Chapters

Table of Contents

Troubleshooting

Summary of Contents for Mercury MerCruiser MCM 454 Mag MPI

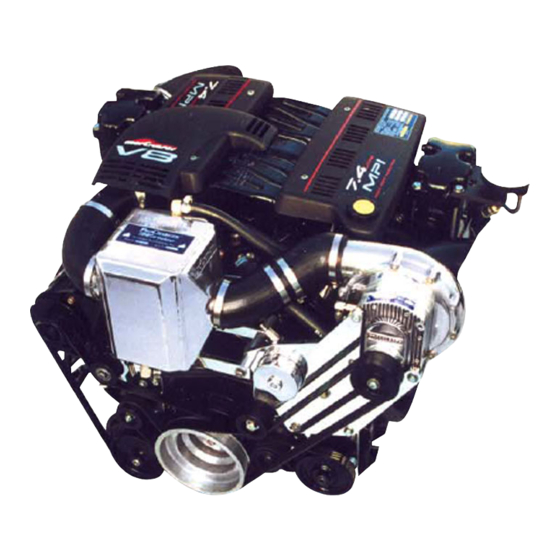

- Page 1 MAIN MENU SERVICE MANUAL Number 23 MARINE ENGINES GM V8 454 cid (7.4L) / 502 cid (8.2L) Book 1 of 2 Sections 1 thru 4 1999, Mercury Marine Printed in U.S.A. 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 2 Mercury Marine, that they have been trained in the recommended servicing procedures of these products which in- cludes the use of mechanics’ common hand tools and the special Mercury Marine or recom- mended tools from other suppliers.

- Page 3 It is important to note, during any maintenance procedure replacement fasteners must have the same measurements and strength as those removed. Numbers on the heads of the met- ric bolts and on the surfaces of metric nuts indicate their strength. American bolts use radial lines for this purpose, while most American nuts do not have strength markings.

- Page 4 Models Covered in This Manual Gen. VI Engines Sterndrive (MCM) Model Serial Number MCM 454 Mag MPI 0L010029 & Up MCM 502 Mag MPI 0L017000 & Up Inboard (MIE) Model Serial Number MIE 454 Mag MPI Horizon 0L002200 & Up MIE 8.2L MPI 0L002450 &...

- Page 5 THIS PAGE IS INTENTIONALLY BLANK Page iv 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 6 NOTE:Outline contains book 1 and 2 Service Manual Outline Important Information Section 1 - Important Information A - General Information B - Maintenance C - Troubleshooting Removal And Installation Section 2 - Removal and Installation A - MCM Models - Bravo and Blackhawk Drives B - MCM Models - Bravo and Blackhawk Drives with Engine Driveshaft Extension...

- Page 7 THIS PAGE IS INTENTIONALLY BLANK Page vi 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

-

Page 8: Table Of Contents

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 IMPORTANT INFORMATION Section 1A - General Information Table of Contents Introduction ......1A-2 Water Testing New Engines . -

Page 9: Introduction

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Introduction This comprehensive overhaul and repair manual is designed as a service guide for the models previously listed. It provides specific information, including procedures for disassembly, inspection, assembly and adjustment to enable dealers and service mechanics to repair and tune these engines. -

Page 10: How To Read A Parts Manual

CABLE TIE REF. NO. : Number shown next to part on exploded view PART NO. : Mercury Part Number for ordering. If NSS (not sold separately) sometimes GM part number will be given in description column. QTY. : The quantity that must be ordered. -

Page 11: Directional References

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Directional References Front of boat is bow; rear is stern. Starboard side is right side; port side is left side. In this service manual, all directional references are given as they appear when viewing boat from stern looking toward bow. -

Page 12: Engine Serial Number Locations

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Engine Serial Number Locations 72923 Stern Drive (MCM) Serial Number Plate Starter Motor 72924 Inboard (MIE) Serial Number Plate Starter Motor Index Index 90-861326--1 MARCH 1999 Page 1A-5 Downloaded from https://needmanual.com/... -

Page 13: Propeller Information

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Propeller Information Refer to the “Propeller” section in appropriate MerCruiser Sterndrive Service Manual, or order publication 90-86144-92, “Everything you need to know about propellers.” Changing diameter, pitch or coupling of a propeller will affect engine rpm and boat perfor- mance. -

Page 14: Boat And Engine Performance

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Boat and Engine Performance Boat Bottom For maximum speed, a boat bottom should be as flat as possible in a fore-aft direction (longitudinally) for approximately the last 5 ft (1.5 m). 72002 Critical Bottom Area For best speed and minimum spray, the corner between the bottom and the transom should be sharp. -

Page 15: Marine Fouling

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 A “rocker” is the reverse of a hook. The bottom is convex or bulged in the fore-and-aft direc- tion. It can cause the boat to porpoise. 72005 Rocker Transom (Stern) Any hook, rocker or surface roughness on the bottom, particularly in the critical center-aft portion will have a negative effect on speed, often several miles per hour on a fast boat. -

Page 16: Weight Distribution

GENERAL INFORMATION SERVICE MANUAL NUMBER 23 Weight Distribution Weight distribution is extremely important; it affects a boat’s running angle or attitude. For best top speed, all movable weight - cargo and passengers - should be as far aft as possible to allow the bow to come up to a more efficient angle (3 to 5 degrees). - Page 17 GENERAL INFORMATION SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 1A-10 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 18 MAINTENANCE SERVICE MANUAL NUMBER 23 IMPORTANT INFORMATION Section 1B - Maintenance Table of Contents Lubricants / Sealants / Adhesives ..1B-2 Changing Water Separating Fuel Filter 1B-19 Maintenance Schedules ....1B-3 MCM (Sterndrive) Models .

-

Page 19: Lubricants / Sealants / Adhesives

MAINTENANCE SERVICE MANUAL NUMBER 23 Lubricants / Sealants / Adhesives DESCRIPTION PART NUMBER Quicksilver Liquid Neoprene 92-25711--3 Quicksilver 2-4-C Marine Lubricant With 92-825407A3 Teflon Loctite Pipe Sealant With Teflon Obtain Locally Quicksilver U-Joint and Gimbal Bearing 92-828052A2 Grease Index Index Page 1B-2 90-861326--1 MARCH 1999 Downloaded from... -

Page 20: Maintenance Schedules

MAINTENANCE SERVICE MANUAL NUMBER 23 Maintenance Schedules Maintenance Intervals Maintenance intervals and the tasks to be performed, as shown in this current schedule, or as found in a previously printed schedules, are generally based on an average boating application and environment. However, individual operating habits and personal mainte- nance preferences can have an impact on the suggested intervals. -

Page 21: Scheduled Maintenance That Should Be Done By Dealer

MAINTENANCE SERVICE MANUAL NUMBER 23 Scheduled Maintenance That Should Be Done by Dealer NON-HORIZON MODELS NOTE: Only perform maintenance which applies to your particular power package. Task Interval Whenever Insufficient Seawater Flow Is Seawater Pickup Pump - Disassemble Suspected. (If Operating Temperature And Inspect Exceeds Normal Range.) Crankcase Oil and Filter - Change... -

Page 22: Scheduled Maintenance That Should Be Done By Dealer

MAINTENANCE SERVICE MANUAL NUMBER 23 Scheduled Maintenance That Should Be Done by Dealer NON-HORIZON MODELS NOTE: Only perform maintenance which applies to your particular power package. Task Interval Steering Head and Remote Control - End Of First Boating Season And Inspect And Lubricate Thereafter, Every 100 Hours Of Operation Or Once Yearly, Whichever Occurs First... -

Page 23: Scheduled Maintenance That Can Be Performed By An Owner/Operator

MAINTENANCE SERVICE MANUAL NUMBER 23 Scheduled Maintenance That Can Be Performed By An Owner/Operator HORIZON MODELS Recommended Maintenance Interval Engine Oil - Check Level Transmission Fluid - Check Level Before Every Use Closed Cooling - Check Level Power Package Surfaces - Spray with Saltwater Use: Yearly Quicksilver Corrosion Guard Scheduled Maintenance That Should Be Done by Dealer... - Page 24 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-7 Downloaded from https://needmanual.com/...

- Page 25 MAINTENANCE SERVICE MANUAL NUMBER 23 Tune-Up Specifications MCM (Sterndrive) Models MCM 454 Mag MCM 502 Mag Model MCM 7.4L MPI Propshaft Horsepower (SAV1 Rating) (275 Propshaft Kilowatts (SAV1 Rating) (205 Number of Cylinders 502 C.I.D. Displacement 454 C.I.D (7.4L) (8.2L) 4.47 x 4.00 Bore/Stroke In.

- Page 26 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-9 Downloaded from https://needmanual.com/...

