Advertisement

Table of Contents

- 1 General Safety Instructions

- 2 Table of Contents

- 3 Specifications

- 4 Air Line Piping Installation

- 5 Operating Instructions

- 6 Adjustments

- 7 Parts Removal and Replacement

- 8 Air Logic and Diagram

- 9 Air Motor Identification

- 10 Parts List, Air Motors

- 11 Parts List, Tool

- 12 Troubleshooting

- 13 Maintenance

- 14 Tool Options

- 15 EU Declaration of Conformity

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Signode TENSION-WELD VXL-2000-Z

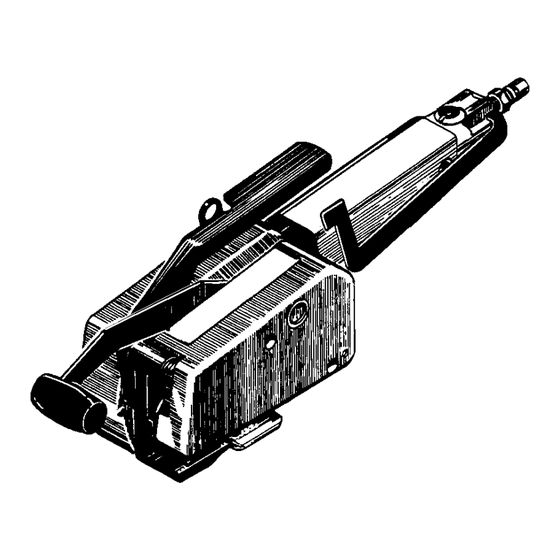

- Page 1 VXL-2000-Z and VXM-2000-Z TENSION-WELD® STRAPPING TOOLS...

-

Page 2: General Safety Instructions

Use the correct Signode products for your application. 2. TRAINING. This tool must not be used by persons not properly trained in its use. Be certain that you receive proper training from your employer. If you have any questions contact your Signode Representative. 3. EYE INJURY HAZARD. - Page 3 Several types of strap can be used with this tool. Use the correct Signode products for your application. If you need help contact your Signode Representative. Signode tools and machines are designed and warranted to work together with Signode strapping and seals. Use of non-Signode strap, seals and/or manufactured or specified replacement parts may result in strap breakage or joint separation while applying strapping to a load or during normal shipping and handling.

-

Page 4: Table Of Contents

NOTE: Strap sizes shown in brackets { } indicates strap sizes that (due to tension capabilities) may require use of the VXL model only or the use of Tension Control Kit (Signode Part No. 422540 shown on page 33). Successful use of these strap sizes depends upon air pressure, tool condition... -

Page 5: Air Line Piping Installation

Never operate this tool using a bottled air or gas source. Bottled air/gas sources do not provide consistant operating pressure. A filter-regulator-lubricator unit (Signode P/N 008559) must be installed as close to the air tool as possible, preferably within 10 feet. - Page 6 The remaining moisture is removed at the water leg in the piping system or in the filter (Signode Part No. 008559). NOTE: Additional information is available in the Signode publication, "Air Supply Manual" (E- 186038). If you have any questions, contact your local Signode Representative.

- Page 7 Air pressure is assumed to be 90 psig (6.2 Bar) with recommended size and length of air hose. Volume of air is at room temperature and sea level pressure, or so-called "free air" conditions. For more detailed information about air supply systems refer to Signode manual Part No. 186038. COLD WEATHER OPERATION If a tool does not operate satisfactorily in freezing temperatures, certain steps can correct the problem.

-

Page 8: Operating Instructions

OPERATING INSTRUCTIONS 3. When the motor stalls, indicating completion of tension, continue to hold the motor lever fully closed against the motor housing and pull back the weld handle with your left hand. The handle Wear safety glasses. should be pulled quickly all the way back without hesitation. - Page 9 position with your left hand. The motor lever will return to the OFF position as the weld handle is moved forward. SEALING OPERATION This tool is a Tension Weld® type sealer. A properly made joint will appear as shown in the illustration. If the joint does not appear as shown, then the operator must proceed as follows:...

-

Page 10: Adjustments

4. If you are unable to produce an acceptable joint or if you have any questions as to whether your tool is producing good weld strength, contact - your Signode Sales Representative. - Page 11 When the strap cutter begins to wear or strapping seems difficult to cut off the strap cutter may need adjustment. Contact the Signode tool repair center or your Signode representative for information on accessing the adjustment screw. Before attempting to adjust the cutter, first...

