Table of Contents

Advertisement

Quick Links

NuMaker-M252KG

®

®

ARM

Cortex

-M

32-bit Microcontroller

NuMaker-M252KG

User Manual

®

NuMicro

M252 Series

The information described in this document is the exclusive intellectual property of

Nuvoton Technology Corporation and shall not be reproduced without permission from Nuvoton.

Nuvoton is providing this document only for reference purposes of NuMicro microcontroller based system

design. Nuvoton assumes no responsibility for errors or omissions.

All data and specifications are subject to change without notice.

For additional information or questions, please contact: Nuvoton Technology Corporation.

www.nuvoton.com

July.

08, 2020

Page 1 of 49

Rev 1.00

Advertisement

Table of Contents

Summary of Contents for Nuvoton NuMicro M252 Series

- Page 1 The information described in this document is the exclusive intellectual property of Nuvoton Technology Corporation and shall not be reproduced without permission from Nuvoton. Nuvoton is providing this document only for reference purposes of NuMicro microcontroller based system design. Nuvoton assumes no responsibility for errors or omissions.

-

Page 2: Table Of Contents

Status LEDs ....................27 3.11.2 Quick Start ..................28 Toolchains Supporting ................28 Nuvoton Nu-Link Driver Installation ..............28 BSP Firmware Download ................30 Hardware Setup ..................30 Find the Example Project ................32 Execute the Project under Toolchains ............. 32 July. - Page 3 NuMaker-M252KG Keil MDK ....................... 32 4.6.1 IAR EWARM ....................36 4.6.2 NuEclipse ...................... 37 4.6.3 NuMaker-M252KG Schematics ..............44 Nu-Link2-Me ................... 44 M252 platform ..................45 Extension Connector ................. 46 PCB Placement ..................47 REVISION HISTORY ................48 July. 08, 2020 Page 3 of 49 Rev 1.00...

- Page 4 NuMaker-M252KG List of Figures Figure 1-1 NuMaker-M252KG Board ....................7 Figure 3-1 Front View of NuMaker-M252KG ................... 9 Figure 3-2 Rear View of NuMaker-M252KG .................. 10 Figure 3-3 M252KG6AE Extension Connectors ................11 Figure 3-4 Arduino UNO Compatible Extension Connectors ............17 Figure 3-5 External Power Supply Sources on Nu-Link2-Me ............

- Page 5 NuMaker-M252KG Figure 4-28 NuEclipse Debug Mode ....................43 Figure 4-29 Debug Message on Serial Port Terminal Windows ............ 43 Figure 5-1 Nu-Link2-Me Circuit ...................... 44 Figure 5-2 M252 platform Circuit....................45 Figure 5-3 Extension Connectors Circuit ..................46 Figure 5-4 Front Placement ......................47 Figure 5-5 Rear Placement ......................

- Page 6 NuMaker-M252KG List of Tables Table 3-1 Extension Connectors ....................11 Table 3-2 M252KG6AE Full-pin Extension Connectors and GPIO Function List ......16 Table 3-3 Arduino UNO Extension Connectors and M252KG6AE Mapping GPIO List ....18 Table 3-4 Vin Power Source ......................19 Table 3-5 5V Power Sources ......................

-

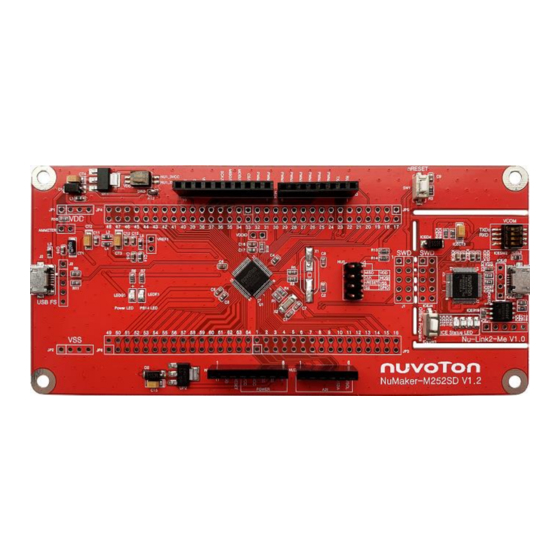

Page 7: Overview

M252KG6AE. For the development flexibility, the M252 platform provides the extension connectors of M252KG6AE, the Arduino UNO compatible headers and able to adopt multiple power supply. Furthermore, the Nuvoton-designed ammeter connector can measure the power consumption instantly, which is essential for the prototype evaluation. -

