Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Texas Instruments TPS40090EVM-002

- Page 1 User’s Guide Using the TPS40090EVM-002 User’s Guide...

-

Page 2: Evm Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions: This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety measures typically found in the end product incorporating the goods. - Page 3 These types of devices can be identified using the EVM schematic located in the EVM User’s Guide. When placing measurement probes near these devices during operation, please be aware that these devices may be very warm to the touch. Copyright 2004, Texas Instruments Incorporated Mailing Address: Texas Instruments...

-

Page 4: Table Of Contents

Device operation is specified in the TPS40090 datasheet TPS40090EVM-002 can be configured into 2-, 3− or 4-phase operation. For 2-phase operation, populate R65 and R66 to tie PWM2 and PWM4 up to internal 5-V and leave components in related phases unpopulated. -

Page 5: Features

Features Table 1. TPS40090EVM−002 Performance Summary PARAMETER Input voltage range Output voltage set point Output current range Line regulation (1) Load regulation Load transient response voltage Load transient response voltage change Load transient response recovery Load transient response recovery time Loop bandwidth Phase margin Input ripple voltage... - Page 6 SLUU195 − June 2004 TRANS_EN Figure 2. TPS40090EVM−002 Schematic Part 2 − Driver Circuit and Load Transient Generator TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A...

-

Page 7: Component Selection

Figure 3. TPS40090EVM−002 Schematic Part 3 − Power Stage Component Selection Frequency of Operation The clock oscillator frequency for the TPS40090 is programmed with a single resistor from RT (pin 16) to signal ground. Equation (1) from the datasheet allows selection of the R kΩ... - Page 8 SLUU195 − June 2004 Inductance Value The output inductor value for each phase can be calculated from the volt-second during off time, shown in equation (2). RIPPLE where • is usually chosen to be between 10% and 40% of maximum phase current I RIPPLE With I = 20% of I...

- Page 9 N PH = 3 N PH = 6 Figure 4. Input Ripple Current RMS Value Overload Current The maximum input ripple RMS current can be estimated as shown in (4). I ^ I 4, D IN(nom) It is also important to consider a minimum capacitance value which limits the voltage ripple to a specified value if all the current is supplied by the onboard capacitor.

- Page 10 SLUU195 − June 2004 where • D is the duty cycle for a single phase • is the number of active phases • K (N ) is the intermediate function for calculation In this case, N =4 and D The actual output ripple is calculated in equation (7) RIPPLE N PH = 6 Figure 5.

-

Page 11: Current Sensing

3. Transient consideration. An additional consideration in the selection of the output inductor and capacitance value can be derived from examining the transient voltage overshoot which can be initiated with a load step from full load to no load. By equating the inductive energy with the capacitive energy the equation (10) can be derived. - Page 12 SLUU195 − June 2004 With the chosen inductor described in Inductance Value, (section 4.2, of this document) the following values are used. • R=19.6 kΩ • C=10 nF • =100 kΩ • R1=124 kΩ • R2=22.6 kΩ V DCR V IN Figure 6.

- Page 13 Compensation Components The TPS40090 uses peak current mode control. Type II network is used here, which is implemented to provide one zero and two poles. The first pole is placed at the origin to improve DC regulation. The ESR zero of the power stage is: ESRZ The zero is placed near 3.96 kHz to produce a reasonable time constant.

