Table of Contents

Advertisement

FROM MACHINE: 3294316, 3294281,3294325 ->

OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

FARMI 260

PLEASE READ THE OPERATING AND MAINTENANCE INSTRUCTIONS OF THE CHIPPER

AND THE SEPARATE OPERATING AND MAINTENANCE INSTRUCTIONS OF THE FEED UNIT

CHIPPER FARMI 260

BEFORE YOU OPERATE THE CHIPPER.

TRANSLATION OF THE INSTRUCTION MANUAL

Machine combinations for manual feed:

FARMI 260 + F260

FARMI 260 + HF231-HM EUR

FARMI 260 + HF260-EM

F260

HF231-HM EUR

EXCLUSIVELY FOR MANUAL FEED!

GRAB LOADER FEED PROHIBITED!

Machine combinations for grab loader feed:

FARMI 260 + HF260-EL-0

FARMI 260 + HF260-EL-SM

FARMI 260 + HFC260

HF260-EL-0

HF260-EL-SM

EXCLUSIVELY FOR GRAB LOADER FEED!

MANUAL FEED PROHIBITED!

Farmi Forest Corporation

Ahmolantie 6

FIN-74510 Iisalmi, Finland

Tel. +358 (0)17 83 241

Fax. +358 (0)17 8324 372

www.farmiforest.fi

03299720

E-EN-210512-ER

HF260-EM

HFC260

Advertisement

Table of Contents

Summary of Contents for Farmi Forest FARMI 260

- Page 1 TRANSLATION OF THE INSTRUCTION MANUAL OPERATION, MAINTENANCE AND SPARE PARTS MANUAL CHIPPER FARMI 260 Machine combinations for manual feed: FARMI 260 + F260 FARMI 260 + HF231-HM EUR FARMI 260 + HF260-EM F260 HF231-HM EUR HF260-EM EXCLUSIVELY FOR MANUAL FEED!

-

Page 2: General Description And Intended Use Of The Chipper

The chipper can shred wood with a max. trunk diameter of 260 mm. The FARMI 260 chipper is mounted to the 3-point hitch of a tractor. It is driven by the tractor PTO. The driving... - Page 3 Address: Ahmolantie 6, FIN-74510 IISALMI, Finland Commercial name: Farmi Machine denomination: Farmi wood chipper with attachable Farmi feed hopper Machine type: Wood chipper: FARMI 260 Available feed hoppers for manual feed: F260 HF231-HM EUR HF260-EM Available feed hoppers for grab loader feed: HF260-EL-0...

-

Page 4: Table Of Contents

FARMI 260 TABLE OF CONTENTS GENERAL DESCRIPTION AND INTENDED USE OF THE CHIPPER PRODUCT WARRANTY GENERAL SAFETY INSTRUCTIONS GENERAL SAFETY INSTRUCTIONS FOR THE CHIPPER STICKERS AND PLATES TECHNICAL INFORMATION MOUNTING LIFTING MOUNTING OF THE DRAWBAR MOUNTING OF THE FEED UNIT... - Page 5 FARMI 260 WARNING SYMBOLS IN THIS MANUAL • imminent danger which could cause serious personal injury or death DANGER! • danger which could cause personal injury WARNING! • conditions or misuse that could damage equipment or machinery CAUTION! NOTE! • reminders, such as for performing checks or carrying out maintenance...

-

Page 6: General Safety Instructions

FARMI 260 GENERAL SAFETY INSTRUCTIONS Written authorization must be requested from the manufacturer for any alterations to the machine. These safety instructions are meant for the owners of FARMI equipment, as well as those who operate, service or repair it. - Page 7 FARMI 260 TRANSPORT • Never insert any body part into the machine with the engine running. • Before driving with the machine, ensure the safe • If any faults arise that may jeopardize occupatio- mounting of the machine. Make sure that the nal safety, turn off the machine.

- Page 8 FARMI 260 • When servicing the machine, place it on a level 4. Check that all hose connectors, lengths and surface and ensure that it cannot be moved. qualities comply with applicable requirements. When replacing or repairing hoses, use origi- •...