Page 8: Features

NuMaker-M252KG FEATURES ® NuMicro M252KG6AE microcontroller with function compatible with: M252SG6AE M252LG6AE M252KG6AE extension connectors Arduino UNO compatible extension connectors Ammeter connector for measuring the microcontroller’s power consumption Fixable board power supply: External V power connector ... -

Page 9: Hardware Configuration

NuMaker-M252KG HARDWARE CONFIGURATION Front View Arduino UNO Compatible Extension Switch Connector Reset Button External V Connector Ammeter VCOM Switch External V Connector ICE USB Connector USB FS Connector ICE Chip: M48SSIDAE Power LED ICE Status LED PB14 LED Off-line Program Button External V Connector M252 Platform... -

Page 10: Rear View

NuMaker-M252KG Rear View Figure 3-2 shows the main components and connectors from the rear side of NuMaker-M252KG. The following lists components and connectors from the rear view: Nu-Link2-Me MCUVCC Power Switch (ICEJPR1) ICEVCC Power Switch (ICEJPR2) ICEVCC Power Switch MCUVCC Power Switch Figure 3-2 Rear View of NuMaker-M252KG... -

Page 11: Extension Connectors

NuMaker-M252KG Extension Connectors Table 3-1 presents the extension connectors. Connector Description JP3, JP4, JP5 and JP6 Full pins extension connectors on the NuMaker-M252KG. NU1, NU2, NU3 and NU4 Arduino UNO compatible pins on the NuMaker-M252KG. Table 3-1 Extension Connectors 3.3.1 Pin Assignment for Extension Connectors The NuMaker-M252KG provides the M252KG6AE target chip onboard and full pins extension connectors (JP3, JP4, JP5 and JP6). - Page 12 NuMaker-M252KG M252KG6AE Header Pin No. Function PB.5/EADC0_CH5/ACMP1_N/EBI_ADR0/I2C0_SCL/USCI1_CTL0/SC0_CLK/PWM0_CH0/PSIO0_C JP3.1 H4/UART2_TXD/TM0/INT0 PB.4/EADC0_CH4/ACMP1_P1/EBI_ADR1/I2C0_SDA/USCI1_CTL1/SC0_DAT/PWM0_CH1/PSIO0_ JP3.2 CH5/UART2_RXD/TM1/INT1 PB.3/EADC0_CH3/ACMP0_N/EBI_ADR2/I2C1_SCL/UART1_TXD/USCI1_DAT1/SC0_RST/PWM0_ JP3.3 CH2/PSIO0_CH6/PWM0_BRAKE0/TM2/INT2 PB.2/EADC0_CH2/ACMP0_P1/OPA0_O/EBI_ADR3/I2C1_SDA/UART1_RXD/USCI1_DAT0/SC0_P JP3.4 WR/PWM0_CH3/PSIO0_CH7/TM3/INT3 PC.12/EBI_ADR4/UART0_TXD/I2C0_SCL/SC0_nCD/PWM1_CH0/ACMP0_O JP3.5 PC.11/EBI_ADR5/UART0_RXD/I2C0_SDA/PWM1_CH1/ACMP1_O JP3.6 PC.10/EBI_ADR6/PWM1_CH2 JP3.7 PC.9/EBI_ADR7/PWM1_CH3 JP3.8 PB.1/EADC0_CH1/OPA0_N/EBI_ADR8/UART2_TXD/USCI1_CLK/I2C1_SCL/QSPI0_MISO1/PWM0 JP3.9 _CH4/PWM1_CH4/PWM0_BRAKE0 PB.0/EADC0_CH0/OPA0_P/EBI_ADR9/UART2_RXD/SPI0_I2SMCLK/I2C1_SDA/QSPI0_MOSI1/P JP3.10 WM0_CH5/PWM1_CH5/PWM0_BRAKE1 JP3.11 JP3.12 PA.11/ACMP0_P0/EBI_nRD/USCI0_CLK/BPWM0_CH0/TM0_EXT JP3.13 PA.10/ACMP1_P0/EBI_nWR/USCI0_DAT0/BPWM0_CH1/TM1_EXT/DAC0_ST JP3.14 PA.9/EBI_MCLK/USCI0_DAT1/UART1_TXD/BPWM0_CH2/TM2_EXT JP3.15 PA.8/EBI_ALE/USCI0_CTL1/UART1_RXD/BPWM0_CH3/TM3_EXT/INT4 JP3.16 JP3.17...

