Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Metrohm 843 Pump Station

- Page 1 843 Pump Station with membrane pumps Manual 8.843.8001EN/2019-11-29...

- Page 3 Metrohm AG CH-9100 Herisau Switzerland Phone +41 71 353 85 85 Fax +41 71 353 89 01 info@metrohm.com www.metrohm.com 843 Pump Station with membrane pumps Manual 8.843.8001EN/2019-11-29...

- Page 4 Technical Communication Metrohm AG CH-9100 Herisau techcom@metrohm.com This documentation is protected by copyright. All rights reserved. This documentation has been prepared with great care. However, errors can never be entirely ruled out. Please send comments regarding possible errors to the address above.

-

Page 5: Table Of Contents

5 Operation and maintenance General notes ..............16 5.1.1 Care ..................16 5.1.2 Maintenance by Metrohm Service .......... 16 Tubings ................17 6 Troubleshooting Problems ................18 7 Appendix Functioning of the membrane pump ........ 19 ■■■■■■■■ 843 Pump Station with membrane pumps... - Page 6 Pin allocation of the remote interface ........20 8 Technical specifications Membrane pump ..............22 Power connection ............... 22 Ambient temperature ............22 Reference conditions ............22 Dimensions ................23 Interfaces ................23 9 Accessories Index ■■■■■■■■ 843 Pump Station with membrane pumps...

- Page 7 ■■■■■■■■■■■■■■■■■■■■■■ Table of figures Table of figures Figure 1 Front of 843 Pump Station with membrane pumps ......5 Figure 2 Rear 843 Pump Station with membrane pumps ......... 6 Figure 3 Membrane pump with inlet and outlet tubing ........7 Figure 4 Remote connection 869 —...

-

Page 9: Introduction

– Remote 2 for connecting other instruments. An integrated power supply unit (100 – 240 V) which runs the mem- ■ brane pumps. Sales versions The 843 Pump Station is available in three different sales versions: 2.843.0020 Standard instrument 2.843.0030 Standard instrument with special accessories for... -

Page 10: Safety Instructions

This instrument left the factory in a flawless state in terms of technical safety. To maintain this state and ensure non-hazardous operation of the instrument, the following instructions must be observed carefully. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 11: Electrical Safety

The electrical safety when working with the instrument is ensured as part of the international standard IEC 61010. WARNING Only personnel qualified by Metrohm are authorized to carry out service work on electronic components. WARNING Never open the housing of the instrument. The instrument could be damaged by this. -

Page 12: Working With Liquids

The correct disposal of your old instrument will help to prevent negative effects on the environment and public health. More details about the disposal of your old instrument can be obtained from your local authorities, from waste disposal companies or from your local dealer. ■■■■■■■■ 843 Pump Station with membrane pumps... -

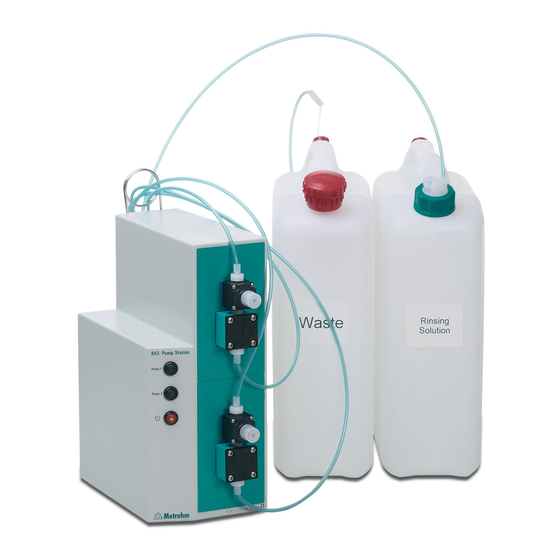

Page 13: Overview Of The Instrument

2 Overview of the instrument 2 Overview of the instrument Front of the instrument Figure 1 Front of 843 Pump Station with membrane pumps Pump 1 Pump 2 For switching membrane pump 1 on and For switching membrane pump 2 on and off. -

Page 14: Rear Panel Of The Instrument

■■■■■■■■■■■■■■■■■■■■■■ 2.2 Rear panel of the instrument Rear panel of the instrument Figure 2 Rear 843 Pump Station with membrane pumps Tubing guide Bore hole For fixing the tubings in place. Additional hole for screwing in the tubing guide in situations where Pump Station is to be operated in a lying position. -

Page 15: Membrane Pump

Membrane pump with inlet and outlet tubing Outlet tubing (e. g. 6.1812.000) Union nut Valve opening with protective cap Specification of flow direction Inlet tubing (e. g. 6.1812.000) Tube connection Valve Pump head ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 16: Installation

If your application allows, mount PVC tubing at least as outlet tubing (3-1) because the valve (3-7) in particular can generate loud pump noise. Mounting the tubing Mount the tubing as follows: 1 Cut the inlet and outlet tubing to the appropriate lengths. ■■■■■■■■ 843 Pump Station with membrane pumps... - Page 17 2 Unscrew the union nut on both tubing connectors of the membrane pump. 3 Pull the union nut onto the tubing end to be fastened. 4 Mount the inlet and outlet tubing on the connection nipples of the tubing connectors. ■■■■■■■■ 843 Pump Station with membrane pumps...