-

Page 9: General Safety Instructions For The Chipper

FARMI 260 GENERAL SAFETY INSTRUCTIONS FOR THE CHIPPER DANGER! • Please make sure any machine operator has the required personal protective equipment: safety helmet, protective goggles, cut resistant safety boots and required protective clothing. • The chipper must not be used without being mounted to a tractor. -

Page 10: Stickers And Plates

STICKERS AND PLATES The following plates and labels must be correctly attached to the chipper. Missing safety plates / labels must be replaced immediately. 1. Machine plate FARMI 260 (41011750) 2. CAUTION! Please read the instruction manuals of the machine meticulously before you operate, maintain or repair the machine. - Page 11 4. Wear personal protective equipment. (40142080). 5. Cutting hazard! (40147010) 6. Lifting point sticker (41014270). 7. SPEED sticker (40141160) Recommended speed range. The rated speed must not be exceeded. 8. FARMI Forest -sticker (40146900). 9. 260 (40147130)

-

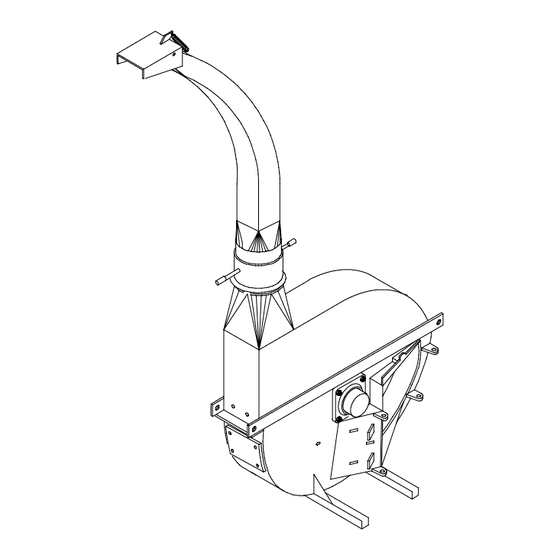

Page 12: Technical Information

FARMI 260 TECHNICAL INFORMATION MAIN COMPONENTS 1. UPPER CHAMBER 2. LOWER CHAMBER 3. DISK 4. KNIFE 5. VERTICAL ANVIL 6. HORIZONTAL ANVIL 7. BREAKER/SCREEN 8. DISCHARGE PIPE 9. WATER DRAINAGE HOLES 10. LIFTING POINT 11. HOLDING DEVICE FOR THE PTO SHAFT... - Page 13 FARMI 260 DIMENSIONS 965 (38”) 1150 (4 6”) 990--109 2 (39”--43”) TECHNICAL INFORMATION FARMI 260 Type Disk chipper Output 10-40 m Chip lenght 7-25 mm Max. wood diameter 260 mm Power demand 40-115 kW PTO speed 540 / 1000 rpm...

-

Page 14: Mounting

FARMI 260 MOUNTING LIFTING Lifting points for each machine are marked with hook symbols. CAUTION! Lift only using the proper type of lifting device and ensure that it has an appropriate lifting capacity. Check the lifting slings, cables, and chains regularly. -

Page 15: Mounting Of The Drawbar

FARMI 260 MOUNTING OF THE DRAWBAR • Attach the drawbar to the outermost holes of the chipper in order to use as long a PTO shaft as pos- sible; this increases the shaft’s service life. • Mount the chipper on the tractor’s 3-point hitch. If... -

Page 16: Shortening The Pto Shaft

FARMI 260 SHORTENING THE PTO SHAFT The use of too long a PTO shaft with a 3-point hitch could damage the chipper’s bearings or the tractor’s PTO shaft. Both halves Fig. 8. Measure distance A when the distance between of the PTO shaft must be shorte- CAUTION! the splined shafts is at its shortest. -

Page 17: Installing The Screen And Breaker

• misuse of the product • inadequate maintenance The FARMI 260 chipper can also be used to shred hard • modifications of the product made without plastics. For this purpose, the twig or high-power the manufacture’s consent... -