- Page 13 NuMaker-M252KG M252KG6AE Header Pin No. Function JP3.30 PF.5/UART2_RXD/UART2_nCTS/PWM0_CH0/BPWM0_CH4/X32_IN/EADC0_ST JP3.31 PF.4/UART2_TXD/UART2_nRTS/PWM0_CH1/BPWM0_CH5/X32_OUT JP3.32 JP5.1 JP5.2 JP5.3 JP5.4 PF.3/EBI_nCS0/UART0_TXD/I2C0_SCL/XT1_IN/BPWM1_CH0 JP5.5 PF.2/EBI_nCS1/UART0_RXD/I2C0_SDA/QSPI0_CLK/XT1_OUT/BPWM1_CH1 JP5.6 JP5.7 JP5.8 PE.8/EBI_ADR10/USCI1_CTL1/UART2_TXD/PWM0_CH0/PWM0_BRAKE0 JP5.9 PE.9/EBI_ADR11/USCI1_CTL0/UART2_RXD/PWM0_CH1/PWM0_BRAKE1 JP5.10 PE.10/EBI_ADR12/USCI1_DAT0/PWM0_CH2/PWM1_BRAKE0 JP5.11 PE.11/EBI_ADR13/USCI1_DAT1/UART1_nCTS/PWM0_CH3/PWM1_BRAKE1 JP5.12 PE.12/EBI_ADR14/USCI1_CLK/UART1_nRTS/PWM0_CH4 JP5.13 PE.13/EBI_ADR15/I2C0_SCL/UART1_TXD/PWM0_CH5/PWM1_CH0/BPWM1_CH5 JP5.14 PC.8/EBI_ADR16/I2C0_SDA/UART1_RXD/PWM1_CH1/BPWM1_CH4 JP5.15 PC.7/EBI_AD9/UART0_nCTS/I2C1_SMBAL/PWM1_CH2/BPWM1_CH0/TM0/INT3 JP5.16 PC.6/EBI_AD8/UART0_nRTS/I2C1_SMBSUS/PWM1_CH3/BPWM1_CH1/TM1/INT2 JP5.17 PA.7/EBI_AD7/UART0_TXD/I2C1_SCL/PWM1_CH4/BPWM1_CH2/ACMP0_WLAT/TM2/INT1 JP5.18 PA.6/EBI_AD6/UART0_RXD/I2C1_SDA/PWM1_CH5/BPWM1_CH3/ACMP1_WLAT/TM3/INT0 JP5.19...

- Page 14 NuMaker-M252KG M252KG6AE Header Pin No. Function BPWM0_CH0/PWM0_CH5/DAC0_ST JP5.29 DDIO PE.14/EBI_AD8/UART2_TXD/PSIO0_CH0 JP5.30 PE.15/EBI_AD9/UART2_RXD/PSIO0_CH1 JP5.31 nRESET JP5.32 Note: It is recommended to use 10 kΩ pull-up resistor and 10 uF capacitor on nRESET pin. PF.0/UART1_TXD/I2C1_SCL/UART0_TXD/BPWM1_CH0/ICE_DAT JP4.1 Note: It is recommended to use 100 kΩ pull-up resistor on ICE_DAT pin. PF.1/UART1_RXD/I2C1_SDA/UART0_RXD/BPWM1_CH1/ICE_CLK JP4.2 Note: It is recommended to use 100 kΩ...

