Table of Contents

Advertisement

Quick Links

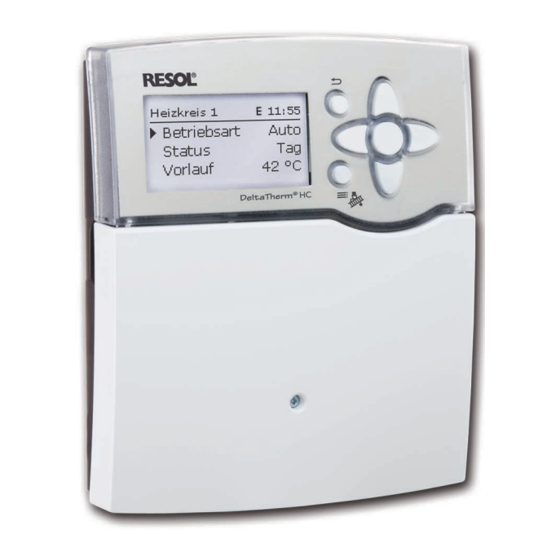

HC

DeltaTherm

®

version 1.04

Heating controller

Manual for the

specialised craftsman

Mounting

Connection

Operation

Troubleshooting

Application examples

Adjust your heating via app

en

Thank you for buying this RESOL product.

Manual

Please read this manual carefully to get the best performance from this unit.

Please keep this manual carefully.

www.resol.com

Advertisement

Table of Contents

Summary of Contents for Resol DeltaTherm HC

- Page 1 Mounting Connection Operation Troubleshooting Application examples Adjust your heating via app Thank you for buying this RESOL product. Manual Please read this manual carefully to get the best performance from this unit. Please keep this manual carefully. www.resol.com...

- Page 2 The product complies with the relevant directives and is therefore la- Notes are indicated with an information symbol. belled with the CE mark. The Declaration of Conformity is available upon request, please contact RESOL. Î Arrows indicate instruction steps that should be carried out. Note Strong electromagnetic fields can impair the function of the controller.

-

Page 3: Table Of Contents

DeltaTherm HC Heating controller ® Contents HQM ....................48 Overview ................... 4 Installation ..................5 Basic settings .................. 50 2.1 Mounting ........................5 10 SD card ................... 50 11 Manual mode ................. 51 2.2 Electrical connection ....................5 12 User code ..................52 2.4 SD card slot ........................6 13 In- / Outputs .................. -

Page 4: Overview

• Thermal disinfection (with EM extension module) Supply connection: type Y attachment • Pre-programmed optional functions (with EM extension module) Standby power consumption: < 1W • RESOL VBus ® Mode of operation: type 1.B.C.Y • Energy-efficient switching-mode power supply Rated impulse voltage: 2,5 kV Interfaces: RESOL VBus ®... -

Page 5: Installation

Installation WARNING! Electric shock! Upon opening the housing, live parts are exposed! Î Always disconnect the controller from power supply before opening the housing! screw Mounting The unit must only be located in dry interior rooms. The controller must additionally be supplied from a double pole switch with contact gap of at least 3 mm. -

Page 6: Sd Card Slot

Connect the digital Grundfos Direct Sensors™ to the RPD and VFD inputs. • RESOL EM Extension module The controller is supplied with power via a mains cable. The power supply of the Furthermore, the controller can be connected to a PC via the RESOL VBus / USB ®... -

Page 7: Operation And Function

Operation and function Buttons Chimney sweeper / screed The controller is operated via the 7 buttons next to the display. They have the following functions: The chimney sweeper function or the screed drying function can be triggered with button ➅. The chimney sweeper function is activated by default. In order Button ❶... - Page 8 adjusted value adjustment channel (not yet confi rmed) If only one item of several can be selected, they will be indicated with “radio but- tons”. When one item has been selected, the radio button in front of it is fi lled. minimum value current value saved maximum value...