- Page 27 MAINTENANCE SERVICE MANUAL NUMBER 23 MIE (Inboard) Models MIE 454 Mag Model MIE 7.4L MPI MIE 8.2L MPI MPI Horizon Propshaft Horsepower (SAV1 Rating) (275 Propshaft Kilowatts (SAV1 Rating) (205 Number of Cylinders 502 C.I.D. Displacement 454 C.I.D (7.4L) (8.2L) 4.47 x 4.00 Bore/Stroke In.

-

Page 28: Firing Order

MAINTENANCE SERVICE MANUAL NUMBER 23 Firing Order 72008 LH ROTATION FRONT FIRING ORDER 1-8-4-3-6-5-7-2 Fluid Capacities Engines NOTICE Unit Of Measurement: U.S. Quarts (Liters) All capacities are approximate fluid measures. MCM AND MIE MCM AND MIE MODEL 454 cid / 7.4L 502 cid / 8.2L Crankcase Oil (With Filter) -

Page 29: Transmissions

MAINTENANCE SERVICE MANUAL NUMBER 23 Transmissions NOTICE Unit Of Measurement: U.S. Quarts (Liters) All capacities are approximate fluid measures. CAPACITY MAKE AND MODEL FLUID TYPE QUARTS (LITERS) Velvet Drive 72C In-Line 1.5 (1.3) 5000A Dexron III Automatic 3 (2 75) 3 (2.75) Transmission Fluid 5000V... -

Page 30: After Break-In Period

MAINTENANCE SERVICE MANUAL NUMBER 23 After Break-in Period To help extend the life of your MerCruiser power package, the following recommendations should be considered; Use a propeller that allows the engine to operate at or near the top of the maximum rpm range (See “Specifications”... -

Page 31: Specifications

MAINTENANCE SERVICE MANUAL NUMBER 23 CA261 Specifications Fuel Recommendations IMPORTANT: Use of improper gasoline can damage your engine seriously. Engine damage resulting from use of improper gasoline is considered misuse of engine, and damage caused thereby will not be covered under the limited warranty. FUEL RATINGS MerCruiser engines will operate satisfactorily when using a major brand of unleaded gaso- line as follows:... -

Page 32: Test For Alcohol Content In Gasoline

MAINTENANCE SERVICE MANUAL NUMBER 23 WARNING FIRE AND EXPLOSION HAZARD: Fuel leakage from any part of fuel system can be a fire and explosion hazard which can cause serious bodily injury or death. Careful periodic inspection of entire fuel system is mandatory, particularly after storage. All fuel components including fuel tanks, whether plastic metal or fiberglass, fuel lines, fittings, fuel filters and carburetors/fuel injection components should be in- spected for leakage, softening, hardening, swelling or corrosion. -

Page 33: Coolant For Closed Cooling System

MAINTENANCE SERVICE MANUAL NUMBER 23 Coolant for Closed Cooling System CAUTION Alcohol or Methanol base antifreeze or plain water, are not recommended for use in fresh water section of cooling system at any time. We recommend that the coolant section of closed cooling system be filled with Extended Life Ethylene Glycol 5/100 Antifreeze/Coolant mixed 50/50 with purified water. -

Page 34: Overfilled Crankcase

MAINTENANCE SERVICE MANUAL NUMBER 23 Overfilled Crankcase Overfilled crankcases (oil level being too high) can cause a fluctuation or drop in oil pressure and rocker arm “clatter” on MerCruiser engines. The over-full condition results in the engine crankshaft splashing and agitating the oil, causing it to foam (become aerated). The aerated oil causes the hydraulic valve lifters to “bleed down.”... -

Page 35: Changing Oil And Filter

MAINTENANCE SERVICE MANUAL NUMBER 23 7. Remove oil filler cap from valve rocker arm cover. 75988 Oil Cap 8. Add required amount of oil to bring level up to, but not over the FULL mark on dipstick. Changing Oil and Filter 1. -

Page 36: Changing Water Separating Fuel Filter

MAINTENANCE SERVICE MANUAL NUMBER 23 Changing Water Separating Fuel Filter WARNING Be careful when changing water separating fuel filter. Gasoline is extremely flammable and highly explosive under certain conditions. Be sure ignition key is OFF. Do not smoke or allow spark or open flame in area when changing fuel filter. Wipe up any spilled fuel immediately. -

Page 37: Mie (Inboard) Models

MAINTENANCE SERVICE MANUAL NUMBER 23 2. Remove water separating fuel filter and sealing ring from mounting bracket and discard. 70573 Fuel Filter Sealing Ring 3. Coat sealing ring on new filter with motor oil. Thread filter onto bracket and tighten securely by hand. -

Page 38: Power Steering System

MAINTENANCE SERVICE MANUAL NUMBER 23 Power Steering System Checking Fluid Level ENGINE WARM 1. Stop engine and position drive unit so that it is straight back. 2. Remove fill cap/dipstick from power steering pump and note fluid level. 75484 Fill Cap / Dipstick Power Steering Pump 3. -

Page 39: Filling And Bleeding

MAINTENANCE SERVICE MANUAL NUMBER 23 ENGINE COLD 1. With engine stopped, position drive unit so that it is straight back. 2. Remove fill cap/dipstick from power steering pump and note fluid level. 3. Level should be between FULL COLD mark and bottom of dipstick. 72519 Proper Fluid Level with Engine Cold 4. -

Page 40: Closed Cooling System

MAINTENANCE SERVICE MANUAL NUMBER 23 5. Position drive unit so that it is straight back and stop engine. Remove fill cap from pump. Allow any foam in pump reservoir to disperse, then check fluid level and add fluid, as required, to bring level up to FULL HOT mark on dipstick. DO NOT OVERFILL. Reinstall fill cap securely. -

Page 41: Flushing System Mcm (Sterndrive)

MAINTENANCE SERVICE MANUAL NUMBER 23 Flushing System MCM (Sterndrive) If engine is operated in salty, polluted or mineral-laden water, flush cooling system (prefer- ably after each use) to reduce corrosion and prevent the accumulation of deposits in the system. Thoroughly flush cooling system prior to storage. NOTE: For additional protection against freezing and rust to the exhaust manifolds and other components, a 50-50 mixture of antifreeze and water can be run through the engine during Power Package Layup. - Page 42 MAINTENANCE SERVICE MANUAL NUMBER 23 BOAT IN WATER 1. Raise drive unit to full UP position. 2. Install flushing attachment over water pickup holes in gear housing as shown. 3. Attach a hose between the flushing attachment and a water tap. 72693 Flushing Attachment Hose...

-

Page 43: Flushing System Mie (Inboard) - Except 454 Mag Mpi Horizon

MAINTENANCE SERVICE MANUAL NUMBER 23 Flushing System MIE (Inboard) - Except 454 Mag MPI Horizon CAUTION If boat is in the water, seacock, if so equipped, must remain closed until engine is to be re-started, to prevent water from flowing back into cooling system and/or boat. If boat is not fitted with a seacock, water inlet hose must remain disconnected and plugged (to prevent water from flowing back into cooling system and/or boat). - Page 44 MAINTENANCE SERVICE MANUAL NUMBER 23 WARNING When flushing, be certain the area around propeller is clear, and no one is standing nearby. To avoid possible injury, remove propeller. CAUTION Do not run engine above 1500 rpm when flushing. Suction created by seawater pick- up pump may collapse flushing hose, causing engine to overheat.

-

Page 45: Flushing System Mie (Inboard) 454 Mag Mpi Horizon

MAINTENANCE SERVICE MANUAL NUMBER 23 Flushing System MIE (Inboard) 454 Mag MPI Horizon EARLY MODEL FLUSHING SYSTEM NOTE: This system has a black hose connecting the hose fitting to the flush valve. CAUTION Do NOT start engine at any point in this procedure. If boat is in the water, starting engine during this procedure will pull in seawater. - Page 46 MAINTENANCE SERVICE MANUAL NUMBER 23 3. Turn on water to highest pressure. 4. Attach flush socket to engine flush valve on exhaust elbow. 5. Allow engine to flush for 5 minutes. 6. Attach to next engine, if equipped, and repeat procedure. 7.

- Page 47 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 1B-30 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 48 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-31 Downloaded from https://needmanual.com/...

