Summary of Contents for Viega 2281.7

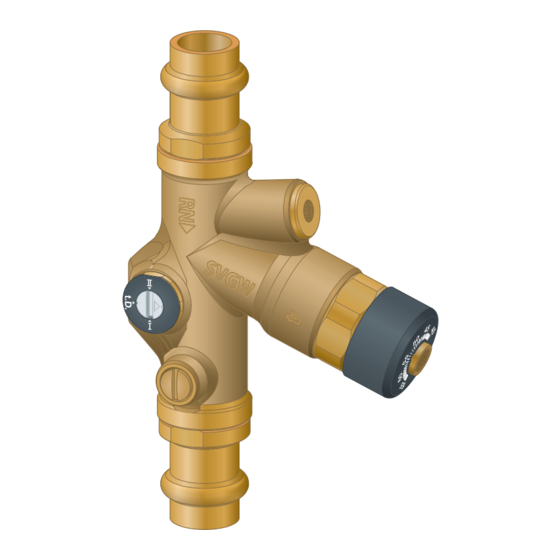

- Page 1 Easytop circulation regulation valve S/E with SC-Contur Instructions for Use For thermal / hydraulic line calibration in potable water installa‐ tions Model Year built: 2281.7 from 03/2019 en_INT...

- Page 2 Easytop circulation regulation valve S/E with SC-Contur 2 from 27...

-

Page 3: Table Of Contents

Table of contents Table of contents About these instructions for use Target groups Labelling of notes About this translated version Product information Standards and regulations Intended use 2.2.1 Areas of use 2.2.2 Media Product description 2.3.1 Overview 2.3.2 Press connection with SC-Contur 2.3.3 Sealing elements 2.3.4... -

Page 4: About These Instructions For Use

This restriction does not extend to possible operating instructions. The installation of Viega products must take place in accordance with the general rules of engineering and the Viega instructions for use. -

Page 5: About This Translated Version

About these instructions for use About this translated version This instruction for use contains important information about the choice of product or system, assembly and commissioning as well as intended use and, if required, maintenance measures. The information about the products, their properties and application technology are based on the current standards in Europe (e.g. -

Page 6: Product Information

Product information 2 Product information Standards and regulations The following standards and regulations apply to Germany / Europe and are provided as a support feature. Regulations from section: Fields of application Scope / Notice Regulations applicable in Ger‐ many Planning, execution, operation DIN EN 806, part 1 and maintenance of potable water installations... - Page 7 Product information Regulations from section: Media Scope / Notice Regulations applicable in Ger‐ many Suitability for drinking water Trinkwasserverordnung (TrinkwV) Regulations from section: Product description Scope / Notice Regulations applicable in Ger‐ many Suitability for potable water instal‐ Trinkwasserverordnung (TrinkwV) lations Suitability for potable water instal‐...

-

Page 8: Intended Use

Intended use Coordinate the use of the model for areas of use and media other than those described with the Viega Service Center. The functionality of the valve is only ensured by professional design and assembly of the complete system. -

Page 9: Product Description

Product information Product description According to the applicable regulations, Easytop system fittings can be used for all types of potable water and are DVGW certified, see Ä „Reg‐ ulations from section: Product description“ on page 7. Their plastic components comply with the KTW recommendation and the require‐ ments pursuant to the applicable regulations. -

Page 10: Sealing Elements

SC-Contur Fig. 2: SC-Contur Viega press connectors are equipped with the SC-Contur. The SC- Contur is a safety technology that is certified by the DVGW and ensures that the connection is guaranteed to be leaky in an unpressed state. In this way, unpressed connections are noticed immediately during a leakage test. -

Page 11: Markings On Components

Product information 2.3.4 Markings on components The model is marked as follows: flow direction indicator Dimension DVGW writing position indicator for operating mode green dot for potable water 2.3.5 Compatible components The model is equipped with press connections and compatible with the Profipress, Sanpress and Sanpress Inox system. -

Page 12: Technical Data

Product information Fig. 3: Diagram minimum flowthrough / temperature 2.3.7 Technical data Observe the following operating conditions for the installation of the model: Operating temperature [T 80 °C Operating pressure [P 1.0 MPa (10 bar) Temperature range (settable) 40 °C up to 65 °C Factory settings 57 °C Easytop circulation regulation valve S/E with SC-Contur... - Page 13 Product information Pressure loss Fig. 4: Diagram operating modes / Pressure losses Easytop circulation regulation valve S/E with SC-Contur 13 from 27...