- Page 15 NuMaker-M252KG M252KG6AE Header Pin No. Function PD.1/EBI_AD12/USCI0_DAT0/SPI0_MISO JP4.26 PD.0/EBI_AD13/USCI0_CLK/SPI0_MOSI/TM2 JP4.27 PD.13/EBI_AD10/SPI0_I2SMCLK/USCI2_CTL0 JP4.28 USB_VBUS JP4.29 USB_D- JP4.30 USB_D+ JP4.31 USB_VDD33_CAP JP4.32 PE.7/PSIO0_CH0/PWM0_CH0/BPWM0_CH5 JP6.1 PE.6/SC0_nCD/USCI0_CTL0/PSIO0_CH1/PWM0_CH1/BPWM0_CH4 JP6.2 PE.5/EBI_nRD/SC0_PWR/USCI0_CTL1/PSIO0_CH2/PWM0_CH2/BPWM0_CH3 JP6.3 PE.4/EBI_nWR/SC0_RST/USCI0_DAT1/PSIO0_CH3/PWM0_CH3/BPWM0_CH2 JP6.4 PE.3/EBI_MCLK/SC0_DAT/USCI0_DAT0/PWM0_CH4/BPWM0_CH1 JP6.5 PE.2/EBI_ALE/SC0_CLK/USCI0_CLK/USCI2_CTL0/PWM0_CH5/BPWM0_CH0 JP6.6 JP6.7 JP6.8 PE.1/EBI_AD10/QSPI0_MISO0/I2C1_SCL/USCI2_DAT1 JP6.9 PE.0/EBI_AD11/QSPI0_MOSI0/I2C1_SDA/USCI2_DAT0 JP6.10 JP6.11 JP6.12 JP6.13 JP6.14 JP6.15...

-

Page 16: Table 3-2 M252Kg6Ae Full-Pin Extension Connectors And Gpio Function List

NuMaker-M252KG M252KG6AE Header Pin No. Function JP6.25 JP6.26 PB.11/EADC0_CH11/EBI_ADR16/UART0_nCTS/I2C1_SCL/SPI0_I2SMCLK/BPWM1_CH0 JP6.27 PB.10/EADC0_CH10/EBI_ADR17/USCI1_CTL0/UART0_nRTS/I2C1_SDA/BPWM1_CH1 JP6.28 PB.9/EADC0_CH9/EBI_ADR18/USCI1_CTL1/UART0_TXD/UART1_nCTS/I2C1_SMBAL/BPWM1_C JP6.29 PB.8/EADC0_CH8/EBI_ADR19/USCI1_CLK/UART0_RXD/UART1_nRTS/I2C1_SMBSUS/BPWM1_ JP6.30 PB.7/EADC0_CH7/EBI_nWRL/USCI1_DAT0/UART1_TXD/EBI_nCS0/BPWM1_CH4/PWM1_BRAKE JP6.31 0/PWM1_CH4/INT5/ACMP0_O PB.6/EADC0_CH6/EBI_nWRH/USCI1_DAT1/UART1_RXD/EBI_nCS1/BPWM1_CH5/PWM1_BRAK JP6.32 E1/PWM1_CH5/INT4/ACMP1_O Table 3-2 M252KG6AE Full-pin Extension Connectors and GPIO Function List July. 08, 2020 Page 16 of 49 Rev 1.00... -

Page 17: Arduino Uno Compatible Extension Connectors

NuMaker-M252KG 3.3.2 Arduino UNO Compatible Extension Connectors Figure 3-4 shows the Arduino UNO compatible extension connectors. MOSI PA.10 PB.15 USCI0_DAT0 MISO RESET PA.9 PA.11 nRESET PA.8 USCI0_DAT1 USCI0_CLK UART1_RXD PWM0_CH3 PB.2 PB.1 EADC0_CH1 I2C1_SCL UART2_TXD PB.0 EADC0_CH0 I2C1_SDA UART2_RXD UART1_TXD PWM0_CH2 PB.3 PB.4... -

Page 18: Table 3-3 Arduino Uno Extension Connectors And M252Kg6Ae Mapping Gpio List

NuMaker-M252KG NuMaker-M252KG NuMaker-M252KG Header Header Compatible to Compatible to GPIO Pin of M252 GPIO Pin of M252 Arduino UNO Arduino UNO NU3.1 PB.2 NU2.6 PB.1 NU3.2 PB.3 NU2.5 PB.0 NU3.3 PC.4 NU2.4 PB.4 NU3.4 PC.5 NU2.3 PB.5 NU3.5 PC.3 NU2.2 PB.6 NU3.6 PC.2... -