-

Page 49: Transmission Fluid

MAINTENANCE SERVICE MANUAL NUMBER 23 Transmission Fluid Checking Fluid Level NOTE: Due to the various installation angles and oil cooler set-ups, it may be necessary to adjust oil level. WARNING Do not remove dipstick with engine running. Hot oil can cause burns. CAUTION Clean around the area of the dipstick before removing. -

Page 50: Lubrication

MAINTENANCE SERVICE MANUAL NUMBER 23 TRANSMISSION COLD NOTE: For ease of checking the oil prior to engine start-up, a cold oil level mark can be made. To find the cold oil level mark, the oil level must first be set according to the warm oil level checking procedure. -

Page 51: Shift Cable

MAINTENANCE SERVICE MANUAL NUMBER 23 Shift Cable MCM MODELS 72016 Typical Shift Cable Pivot Points Guide Contact Surface Shift Cable and Transmission Linkage MIE MODELS 72528 Typical Shift Cable And Transmission Linkage Pivot Points Guide Contact Surface Index Index Page 1B-34 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/... -

Page 52: Engine Coupler / U-Joint Shaft Splines

MAINTENANCE SERVICE MANUAL NUMBER 23 Engine Coupler / U-Joint Shaft Splines MCM MODELS NOTE: Engine coupler and shaft splines are greased with Quicksilver Engine Coupler Spline Grease, 92-816391A4; universal joints are greased with Quicksilver 2-4-C Marine Lubricant. NOTE: Refer to MerCruiser Sterndrive Service Manual for sterndrive unit removal and installation, if necessary. -

Page 53: Drive Shaft Extension Models

MAINTENANCE SERVICE MANUAL NUMBER 23 Drive Shaft Extension Models 72018 Bearings at Transom End Lubrication Points 72028 Bearings at Engine End Lubrication Points Index Index Page 1B-36 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/... -

Page 54: Starter Motor

MAINTENANCE SERVICE MANUAL NUMBER 23 Starter Motor MIE MODELS WARNING When performing the following procedure, be sure to observe the following: Be sure that engine compartment is well ventilated and that no gasoline vapors are present to avoid the possibility of a fire. Be sure to ground coil high-tension wire to block. -

Page 55: Cleaning Flame Arrestor

MAINTENANCE SERVICE MANUAL NUMBER 23 Cleaning Flame Arrestor WARNING Avoid gasoline fire or explosion. Gasoline is extremely flammable and highly explosive under certain conditions. Be careful when cleaning flame arrestor and crankcase ventilation hoses. Be sure that ignition is OFF. DO NOT smoke or allow sources of spark or open flame in area when cleaning flame arrestor and crankcase ventilation hoses. -

Page 56: Plastic Front Mounted Flame Arrestor 1B-39

MAINTENANCE SERVICE MANUAL NUMBER 23 Plastic Front Mounted Flame Arrestor 1. Remove starboard side engine cover. 2. Loosen clamp. 3. Remove flame arrestor. 75447 Cover Clamp Flame Arrestor 4. Clean flame arrestor in solvent. Blow dry with compressed air. 5. Reinstall flame arrestor. Tighten clamp securely. 6. -

Page 57: Serpentine Drive Belt

MAINTENANCE SERVICE MANUAL NUMBER 23 3. Remove flame arrestor. 4. Clean flame arrestor in solvent. Blow dry with compressed air. 5. Clean crankcase ventilation hoses in solvent. Blow dry with compressed air. 6. Inspect crankcase ventilation hoses for cracks or deterioration, and replace if necessary. - Page 58 MAINTENANCE SERVICE MANUAL NUMBER 23 NOTE: Some models will have components arranged in a different order. All configurations are not shown. Checking, replacing and adjustment procedures are the same. 75424 Inboard Model Idler Pulley Seawater Pump Pulley Crankshaft Pulley Circulating Pump Pulley Alternator Pulley 75487 Sterndrive Model...

-

Page 59: Inspecting

MAINTENANCE SERVICE MANUAL NUMBER 23 Inspecting 1. Inspect drive belt for the following: Excessive wear Cracks NOTE: Minor, transverse cracks (across the belt width) may be acceptable. Longitudinal cracks (in direction of belt length) that join transverse cracks are NOT acceptable. Fraying Glazed surfaces 75130... -

Page 60: Ignition Timing

MAINTENANCE SERVICE MANUAL NUMBER 23 Ignition Timing Two items of test equipment are required: an inductive pickup timing light and a Scan Tool. 1. Connect timing light (91-99379 or similar) to No. 1 spark plug wire. Connect power supply leads, if applicable, on light to 12 volt battery. Refer to Specifications - “Engine Rotation and Firing Order,”... -

Page 61: Cold Weather Or Extended Storage

MAINTENANCE SERVICE MANUAL NUMBER 23 10. Manually close the throttle to bring engine rpm back to idle. IMPORTANT: Set the tool to NORMAL MODE before attempting to resume normal op- erations. If the setting of the tool remains in SERVICE MODE, the ignition system will operate only in the “Service Mode.”... -

Page 62: Power Package Layup

MAINTENANCE SERVICE MANUAL NUMBER 23 IMPORTANT: To prevent threads in manifolds, elbows and cylinder blocks from rust- ing out during storage, reinstall plugs using Quicksilver Perfect Seal (92-34227--1) on threads. Never leave drain plugs out during storage. CAUTION Sterndrive unit should be stored in full “down” position. Universal Joint bellows may develop a “set”... - Page 63 MAINTENANCE SERVICE MANUAL NUMBER 23 7. Prepare fuel system for extended storage as follows: a. Allow engine to cool down. b. Remove the water separating fuel filter. c. Pour out a small amount of fuel into a suitable container, then add approximately 2 fluid ounces (60 ml) of Quicksilver 2-Cycle Outboard Oil to fuel in the water separat- ing fuel filter.

- Page 64 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-47 Downloaded from https://needmanual.com/...

- Page 65 MAINTENANCE SERVICE MANUAL NUMBER 23 Draining Instructions DRAINING SEAWATER (RAW-WATER) COOLED MODELS NOTICE Refer to “Cold Weather or Extended Storage,” “Precautions,” in this section, BEFORE proceeding. MCM (Sterndrive) Models: 1. Engine must be as level as possible to ensure complete draining of cooling system. 2.

- Page 66 MAINTENANCE SERVICE MANUAL NUMBER 23 6. Remove the engine water circulating pump hose as shown. 72587 Hose, Water Circulating Pump To Thermostat Housing 7. Remove the drain plug from the fuel cooler. 75081 Drain Plug 8. Remove both hoses from seawater pump. 75533 Seawater Inlet Hose Hose To Cooler...

- Page 67 MAINTENANCE SERVICE MANUAL NUMBER 23 9. Insert a small wire (repeatedly) to make sure that speedometer pitot tube, anode cavity vent hole, and anode cavity drain passage are unobstructed and drained. 71217 Typical Bravo Drive Unit Speedometer Pitot Tube Anode Cavity Vent Hole Anode Cavity Drain Passage 10.

- Page 68 MAINTENANCE SERVICE MANUAL NUMBER 23 MIE (Inboard) Models: NOTICE Refer to “Cold Weather or Extended Storage,” “Precautions,” in this section, BEFORE proceeding. 1. Engine must be as level as possible to ensure complete draining of cooling system. 2. Remove drain plugs (port and starboard) from cylinder block. 75481 74130 Starboard Side Shown (Port Similar)

- Page 69 MAINTENANCE SERVICE MANUAL NUMBER 23 4. Repeatedly clean out drain holes using a stiff piece of wire. Do this until entire system is drained. 5. Remove the engine water circulating pump hose as shown. 72587 Hose, Water Circulating Pump To Thermostat Housing 6.

- Page 70 MAINTENANCE SERVICE MANUAL NUMBER 23 8. On Horizon Model: Remove drain plugs from fittings on each seawater pump hose. 75536 Drain Plugs - One Is Hidden From View 9. Crank engine over slightly with starter motor to purge any water trapped in seawater pickup pump.

- Page 71 MAINTENANCE SERVICE MANUAL NUMBER 23 DRAINING CLOSED COOLING (COOLANT) MODELS NOTE: All factory installed closed cooling systems come filled with DexCool Extended Life Coolant. This antifreeze requires draining and replacing every five years. The color of this antifreeze is orange. For best results any “top-off” fluid used should be DexCool Extended Life Coolant.

- Page 72 MAINTENANCE SERVICE MANUAL NUMBER 23 MCM (Sterndrive) Models: NOTICE Refer to “Cold Weather or Extended Storage,” “Precautions,” in this section, BEFORE proceeding. 1. Engine must be as level as possible to ensure complete draining of cooling system. 2. Remove end caps, sealing washers and gaskets from the heat exchanger. 71515 Heat Exchanger Sealing Washer...

- Page 73 MAINTENANCE SERVICE MANUAL NUMBER 23 4. Remove the drain plug from the fuel cooler. 75081 Drain Plug 5. Repeatedly clean out drain holes using a stiff piece of wire. Do this until entire system is drained. 6. Remove both hoses from seawater pump. 75533 Seawater Inlet Hose Hose To Cooler...

- Page 74 MAINTENANCE SERVICE MANUAL NUMBER 23 7. Insert a small wire (repeatedly) to make sure that speedometer pitot tube, trim tab cavity vent hole, and trim tab cavity drain passage are unobstructed and drained. 71217 Typical Bravo Drive Unit Speedometer Pitot Tube Anode Cavity Vent Hole Anode Cavity Drain Passage 8.

