Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Festo DGC-HD Series

- Page 1 DGC-HD Linear drive Instructions | Operat- 8100423 8100423 2018-10b [8100425]...

- Page 2 Translation of the original instructions Festo — DGC-HD — 2018-10b...

-

Page 3: Table Of Contents

Installing the product....................6 6.1.2 Installation of the payload..................8 6.1.3 Installation of accessories..................9 Pneumatic installation....................9 Commissioning......................11 Maintenance and care....................12 Repair........................... 14 Accessories........................14 Fault clearance......................15 Technical data......................16 Characteristic curves....................17 Festo — DGC-HD — 2018-10b... -

Page 4: Applicable Documents

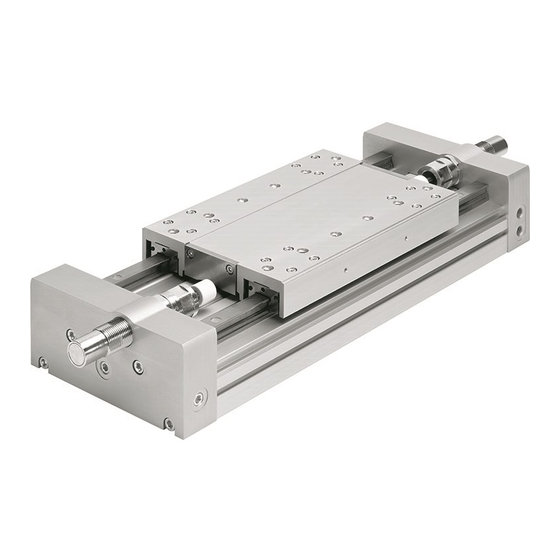

Applicable documents Applicable documents All available documents for the product è www.festo.com/pk. Operating elements and connections 1 Shock absorber (2x) 7 Supply ports 2 Guide rail (2x) 8 Surface for profile mounting 3 Lubrication hole for bearing guide (4x) 9 Slot for accessories (at both ends) -

Page 5: Transport And Storage

Observe the warnings and notes on the product and in the relevant operating instructions. – Remove transport packaging, such as films, caps and cardboard. The material used in the packaging has been specifically chosen for its recyclability (exception: oiled paper = residual waste). Festo — DGC-HD — 2018-10b... -

Page 6: Installation

Ensure an installation without distortions and bends (evenness of the bearing surface ≤ 0.05 % of the stroke length; max. 0.5 mm). For gantry applications, attention must also be paid to parallel alignment when aligning the axes. For additional information, please contact your local Festo Ser- vice. - Page 7 Installation 2. Please select the corresponding accessories from our catalogue (è www.festo.com/catalogue). Profile mounting Slot nut mounting Profile mounting in the slot for the mounting Slot nut mounting in the slot Fig. 1. aJ è surface Fig. 1. When tilting, the slot nuts glide into the slot at 8è...

-

Page 8: Installation Of The Payload

2. Ensure that the tightening torques and the max. screw-in depth D are observed. Fig. 6 Size Screw (side/top) Max. screw-in depth D [mm] Centring hole (H7) [mm] Æ Æ Æ Tightening torque [Nm] Tab. 3 For payloads with own guide: Festo — DGC-HD — 2018-10b... -

Page 9: Installation Of Accessories

• Use an emergency buffer or shock absorber (è assembly instructions for the accessories used). To avoid contamination: • Use slot covers in all unused slots. Pneumatic installation For installation in a vertical or sloping position: Festo — DGC-HD — 2018-10b... - Page 10 Supply port ex works (movement to connection side Alternative connection (movement to shutoff side Alternative connection (movement to connection side Shutoff side Connection side Tab. 4 To set the speed: • Screw the one-way flow control valves GRLA into the check valves. Festo — DGC-HD — 2018-10b...

-

Page 11: Commissioning

Initially simultaneously at both sides. This causes the slide to move slightly to a point of bal- ance. – Then exhaust the DGC-HD on just one side. This prevents peak loads on the DGC-HD and in the compressed air system. 3. Start a test run. Festo — DGC-HD — 2018-10b... -

Page 12: Maintenance And Care

1. Clean the belt system and the guide rail with a soft cloth as required. Any agents that do not dam- age the material may be used as cleaning agents. 2. Avoid cleaning agents which will damage the belt system (PU). Excessive friction or grease-solvent cleaning agents (e.g. soap suds) will damage the grease layer. Festo — DGC-HD — 2018-10b... - Page 13 1. Calculate the load comparison factor fv with the help of the formula for combined loads (è 12 Technical data) and determine the lubricating interval Sint (è Fig.12). Fig. 12 2. Grease the bearing guide on both sides at all lubrication holes 3. Festo — DGC-HD — 2018-10b...

-

Page 14: Repair

Repair Fig. 13 3. Move the slide along the complete positioning path during lubrication in order to distribute the grease evenly. Alternatively, Festo offers inspection services including re-lubrication. Otherwise, the DGC-HD is main- tenance-free. Repair – Recommendation: Send the DGC-HD to our repair service. -

Page 15: Fault Clearance

Roller bearing/bearing guide is defect- Grease the DGC-HD 8 Maintenance and care) è Send the DGC-HD to Festo for repair Slide does not Loads too high Reduce payload/travel speed move Retaining screws for the payload are... -

Page 16: Technical Data

13000 Permissible torques on the slide Mx [Nm] My = Mz [Nm] 1450 Condition for combined loads: Note on materials Contains paint-wetting impairment substances Materials Profile, cover, slide Aluminium Ball bearing, guide, screws Steel Scraper Festo — DGC-HD — 2018-10b... -

Page 17: Characteristic Curves

The following tool is available for sizing tasks: "DGC-QuickCalc" engineering software ( www.festo.com/sp) Tab. 9 Characteristic curves Max. permissible support spacing l depending on the force F Fig. 14 DGC-HD 10000 1000 1500 2500 3500 l [mm] DGC-18-HD DGC-40-HD DGC-25-HD Fig. 15 Festo — DGC-HD — 2018-10b... - Page 18 Characteristic curves Fig. 16 DGC-HD 10000 1000 1000 2000 3000 4000 5000 l [mm] DGC-18-HD DGC-40-HD DGC-25-HD Fig. 17 Festo — DGC-HD — 2018-10b...

- Page 20 Copyright: Festo AG & Co. KG Ruiter Straße 82 73734 Esslingen Germany Phone: +49 711 347-0 Fax: +49 711 347-2144 Reproduction, distribution or sale of this document or communic- e-mail: ation of its contents to others without express authorization is service_international@festo.com...

Need help?

Do you have a question about the DGC-HD Series and is the answer not in the manual?

Questions and answers