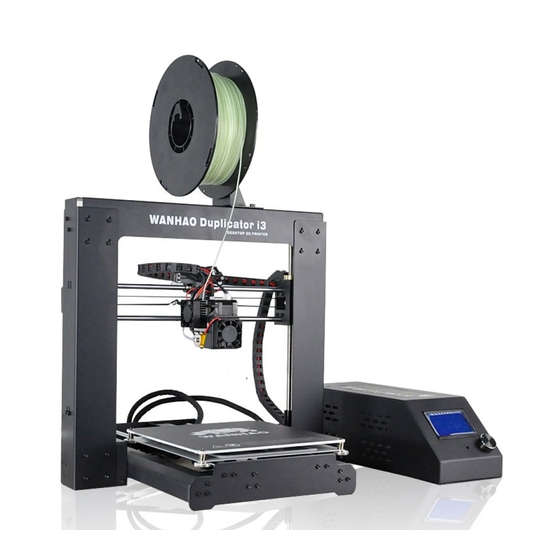

WANHAO i3 Step By Step Installation Instructions

All metal hotend w/ slotted cooling block

Hide thumbs

Also See for i3:

- Software user manual (25 pages) ,

- User manual (16 pages) ,

- First run experience (12 pages)

Advertisement

Quick Links

Download this manual

See also:

User Manual

WANHAO i3 All Metal Hotend w/ Slotted Cooling Block, Step by Step Installation Instructions

Included in the kit:

Wanhao i3 Cooling Block

MK10 Allmetal Thermal Barrier Tube

Nozzle for MK10 Allmetal Hotend Kit

3/32 Allen Key

Tools Needed:

Small Adjustable Wrench

9mm wrench

6mm wrench

2.5mm Allen Key

2.0mm Allen Key

3/32 Allen Key (included with kit)

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for WANHAO i3

- Page 1 WANHAO i3 All Metal Hotend w/ Slotted Cooling Block, Step by Step Installation Instructions Included in the kit: Wanhao i3 Cooling Block MK10 Allmetal Thermal Barrier Tube Nozzle for MK10 Allmetal Hotend Kit 3/32 Allen Key Tools Needed: ...

- Page 2 1. Raise the Z axis to have enough clearance for disassembly. 2. Remove Cooling Fan Duct.

- Page 3 3. Preheat the extruder to 250C. 4. Remove original nozzle while supporting heater block with adjustable wrench. Be very careful, nozzle is extremely hot. Use 9mm wrench for the nozzle.

- Page 4 Shut the power off. Let the machine and nozzle cool down before proceeding 6. Unplug Stepper motor connector.

- Page 5 7. Unscrew and remove fan/heatsink assembly while holding the stepper motor. Use 2.5mm Allen key. 8. Set it aside as shown.

- Page 6 9. Remove original cooling block using 2.5mm Allen key. 10. Loosen the setscrew holding thermal tube in place.

- Page 7 11. Take the thermal tube out of cooling block and set it aside. 12. Remove thermal tube from the heater block. If plastic has leaked, it can be difficult to remove thermal tube. You might have to use adjustable wrench and 6mm wrench to unscrew it. In worst case, preheat the hotend a little bit.

- Page 8 then 13. Install Micro Siwss Allmetal Hotend Nozzle. Screw it in all the way in, until it bottoms out, back off ¼ of a turn. bottoms out. (make sure ) 14. Using finger pressure, screw in Allmetal thermal barrier tube, until it...

- Page 9 15. Install thermal tube into a cooling block. Notice the orientation of heater block with regard to cooling block. Aluminum piece of thermal tube should be sticking out about 1.7mm from the top of cooling block. 16. Tighten the slot with a 3/32 Allen key provided.

- Page 10 17. Install the assembly back on the carriage. 18. Install the fan, heatsink and stepper motor assembly and connect stepper motor cables.

- Page 11 19. Preheat the nozzle to 250C. 20. Tighten and seat the nozzle while supporting heater block with adjustable wrench.

- Page 12 For PETG, try 1.0mm retraction. For PLA, you might need to increase extruder temperature 10-15 degrees. If temperature is not stable after conversion, PID tuning might be required. Highly recommend to change stock Wanhao i3 extruder gear to D4 style gear.

Need help?

Do you have a question about the i3 and is the answer not in the manual?

Questions and answers