Page 19: Power Supply Configuration

NuMaker-M252KG Power Supply Configuration The NuMaker-M252KG is able to adopt multiple power supply. External power source includes NU1 Vin (7 V to 12 V), VDD (depends on target chip operating voltage), and PC through USB connector. By using switches and voltage regulator, multiple power domains can be created on the NuMaker- M252KG. -

Page 20: Power Sources

NuMaker-M252KG 3.4.2 5 V Power Sources Table 3-5 presents the 5 V power sources. Net Name in Connector Comment Schematic ICE USB connector supplies 5 V power from PC to ICEJ3 USB_HS_VBUS M252 platform and Nu-Link2-Me. USB connector on NuMaker-M252KG supplies 5 V USB_VBUS power from PC to M252 platform and Nu-Link2-Me. -

Page 21: Power Connectors

NuMaker-M252KG 3.4.5 Power Connectors Table 3-8 presents the power connectors. Connector Comment connector on the NuMaker-M252KG connector on the NuMaker-M252KG. Table 3-8 Power Connectors 3.4.6 USB Connectors Table 3-9 presents the USB connectors. Connector Comment ICE USB connector on Nu-Link2-Me for power supply, debugging and ICEJ3 programming from PC. -

Page 22: Power Supply Models

NuMaker-M252KG 3.4.8 Power Supply Models External Power Supply through Nu-Link2-Me to Target Chip The external power supply source on Nu-Link2-Me is shown in Figure 3-5. ICE USB Connector (ICEJ3) Nu-Link2-Me NuMaker-RoLaD-M252 V1.1 Figure 3-5 External Power Supply Sources on Nu-Link2-Me To use ICEJ3 as external power supply source with Nu-Link2-Me, please follow the below steps: 1. -

Page 23: Figure 3-6 External Power Supply Sources On M252 Platform

NuMaker-M252KG External Power Supply through M252 platform to Target Chip The external power supply sources on M252 platform are shown in Figure 3-6. External V Connector (JP1) USB Power Connector (J2) External V Connector (JP2) NU1 pin8 (Vin) Figure 3-6 External Power Supply Sources on M252 platform To use Vin or J2 as external power supply source, please follow the below steps: 1. -

Page 24: Figure 3-7 Separate The Nu-Link2-Me From Numaker-M252Kg

NuMaker-M252KG External V Connector (JP1) USB Power Connector (J2) External V Connector " (JP2) Separate Nu-Link2-Me NU1 pin8 (Vin) Figure 3-7 Separate the Nu-Link2-Me from NuMaker-M252KG Table 3-12 presents all power models when supplies external power through M252 platform. The M252 platform external power sources are highlighted in yellow. -

Page 25: External Reference Voltage Connector

NuMaker-M252KG External Reference Voltage Connector Table 3-13 presents the external reference voltage connector. Connector Comment Connector for user to easily connect to the external reference voltage pin VREF1 of the target chip. User needs to remove the L5 ferrite bead. Table 3-13 External Reference Voltage Connector Voltage Adjustable Interface(VAI) Connector Table 3-14 presents the voltage adjustable interface connector. -

Page 26: Push-Buttons

NuMaker-M252KG Push-Buttons Table 3-17 presents the push-buttons. Component Comment ICESW1 Off-line program button to start off-line programming the target chip. Reset button to reset the target chip. Table 3-17 Push-Buttons LEDs Table 3-18 presents the LEDs. Component Comment Power LED The power LED indicates that the NuMaker-M252KG is powered. -

Page 27: 3.11.2 Status Leds

NuMaker-M252KG 3.11.2 Status LEDs Table 3-20 presents the status LEDs patterns for different operation on Nu-Link2-Me. Status LED Operation Status ICES0 ICES1 ICES2 ICES3 Power on Flash x 3 Flash x 3 Flash x 3 Flash x 3 Connected to IDE/NuTool Flash x 3 Flash x 3 Flash x 3... -

Page 28: Quick Start

KEIL MDK Nuvoton edition M0/M23 IAR EWARM NuEclipse GCC (for Windows) NuEclipse GCC (for Linux) Nuvoton Nu-Link Driver Installation Download and install the latest Nuvoton Nu-Link Driver. Download and install Nu-Link_Keil_Driver when using Keil MDK. Download and install Nu-Link_IAR_Driver when using IAR EWARM. -

