Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Genmitsu 3018-PRO

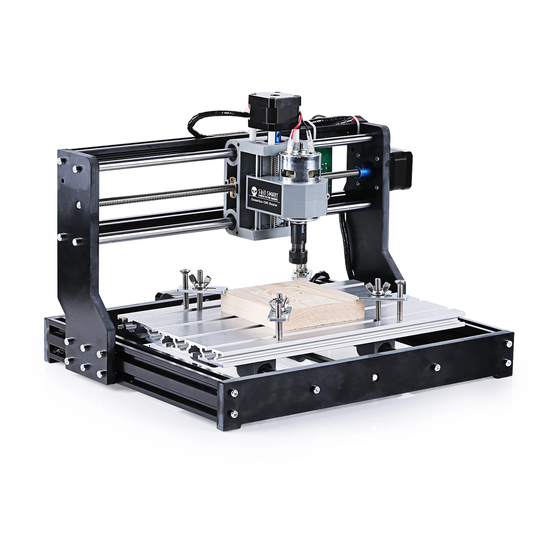

- Page 1 Genmitsu CNC Router 3018-PRO V1.1 Sept 2020...

- Page 2 Contents ............................Welcome ............................Disclaimer ........................... Part 1 - Unboxing ........................... Part 2 - Assembly ......................Part 3 - Software & Drivers ......................... Part 4 - Getting Started ......................Part 5 - Offline Controller...

- Page 3 Welcome Thank you for purchasing the Genmitsu 3018-PRO CNC Router from SainSmart. Included in your package will be a Micro SD card. On the Micro SD Card, you will find: ● Assembly instruction videos ● PDF version of this manual ●...

- Page 4 SainSmart cannot control the conditions in which you assemble your Genmitsu CNC machine or verify if it was done properly. We do not assume responsibility and expressly disclaim liability for loss, injuries, damage, or expense arising out of, or in any way connected with the assembly, handling, storage, use, or disposal of the product.

- Page 5 Part 1 - Unboxing Please make sure all the following parts are included. If you are missing any part or have any questions, please email us at support@sainsmart.com. (2) Aluminum Profile (2) Aluminum Profile Aluminum Profile (2) Guide Rail 20 x 40 x 290 mm 20 x 20 x 360mm 300 x 180mm X Axis, Ø10 x 360mm...

- Page 6 Spindle with ER11 installed X-Z Axis Assembly (4) Slider (10) Milling Cutter Control Board & (3) 4-Pin Motor Harness Spindle Motor Harness 24V Power Supply Fan & Case (4) Allen Wrench (4) Plate Clamp Spiral Wire Wrap USB Disk with SD Card 2.0mm,2.5mm, 3.0mm,4.0mm...

- Page 7 (4) Bolt M5 x 10 (34) Bolt M5 x 16 (8) Bolt M3 x 14 (2) Copper Nut (16) T-Nut 20M5 (10) T-Nut 30M5 (2) Anti-Backlash Spring (3) Coupling & Set Screw Nut Seat...

- Page 8 Optional Accessories (Not Included) Consider following optional upgrades or accessories to make your CNC experience better! You can find them on www.sainsmart.com. Save 10% with discount code 3018PRO10 Resin Board for CNC Acrylic Sheet for CNC, 5.5W Laser Module CNC Router Bits Essential Kit Engraving, 2-Pack 180 x 100 x 5mm, 4-Pcs Scan QR codes to learn more...

- Page 9 Part 2 - Assembly Step 1 Base Installation What you will need (2) Aluminum Profile (2) Guide Rail Bakelite Resin Plate A 20 x 40 x 290 mm Y Axis, Ø10 x 290mm Bakelite Resin Plate B (4) Slider (12) Bolt M5 x 16...

- Page 10 Bakelite Resin Plate B (2) Aluminum Profile 20 x 40 x 290 mm (2) Guide Rail Y Axis, Ø10 x 290mm (4) Slider (12) Bolt Bakelite M5 x 16 Resin Plate A Notes: Make sure this assembly is square and that the sliders are installed on the guide rails with the holes to the front and rear of the base.

- Page 11 Step 2 Worktable Assembly What you will need Aluminum Profile Lead Screw 295mm Stepper motor 300 x 180mm (10) Bolt M5 x 16 (4) Bolt M3 x 14 Copper Nut Anti-Backlash Coupling (10) T-Nut 30M5 Nut Seat Spring & Set Screw...

- Page 12 (10) Bolt M5 x 16 (10) T-Nut Stepper motor Coupling Lead 30M5 & Set Screw Screw 295mm (4) Bolt M3 x 14 Aluminum Profile 300 x 180mm...

- Page 13 Step 3 Base Assembly - Completed View Top view...

- Page 14 Top view...

- Page 15 Step 4 Top Frame Assembly What you will need Bakelite Resin Plate C (6) Bolt M5 x 16 (6) T-Nut 20M5 STEP 1: Position the Bakelite Pillars with a spacing of 46.5mm between rear frame piece and back of the pillar as shown in the Completed View on the next page. Tip: When installing T-Nuts it helps to twist them onto the bolts a few turns keeping them in place before placing into the Aluminum slot.

- Page 16 Step 5 Completed View Note: Back edge of Bakelite-C must be 90 degrees to the base.