- Page 9 Adjusting the timer Adding a time frame: When the Timer option is activated, a timer is indicated in which time frames for the function can be adjusted. The time frames can be adjusted in steps of 15 minutes. First of all, an overview of the current adjustments is displayed. For each day of the week there is an overview display.

- Page 10 Removing a time frame: In order to remove an active time frame, pro- ceed as follows: Î Determine the point from which on the time frame is to be removed by pressing button ❸. Î Move the cursor to the desired ending point of the time frame by pressing but- tons ❷...

-

Page 11: Commissioning

1. Language: Commissioning Î Adjust the desired menu language. Initial commissioning When the hydraulic system is fi lled and ready for operation, connect the control- ler to the mains. The controller runs an initialisation phase in which the directional pad fl ashes red. When the controller is commissioned for the fi rst time or when it is reset, it 2. -

Page 12: Schemes With Basic Settings

Schemes with basic settings 4. Time: The controller is pre-programmed for 9 basic systems. The basic pre-adjustments Î Adjust the clock time. First of all adjust the have already been made. For afterheating it is necessary to allocate the demand hours, then the minutes. - Page 13 Scheme 1: one mixed heating circuit Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors Free 3 / GND L' L Free 4 / GND Free 5 / GND Free 6 / GND Free 7 / GND Free...

- Page 14 Scheme 2: one mixed heating circuit with afterheating (demand) Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors Free 3 / GND L' L Afterheating / boiler 4 / GND Free 5 / GND Free 6 / GND Free...

- Page 15 Scheme 3: one mixed heating circuit with afterheating (demand and boilder loading pump) Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors Free 3 / GND L' L Afterheating / boiler 4 / GND Free 5 / GND Free...

- Page 16 Scheme 4: one mixed heating circuit with DHW heating Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors 3 / GND L' L Free 4 / GND Free 5 / GND Free 6 / GND Free 7 / GND Free...

- Page 17 Scheme 5: one mixed heating circuit with DHW heating and afterheating (demand for heating circuit and DHW) Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors 3 / GND L' L Afterheating / boiler 4 / GND Free 5 / GND...

- Page 18 Scheme 6: one mixed and one unmixed heating circuit Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors Flow HC2 3 / GND L' L Free 4 / GND Free 5 / GND Free 6 / GND Free...

- Page 19 Scheme 7: one mixed and one unmixed heating circuit with afterheating (demand) Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Outdoor 2 / GND Temperature sensors Flow HC2 3 / GND L' L Afterheating / boiler 4 / GND Free 5 / GND Free...

- Page 20 Scheme 8: one mixed heating circuit with solid fuel boiler Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V Temperature sensors IP20 Outdoor 2 / GND Solid fuel boiler 3 / GND L' L Free 4 / GND Store 5 / GND Free 6 / GND Free...

- Page 21 Scheme 9: one mixed heating circuit with solid fuel boiler and afterheating (demand) Sensors Relay outputs Flow HC1 1 / GND PWM/0-10V IP20 Temperature sensors Outdoor 2 / GND Solid fuel boiler 3 / GND L' L Afterheating / boiler 4 / GND Store 5 / GND...

-

Page 22: Step-By-Step Parameterisation

Step-by-step parameterisation 4. Adjusting the operating mode The DeltaTherm ® HC heating controller is a controller that offers a broad variety of functions to the user. At the same time, the user has a lot of freedom After commissioning, the heating circuit is in automatic mode. The operating in configurating them. -

Page 23: Functions And Options

Functions and options Menu structure Main menu Heating Status Shared relays Heating Heating circuits Arrangement Optional functions Screed drying Optional functions Basic settings DHW heating SD card Th. Disinfection Manual mode Circulation Arrangement User code Optional functions In- / Outputs Optional functions Basic settings Heat exchange... -