Page 29: Figure 4-2 Nu-Link Usb Driver Installation

NuMaker-M252KG Figure 4-2 Nu-Link USB Driver Installation July. 08, 2020 Page 29 of 49 Rev 1.00... -

Page 30: Bsp Firmware Download

2. Connect the ICE USB connector shown in Figure 4-4 to the PC USB port through USB cable. NuMaker-RoLaD-M252 V1.0 Figure 4-4 ICE USB Connector 3. Find the “Nuvoton Virtual COM Port” on the Device Manger as Figure 4-5. July. 08, 2020 Page 30 of 49 Rev 1.00... -

Page 31: Figure 4-5 Device Manger

NuMaker-M252KG Figure 4-5 Device Manger 4. Open a serial port terminal, PuTTY for example, to print out debug message. Set the speed to 115200. Figure 4-6 presents the PuTTY session setting. Figure 4-6 PuTTY Session Setting July. 08, 2020 Page 31 of 49 Rev 1.00... -

Page 32: Find The Example Project

NuMaker-M252KG Find the Example Project Use the “Template” project as an example. The project can be found under the BSP folder as shown in Figure 4-7. M251_Series_BSP_CMSIS_V3.XX.XXX SampleCode Template Keil Figure 4-7 Template Project Folder Path Execute the Project under Toolchains Open and execute the project under the toolchain. -

Page 33: Figure 4-9 Project File Migrate To Version 5 Format

Figure 4-9 Project File Migrate to Version 5 Format 2. Make sure the debugger is “Nuvoton Nu-Link Debugger” as shown in Figure 4-10 and Figure 4-11. Note: If the dropdown menu in Figure 4-10 does not contain “Nuvoton Nu-Link Debugger” item,... -

Page 34: Figure 4-11 Programming Setting In Options Window

NuMaker-M252KG Figure 4-11 Programming Setting in Options Window 3. Rebuild all target files. After successfully compile the project, download code to the flash memory. Click “Start/Stop Debug Section” button can enter debug mode. 1. Rebuild 2. Successfully compile 3. Download 4. -

Page 35: Figure 4-13 Keil Mdk Debug Mode

NuMaker-M252KG source code, assembly language, peripherals’ registers, and setting breakpoint, step run, value monitor, etc. 3 1 2 1. Run 2. Stop 3. Reset Figure 4-13 Keil MDK Debug Mode Figure 4-14 Debug Message on Serial Port Terminal Windows July. 08, 2020 Page 35 of 49 Rev 1.00... -

Page 36: Iar Ewarm

NuMaker-M252KG 4.6.2 IAR EWARM This section provides steps to beginners on how to run a project by using IAR EWARM. 1. Double click the “Template.eww” to open the project. 2. Make sure the toolbar contain “Nu-Link” item as shown in Figure 4-15. Note: If the toolbar does not contain “Nu-Link”... -

Page 37: Nueclipse

NuMaker-M252KG 4. Figure 4-17 shows the debug mode under IAR EWARN. Click “Go” and the debug message will be printed out as shown in Figure 4-18. User can debug the project under debug mode by checking source code, assembly language, peripherals’ registers, and setting breakpoint, step run, value monitor, etc. -

Page 38: Figure 4-19 Import The Project In Nueclipse

NuMaker-M252KG Figure 4-19 Import the Project in NuEclipse M251_252_Series_BSP_CMSIS_V3.XX.XXX\SampleCod e\Templ M251_252__Series_BSP_CMSIS_V3.XX.XXX\SampleCode\Te mplate\G Figure 4-20 Import Projects Windows 3. Click the “Template” project and find the project properties as shown in Figure 4-21. Make sure the settings are the same as settings in Figure 4-22. July. -

Page 39: Figure 4-21 Open Project Properties Window

NuMaker-M252KG Figure 4-21 Open Project Properties Window Figure 4-22 Project Properties Settings 4. Click the “Template” project and build the project. July. 08, 2020 Page 39 of 49 Rev 1.00... -

