatically query the parameters, DIP switch must be turned on (DIP switch location see Fig. -

Page 14: Changing Parameters

FU3E • Motor data P.100 – P.103 The following parameter setting is used to teach the TST FU3E door controller the motor type being used. Read the data from the nameplate and enter in the corresponding parameters. manufacturer Type signification P.100: Motor frequency... -

Page 15: Startup

(increases power at slow speeds) to give the motor more power. (see Section 7.4) IMPORTANT The distance depends greatly on the door type and the speed; increase this value for fast moving doors. FEIG ELECTRONIC GmbH Page 15 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 16: New Request For Teaching End Positions

You can use diagnostic parameter P.910 = 2 to display the motor current. The boost should be set so that the motor current remains as low as possible. FEIG ELECTRONIC GmbH Page 16 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 17: Additional Connection Possibilities

S1a S2a S1b S2b Photo eye External triggering device Fig. 17: External triggering devices Fig. 16: Photo eye connection Overview of outputs K4: Door is OPEN K3: Break K5: Door is CLOSE FEIG ELECTRONIC GmbH Page 17 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 18: Overview Of Inputs

13 15 17 19 21 23 25 27 29 31 S1b S2b 10 12 14 16 18 20 22 24 26 28 30 32 Absolut encoder Absolut encoder Mechanical limit switch Incremental encoder FEIG ELECTRONIC GmbH Page 18 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 19: Functions

2. Incremental encoder (reference switch in lower end position) 3. Absolute encoder DES-A 4. Absolute encoder TST PB-A 5. SSI encoder (only with UL-Version) 6. Reserved 7. Absolute encoder DES-B 8. Absolute encoder TST PD FEIG ELECTRONIC GmbH Page 19 of 29 FU3E_Inbetriebnahme_7_GB.doc... - Page 20 (travel frequency until Upper pre-limit switch) → adjust pre-limit switch as necessary [Hz] Frequency for fast close 6..200 (travel frequency until Lower pre-limit switch) → adjust pre-limit switch as necessary ATTENTION: Note closing forces on safety edge! FEIG ELECTRONIC GmbH Page 20 of 29 FU3E_Inbetriebnahme_7_GB.doc...

- Page 21 Eb - • Ebcl → Clear entire error memory • Eb - → Cancel (Display noEr: no error) Software version display Motor run-time during last door move 0..120.0 Line supply voltage display FEIG ELECTRONIC GmbH Page 21 of 29 FU3E_Inbetriebnahme_7_GB.doc...

- Page 22 1: Deadman Close (manual mode close / automatic mode open) 2: Deadman (manual mode for open and close) 3: Emergency (deadman open and close, all errors and securities are ignored). 0..FFFF Password entry FEIG ELECTRONIC GmbH Page 22 of 29 FU3E_Inbetriebnahme_7_GB.doc...

-

Page 23: Message Overview

F.052 recognized during automatic synchronization after power-on • The reference switch is not recognized in the associated end position. Maintenance counter exceeded Fault: Maintenance is required • Service counter has expired F.080 FEIG ELECTRONIC GmbH Page 23 of 29 FU3E_Inbetriebnahme_7_GB.doc... - Page 24 No module plugged in but was reported as present by a F.379 defective (coding pin or parameter parameter setting) • The controller was started up with another module than the one currently plugged in FEIG ELECTRONIC GmbH Page 24 of 29 FU3E_Inbetriebnahme_7_GB.doc...

- Page 25 • Overvoltage in intermediate Input voltage supply too low, usually at load F.521 circuit • Load too great / final stage or brake chopper fault FEIG ELECTRONIC GmbH Page 25 of 29 FU3E_Inbetriebnahme_7_GB.doc...

- Page 26 Absolute encoder processing electronics defective • Defective hardware or electrically noisy environment Distance Channel 1 <-> • Position encoder drive defective F.761 Channel 2 outside allowed • Defective hardware or electrically noisy environment window FEIG ELECTRONIC GmbH Page 26 of 29 FU3E_Inbetriebnahme_7_GB.doc...

-

Page 27: Internal System-Related Errors F.9Xx

Position values during calibration not correct or values are no longer plausible 12.1 Internal system-related errors F.9xx These are internal errors which cannot be eliminated by the user. If such an error occurs, call customer service immediately. FEIG ELECTRONIC GmbH Page 27 of 29 FU3E_Inbetriebnahme_7_GB.doc... -

Page 28: Information Messages

Forced opening being performed I.170 Wait for acknowledgement (operator call), display flashes I.185 Door cycle not plausible (re-initialize Parameters) I.199 Reference position corrected or recognized (after calibration) I.200 Reference position re-initialized I.201 FEIG ELECTRONIC GmbH Page 28 of 29 FU3E_Inbetriebnahme_7_GB.doc... - Page 29 E.379 RC plug-in module RC Channel 1 E.401 RC Channel 2 E.402 Induction loop processor plug-in module Detector Channel 1 E.501 Detector Channel 2 E.502 Internal inputs Controller chip fault signal E.900 FEIG ELECTRONIC GmbH Page 29 of 29 FU3E_Inbetriebnahme_7_GB.doc...

Need help?

Do you have a question about the TST FU3E and is the answer not in the manual?

Questions and answers