Page 24: Status Menu

Status menu Arrangement The status menu contains information about the current states of all activated In the Status / Arrangement menu, the status information (Active, Inactive, heating circuits, optional functions and HQM. Furthermore, measured and bal- Deactivated), the temperatures of the relevant sensors and the relays states are ance values as well as messages are indicated. -

Page 25: Messages

Heating When a line with a measurement value is selected, another sub-menu will open. In this menu, all adjustments for the heating part of the arrangement or for the heating circuits respectively can be made. Shared relays for demands, loading pumps or valves can be activated, heating circuits can be confi gured and optional functions can be selected and adjusted. - Page 26 Demand For demand of a boiler, for example, the shared relays Demand 1 and Demand 2 are available. The options Boiler pr. min and Boiler pr. max can be activated for the shared relays, allowing temperature-dependent control of the boiler de- mands.

-

Page 27: Heating Circuits

Heating circuits The controller has 1 mixed and 1 unmixed weather-compensated heating circuit and is able to control up to 5 further mixed heating circuits by means of extension modules. The heating system Constant aims to keep the set fl ow temperature to a con- stant value which can be adjusted by means of the parameter Set temperature. - Page 28 The automatic summer mode becomes active when the outdoor temperature If the outdoor temperature sensor is defective, an error message will be indi- exceeds the adjusted summer temperature TSummer. This can be limited to a cated. For the duration of this condition, the maximum fl ow temperature -5 K is daytime frame with the parameters Daytime on and Daytime off.

- Page 29 Day / Night: A reduced set fl ow temperature (night correction) is used during night operation. Day / Off: The heating circuit and the optionally activated afterheating are switched off during night operation. Room / Off: The heating circuit and the afterheating are switched off during night operation.

- Page 30 To each room thermostat, an additional relay can be allocated. That relay will be energised if the temperature at the allocated sensor falls below the adjusted room temperature. This way, the room in question can be unlinked from the heating cir- cuit via a valve as long as the room temperature is reached has the desired value.

- Page 31 Heating / Heating circuits / New HC... / Internal or Module 1 ...5 Adjustment Description Adjustment range / selection Factory setting channel Pump HC Heating circuit pump relay selection system dependent system dependent Mixer open Relay selection mixer open system dependent system dependent Mixer close Relay selection mixer closed...

- Page 32 Adjustment Description Adjustment range / selection Factory setting channel Starting t. Afterheating starting time 0 … 120 min 0 min Demand Demand option Yes, No Relay Relay selection system dependent system dependent Boiler loading p. Boiler loading pump option Yes, No Relay Relay selection system dependent...

- Page 33 Chimney sweeper function Screed drying The chimney sweeper function can be used for enabling a quick access to meas- This function is used for time- and temperature-controlled screed drying in se- urement conditions without menu operation for the chimney sweeper. lectable heating circuits.

- Page 34 If button ➅ is pressed again and held down for at least 5 s, the screed drying pro- If the set fl ow temperature is not reached within 24 hours or after the rise time gramme will be aborted. For this reason, a security enquiry appears. If you wish to respectively, or if it is constantly exceeded, the screed drying function will be interrupt the screed drying function, confi rm the security enquiry.

-

Page 35: Optional Functions

Optional functions In the Boiler loading pump menu, a loading pump can be allocated to the after- heating. Not only is it possible to directly allocate a relay, it is also possible to select a shared relay Pump 1 / 2. When selecting shared relays, further options such as the boiler protection, Start-up or overrun function are available (see page 25). - Page 36 When the Timer option is activated, a timer is indicated in which time frames If the menu item Delete function is confi rmed by pressing button ➄, a security for the function can be adjusted. enquiry appears. The setting can be changed between Yes and No by pressing buttons ❷...

- Page 37 Thermal disinfection This function helps to contain the spread of Legionella in DHW stores by system- atically activating the afterheating. Due to the fl exible control logic, the exact time of thermal disinfection is not predictable. In order to set a fi xed time for the disinfection, the starting delay can be used.