- Page 75 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 1B-58 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 76 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-59 Downloaded from https://needmanual.com/...

- Page 77 MAINTENANCE SERVICE MANUAL NUMBER 23 MIE (Inboard) Models NOTICE Refer to “Cold Weather or Extended Storage,” “Precautions,” in this section, BEFORE proceeding. 1. Ensure that the boat is as level as possible to ensure complete draining of cooling system. 2. Remove end caps, sealing washers and gaskets from the heat exchanger. 71515 Heat Exchanger Sealing Washer...

- Page 78 MAINTENANCE SERVICE MANUAL NUMBER 23 4. Remove drain plug from the fuel cooler. 74130 Drain Plug 5. On All Models Except Horizon: Remove both hoses from seawater pump. 75533 Seawater Inlet Hose Hose To Cooler 6. On Horizon Model: Remove drain plugs from fittings on each seawater pump hose. 75536 Drain Plugs - One Is Hidden From View 7.

- Page 79 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 1B-62 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 80 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-63 Downloaded from https://needmanual.com/...

- Page 81 MAINTENANCE SERVICE MANUAL NUMBER 23 Recommissioning NOTICE Refer to “Cold Weather or Extended Storage,” “Precautions,” in this section, BEFORE proceeding. 1. Check that all cooling system hoses are connected and tight and all petcocks and drain plugs are installed and tight. 2.

- Page 82 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1B-65 Downloaded from https://needmanual.com/...

- Page 83 MAINTENANCE SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 1B-66 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 84 TROUBLESHOOTING SERVICE MANUAL NUMBER 23 IMPORTANT INFORMATION Section 1C - Troubleshooting Table of Contents Precautions ......1C-2 Engine Runs Poorly at Idle .

-

Page 85: Precautions

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Precautions WARNING Always disconnect battery cables from battery BEFORE working on fuel system to prevent fire or explosion. WARNING Be careful when cleaning flame arrestor and crankcase ventilation hose; gasoline is extremely flammable and highly explosive under certain conditions. Be sure that ignition key is OFF. -

Page 86: Used Spark Plug Analysis

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 CAUTION DO NOT run engine above 1500 rpm, as suction created by seawater pickup pump may collapse water supply hose and cause engine to overheat. WARNING Be sure that engine compartment is well ventilated and that no gasoline vapors are present to prevent the possibility of a FIRE or EXPLOSION. -

Page 87: Spark Plug Analysis

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Spark Plug Analysis Normal Condition Few deposits are present and probably will be light tan or gray in color. This plug shows that plug heat range is compatible with engine, and engine is electrically and mechanically in good running condition. -

Page 88: Cold Fouling

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Cold Fouling Dry, black deposits indicate rich fuel mixture or weak ignition. Clogged flame arrestor or weak ignition components all are probable causes. If, however, only one or two plugs in set are fouled, check for sticking valves or bad ignition leads. After correcting cause, service (clean, file and re-gap) plugs and reinstall. -

Page 89: Scavenger Deposits

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Scavenger Deposits Powdery white or yellow deposits are built up on shell, insulator and electrodes. This is normal appearance with certain branded fuels. Accumulation on ground electrodes and shell areas may be unusually heavy, but may be easily chipped off. Plugs can be serviced (clean, file and re-gap) and reinstalled. -

Page 90: Splashed Deposits

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Splashed Deposits Spotted deposits, which sometimes occur after long delayed tune-up, accumulate after a long period of misfiring. When normal combustion temperatures are restored, upon installation of new plugs, deposits loosen from top of piston and head and are thrown against hot insulator. -

Page 91: Poor Boat Performance And/Or Poor Maneuverability

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Poor Boat Performance and/or Poor Maneuverability Symptom Cause A. Improper drive unit trim angle B. Improper weight distribution C. Boat is underpowered D. Permanent or power hook in boat bot- Bow too low E. False bottom full of water F. -

Page 92: Improper Full Throttle Engine Rpm

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Improper Full Throttle Engine RPM RPM Too High Cause Special Information Damaged; pitch too low; diameter too Propeller small; propeller hub slipping. Water pickup or through hull fittings mounted too close to propeller (ventilation); keel located too close to Boat propeller and/or too deep in the water (ventilation). -

Page 93: Engine Cranks Over But Will Not Start Or Starts Hard

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Engine Cranks Over But Will Not Start Or Starts Hard Important Information 1. First, determine which engine system is causing the problem. To make an engine run, basic components - fuel, spark (ignition), and compression - are required. If all three components are present, the engine should run. -

Page 94: Engine Will Not Crank Over

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Engine Will Not Crank Over Cause Special Information Remote control lever not in neutral posi- tion Battery charge low; damaged wiring; loose electrical connections Circuit breaker tripped Blown fuse Ignition switch Slave solenoid Faulty neutral start safety switch Open circuit Starter solenoid Starter motor... -

Page 95: Noisy Alternator

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Noisy Alternator Cause Special Information Loose mounting bolts Drive belt Worn, frayed, loose Loose drive pulley Worn or dirty bearings Faulty diode trio or stator Instrumentation Malfunction Cause Special Information Faulty wiring, loose or corroded terminals Faulty key switch Test, as outlined in SECTION 4D Faulty gauge... -

Page 96: Poor Fuel Economy

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Poor Fuel Economy Cause Special Information Fuel leaks Prolonged idling; slow acceleration; failure to cut back on throttle once boat is on Operator habits plane; boat overloaded; uneven weight distribution Bent, damaged, or wrong propeller. Water Engine laboring test boat for proper operating rpm at wide- open-throttle... -

Page 97: Engine Runs Poorly At High Rpm

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Engine Runs Poorly At High RPM Cause Special Information Also refer to “Poor Boat Performance” Crankcase overfilled with oil Check oil level with boat at rest in the water. Anti-siphon valve (if equipped) Restricting fuel supply Plugged fuel tank vent Fuel supply Refer to “Fuel Injection Troubleshooting,”... -

Page 98: Troubleshooting With Vacuum Gauge

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Troubleshooting with Vacuum Gauge Reading Cause Steady reading between 15-21 inches at Normal idle rpm Extremely low reading, but steady at idle Vacuum leak; incorrect timing; underpowered boat; faulty boat bottom Fluctuates between high and low at idle Blown head gasket between two adjacent cylinders Fluctuates 4 or 5 inches very slowly at idle... -

Page 99: Valve Cover Area

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Valve Cover Area Location Possible Causes Rocker arm striking valve cover Rocker arm out of adjustment Valve cover area, timed to one-half engine speed, noise could be confined to one ld b Worn rocker arm cylinder or may be found in any multitude of cylinders Bent push rod... -

Page 100: Camshaft Area

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Camshaft Area Location Possible Causes Crankshaft timing sprocket Timing chain Camshaft area, front of engine, timed to one half engine speed Valve Lifter Cam Bearings Fuel Pump Camshaft area, center of engine, timed to h ft Valve Lifter one half engine speed Cam bearing... -

Page 101: Miscellaneous

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Miscellaneous Noise Possible Cause Advanced timing Low octane fuel Engine spark knock Engine s ark knock Engine running hot Carbon deposits in engine Vacuum leak Leaking exhaust (manifolds or pipes) Hissing Hissing Loose cylinder heads Blown head gasket Vacuum leak Whistle... -

Page 102: Oil Pressure

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Oil Pressure Miscellaneous Cause Special Information Use a good automotive oil pressure test Measuring oil pressure gauge. Do not rely on the oil pressure gauge in the boat. Check engine oil level with boat at rest in Oil level should be between the ADD and the water FULL marks... -

Page 103: Low Oil Pressure

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Low Oil Pressure Cause Special Information Low oil level in crankcase Verify with an automotive test gauge. Defective oil pressure gauge and/or Refer to SECTION 4D for instrument sender testing. Oil broken down; contains water or gas; wrong viscosity;... -

Page 104: Excessive Oil Consumption

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Excessive Oil Consumption Cause Special Information One quart of oil consumed in 5-15 hours Normal consumption. of operation at wide-open-throttle (espe- cially in a new or rebuilt engine) is normal Clean bilge, run engine with clean white Oil leaks paper on bilge floor, locate oil leak(s) Oil too thin... -

Page 105: Water In Engine

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Water In Engine Important Information IMPORTANT: First determine location of water in engine. This information can be of great help when trying to determine where the water came from and how it got into the engine. The three most common problems are “water on top of pistons, water in crankcase oil, water in crankcase oil and on top of pistons.”... -