- Page 17 Step 6 X-Z Axis Assembly Installation What you will need (2) Aluminum Profile (2) Guide Rail Lead Screw 365mm 20 x 20 x 360mm X Axis, Ø10 x 360mm (2) Stepper motor X-Z Axis Assembly (4) Bolt M5 x 16 (4) Bolt M3 x 14 Copper Nut Anti-Backlash Spring...

- Page 18 (2) Aluminum Profile 20 x 20 x 360mm Lead Screw 365mm (2) Guide Stepper Rail X Axis motor Ø10 x 360mm Coupling & Set Screw (4) Bolt M5 x 16 (4) Bolt M3 x 14 X-Z Axis Assembly Brass Nut...

- Page 19 Step 7 Bakelite-D Installation What you will need Bakelite Resin Plate D (10) Bolt M5 x 16 (6) T-Nut (10) Bolt 20M5 M5 x 16 Bakelite Resin Plate D (6) T-Nut 20M5...

- Page 20 Step 8 Z - Axis Assembly Step 1: Prepare the Z Axis Carriage and Leadscrew. Compress the Anti-Backlash Spring into the Hole shown below. Use the Copper Nut to slide into the spring and hold it into place. While compressed, thread the Leadscrew through the assembly.

- Page 21 Step 9 X-Axis Assembly Step 1: Install (2) Aluminum Frame pieces to Bakelite Pillar C with M5x16mm Bolts. Step 2: Install (2) Linear Rods into the holes next to the Frame pieces using M5x16mm Bolts. Step 3: Prepare the Stepper Motor and Install the Coupler and screw. Set the screw positioned on the Flat side of the Stepper Motor Shaft.

- Page 22 Step 10 X - Control Board Installation...

- Page 23 Do not overtighten the bolt. This can damage the holder. Slide the Spindle down until about half an inch of sleeve is showing. Caution...

- Page 24 Step 11 Control Board Installation What you will need Control Board & Fan & Case Control Board & Fan & Case (4) Bolt M5 x 10 (4) T-Nut 20M5 (4) Bolt M5 x 10 (4) T-Nut 20M5...

- Page 25 Step 12 Wiring Diagram Connect the red wire to the Stepmotor port next to the red mark Spindle Laser (12V 5Amax) (Not include) 24V DC Power adapter Connect your CNC to computer using the bundled USB cable POWER Offline controller ON/OFF...

- Page 26 Part 3 - Software & Drivers 1. Install the driver ( software Driver CH340SER.exe )

- Page 27 2. To Determine your Machine's COM port: • Windows XP: Right click on "My Computer", select "Manage", select "Device Manager". • Windows 7: Click "Start" Right click "Computer" Select "Manage" Select "Device Manager" from left pane. • In the tree, expand "Ports (COM & LPT)" •...

- Page 28 3. Open Grblcontrol software(software Grblcontrol GrblControl.exe) choose the correct port...

- Page 29 • Console window print ” [CTRL+X] < Grbl 1.1f ['$' for help]” If the connection is successful. • Console window print ” Serial port error 1: No such file or directory “ indicate that the connection is failed. successful unsuccessful...

- Page 30 • Grblcontrol Use The spindle speed: It does not represent the actual speed, and it represents the ratio. And this percentage is not linear. 100 = 100/1000 spindle 1000 = 1000/1000 100% max on/off 100% The X Y Z axis jog...

- Page 31 • Tool setting spindle should be on when moving the bits zero XY zero Z Use the jog to move the milling cutter. Then click button zeroXY and zeroZ. Open the G-code file Start working End...

- Page 32 Part 4 - Getting Started Basic Machine Tests Now that you have your CNC machine all assembled and wired, it is time to make sure that it operates correctly. This is the recommended start up order for the system. 1. Make sure that the USB cable from the CNC machine is plugged into your computer, then start the computer. 2.

- Page 33 Part 5 - Offline Controller Notice: When using the offline controller, remove the USB cable from the PC. Offline controller and PC cannot be used together. 1. Connect offline controller to PC via USB cable.

- Page 34 2. Then copy the NC file to the offline controller.

- Page 35 3. Offline controller connected to the control board. 4. Press the [X+/X-/Y+/Y-/Z+/Z-] key to move the spindle to the machine origin, select the engraving file, click the [OK] key to start engraving.

- Page 36 5. Interface introduction A. Menu Page Ctrl Machine Control File Use the G-code file Press key [Y+] or [Y-] to select Press key [OK] to Enter...

- Page 37 B. Ctrl Page Reference direction X-axis positive direction X-axis negative direction Y-axis positive direction Y-axis negative direction Z-axis positive direction Z-axis negative direction OK/Spindle(SP) Spindle On/Off Long press to exit, short press to Exit/Step change step (0.1/1/5/10mm) Power to spindle (Press [OK]+[Z+]=add, SP:1% Press [OK]+[Z+]=reduce)

- Page 38 C. File Page Press key [Y+] or [Y-] to select file Press key [OK] to Enter Press key [OK] to begin if you are ready.

- Page 39 Genmitsu Desktop CNC & Laser www.sainsmart.com support@sainsmart.com Vastmind LLC, 5892 Losee Rd Ste. 132, N. Las Vegas, NV 89081...

Need help?

Do you have a question about the 3018-PRO and is the answer not in the manual?

Questions and answers

I HAVE ONE 3018 PRO VER MY SPINDLE RUN SLOW AND HAVE A OUND AND ONE BLUE LIGHT ON TO YOU KNOW WHY