Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ESAB PKB 250

- Page 1 ™ ™ Instruction manual 0154 117 201 GB 20110816...

- Page 2 - 2 -...

-

Page 3: Table Of Contents

1 SAFETY ............2 INTRODUCTION . -

Page 4: Safety

SAFETY ESAB can provide you with all necessary welding protection and accessories. WARNING Arc welding and cutting can be injurious to yourself and others. Take precausions when welding and cutting. Ask for your employer's safety practices which should be based on manufacturers' hazard data. -

Page 5: Introduction

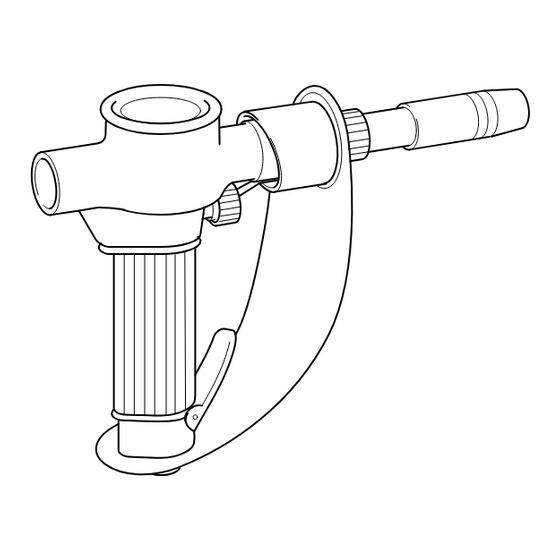

Different welding speeds can be selected by way of a valve regulating the speed of the motor. The welding gun is available in two models, PKB 250 and PKB 400. In the PKB 400 model the outgoing air is used for forced cooling of the gun. -

Page 6: Installation

Remove the plastic cover (d) from the gun housing. Undo the locking screw (e) and press the other end of the hose into the gun. Tighten the locking screw and fit the plastic cover. - 6 - © ESAB AB 1999 bg03d1ea... -

Page 7: Operation

General safety regulations for handling the equipment can be found on page 4. Read through before you start using the equipment! Welding Gun PKB 250 and PKB 400 Before starting to use of a new welding gun, or after replacement of the motor, the gun is to be operated at full air pressure for a short while. -

Page 8: Replacing The Air Filter

30 mm outside the inlet end of the hose. Insert the o-rings round the wire guide and then fasten the compression gland (b) with screws. Press in the inlet nozzle (a). - 8 - © ESAB AB 1999 bg03d1ea... -

Page 9: Dismantling The Motor

3. Insert a 90 mm long metal rod with a diameter of 2 mm through the hose connection hole in the gun housing. Push out the roll pin (f) in the motor shaft which holds the feed roller of the motor shaft in place. Remove the feed roller. - 9 - © ESAB AB 1999 bg03d1ea... -

Page 10: Mounting The Motor

(p) of the motor shaft and the wire feed unit (q).. The connection tube (h) and the three o-rings (g) are to be fitted very snugly. Cement the rubber handle using Bostik 292 or the like. - 10 - © ESAB AB 1999 bg03d1ea... -

Page 11: Trouble Shooting

Dry and clean the gun using compressed air. ORDERING OF SPARE PARTS PKB 250, PKB 400 is designed and tested in accordance with the international and Eu ropean standards EN60974-7 and EN . It is the obligation of the service unit which has carried out the service or repair work to make sure that the product still conforms to the said standard. -

Page 12: Order Number

PKBt 400 Straight swanneck 0152 470 882 Welding gun PKBt 400 Curved swanneck 0157 117 990 Spare parts list Instruction manuals and the spare parts list are available on the Internet at www.esab.com - 12 - © ESAB AB 1999 bg03o... -

Page 13: Wear Parts

™ 250, ™ 400 Wear parts Item Ordering no. Denomination Notes 0152 700 881 PKB 250 complete push-pull gun 0460 101 880 Feed roll driving 0455 588 001 Valve complete Soft start 0458 464 882 Gas nozzle, std Straight/Curved swanneck... - Page 14 Contact tip Straight/Curved swanneck 0366 394 002 Tip adapter Straight/Curved swanneck 0468 221 003 Wearing tube Straight swanneck, 0468 221 004 Wearing tube Curved swanneck 0333 227 001 Guide nozzle Straight/Curved swanneck - 14 - bg03w © ESAB AB 1999...

- Page 15 0468 502 009 0468 502 010 Item Ordering no. Denomination 0458 474 001 Compressed air motor complete 0152 475 023 Lamellae 0671 126 081 Feed mechanism complete 0460 104 880 Feed roller - 15 - bg03w © ESAB AB 1999...

- Page 16 0258 002 582 0258 002 582 Inlet nozzle Ø 1.0 mm 0258 002 583 0258 002 583 Inlet nozzle Ø 1.2 mm 0258 002 584 0258 002 584 Inlet nozzle Ø 1.6 mm - 16 - bg03w © ESAB AB 1999...

-

Page 17: Accessories

™ 400 Accessories Item Ordering no. Denomination Notes 0152 700 881 PKB 250 complete 0152 475 025 Valve complete Direct start 0693 201 201 Grease injector 0151 370 001 Plastic oil capsule 0367 581 881 Swanneck complete Ø 9 mm Curved swanneck 0368 002 883 Swanneck complete Ø... - Page 18 0458 470 883 Gas nozzle, straight Ø 19 mm Straight/Curved swanneck 0368 311 001 Tip adapter HELIX Straight/Curved swanneck 0368 643 004 Spiral (for hollow wire) Straight swanneck 0368 643 002 Spiral (for hollow wire) Curved swanneck - 18 - bg03a © ESAB AB 1999...

- Page 19 0368 313 882 1.0 mm 0368 313 883 1.2 mm 0368 313 884 1.4 mm 0368 313 885 1.6 mm 0368 313 886 Lubricant Ordering number Shell Super Oil 10 W/50 0151 370 001 - 19 - bg03a © ESAB AB 1999...

- Page 20 ESAB Romania Trading SRL ESAB VAMBERK s.r.o. SOUTH AFRICA ESAB Mexico S.A. Bucharest Vamberk ESAB Africa Welding & Cutting Ltd Monterrey Tel: +40 316 900 600 Tel: +420 2 819 40 885 Durbanvill 7570 - Cape Town Tel: +52 8 350 5959...

Need help?

Do you have a question about the PKB 250 and is the answer not in the manual?

Questions and answers