Page 106: Water On Top Of Pistons

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Water on Top of Pistons Cause Special Information Operator shut engine off at high rpm Poor fuel, high idle rpm, timing set too Engine “diesels” or tries to run backwards high Rain water running into flame arrestor Hatch cover Improper combustion causes moisture in Spark plug misfiring... -

Page 107: Engine Overheats

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Engine Overheats Mechanical Cause Special Information Engine rpm below specifications at wide- Damaged or wrong propeller; growth on open-throttle (engine laboring) boat bottom; false bottom full of water Wrong ignition timing Timing too far advanced or retarded Sticking distributor advance weights Spark plug wires crossed (wrong firing order) -

Page 108: Engine Overheats

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Engine Overheats Cooling System Cause Special Information IMPORTANT: The first step is to verify if the engine is actually overheating or the temperature gauge or sender is faulty. IMPORTANT: Best way to test gauge or sender is to replace them. Loose or broken drive belt Seawater shutoff valve partially or fully closed (if equipped) -

Page 109: Insufficient Water Flow From Belt Driven Seawater Pickup Pump

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Insufficient Water Flow from Belt Driven Seawater Pickup Pump Cause Special Information Drive belt Loose, worn or broken Seawater shutoff valve partially or fully closed Clogged or improperly installed sea strainer Pump will suck air, pump may fail to prime Loose hose connections between seawa- or will force air bubbles into cooling ter pickup and seawater pump inlet... -

Page 110: Power Steering

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Power Steering Poor, Erratic, or No Assist Cause Special Information Drive belt Worn, broken or out of adjustment Low fluid level Air leak in lines, pump, or air from Air in system installation. Refer to SECTION 9A for bleeding procedure. -

Page 111: Noisy Pump

TROUBLESHOOTING SERVICE MANUAL NUMBER 23 Noisy Pump Cause Special Information Drive belt Check belt tension Low fluid level Air leak in lines, pump, or air from Air in fluid installation Use stethoscope to listen for noise in Faulty pump pump Kinks or debris in hoses or debris in Restricted fluid passages passages... - Page 112 TROUBLESHOOTING SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 1C-29 Downloaded from https://needmanual.com/...

- Page 113 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 REMOVAL AND INSTALLATION Section 2A - MCM Models - Bravo and Blackhawk Drives Table of Contents Torque Specifications ....2A-2 Tools .

-

Page 114: Torque Specifications

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 Torque Specifications FASTENER LOCATION lb-in. lb-ft Cable Barrel Spread Cotter Key Drive Unit Drive Unit Cable End Shift Cable See Note Guide Hose Clamps Securely Rear Engine Mounts 35-40 47-54 Power Steering Fluid Hose Fitting Rear Engine Mounts... -

Page 115: Preparation

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 Preparation IMPORTANT: Sterndrive unit must be removed prior to engine removal. Refer to Bravo Sterndrive Service Manual. Removal 1. Disconnect battery cables from battery. 2. Remove instrument harness connector plug from engine harness receptacle after loosening clamp. -

Page 116: Installation

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 12. Support engine with suitable sling through lifting eyes on engine and remove front and rear engine mounting bolts. Retain hardware. 75505 Suitable Sling Engine Lifting Eyes 13. Carefully remove engine. DO NOT hit power steering control valve. Installation Engine Installation/Alignment 1. - Page 117 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 CAUTION Center lifting eye (located on top of thermostat housing) is used for engine alignment only. DO NOT use to lift entire engine. CAUTION Engine MUST be lifted with a lifting arm or damage to engine components will occur. DO NOT allow lifting sling to hook or compress engine components or damage will occur.

- Page 118 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 10. Set engine down on stringers and relieve hoist tension. Disconnect sling from engine lifting eyes and move sling to center lifting eye. 75988 Center Lifting Eye (If Equipped) CAUTION DO NOT use an alignment tool from another manufacturer.

- Page 119 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 c. Repeat step “b” until the alignment tool installs easily (SLIDES IN AND OUT FREELY WITH TWO FINGERS) all the way into and out of engine coupler splines. 70013 Alignment Tool (Use Only Quicksilver Alignment Tool-91-805475A1) Insert This End Of Alignment Tool Through Gimbal Housing Assembly 27647...

- Page 120 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 h. Bend tab washer down against flat on adjusting nut. 72922 Locknut Adjustment Nut Turn Adjustment Nut In This Direction (Counterclockwise) To Raise Front Of Engine Slotted Hole To Front Of Engine Tab Washer Remove alignment tool if not already removed.

- Page 121 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 b. On Engines with Through-Transom Exhaust: NOTICE (Through Transom Exhaust) Exhaust hoses must be connected to exhaust elbows so that they do not restrict the flow of discharge water from exhaust elbow. If hoses are connected incorrectly, discharge water from exhaust elbow will not flow around entire inside diameter of hose.

-

Page 122: Water Hose Connections

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 Water Hose Connections IMPORTANT: When routing all wire harnesses and hoses, be sure they are routed and secured to avoid coming in contact with hot spots on engine and avoid contact with moving parts. - Page 123 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 2. Connect trim position sender leads from gimbal housing to leads from engine harness. 72582 BROWN/WHITE (From Engine Harness) BLACK (From Engine Harness) BLACK (From Transom) BLACK (From Transom Assembly) IMPORTANT: Do not attach any accessory ground (–) wires to transom plate ground point.

- Page 124 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 5. Connect wires to MerCathode controller assembly as shown. Apply a thin coat of Quick- silver Liquid Neoprene to all connections. 22232 ORANGE Wire - From Electrode On Transom Assembly RED/PURPLE Wire - Connect (Other End) To Positive (+) Battery Terminal BLACK Wire - From Engine Harness BROWN Wire - From Electrode on Transom Assembly...

-

Page 125: Fuel Supply Connections

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 Fuel Supply Connections WARNING Be careful when working on fuel system. Gasoline is extremely flammable and highly explosive under certain conditions. Do not smoke or allow spark or open flame in area. -

Page 126: Throttle Cable Installation And Adjustment

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 Throttle Cable Installation and Adjustment MPI MODELS (EXCEPT 7.4L MPI) 1. Place remote control handle(s) in neutral idle position. IMPORTANT: Be sure that cable is routed to avoid sharp bends and/or contact with moving parts. - Page 127 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 3. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

- Page 128 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 7. Reinstall flame arrestor and tighten screws securely. Connect crankcase vent hose to flame arrestor as shown. 75115 Crankcase Vent Hose 7.4L MPI MODELS 1. Place remote control handle(s) in neutral idle position. 2.

- Page 129 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 4. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

-

Page 130: Power Steering Connections

MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 7. Return remote control throttle lever to idle position and ensure that throttle plate is completely closed. 75452 Throttle Plate 8. Reinstall flame arrestor and tighten clamp securely. IMPORTANT: Adjust shift cables as outlined in appropriate Sterndrive Service Manual. - Page 131 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 2A-19 Downloaded from https://needmanual.com/...

- Page 132 MCM MODELS - BRAVO AND BLACKHAWK DRIVES SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 2A-20 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 133 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 REMOVAL AND INSTALLATION Section 2B - MCM Models - Bravo And Blackhawk Drives With Driveshaft Extension Table of Contents Torque Specifications ....2B-2 Tools .

- Page 134 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Torque Specifications Fastener Location lb-in. lb-ft Bearing Support (Tailstock) To Inner Transom Plate 35-40 47-54 Drive Shaft Rear Engine Mount Bracket Drive Shaft Shield Extension Housing To Flywheel Housing Flywheel Housing Power Steering Hose Fittings Remote Control Throttle Cable Cable Barrel...

- Page 135 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Preparation IMPORTANT: It is not necessary to remove the engine to service the drive shaft and/or bearing support (tailstock). Refer to instructions as outlined in SECTION 8F “Drive Shaft Repair”...

- Page 136 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Removal WARNING Be careful when working on fuel system. Gasoline is extremely flammable and highly explosive under certain conditions. Do not smoke or allow spark or open flame in area.

- Page 137 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Installation Engine Installation/Alignment ENGINE MOUNT ADJUSTMENT WAS NOT DISTURBED DURING SERVICE CAUTION Center lifting eye (located on top of thermostat housing) is used for engine align- ment only.

- Page 138 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 IMPORTANT: Failure to properly position output shaft flange may result in bearing damage. 6. Relieve hoist tension from engine, then slide engine fore or aft as needed to obtain 1/4 in.

- Page 139 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 9. Apply Loctite 271 to threads of bottom drive shaft shield retaining screws and install bottom shield on engine end as shown. Torque screws to 30 lb-ft (41 Nm). Then install top shield as shown.

- Page 140 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 ENGINE MOUNT ADJUSTMENT WAS DISTURBED DURING SERVICE NOTE: A Universal Protractor is recommended for measuring the angles in the following steps. IMPORTANT: In the following steps, the protractor readings will be taken off of vertical and horizontal surfaces;...