Page 18: Mounting Of The Discharge Pipe

FARMI 260 MOUNTING OF THE DISCHARGE PIPE Direct the discharge pipe so that the thrown out chips do not pose • For the installation of the discharge pipe, always a risk to the operator of the chip- use a support of approx. 60 cm height. It is prohi- per or to or anyone else. -

Page 19: Mounting Of The Chipper And Pre-Operation Inspections

FARMI 260 MOUNTING OF THE CHIPPER AND PRE-OPERATION STARTING THE CHIPPER INSPECTIONS • Start the chipper with caution while operating the • For mounting or dismounting the chipper, always tractor at low speed. Slowly increase the speed turn off the tractor and apply the parking brake... -

Page 20: Chipping

FARMI 260 CHIPPING • FIRE HAZARD! Always keep adequate fire-fighting equipment on hand when using the chipper. During chipping, please observe Regularly check the surface temperature of the the following safety instructions: chipper. If the chipper suddenly heats up abnor- mally, stop the chipper and determine the cause of overheating. -

Page 21: Maintenance

FARMI 260 MAINTENANCE PERIODIC MAINTENANCE Before beginning maintenance WARNING! and repair • place the chipper onto level and hard ground and make sure it cannot tip; • turn off the tractor and disconnect the PTO drive shaft; • disconnect the hydraulic hoses from the tractor;... - Page 22 FARMI 260 PERIODIC INSPECTIONS MAINTENANCE • With new machines, check the mounting bolts for Check the tightness of the bolts and tighten if ne- tightness after the first operating hour, tightening cessary. Check the tightness of all fastenings once a them if necessary.

-

Page 23: Knife And Anvil Maintenance

FARMI 260 KNIFE AND ANVIL MAINTENANCE REMOVING THE KNIVES FROM THE KNIFE BRACKETS Read the safety instructions. 1. Remove the knife lock nuts (M12). Fig. 16. The disk continues rotating like 2. Remove the knife fastening bolts (M12). Turn the... - Page 24 FARMI 260 SHARPENING THE KNIVES The hone angle is ground to a 45° angle with two to three longitudinal strokes, using a level sharpening Sharpen all knives equally. This stone. ensures disk balance. Burrs are removed from the knife fastening bolt side, grinding with the surface.

- Page 25 FARMI 260 60° 1,5 mm (1/16”) Fig 22. Vertical anvil profile INSTALLING THE KNIVES AND ANVILS • Check the condition of the fastening bolts and Fig 23. Clearance nuts. • Install the knives and anvils and tighten the faste- ning bolts to the torques specified in Table 2.

-

Page 26: Adjusting The Chip Length

FARMI 260 ADJUSTING THE CHIP LENGTH The chip length is determined by the distance bet- ween the knife and the cutting disk (see fig. 25). The chip length is adjusted by changing the position of the knife brackets. The chip length can be adjusted between 7 and 25 mm. -

Page 27: Replacing The Splined Shaft

FARMI 260 REPLACING THE SPLINED SHAFT The remaining knives are adjusted as follows: 1. Measure the knife-to-chamber distances for both 1. Remove the upper chamber. ends of the adjusted knife. The knife-to-chamber 2. Remove the bearings (Fig 32). Welding damages the distance is the distance between the edge of the bearings. - Page 28 FARMI 260 Knife to chamber distance 1,5 mm Disc Lower chamber Anvils Knife bracket Fig. 31. Cross-sectional view of cutting disk and knives Fig. 32. Cross-sectional view of the bearing system...

- Page 29 FARMI 260...

-

Page 30: Farmi 260

FARMI 260 When ordering spare parts, please indicate the machine’s type and serial number FARMI 260 from the machine plate, spare part’s order number, description and quantity required. Example. CH260, serial number xxxxxxx, 43298410, knife, 2 pc 48 47 20.6 20.2... - Page 31 FARMI 260 FARMI 260 Part Order no Description Remarks 13297010 Lower chamber 43297620 Upper chamber 33298590 Disk 2-knife from machine: 3295001 13298580 Disk 3-knife from machine: 3295001 43483870 Splined shaft from machine: 3295001 43563080 Flange 33296470 Twig blade 43297090 Horizontal anvil...