-

Page 12: Parts Removal And Replacement

PARTS REMOVAL & REPLACEMENT FEEDWHEEL AND GRIPPER PLUG 6. Lift the torsion spring (23) and the 1. Place the tool on its side and remove the tensioner foot (16) off the support pin two socket head cap screws (75) from the (25). - Page 13 CUTTER BLADE 1. Place the tool on its side and remove the 7. Examine the cutter blade (46), spring (84) two socket head cap screws (75) from the and pin (74) for a worn or damaged areas. weld housing (24). Replace if necessary.

- Page 14 1. Remove the idler gear (27) from the pin When reinstalling a lower gripper, use (30) and examine both parts for wear. Loctite "380 Black Max" (Signode Part No. 274111) or an equivalent instant 2. Remove the eccentric shaft (26) and adhesive to ensure the lower gripper will examine it for wear.

- Page 15 NEEDLE BEARING (ECCENTRIC SHAFT) Use a 1/4-20x3 socket head cap screw and an 3. Remove the extra spacer from the SHCS extra spacer (86) to remove the needle and thread the screw into the spacer. bearing (29) from the back of the gear Clamp the screw head in a vise and housing (72).

- Page 16 CLUTCH AND BRAKE 1. You now have access to the clutch (37) 6. Assemble the clutch spring (36) and the and the drive gear assembly (39). clutch (37) on the spline of the Spiroid Normally, the drive gear will remain in the worm and press down to weld position.

- Page 17 AIR MOTOR This tool is manufactured with one of two available air motors. Inspect the air motor housing to determine which specific air motor instructions to follow. The two motors available for this tool are part number 422550 A small compression spring (84) is and 423150.

- Page 18 NOTE: If disassembling a tool with the 11. Disassemble the rotor by sliding off the alternate style locking ring, use socket front end plate (20), and any ball adapter Part No. 422341. bearing(s) and spacers. Then slide the back end plate (14) and the rotor 6.

- Page 19 Remove the air motor from the vise. 21. The air motor/mount assembly can now Clean the motor mounting threads with be mounted to the gear housing an appropriate solvent, also clean the assembly. threads of the motor mount. Remove the valve housing assembly and O-ring 22.

-

Page 20: Air Logic And Diagram

PILOT VALVE Remove the pilot valve as follows: Remove the valve cap (35) using cap tool (P/N 422449). Lift out the spring and pull out the pilot valve (33) from the valve housing (36). Replace the pilot valve assembly if necessary, being careful not to cut the "O"... -

Page 21: Air Motor Identification

AIR LOGIC AND DIAGRAM (AIR MOTOR N20R38VA) SEQUENCE OF OPERATION 1. Tool at Rest - Air flows through the pilot valve, throttle valve and stops at the air valve. Air also flows to the 3-way valve. 2. Motor control lever is depressed, initiating the tensioning portion of the cycle. Air flows through the pilot valve, throttle valve (used to control strap tension) and the air valve to the rotor/cylinder section of the air motor, causing the air motor to turn. -

Page 22: Parts List, Air Motors

PARTS LIST, AIR MOTOR N20R38VA (422550) PART# DESCRIPTION 020704 Quick disconnect plug 024631 Filter assembly 273822 Fitting 024688 Truarc, #N5000-45 024686 Valve sleeve 091624 O-ring 024685 Valve stem 020728 O-ring 024683 Valve spring 004658 Roll pin 1/8 x 13/16 422592 Motor housing 024633 Ball bearing... - Page 23 • The pilot valve (Key 33) must only be serviced by an authorized Signode Service Facility or a maintenance person trained by Signode. • NEVER remove the pilot valve when air is connected to the tool. Removing a pilot valve with air to the tool will cause the valve to violently release from the tool.

- Page 24 PARTS LIST, AIR MOTOR N20R38V(423150) PART# DESCRIPTION 020704 Quick disconnect plug 024631 Filter assembly 273822 Fitting 024688 Truarc, #N5000-45 024686 Valve sleeve 091624 O-ring 024685 Valve stem 020728 O-ring 024683 Valve spring 004658 Roll pin 1/8 x 13/16 273888 Motor housing 024633 Ball bearing 024643...

- Page 25 • The pilot valve (Key 33) must only be serviced by an authorized Signode Service Facility or a maintenance person trained by Signode. • NEVER remove the pilot valve when air is connected to the tool. Removing a pilot valve with air to the tool will cause the valve to violently release from the tool.