- Page 141 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 3. Adjust engine mounts so that an equal amount of up and down adjustment exists. 4. Attach a suitable lifting chain to lifting eyes on engine and adjust so that engine will be level when suspended.

- Page 142 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 8. Relieve hoist tension from engine, then slide engine fore or aft as needed to obtain 1/4 in. (6.4 mm) between flange shoulder and extension shaft housing bearing, as shown. 72591 Flange Shoulder Bearing...

- Page 143 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 10. After engine has been aligned correctly, fasten front and rear engine mounts to stringers. Tighten securely. 72922 Typical Mounting Shown Mounting Bolts 11. Position protractor on starter housing cover plate, as shown. Now, raise or lower front engine mount adjusting nuts as required so that protractor needle reads exactly the same number of degrees as that recorded in Step 1.

- Page 144 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 13. Tighten ALL engine mount nuts securely. Bend washer tab down on each adjustment nut. 72922 Locknut Adjustment Nut Turn Nut In This Direction (Counterclockwise) To Raise Front Of Engine Slotted Hole Toward Front Of Engine Tab Washer 14.

- Page 145 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Engine Connections Water Hose Connections IMPORTANT: When routing all wire harnesses and hoses, be sure they are routed and secured to avoid coming in contact with hot spots on engine and avoid contact with moving parts.

- Page 146 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 2. Connect trim position sender leads from gimbal housing to leads from engine harness. 72582 BROWN/WHITE (From Engine Harness) BLACK (From Engine Harness) BLACK (From Transom) BLACK (From Transom Assembly) IMPORTANT: Do not attach any accessory ground (–) wires to transom plate ground point.

- Page 147 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 5. Connect wires to MerCathode controller assembly as shown. Apply a thin coat of Quick- silver Liquid Neoprene to all connections. 22232 ORANGE Wire - From Electrode On Transom Assembly RED/PURPLE Wire - Connect (Other End) to Positive (+) Battery Terminal BLACK Wire - From Engine Harness BROWN Wire - From Electrode on Transom Assembly...

- Page 148 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Fuel Supply Connections WARNING Be careful when working on fuel system. Gasoline is extremely flammable and highly explosive under certain conditions. Do not smoke or allow spark or open flame in area.

- Page 149 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 Throttle Cable Installation and Adjustment MPI MODELS (EXCEPT 7.4L MPI) 1. Place remote control handle(s) in neutral idle position. IMPORTANT: Be sure that cable is routed to avoid sharp bends and/or contact with moving parts.

- Page 150 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 3. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

- Page 151 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 7. Reinstall flame arrestor and tighten screws securely. Connect crankcase vent hose to flame arrestor as shown. 75115 Crankcase Vent Hose 7.4L MPI MODELS 1. Place remote control handle(s) in neutral idle position. 2.

- Page 152 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 4. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

- Page 153 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 7. Return remote control throttle lever to idle position. Ensure that throttle plate is com- pletely closed. 75452 Throttle Plate 8. Reinstall flame arrestor and tighten clamp securely. IMPORTANT: Adjust shift cables as outlined in appropriate Sterndrive Service Manual.

- Page 154 MCM MODELS - BRAVO AND BLACKHAWK DRIVES WITH DRIVESHAFT EXTENSION SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Page 2B-22 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 155 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 REMOVAL AND INSTALLATION Section 2C - MIE Models - Velvet Drive Transmission Table of Contents Torque Specifications ....2C-2 Engine Connections .

- Page 156 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 Torque Specifications FASTENER LOCATION lb-ft Battery Cables Engine Mount Pads Securely Hose Clamps Securely Mount Locking Nut NOTE 2 Propeller Shaft Coupler To Transmission Output Flange Trunnion Clamping Bolt / Nut Cable Barrel Securely Remote Control Shift Cable...

-

Page 157: Preparation

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 Preparation 1. Disconnect battery cables from battery. 2. Remove instrument panel harness connector plug from engine harness receptacle after loosening clamp. 3. Using wrench to stabilize brass coupling at fuel inlet, loosen fuel line fitting, disconnect and suitably plug fuel line to prevent fuel in tank from leaking into bilge. -

Page 158: Installation

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 2. Remove front and rear engine mounting bolts. Retain hardware. 72638 All Engines Bolts Or Lag Screws (With Washers) Slot Forward (If So Designed) 3. Carefully remove engine. Installation Engine Installation and Initial Alignment 1. - Page 159 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 d. Each mount base is downward. Tighten clamping bolts and nuts slightly to prevent moving in or out. Mounts must be free to pivot when installing engine. 72594 72638 Front Mount - All Engine Rear Mount - Typical 71182 Rear Mount - Typical...

-

Page 160: Engine Final Alignment

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 IMPORTANT: Engine bed must position engine so that a minimum of 1/4 in. (6 mm) up and down adjustment still exists on all four mounts after performing final alignment. This is necessary to allow for final engine alignment. 4. - Page 161 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 3. Ensure coupling centerlines align by butting propeller shaft coupler against transmis- sion output flange. Shoulder on propeller shaft coupler should engage recess on trans- mission output flange face with no resistance. NOTE: Some propeller shaft couplers may not have a shoulder on mating face.

- Page 162 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 5. If coupling centerlines are not aligned or if coupling faces are more than .003 in. (0.07 mm) out of parallel, adjust engine mounts as follows: a. TO ADJUST ENGINE UP OR DOWN: Loosen locking nut on mounts requiring adjustment and turn both front mount or rear mount adjusting nuts equally.

-

Page 163: Engine Connections

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 c. After engine has been properly aligned: Tighten engine mount nuts securely, and be certain to bend one of the tabs on the tab washer down onto flat of mount adjusting nut. -

Page 164: Electrical Connections

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 Electrical Connections 1. Connect instrument harness to engine harness with hose clamp. Tighten clamp securely. 75441 7.4L MPI Shown Instrumentation Wiring Harness Plug Fuel Supply Connections WARNING Be careful when working on fuel system. Gasoline is extremely flammable and highly explosive under certain conditions. -

Page 165: Exhaust Hose Connection

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 Exhaust Hose Connection 1. Connect exhaust system tubes and hoses using at least two hose clamps at each con- nection. Tighten hose clamps securely. NOTICE Exhaust hoses must be connected to exhaust elbows so that they do not restrict the flow of discharge water from exhaust elbow. - Page 166 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 3. On 454 Mag MPI Horizon Model: Remove flame arrestor as follows: a. Remove locknuts. 71481 Locknuts b. Move crankcase ventilation hose away from against flame arrestor and rocker arm cover fittings.

- Page 167 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 4. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

- Page 168 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 8. On 8.2L MPI Model a. Install flame arrestor. b. Connect crankcase ventilation hose. c. Install flame arrestor screws and tighten securely. 75113 75142 8.2L MPI Shown Flame Arrestor Screws Vent Hose 9.

- Page 169 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 7.4L MPI MODEL 1. Place remote control handle(s) in neutral idle position. 2. Remove port side engine cover. IMPORTANT: Be sure that cable is routed to avoid sharp bends and/or contact with moving parts.

- Page 170 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 5. Secure throttle cable with hardware as shown and tighten securely. 75454 Washer and Locknut 6. Place remote control throttle lever in the wide open throttle (W.O.T.) position. Ensure that throttle plate is completely open. 75453 Throttle Plate 7.

-

Page 171: Shift Cable Installation And Adjustment

MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 Shift Cable Installation And Adjustment IMPORTANT: When installing shift cables, be sure that cables are routed in such a way as to avoid contact with moving parts and/or sharp bends [all bends must make greater than an 8 inch (203 mm) radius]. - Page 172 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 2. Place remote control shift lever, and transmission shift lever in neutral position. 3. Remove nuts and washers from shift cable attaching studs. 4. Locate center of remote control and control shift cable play (backlash), as follows: a.

- Page 173 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 11. Reattach nut and washer to cable barrel stud. Tighten until contact. Tighten securely, but DO NOT OVERTIGHTEN. 50947 50947 Rear Entry Single Station Rear Entry Dual Station Installation Installation In-Line And Remote V-Drive In-Line And V-Drive Cable End Guide Cable Barrel...

- Page 174 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 NOTE: For models equipped with a dual station shift bracket such as the one shown, refer to shift cable manufacturer’s instructions for adjusting the cable. Shift lever must be positioned as stated in the preceding steps. 22457 5000 SERIES (8 DOWN ANGLE AND V-DRIVE) For Left-Hand Propeller Shaft Rotation: Shift cable hookup at remote control must result...

- Page 175 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 IMPORTANT: The distance between studs (Dimension “C”) shown in the following illustration is set at 7-1/8 in. (318 mm). 73284 8 Down Angle Shown (V-Drive Similar) Shift Lever Anchor Stud Dimension Between Studs - 7-1/8 In.

