Subscribe to Our Youtube Channel

Summary of Contents for Tractel tirfor TU Series

-

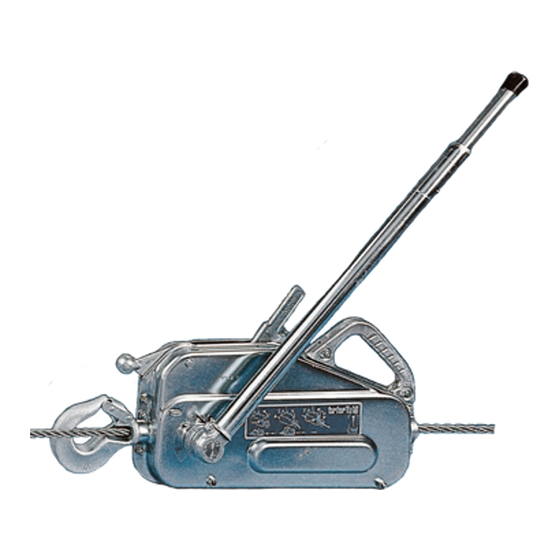

Page 1: Fig

® tirfor lifting and pulling machines operating and maintenance instructions models TU : TU-8 TU-16 TU-32 T-500D : T-508D T-516D T-532D equipment in accordance with CE directives 0086086.03 - 01/95 ® ®... -

Page 2: Table Of Contents

The companies of the TRACTEL Group and their agents or distributors will supply on request descriptive documentation on the full range of TRACTEL products : lifting and pulling machines, permanent and temporary 1. Hook / anchor pin access equipment, safety devices, electronic load 2. -

Page 3: General Warning

5- The models as described in this manual must not be used for lifting people. 6- Moreover, these models are designed for manual operation and must not be motorised. The TRACTEL Group has designed special motorised models (TU-16H and TU-32H). 7- Never attempt to overload the machine. -

Page 4: Description Of Equipment

1. DESCRIPTION OF EQUIPMENT Fig. 2.1 Fig. 2.2 The TIRFOR machine is a hand-operated lifting and pulling machine. It is versatile, portable and multi-purpose, not only for pulling and lifting but also for lowering, tensioning and guying. The originality of the TIRFOR machine is the principle of operation directly on the wire rope which passes through the mechanism rather than being reeled onto a drum of a hoist or conventional... -

Page 5: Installing The Wire Rope

7. Anchor the TIRFOR machine or the wire rope to described in this manual, please consult the appropriate fixed point (See section 5 : TRACTEL S.A. or a competent specialist «Anchoring») taking care to ensure that the engineer before operating the machine . - Page 6 4.1. TU-8 or TU-16 (Fig.7) Releasing : 1. Completely press the rope release safety catch RELEASED (5) and lift the rope release lever (4). 2. Release the safety catch and continue to lift the rope release lever until it locks into position. The internal mechanism is in the released position.

-

Page 7: Anchoring

Optional hooks are available to fit the anchor point ANCHORING of models T-500D and TU-32. Failure to anchor the TIRFOR machine correctly To anchor using the anchor pin, follow the runs the risk of a serious accident. The user procedure below: must always ensure before operation that the anchor point(s) for the machine and wire-rope 1. -

Page 8: Operation

Fig. 13 - Anchor pin in position. Fig. 14 - Anchor pin removed. Fig. 15 - Spring clip closed. Fig. 16 - Spring clip open. 6. OPERATION 7. RELEASING THE WIRE ROPE AND STORAGE TIRFOR machines are very easy to use. Place the It is essential to take the load off the machine telescopic operating handle on either the forward before attempting to release the jaws. -

Page 9: Safety Devices

8. SAFETY DEVICES 8.1 Overload limiting safety devices All TIRFOR machines incorporate a shear pin system. In case of overload, one or more pins (depending on the model), fitted to the forward operating lever, shear and prevent further forward or lifting operations. Reverse operation is still possible to enable the load to be lowered or the wire rope to be slackened. -

Page 10: Wire Rope

The wire rope should be examined daily to detect lubricated at regular intervals, at least annually, by any signs of wear ( damage or broken wires : See an approved TRACTEL S.A. repairer. Never use examples in Fig. 23). grease or oil containing graphite additives or In case of any apparent wear, have the wire rope molybdenum disulphide . -

Page 11: Warnings Against Hazardous Operations

Otherwise the ferrule is likely to foul the casing (models TU-8 and TU-16), should be returned to and push the rope guide inside the machine. an approved repairer of TRACTEL S.A.'s network. 13. TROUBLESHOOTING WARNINGS AGAINST HAZARDOUS 1) The forward operating lever moves freely... -

Page 12: Tu-32

Ensure that the labels indicated above in black are in place. Replacement labels can be supplied on request. Accessories for TIRFOR machines Hook for TIRFOR Pulley blocks T-500D and side opening blocks and TU-32 Slings Ground anchors COPYRIGHT - ALL RIGHTS RESERVED Manufactured by TRACTEL S.A.

Need help?

Do you have a question about the tirfor TU Series and is the answer not in the manual?

Questions and answers