- Page 38 Heating / Opt. functions / Add new function / Th. Disinfection Circulation Adjustment Adjustment range / Description Factory setting channel selection Mode Mode selection Therm., Zone Therm. Sensor 1 Reference sensor 1 selection system dependent system dependent Reference sensor 2 selection (if Sensor 2 system dependent system dependent...

- Page 39 Timer The relay is switched on during the adjusted time frames, outside of them it Arrangement / Opt. functions / Add new function / Circulation switches off. For information on how to adjust the timer, see below. Adjustment Adjustment range / Description Factory setting channel...

-

Page 40: Arrangement

Arrangement The menu item Relay is available in all optional functions. Therefore, it will not be In this menu, all adjustments for the non-heating part of the arrangement can be explained in the individual function descriptions. made. With this menu item, a relay can be allocated to the function. All free relays are A range of optional functions can be selected and adjusted. - Page 41 Parallel relay Arrangement / Opt. functions / Add new function / Parallel relay With the menu item Function, an optional function already selected can be tem- Adjustment Adjustment range / Description Factory setting porarily deactivated or re-activated respectively. All adjustments remain stored, channel selection the allocated relays remain occupied and cannot be allocated to another function.

- Page 42 Mixer Zone loading The Zone loading function can be used to load a store zone between 2 sen- Arrangement / Opt. functions / Add new function / Mixer sors (sensor top and sensor base). For monitoring the switch-on and switch-off Adjustment Adjustment range / conditions, 2 sensors are used.

- Page 43 Heat exchange The Heat exchange function can be used for transferring heat from a heat source to a heat sink. The allocated relay is energised when all switch-on conditions are fulfi lled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature difference •...

- Page 44 Return preheating The Return preheating function can be used for transferring heat from a heat source to the heating circuit return. The allocated relay is energised when all switch-on conditions are fulfi lled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature difference •...

- Page 45 Solid fuel boiler The Solid fuel boiler function can be used for transferring heat from a solid fuel boiler to a store. The allocated relay is energised when all switch-on conditions are fulfi lled: • the temperature difference between the allocated sensors has exceeded the switch-on temperature difference •...

- Page 46 Function block Within a function block the functions are interconnected (AND gate). This means In addition to the pre-defi ned optional functions, function blocks consisting of that the conditions of all the activated functions have to be fulfi lled for switch- thermostat functions, timer and differential functions are available.

- Page 47 Arrangement / Opt. functions / Add new function / Function block Thermostat function The relay allocated to the function block is switched on, when the adjusted Adjustment Adjustment range / Description Factory setting switch-on temperature (Th(x)on) is reached. It is switched off when the adjusted channel selection Relay...

-

Page 48: Hqm

Irradiation switch Arrangement / Opt. functions / Add new function / Irradiation switch In the HQM menu, up to 5 internal heat quantity measurements can be activated Adjustment Description Adjustment range / selection Factory setting and adjusted. channel Relay Relay selection system dependent system dependent By selecting the menu item new HQM..., a new heat quantity measurement can... - Page 49 When the Alternative unit is activated, the controller will convert the heat HQM / new HQM... quantity into the quantity of fossil fuels (coal, oil or gas) saved, or the CO emis- Adjustment Adjustment range / Description Factory setting sion saved respectively. The alternative Unit can be selected. A conversion fac- channel selection tor must be adjusted for the calculation.