- Page 176 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 d. Locate center of remote control and control shift cable play (backlash) as follows: (1.) Check that remote control is in neutral position. (2.) Push in on control cable end with enough pressure to remove play; mark position “a”...

- Page 177 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 CAUTION Remote control and shift cable must position transmission shift lever exactly as shown, or transmission failure may occur. Do not remove poppet ball or spring. 73248 Velvet Drive 5000 Series (8 Down Angle Shown, V-Drive Similar) Transmission Shift Lever Poppet Ball Must Be Centered In This Detent Hole When Left-Hand Propeller Shaft Rotation Is Desired...

- Page 178 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 k. Install nut and washer to cable barrel stud. Tighten until contacts. Tighten securely, but DO NOT OVERTIGHTEN. 71972 71780 Typical Single Cable Installation - Rear Approach Cable End Guide Spacer (As Required) Elastic Stop Nut And Washer Bushing(s)

- Page 179 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index 90-861326--1 MARCH 1999 Page 2C-25 Downloaded from https://needmanual.com/...

- Page 180 MIE MODELS - VELVET DRIVE TRANSMISSION SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Index Page 2C-26 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 181 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 REMOVAL AND INSTALLATION Section 2D - MIE Models - Hurth Transmission Table of Contents Torque Specifications ....2D-2 Engine Connections .

-

Page 182: Torque Specifications

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Torque Specifications Fastener Location lb-ft Battery Cables Engine Mount Pads Securely Hose Clamps Mount Locking Nut Propeller Shaft Coupler To Transmission Output Flange Trunnion Clamping Screw / Nut Cable Barrel Securely Remote Control Shift Cable Cable End NOTE 1... -

Page 183: Preparation

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Preparation 1. Disconnect battery cables from battery. 2. Remove instrument panel harness connector plug from engine harness receptacle after loosening clamp. 3. Using wrench to stabilize brass coupling at fuel inlet, loosen fuel line fitting, disconnect and suitably plug fuel line to prevent fuel in tank from leaking into bilge. -

Page 184: Installation

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 2. Remove front and rear engine mounting bolts. Retain hardware. 72638 All Engines Bolts Or Lag Screws (With Washers) Slot Forward (If So Designed) 3. Carefully remove engine. Installation Engine Installation and Initial Alignment 1. - Page 185 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 2. Ensure that all mounts are: a. In the center of their up and down adjustment. b. Mounting hole, which is a slot, is forward (if so designed; new style is not slotted). c.

- Page 186 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 a. Models with Down Angle Transmission: Lift engine into boat and position on engine bed so that transmission output flange and propeller shaft coupler are visibly aligned. No gap should be seen between coupling faces when butted together. Adjust engine bed height, if necessary, to obtain proper alignment.

-

Page 187: Engine Final Alignment

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Engine Final Alignment CAUTION To avoid vibration, noise and damage to transmission output shaft oil seal and bearings, engine must be properly aligned. IMPORTANT: Engine alignment MUST BE RECHECKED with boat in the water, fuel tanks filled and with a normal load on board. - Page 188 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 3. Ensure coupling centerlines align by butting propeller shaft coupler against transmis- sion output flange. Shoulder on propeller shaft coupler should engage recess on trans- mission output flange face with no resistance. NOTE: Some propeller shaft couplers may not have a shoulder on mating face.

- Page 189 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 5. If coupling centerlines are not aligned or if coupling faces are more than .003 in. (0.07 mm) out of parallel, adjust and retighten engine mounts as follows: a. TO ADJUST ENGINE UP OR DOWN: Loosen locking nut on mounts requiring adjustment and turn both front mount or rear mount adjusting nuts equally.

- Page 190 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 c. After engine has been properly aligned: Tighten engine mount nuts securely, and be certain to bend one of the tabs on the tab washer down onto flat of mount adjust- ing nut.

-

Page 191: Engine Connections

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Engine Connections Seawater Hose Connection IMPORTANT: When routing all wire harnesses and hoses, be sure they are routed and secured to avoid coming in contact with hot spots on engine and avoid contact with moving parts. -

Page 192: Fuel Supply Connections

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Fuel Supply Connections WARNING Be careful when working on fuel system. Gasoline is extremely flammable and highly explosive under certain conditions. Do not smoke or allow spark or open flame in area. Wipe up any spilled fuel immediately. WARNING Avoid gasoline fire or explosion. -

Page 193: Exhaust Hose Connection

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Exhaust Hose Connection 1. Connect exhaust system tubes and hoses using at least two hose clamps at each connection. Tighten hose clamps securely. NOTICE Exhaust hoses must be connected to exhaust elbows so that they do not restrict the flow of discharge water from exhaust elbow. - Page 194 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 3. On 454 Mag MPI Horizon Model: Remove flame arrestor as follows: a. Remove locknuts. 71481 Locknuts b. Move crankcase ventilation hose away from flame arrestor and rocker arm cover fit- tings.

- Page 195 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 4. Install cable end guide on throttle lever, then push cable barrel end lightly toward throttle lever end. (This will place a slight preload on shift cable to avoid slack in cable when moving remote control lever.) Adjust barrel on throttle cable to align with hole in anchor plate.

- Page 196 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 8. On 8.2L MPI Model: Install flame arrestor as follows: a. Install flame arrestor. b. Connect crankcase ventilation hose. c. Install flame arrestor screws and tighten securely. 75113 75142 8.2L MPI Shown Flame Arrestor Screws Crankcase Ventilation Hose...

- Page 197 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 c. Position crankcase ventilation hose against flame arrestor and rocker arm cover fittings as shown. 71764 Crankcase Vent Hose 7.4L MPI MODEL 1. Place remote control handle(s) in neutral idle position. 2.

- Page 198 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 5. Secure throttle cable with hardware as shown and tighten securely. 75454 Washer and Locknut 6. Place remote control throttle lever in the wide open throttle (W.O.T.) position. Ensure that throttle plate is completely open. 75453 Throttle Plate 7.

-

Page 199: Shift Cable Installation And Adjustment

MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 Shift Cable Installation And Adjustment IMPORTANT: These Hurth transmissions are full reversing transmissions. Direction of output/propeller rotation is determined by hookup of shift cable at remote control. Shift cable must be hooked up to remote control before starting installation and adjustment procedures. - Page 200 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 2. Check shift lever positioning as indicated. IMPORTANT: Ensure that shift lever is positioned approximately 10 aft of vertical when in the neutral detent position and that the distance (“c”) between studs in the following is set at 7-1/8 in.

- Page 201 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 6. Center cable end play. Adjust cable barrel to align holes in barrel and in cable end guide with attaching points on transmission. 7. Temporarily install shift cable. Do not secure at this time. 73587 Typical Shift Cable End Guide...

- Page 202 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 12. Reattach locknut and washer to cable barrel stud. Tighten until contacts. Tighten securely, but DO NOT OVERTIGHTEN. NOTE: To change cable approach direction on single or dual station installations, only the spacers/bushings have to be switched to the opposite stud (the studs are identical).

- Page 203 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 71211 73590 Typical Dual Cable - Forward Entry Cable End Guides Locknut And Washer Spacer (Fits Over Stud) Bushings Cable Barrel Locations Cable Barrel Stud Cable End Guide Stud 50073 73591 Typical Dual Cable - Rear Entry Cable End Guides Locknut And Washer...

- Page 204 MIE MODELS - HURTH TRANSMISSION SERVICE MANUAL NUMBER 23 THIS PAGE IS INTENTIONALLY BLANK Index Page 2D-24 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 205 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 ENGINE Section 3A - 454 cid (7.4L) / 502 cid (8.2L) Table of Contents Torque Specifications ....3A-3 Cylinder Head and Valve Conditioning 3A-41...

- Page 206 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Crankshaft ......3A-74 Camshaft Bearings .

- Page 207 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Torque Specifications DESCRIPTION lb-in. lb-ft Alternator Bracket to Engine Alternator to Mounting Bracket (Pivot) Alternator to Mounting Bracket (Anchor) Camshaft Sprocket Gear 7.4L MPI (3/8-24 Nuts) 454 / 502 Connecting Rod Caps Mag MPI (7/16-20...

- Page 208 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Torque Specifications (Continued) DESCRIPTION lb-in. lb-ft 7.4L MPI 454 / 502 Plenum to Intake Mag MPI and 8.2L 7.4L MPI 454 / 502 Main Bearing Caps Mag MPI and 8.2L Oil Baffle Nuts Oil Filter Adapter Nuts Oil Pan Bolts...

- Page 209 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Tools MERCURY MARINE SPECIAL TOOLS DESCRIPTION PART NUMBER Piston Ring Expander 91-24697 Engine Coupler Wrench 91-35547 Special Tools KENT-MOORE SPECIAL TOOLS Kent-Moore Special Tools 29784 Little Mack Roseville, MI 48066...