- Page 32 FARMI 260 FARMI 260 48 47 20.6 20.2 20.5 20.3 20.1 20.4...

- Page 33 FARMI 260 FARMI 260 Part Order no Description Remarks 52062148 Screw M16X70 DIN931 88ZN 52110053 M12 DIN934 8ZN 52200078 Washer M16 DIN126 58ZN 52200470 Washer M16 DIN 7989 ZN 43292739 Washer 52060258 Screw M10X40 DIN933 88ZN 43482290 Hose holder 43298060...

-

Page 34: Disk, 2-Knife

FARMI 260 DISK, 2-KNIFE Part Order no Description Remarks 33298590 Disk 2-knife 23293910 Knife bracket 43298410 Knife 43290741 Support plate 52117215 Lock nut M20X1.5,10.9 DIN985 52063592 Screw M12x35 DIN933 10.9ZN 52211059 Spring washer M12 DIN127 ZN 52111051 M12 DIN936 8ZN... -

Page 35: Disk, 3-Knife

FARMI 260 DISK, 3-KNIFE Part Order no Description Remarks 13298580 Disk 3-knife 23293910 Knife bracket 43298410 Knife 43290741 Support plate 52117215 Lock nut M20X1.5,10.9 DIN985 52063592 Screw M12x35 DIN933 10.9ZN 52211059 Spring washer M12 DIN127 ZN 52111051 M12 DIN936 8ZN... -

Page 36: Short Discharge Pipe, Complete

FARMI 260 03296450 SHORT DISCHARGE PIPE, COMPLETE Part Order no Description Remarks 23296430 Discharge pipe 43314509 52117108 Lock nut M10 DIN985 8ZN 43314533 Hinge screw 94612082 Tension spring DU26 DL2,6 L106 03314556 Chain L1600 43482320 Lock band complete 52200045 Washer... -

Page 37: Long Discharge Pipe, Complete

FARMI 260 03297370 LONG DISCHARGE PIPE, COMPLETE Part Order no Description Remarks 33297360 Vertical pipe 43314509 52117108 Lock nut M10 DIN985 8ZN 43314533 Hinge screw 94612082 Tension spring DU26 DL2,6 L106 03312550 Chain L2300 43482320 Lock band complete 52200045 Washer... -

Page 38: Twig Crusher, Complete

FARMI 260 03297650 TWIG CRUSHER, COMPLETE Part Order no Description Remarks 43297560 Twig crusher 43297680 Locking bolt 52214285 Lock washer M16 NORD-LOCK 52117165 Lock nut M16 DIN985 8ZN 52840071 Cotter pin 4X22 DIN1481 03298150 CROSS BRAKER FOR SLAB, COMPLETE Part... -

Page 39: Plastic Shredding Screen, Complete

FARMI 260 03297630 PLASTIC SHREDDING SCREEN, COMPLETE Part Order no Description Remarks 43297640 Plastic shredding screen 43297680 Locking bolt 52214285 Lock washer M16 NORD-LOCK 52117165 Lock nut M16 DIN985 8ZN 52840071 Cotter pin 4X22 DIN1481... - Page 40 FARMI 260...

- Page 41 Send faulty parts, carriage paid, to the manufacturer for inspection. Repairs will be con- ducted by Farmi Forest Oy or an authorized expert. The warranty is valid only if the bottom part of this page is filled in and returned to the manufacturer within 14 days of receipt of the product.

-

Page 42: Product Registration Form

PRODUCT REGISTRATION FORM Date of delivery:_____/_____ 20_____ Dealer: Dealer’s address: Dealer’s tel: Product and type: Serial number: Return to the manufacturer Date of delivery:_____/_____ 20_____ Dealer: Dealer’s address: Dealer’s tel: Customer: Customer’s address: Customer’s tel: E-mail: Product and type: Serial number:... - Page 44 Farmi Forest Corporation Ahmolantie 6 FIN-74510 Iisalmi, Finland Puh. +358 (0)17 83 241 Fax. +358 (0)17 8324 372 www.farmiforest.fi...

Need help?

Do you have a question about the FARMI 260 and is the answer not in the manual?

Questions and answers