-

Page 50: Basic Settings

The controller will only recognise a fi rmware update fi le if it is stored in In the Basic settings menu, all basic parameters for the controller can be ad- a folder named “RESOL\HC” on the fi rst level of the SD card. justed. Normally, these settings have been made during commissioning. They can ÎCreate a folder named “RESOL\HC”... -

Page 51: Manual Mode

Manual mode Note: Because of the increasing size of the data packets, the remaining logging time does not decrease linearly. The data packet size can increase, e. g. with the increasing operating hours value. Storing controller adjustments Î To store the controller adjustments on an SD card, select the menu item Save adjustments. -

Page 52: User Code

User code In- / Outputs In the User code menu, a user code can be entered. Each number of the 4-digit In the In- / Outputs menu, external modules can be registered, sensor offsets can code must be individually adjusted and confi rmed. After the last digit has been be adjusted and relay outputs can be confi gured. -

Page 53: Inputs

13.2 Inputs CS sensor offset If a CS10 irradiation sensor is to be connected, an offset has to be carried out before the connection is made. To carry out the offset, proceed as follows: Î Adjust the CS type in the Type channel Î... -

Page 54: Outputs

13.3 Outputs Note: If PWM is selected for an output, the adjustment range for the cor- responding minimum speed will extend to 20 … 100 %. If C is selected in the Profi le channel, the minimum speed must be set at least to 25 % according to information from the manufacturer. -

Page 55: Pwm Profiles

13.4 PWM profiles PWM A (e. g. manufacturer WILO) PWM D (e. g. manufacturer WILO) 95 100 PWM % PWM % PWM E (e. g. manufacturer Grundfos) PWM B (e. g. manufacturer Grundfos) Solar PM Profile OEM STANDARD PROFILE OEM SOLAR PM-Profile Max Speed Std PWM 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100... -

Page 56: Troubleshooting

Troubleshooting If a malfunction occurs, a message will appear on the display of the controller. WARNING! Electric shock! Upon opening the housing, live parts are exposed! Î Always disconnect the controller from power sup- ply before opening the housing! The controller is protected by a fuse. The fuse holder (which also holds the spare fuse) becomes accessible when the cover is removed. - Page 57 The heating circuit pump does not work, although this is indicated on the Change connection and let the display. Warm water outflow upwards? water flow sidewards or through a siphon (downwards); less store losses now? Display illuminated? If not, press but- .

-

Page 58: Accessories

Accessories Sensors AM1 Alarm module HKM3 Heating circuit extension module Remote control RTA12 VFD and RPD Grundfos EM Extension module Direct Sensors™ V40 fl owmeter DL2 Datalogger VBus ® Touch HC VBus ® / USB & VBus ® / LAN DL3 Datalogger interface adapters... -

Page 59: Sensors And Measuring Instruments

Remote control Be it solar thermal, heating or DHW heat exchange controllers – with the DL3 you can easily and conveniently log system data of up to 6 RESOL controllers. Get VFD and RPD Grundfos Direct Sensors™ a comprehensive overview of all controllers connected with the large full graphic The RPD Grundfos Direct Sensor™... -

Page 60: Interface Adapters

With its standard mini-USB port it enables a fast trans- mission of system data for processing, visualising and archiving data via the VBus ® A full version of the RESOL ServiceCenter software is included. The VBus ®... -

Page 61: Index

Index Afterheating ........................29 Heat exchange ........................ 43 Antifreeze function ......................30 Heating circuit mixer ..................... 27 Automatic mode ......................22 Heating circuit pump ..................... 27 Heating curve ........................27 Heating system ....................... 27 Balance values ......................... 24 Heat quantity measurement ..................48 Basic system ........................ - Page 62 Registering external modules ..................52 Remote control ......................27 Return preheating ......................44 Room thermostat ......................30 Running firmware updates ................... 50 Scheme ..........................12 Screed drying ........................33 Sensor fault, error message ..................25 Sensor offset ........................53 Set flow temperature ....................27 Solid fuel boiler .......................

- Page 64 This mounting- and operation manual including all parts is copyrighted. Another represent some examples. They can only be used at your own risk. No liability use outside the copyright requires the approval of RESOL – Elektronische Rege- is assumed for incorrect, incomplete or false information and / or the resulting lungen GmbH.

Need help?

Do you have a question about the DeltaTherm HC and is the answer not in the manual?

Questions and answers