- Page 210 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Lubricants / Sealants / Adhesives DESCRIPTION PART NUMBER Quicksilver Loctite 27131 92-809820 Quicksilver Perfect Seal 92-34227--1 Quicksilver RTV Sealer / Loctite 587 92-809826 General Motors Cam and Lifter Prelube or Obtain Locally Equivalent Engine Specifications...

-

Page 211: Mag / 502 Mag / 8.2L

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 454 Mag / 502 Mag / 8.2L (Except 7.4L MPI L-29) Engine Specifications (Continued) CYLINDER BORE MODEL 454 MAG 502 MAG / 8.2L 4.2451-4.2525 4.4655-4.4662 Diameter (107.826-108.013) (113.423-113.441) Production .001 (0.025) Max Out of Round Out of Round... - Page 212 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 454 Mag / 502 Mag / 8.2L (Except 7.4L MPI L-29) Engine Specifications (Continued) PISTON RING MODEL 454 MAG 502 MAG / 8.2L .0017-.0032 .0017-.0032 (0.044-0.081) (0.044-0.081) Production Production Groove Side .0017-.0032 .0017-.0032...

- Page 213 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 454 Mag / 502 Mag / 8.2L (Except 7.4L MPI L-29) Engine Specifications (Continued) CRANKSHAFT MODEL 454 MAG 502 MAG / 8.2L No.1,2,3,4, Diameter 2.7482-2.7489 (69.8042-69.8220) Production .0002 (0.005) Max Main Main Taper...

- Page 214 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 454 Mag / 502 Mag / 8.2L (Except 7.4L MPI L-29) Engine Specifications (Continued) VALVE SYSTEM MODEL 454 MAG 502 MAG / 8.2L Lifter Hydraulic Rocker Arm Ratio 1.70 to 1 Face Angle (Intake &...

- Page 215 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 454 Mag / 502 Mag / 8.2L (Except 7.4L MPI L-29) Engine Specifications (Continued) ROLLER TAPPET CAMSHAFT MODEL 454 MAG / 502 MAG / 8.2L Exhaust .301 (7.645) Lobe Lift Lobe Lift .020 (0.051) 020 (0 051)

- Page 216 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 7.4L MPI (L-29) Engine Specifications NOTICE Unit Of Measurement: U.S. Quarts (Liters) All capacities are approximate fluid measures. MODEL 7.4L Displacement 454 cid (7.4L) Bore 4.25 (108) Stroke 4.00 (101.6) Compression Ratio 9.3:1 Heads...

- Page 217 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 7.4L MPI (L-29) Engine Specifications (Continued) PISTON RING MODEL 7.4L Production .0012-.0029 (0.0304-0.0737) Groove Side Groove Side High Production Limit + .010 Clearance Service (0.254) Max Compression .010-.018 (0.254-0.457) Production Production .016-.024 (0.406-0.6096)

- Page 218 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 7.4L MPI (L-29) Engine Specifications (Continued) CRANKSHAFT MODEL 7.4L No. 1, 2, 3, 4, 2.7482-2.7489 Diameter (69.8040-69.8220) Production .0004 (0.0101) Max Taper Ta er Main Journal Main Journal Service .001 (0.0254) Max Production .0004 (0.0101) Max...

- Page 219 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 7.4L MPI (L-29) Engine Specifications (Continued) VALVE SYSTEM MODEL 7.4L Lifter Hydraulic Roller Rocker Arm Ratio 1.70 to 1 Face Angle (Intake & Exhaust) Seat Angle (Intake & Exhaust) Seat Runout (Intake &...

-

Page 220: General Information

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 General Information Some of the repairs in this section must be completed with engine removed from boat. Engine removal depends upon type of repair and boat design. Place engine on repair stand for major repairs. -

Page 221: Cylinder Head Identification

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Cylinder Head Identification 7.4L MPI Cylinder heads are identified by their smaller and rounded intake ports. 72913 454 MAG MPI / 502 MAG MPI / 8.2L MPI Cylinder heads are identified by their large rectangular intake ports. 72914 Engine Rotation Engine rotation terminology at times has caused confusion. -

Page 222: Crankshaft

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Crankshaft The crankshaft is supported in the block by five insert type bearings. Crankshaft end thrust is controlled by flanges on the No. 5 bearing. A torsional damper on the forward end of the crankshaft serves to help dampen any engine torsional vibration. - Page 223 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 After leaving the pump, the pressurized oil flows through a full-flow oil filter. On engines with an engine oil cooler, the oil also flows through the cooler before returning to the block. A bypass valve allows oil to bypass the filter and oil cooler should they become restricted.

-

Page 224: Bearing Failures

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Bearing Failures 70436 Scratched By Dirt Scratches Dirt Imbedded In Bearing Material 70436 Tapered Journal Overlay Gone From Entire Surface 70436 Lack Of Oil Overlay Worn Off 70436 Radius Ride Worn Area Index Page 3A-20... - Page 225 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 70436 Improper Seating Bright Or Polished Sections 70436 Fatigue Failure Craters or Pockets Index 90-861326--1 MARCH 1999 Page 3A-21 Downloaded from https://needmanual.com/...

-

Page 226: Piston Failures

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Piston Failures Pre-Ignition Pre-ignition is abnormal fuel ignition, caused by combustion chamber hot spots. Control of the start of ignition is lost, as combustion pressure rises too early, causing power loss and rough running. -

Page 227: Detonation

NOTE: Engine failures, which result from the foregoing conditions, are beyond the control of Mercury Marine; therefore, no warranty will apply to failures which occur under these con- ditions. Detonation Detonation, commonly called “fuel knock,”... - Page 228 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 NOTE: Engine failures, which result from the foregoing conditions, are beyond the control of MerCruiser; therefore, no warranty will apply to failures which occur under these condi- tions. 72425 Detonation Damage 72315 Combustion Description...

-

Page 229: Engine Mounts

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Engine Mounts 72317 Front Mount - All MCM (Sterndrive) Models 72318 Rear Mount/Flywheel Housing - All MCM (Sterndrive) Models Index 90-861326--1 MARCH 1999 Page 3A-25 Downloaded from https://needmanual.com/... - Page 230 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Engine Mounts (Continued) 73055 Rear Mount Assembly - Most MIE Models 73056 Rear Mount Assembly - MIE Models with Velvet Drive In-Line Transmission Index Page 3A-26 90-861326--1 MARCH 1999 Downloaded from https://needmanual.com/...

- Page 231 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Engine Mounts (Continued) 72319 Front Mount Assembly - All MIE Models 72319 Rear Mount Assembly - MIE 7.4L with Velvet Drive Remote V-Drive Transmission Index 90-861326--1 MARCH 1999 Page 3A-27 Downloaded from https://needmanual.com/...

-

Page 232: Rocker Arm Cover

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Rocker Arm Cover Removal It may be necessary to remove exhaust manifold before removing rocker arm cover. Refer to SECTION 7B for removal. Also remove any component that will interfere with the removal of the manifold. -

Page 233: Intake Manifold

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Intake Manifold NOTICE For repair procedures on “Fuel Injection Engines,” refer to Section 5C. Removal 1. Drain engine cooling system. 2. Disconnect hoses from thermostat housing. 3. Disconnect intake manifold-to-circulating pump by-pass hose from circulating pump. 4. -

Page 234: Installation

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Installation IMPORTANT: When installing intake manifold gaskets, in next step, be sure to do the following: Be sure to install gasket with marked side up. Both gaskets are identical. 1. - Page 235 454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 5. Follow step “a” for 454 Mag / 502 Mag / 8.2L and step “b” for 7.4L MPI engines. a. Carefully install manifold assembly. Torque in sequence to 35 lb-ft (48 Nm). 75640 Intake Manifold Torque Sequence For 454 Mag / 502 Mag / 8.2L MPI Engines b.

-

Page 236: Rocker Arm/Push Rod

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Rocker Arm/Push Rod Removal NOTE: When servicing only one cylinder’s rocker arms, bring that cylinder’s piston up to TDC before removing rocker arms. When servicing all rocker arms, bring No. 1 piston up to TDC before removing rocker arms. -

Page 237: Rocker Arm Stud Kit

454 CID (7.4L) / 502 CID (8.2L) SERVICE MANUAL NUMBER 23 Rocker Arm Stud Kit These engines use a net lash or non-adjustable rocker arm system. Torquing the rocker arm bolt to 40 lb-ft (54 Nm) sets the valve lash. When rebuilding these engines with a net lash, machining of the cylinder deck surface or cylinder head surface or grinding the valve seats or valves may cause an incorrect valve lash condition. -

Page 238: Locating Noisy Lifters