- Page 26 PARTS LIST, AIR MOTOR 20R38V(273830) PART # DESCRIPTION 020704 Quick disconnect plug 024631 Filter assembly 273822 Fitting 024688 Truarc, #N5000-45 024686 Valve sleeve 091624 O-ring 024685 Valve stem 020728 O-ring 024683 Valve spring 004658 Roll pin 1/8 x 13/16 273888 Motor housing 024633 Ball bearing...

- Page 27 • The pilot valve (Key 33) must only be serviced by an authorized Signode Service Facility or a maintenance person trained by Signode. • NEVER remove the pilot valve when air is connected to the tool. Removing a pilot valve with air to the tool will cause the valve to violently release from the tool.

-

Page 28: Parts List, Tool

PARTS LIST, TOOL KEY QTY PART # DESCRIPTION KEY QTY PART # DESCRIPTION 423370 Set screw 422110 Pin, pivot 273881 End cap 422121 Upper gripper "Z" 023096 O-ring 273820 Flow control 023097 Bearing, Faf. #9101K 274442 Fitting 023082 O-ring 273819 3-way valve 023014 Spacer... -

Page 30: Troubleshooting

TROUBLESHOOTING The following items are the most common types of tool malfunctions. For symptoms or remedies not shown, contact your Signode service representative for additional information and details. The following tool conditions are shown in this manual: AIR SUPPLY #1 - The air motor is frozen. - Page 31 #3 CONDITION: The tool runs sluggishly. CAUSE REMEDY The air filter-regulator-lubricator is 1A. Check the regulator to see that the correct air malfunctioning or is not properly maintained. pressure is getting to the tool. 1B. Check to see the filter unit is clean and functioning properly.

- Page 32 TROUBLESHOOTING, Continued #6 CONDITION: The tool stops tensioning before maximum tension is reached, but the air motor continues to run. CAUSE REMEDY This is an indication that the clutch and drive gear These parts must be replaced. See Parts Removal teeth are worn through normal use, or the clutch and and Replacement Section.

- Page 33 CAUSE REMEDY Strap residue jamming cutter mechanism. Clean parts as required. Strap cutter may require adjustment. Contact Signode for information on accessing and adjusting the strap cutter. Cutter blade worn or damaged beyond Follow cutter blade replacement procedures. adjustability. Broken or damaged cutter spring.

-

Page 34: Maintenance

MAINTENANCE TOOL This portion of the tool should be from 1. Always be sure the tensioner foot is free 20% to 50% full of Non-Fluid Oil K-55. and periodically lubricate the support pin. Reinstall the end cap. 2. Clean the teeth on the feedwheel and the gripper plug with the special brush provided, (Part No. -

Page 35: Tool Options

P/N 306397 P/N 274437 P/N 274437 P/N 274164 * Shown with the recommended Overhead Tool Balancer, Signode Model Number P-5602. WEAR PLATE, Part No.306857 An optional wear plate can be installed on any VXL/VXM tools. This option is to protect the base plate from abuse from rough surfaces such as brick and block. - Page 36 This strap conversion kit allows the VXL/VXM tool to use 9mm (1616) type strapping. Consult your Signode Sales Representative about the benefits of this conversion for your tool application. Use the instructions shown in this manual for replacing and adjusting parts.

- Page 37 TENSION CONTROL KIT, Part No. 422540 This option is only available for air motors This kit contains the following items: 20R38V and N20R38V. KEY QTY PART # DESCRIPTION Strap tension can be controlled by turning the adjustment screw in 1/4 increment turns 422587 Hex wrench, 3/32 counter-clockwise using a 3/32 hex wrench 422523 Cover...

-

Page 39: Eu Declaration Of Conformity

It is hereby declared that the undermentioned machinery has been designed and constructed to comply with the health and safety requirements defined in EC Directive 89/392/EEC Machine Supplier: Signode, Division of ITW Ltd. Queensway, Fforestfach Swansea SA5 4ED Machine Description:... - Page 40 Signode reserves the right to replace any tool which proves not to operate per functional specifications with a new or like-new tool of the same model if in Signode's judgement such replacement is appropriate. Any new replacement tool provided to an owner will carry a full sixty (60) day warranty. Any warranty repaired tool or like-new replacement tool will carry a warranty for the balance of the time remaining on the initial sixty (60) day warranty.

Need help?

Do you have a question about the TENSION-WELD VXL-2000-Z and is the answer not in the manual?

Questions and answers