- Page 18 PTFE tubing easier to handle. 6 Hold the inlet and outlet tubing together with a cable tie. 7 Put the tubing through the tubing guide to fix them in place. ■■■■■■■■ 843 Pump Station with membrane pumps...

-

Page 19: Connecting Control Instruments

6 . 2 1 4 1 . 2 3 Figure 4 Remote connection 869 — 843 — 8xx Titrino plus Example 2 Connection of a Dosimat plus, a Compact Sample Changer (Remote 1) and a Titrino plus (Remote 2). ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 20: Figure 5 Remote Connection 8Xx Dosimat Plus - 869 - 843 - 8Xx Titrino

Dosimat plus Figure 6 Remote connection 869 — 843 — 8xx Titrino plus — 8xx Dosimat plus Example 3 Connection of a Compact Autosampler (Remote 2) and a VA Compu- trace (Remote 1). ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 21: Figure 7 Remote Connection 863 - 843 - 797

Power Keyboard MSB2 MSB3 RS 232 6 . 2 1 4 1 . 2 9 6 . 2 1 4 1 . 2 8 Figure 8 Remote connection 838 — 843 — 797 ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 22: Connecting The Instrument To The Power Grid

Unplug the power plug immediately if you suspect that moisture has ■ gotten inside the instrument. Only personnel who have been issued Metrohm qualifications may ■ perform service and repair work on electrical and electronic parts. Connecting the power cord... -

Page 23: Operation

Illumination of the LED indicates ready-for-operation status. Pump 1 Hold down the membrane pump 1 switch for manual rinsing. Pump 2 Hold down the membrane pump 2 switch for manual aspiration. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 24: Operation And Maintenance

5.1.2 Maintenance by Metrohm Service Maintenance of the 843 Pump Station is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. A shorter maintenance interval may be necessary if you frequently work with caustic and corrosive chemicals. -

Page 25: Tubings

5 Operation and maintenance Tubings The tubing requires regular inspection in order to work properly: Do not kink PTFE tubing. ■ Ensure resistance to solvents . ■ Check the tubing regularly for any damage. ■ ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 26: Troubleshooting

Too much air is trapped Contact Metrohm Service at your Metrohm between the membrane representative. platelets during aspirating and pumping. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 27: Appendix

High chemical resistance: the utilization of chemical-resistant materials ■ such as PTFE, PP and FFPM in the components that have contact with the media permits the conveyance of practically all neutral and aggres- sive media. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 28: Remote Interface

Pin allocation of the remote interface Figure 10 Pin allocation of remote socket and plug The above pin allocation display applies for all Metrohm instruments with 9-pin D-Sub remote connectors. The two remote interfaces are linked with one another in the instrument. - Page 29 Pin No. ——— ——— Pump 1 Pump 2 ——— 0 Volt (GND) ——— ——— Inputs (Pin 3 and 4) +5 V approx. 5 kΩ Pull-up > 100 ms active = low, inactive = high ■■■■■■■■ 843 Pump Station with membrane pumps...

-

Page 30: Technical Specifications

1.0 ATH Ambient temperature Nominal function +5 - +45 °C range Storage –40 - +70 °C Transport –40 - +70 °C Reference conditions Ambient tempera- +25 °C (±3 °C) ture ≤ 60% Relative humidity ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 31: Dimensions

0.16 m Height 0.40 m Depth 0.31 m Weight (without 5.26 kg accessories) Material Polyurethane, coated (upper part) Steel housing, stove-enameled (lower part) Interfaces Remote interfaces For connecting instruments with a remote interface. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 32: Accessories

The PDF file with the accessories data is created. NOTICE Once you have received your new product, we recommend download- ing the accessories list from the Internet, printing it out and keeping it together with the manual for reference purposes. ■■■■■■■■ 843 Pump Station with membrane pumps... -

Page 33: Index

Emergency stop switch ..5, 15 Overview of the instrument ..5 Maintenance ...... 17 Mounting ......8 Front of the instrument ....5 Pin allocation ......20 Power connection ....14 Handling liquids ......2 ■■■■■■■■ 843 Pump Station with membrane pumps...

Need help?

Do you have a question about the 843 Pump Station and is the answer not in the manual?

Questions and answers