Advertisement

Service Facts

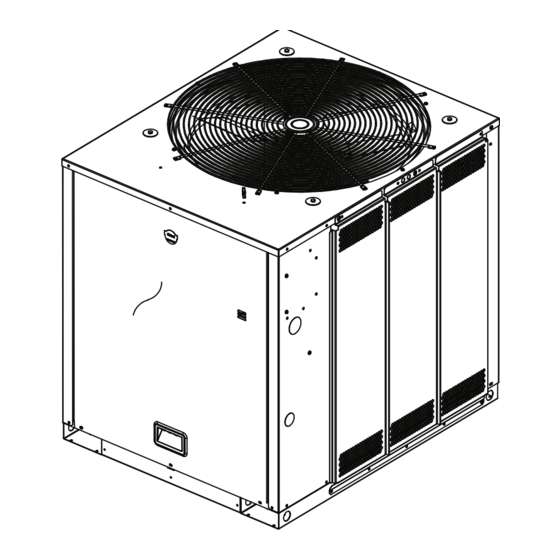

Split System Cooling

Condensers

Single Compressor, R-410A

TTA120D300AA

TTA120D30RAA

TTA120D30SAA

TTA120D30TAA

TTA120D30UAA

TTA120D30WAA

TTA120D400AA

TTA120D40RAA

TTA120D40SAA

TTA120D40TAA

TTA120D40UAA

TTA120D40WAA

August 2009

TTA120DK00AA

TTA120DK0RAA

TTA120DK0SAA

TTA120DK0TAA

TTA120DK0UAA

TTA120DK0WAA

TTA120DW00AA

TTA120DW0RAA

TTA120DW0SAA

TTA120DW0TAA

TTA120DW0UAA

TTA120DW0WAA

TTA120D3H0AA

TTA120D3HRAA

TTA120D3HSAA

TTA120D3HTAA

TTA120D3HUAA

TTA120D3HWAA

TTA120D4H0AA

TTA120D4HRAA

TTA120D4HSAA

TTA120D4HTAA

TTA120D4HUAA

TTA120D4HWAA

SS-SVF15A-EN

TTA120DKH0AA

TTA120DKHRAA

TTA120DKHSAA

TTA120DKHTAA

TTA120DKHUAA

TTA120DKHWAA

TTA120DWH0AA

TTA120DWHRAA

TTA120DWHSAA

TTA120DWHTAA

TTA120DWHUAA

TTA120DWHWAA

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Trane TTA120D300AA

- Page 1 Service Facts Split System Cooling Condensers Single Compressor, R-410A TTA120D300AA TTA120DK00AA TTA120D3H0AA TTA120DKH0AA TTA120D30RAA TTA120DK0RAA TTA120D3HRAA TTA120DKHRAA TTA120D30SAA TTA120DK0SAA TTA120D3HSAA TTA120DKHSAA TTA120D30TAA TTA120DK0TAA TTA120D3HTAA TTA120DKHTAA TTA120D30UAA TTA120DK0UAA TTA120D3HUAA TTA120DKHUAA TTA120D30WAA TTA120DK0WAA TTA120D3HWAA TTA120DKHWAA TTA120D400AA TTA120DW00AA TTA120D4H0AA TTA120DWH0AA TTA120D40RAA TTA120DW0RAA TTA120D4HRAA...

-

Page 2: Warnings, Cautions And Notices

Use ONLY R-410A rated service equipment or components with this unit. For specific handling concerns with R-410A, please contact your local Trane representative. Failure to use R-410A rated service equipment or components and/or failure to follow proper procedures or the use of non-approved refrigerants, refrigerant substitutes, or refrigerant additives could result in death or serious injury or equipment damage. - Page 3 Warnings, Cautions and Notices WARNING Personal Protective Equipment (PPE) Required! Installing/servicing this unit could result in exposure to electrical, mechanical and chemical hazards. • Before installing/servicing this unit, technicians MUST put on all Personal Protective Equipment (PPE) recommended for the work being undertaken. ALWAYS refer to appropriate MSDS and OSHA guidelines for proper PPE.

- Page 4 USED WITH DESCRIPTION Coil Guard BAYGARD059A TTA120D Hail Guard HOT GAS BY-PASS BAYHGBP010A TTA120D Universal Hot Gas Bypass Kit Trane Communication Interface BAYICSI003A TTA120D Comm 3/4 Communications Interface Isolators BAYISLT005A TTA120D Rubber Isolator Kit BAYISLT023A TTA120D Steel Spring Isolator Kit...

-

Page 5: Refrigerant Circuit

Refrigerant Circuit Figure 1. COOLING ONLY CIRCUIT DIAGRAM COOLING ONLY CIRCUIT DIAGRAM DISCHARGE DISCHARGE TEMPERATURE TEMPERATURE LIMIT (DTL) LIMIT (DTL) HIGH PRESSURE HIGH PRESSURE GAUGE GAUGE SWITCH (HPCO) SWITCH (HPCO) CONNECTION CONNECTION NOTE A NOTE A NOTE A NOTE A FIELD SUPPLIED FIELD SUPPLIED INTER-CONNECTING... -

Page 6: Product Specifications

Product Specifications Table 2. General Data — TTA120D 10 Tons Single Compressor TTA120D3, D4, DW, DK Cooling Performance Gross Cooling Capacity Matched Air Handler 124,000 Condensing Unit Only 112,000 ARI Net Cooling Capacity 120,000 Efficiency Matched Air Handler (EER) 11.2 Condensing Unit Only (EER) 12.2 System Integrated Part Load Value (IPLV) -

Page 7: Sequence Of Operation

Sequence of Operation NOTICE Equipment Damage! Ensure the disconnect for the indoor air handler is closed before operating the system. Operating the outdoor unit without the indoor fan energized can cause unit trip-out on high pressure control and/or liquid flood back to the compressor. Electromechanical Controls General Operation of the system cooling (and optional heating) cycles is controlled by the position of the... - Page 8 Sequence of Operation ReliaTel™ Control Cooling Mode For Zone Sensor Control When the system switch is set to the COOL position and the zone temperature rises above the cooling setpoint, the RTRM energizes the compressor contactor, provided the high and low pressure and the discharge temperature limit controls are closed.

- Page 9 Cooling Pressure Curves Figure 2. TWE120D TTA120D with TWE120D (English) TTA120D with TWE120D (Metric) S uction P res s ure at 4 0 0 CFM/ Ton S uction P res s ure at 4 0 0 CFM/ Ton 1150 1100 1050 1000 68/57 DB/WB...

-

Page 10: Charging Chart

Charging Chart Charging Chart Figure 3. TTA120D TTA120D Charging Curve Remove charge charge Liquid Temperature Leaving OD Coil, °F SS-SVF15A-EN... -

Page 11: Troubleshooting

Troubleshooting SYSTEM FAULTS REFRIGERANT CIRCUIT Head Pressure Too High Head Pressure Too Low Suction Pressure Too High Suction Pressure Too Low Liquid Refrig. Floodback (TXV System) I.D. Coil Frosting Compressor Runs Inadequate or No Cooling ELECTRICAL Compressor & O.D. Fan Do Not Start Compr.

Need help?

Do you have a question about the TTA120D300AA and is the answer not in the manual?

Questions and answers