- Page 14 Product information Setting the flowthrough regulation Switch Minimum flow‐ Maximum flow‐ position through

in m through

in m on the storey: 0.042 on the storey: 1.542 in the riser pipe: 0.060 in the riser pipe: 1.560 t. D. thermal disinfection at 70 °C: 0.72 Fig.

-

Page 15: Information For Use

Product information Information for use 2.4.1 Corrosion Overground pipelines and fittings in rooms do not normally require external corrosion protection. There are exceptions in the following cases: Contact with aggressive building materials such as nitrite or mate‐ rials containing ammonium in aggressive surroundings If external corrosion protection is required, observe the pertinent guide‐... - Page 16 Product information Fig. 7: Model 2278.8 Easytop drainage valve Fig. 8: Model 1026.6 Easytop thermometer Fig. 9: Model 2210.50 Easytop insulating shell An EPS insulating shell is available for the circulation regulation valve. The two-piece insulating shell is self-supporting and is mounted without tools and holding grips.

-

Page 17: Handling

Handling 3 Handling Assembly information 3.1.1 Permitted exchange of sealing elements Important instruction With their material-specific qualities, sealing elements in press connectors are adapted for use with the corre‐ sponding media and/or the areas of use of the piping sys‐ tems and are generally only certified for them. -

Page 18: Required Tools

Press jaw or press ring with corresponding hinged adapter jaw, suit‐ able for the pipe diameter and suitable profile Fig. 10: Press jaws Recommended Viega press machines: Pressgun 5 Pressgun 4E / 4B Type PT3-AH... -

Page 19: Assembly

Handling Removal drain plugs An Allen key (size 5) is required to remove the drain plug. Assembly 3.2.1 Replacing the sealing element Removing the sealing element Do not use pointed or sharp-edged objects to remove the sealing element. They may damage the sealing element or the bead. -

Page 20: Shortening The Pipes

Handling 3.2.2 Shortening the pipes NOTICE! Leaky press connections due to damaged material! Press connections can become leaky due to damaged pipes or sealing elements. Observe the following instructions to avoid damage to pipes and sealing elements: – Do not use cutting discs (angle grinders) or flame cutters when cutting to length. - Page 21 Handling Requirements: The pipe end is not bent or damaged. The pipe is deburred. The correct sealing element is in the press connector. EPDM = polished black The sealing element is undamaged. The complete sealing element is in the bead. Push the press connector onto the pipe as far as it will go.

-

Page 22: Installation Position And Settings

Handling Open the press jaw and place it at a right-angle onto the press con‐ nector. Check the insertion depth using the marking. Ensure that the press jaw is placed centrally on the bead of the press connector. Carry out the pressing process. Open and remove the press jaw. - Page 23 Handling Fig. 11: CRV in the riser pipe Easytop circulation regulation valve S/E with SC-Contur 23 from 27...

- Page 24 Handling Fig. 12: CRV on the storey Settings Set the temperature and flow regulation before commissioning. Use in the section: Bring flowthrough control to position II. Use on the storey: Bring flowthrough control to position I. For thermal disinfection: Bring flowthrough control to position t.D.. Temperature setting: Set to calculated target value.

-

Page 25: Mounting The Easytop Drainage Valve And Easytop Thermometer

Handling Temperature setting An Allen key (size 6) is required to set the temperature. Set the temperature at the temperature control valve with Allen key (size 6). Fig. 13: CRV set temperature 3.2.5 Mounting the Easytop drainage valve and Easytop thermometer Unscrew the drain plugs with an Allen key (size 5). -

Page 26: Thermal Disinfection

Handling The Easytop drainage valve has the following functions: Draining Seat sensor actuator set Seat Easytop thermometer Insert the Easytop thermometer into the closed Easytop drainage valve. 3.2.6 Thermal disinfection CAUTION! Risk of scalding from hot water! Inform users and secure the draw-off point before beginning the flushing process. -

Page 27: Leakage Test

Handling Place the converter for the flowthrough regulator on the Easytop cir‐ culation regulation valve to position t.D.. Open every extraction fitting fully and flush for at least 3 minutes after 70 °C has been reached. Place the flowthrough regulator and ball valve in the operating posi‐ tion.

Need help?

Do you have a question about the 2281.7 and is the answer not in the manual?

Questions and answers