Page 40: Figure 4-23 Build Project

NuMaker-M252KG Figure 4-23 Build Project 5. After the project is built, click the “Template” project and set the “Debug Configuration” as shown in Figure 4-24. Follow the settings presented in Figure 4-25, Figure 4-26 and Figure 4-27 to enter debug mode. Figure 4-24 Open Debug Configuration July. -

Page 41: Figure 4-25 Main Tab Configuration

NuMaker-M252KG Note 1: Double click the “GDB Nuvoton Nu-Link Debugging” to create the subitem. Note 2: After the project is built, the “*.elf” file will be shown in “C/C++ Application” frame. Figure 4-25 Main Tab Configuration Figure 4-26 Debugger Tab Configuration July. -

Page 42: Figure 4-27 Startup Tab Configuration

NuMaker-M252KG Note 1: User must follow those settings highlighted in green, and can configure other settings depend on the needs. Figure 4-27 Startup Tab Configuration July. 08, 2020 Page 42 of 49 Rev 1.00... -

Page 43: Figure 4-28 Nueclipse Debug Mode

NuMaker-M252KG 6. Figure 4-28 shows the debug mode under NuEclipse. Click “Resume” and the debug message will be printed out as shown in Figure 4-29. User can debug the project under debug mode by checking source code, assembly language, peripherals’ registers, and setting breakpoint, step run, value monitor, etc. -

Page 44: Numaker-M252Kg Schematics

NuMaker-M252KG NUMAKER-M252KG SCHEMATICS Nu-Link2-Me Figure 5-1 shows the Nu-Link2-Me circuit. The Nu-Link2-Me is a debugger and programmer that supports on-line programming and debugging through SWD interface. 3.3V ICER1 O f f - page C onnect or 200 1% USB_HS_CAP R0603 ICE5V ICEC1 ICEC2... -

Page 45: M252 Platform

NuMaker-M252KG M252 platform Figure 5-2 shows the M252 platform circuit. P1 - P32 P65 - P96 PF0_ICE_DAT PB5_NU2_A2 TICEDAT PF1_ICE_CLK PB4_NU2_A3 TICECLK PB3_NU3_D1/TX PB2_NU3_D0/RX PC12 PC5_NU3_D3 PC11 PC4_NU3_D2 PC10 PC3_NU3_D4 PC2_NU3_D5 PB1_NU2_A5/SCL/TX PC1_NU4_SCL PB0_NU2_A4/SDA/RX PC0_NU4_SDA nRESET PE.15/EBI_AD9/UART2_RXD/PSIO0_CH1 VDD_3 VDD_4 VDD_MCU VDD_MCU PE.14/EBI_AD8/UART2_TXD/PSIO0_CH0 VDDIO... -

Page 46: Extension Connector

NuMaker-M252KG Extension Connector Figure 5-3 shows extension connectors of NuMaker-M252KG. P1 - P32 P65 - P96 PB5_NU2_A2 PB4_NU2_A3 TICEDAT TICECLK PC1_NU4_SCL I2C_SCL PB3_NU3_D1/TX PB2_NU3_D0/RX PC0_NU4_SDA I2C_SDA PC12 PC11 PC5_NU3_D3 PC4_NU3_D2 VREF VREF PC10 PC3_NU3_D4 PC2_NU3_D5 MCUVCC_DIODE PB1_NU2_A5/SCL/TX PB0_NU2_A4/SDA/RX PC1_NU4_SCL PC0_NU4_SDA TICERST PA2_NU3_D13/CLK MCU_RESET... -

Page 47: Pcb Placement

NuMaker-M252KG PCB Placement Figure 5-4 and Figure 5-5 show the front and rear placement of NuMaker-M252KG. Figure 5-4 Front Placement Figure 5-5 Rear Placement July. 08, 2020 Page 47 of 49 Rev 1.00... -

Page 48: Revision History

NuMaker-M252KG REVISION HISTORY Date Revision Description 2019.07.02 1.00 Initially issued. July. 08, 2020 Page 48 of 49 Rev 1.00... - Page 49 NuMaker-M252KG Important Notice Nuvoton Products are neither intended nor warranted for usage in systems or equipment, any malfunction or failure of which may cause loss of human life, bodily injury or severe property damage. Such applications are deemed, “Insecure Usage”.

Need help?

Do you have a question about the NuMicro M252 Series and is the answer not in the manual?

Questions and answers