-

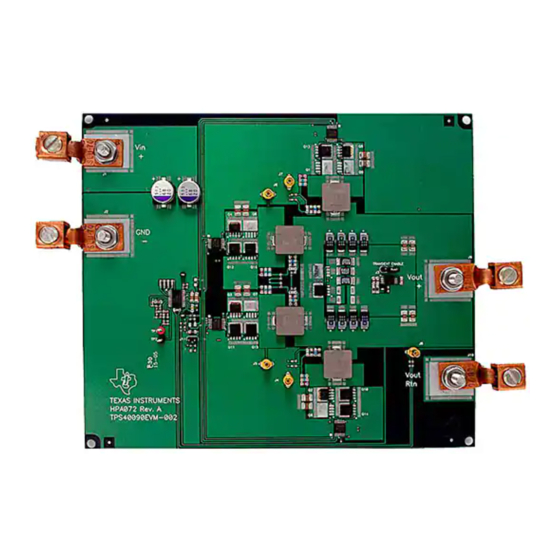

Page 14: Test Setup

SLUU195 − June 2004 Test Setup The HPA072 has the following input/output connections: 12-V input J1 (VIN) and J2 (GND), 1.5-V output J9 (VOUT) and J10 (GND). A diagram showing the connection points is shown in Figure 5. A power supply capable of supplying 18 A should be connected to VIN and GND through a pair of 10 AWG wires. -

Page 15: Test Results/Performance Data

Test Results and Performance Data Efficiency and Power Loss Figure 8 shows the efficiency as the load varies from 10 A to over 100 A. The efficiency at full load is about 84.3%. Figure 7 shows the total loss versus the load current, which is approximately 28.3W at 100 A. OVERALL EFFICIENCY OUTPUT CURRENT V IN = 12 V... -

Page 16: Oscillator Frequency

SLUU195 − June 2004 Closed-Loop Performance The TPS40090 uses peak current-mode control. Figure 10 shows the bode plots at 100 A of load current, where no droop function is implemented. The crossover frequency is at 89 kHz with phase margin of 40°. −20 V IN = 12 V V OUT = 1.5 V... -

Page 17: Transient Response

SLUU195 − June 2004 Transient Response The on-board load transient circuit enables to check the step load transient response on the same board. Simply by putting a jumper to connect Pin1 and 2 of J3, a 90-A step load is created by three 50-mΩ... - Page 18 SLUU195 − June 2004 Start up with Pre-Biased Output In synchronous buck converter, the bottom FET discharges the pre-biased output during start-up. To avoid this, a comparator U9 and surround components are used to pull the SYNC pin of the drivers low, which keeps the bottom FET off during startup. So the output can rise smoothly.

-

Page 19: Layout Considerations

Layout Considerations The PCB layout plays a critical role in the performance in a high frequency switching power supply design. Following the suggestions listed below will help to improve the performance and expedite the design. • To take full advantage of the ripple cancellation factor from interleaving, place the input capacitors before the junction where the input voltage is distributed to each phase. -

Page 20: Evm Assembly Drawing And Pcb Layout

SLUU195 − June 2004 EVM Assembly Drawing and PCB Layout Figure 15. Top Side Component Assembly Figure 16. Bottom Assembly TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A... - Page 21 SLUU195 − June 2004 Figure 17. Top Side Copper Figure 18. Internal 1 (Ground Plane) TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A...

- Page 22 SLUU195 − June 2004 Figure 19. Internal 2 (Power Plane) Figure 20. Internal 3 TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A...

- Page 23 SLUU195 − June 2004 Figure 21. Internal 4 Figure 22. Bottom Layer Copper TPS40090 Multi-Phase Buck Converter and TPS2834 Drivers Steps-Down from 12-V to 1.5-V at 100 A...

-

Page 24: List Of Materials

SLUU195 − June 2004 List of Materials The following table lists the TPS40090EVM−002 components corresponding to the schematic shown in Figure 1. Reference Designator Capacitor, OS−CON, 68 µF, 20 V, 40 mΩ, 20% C1, C4 C2, C5, C7, Capacitor, ceramic, 1000−pF, 25 V, X7R, ±5% C8,C9, C10, C3,C17, C18, Capacitor, dielectric, 1.0 µF, 16 V, X7R, ±10%... - Page 25 Reference Designator R27, R28, R29, Resistor, chip, 2.2 Ω, 1/10−W, 1% R31, R32,R35, Resistor, chip, 19.6 kΩ, 1/10−W, 1% R33, R34, R37, Resistor, chip, 2.7 Ω, 1/16−W, 1% R38, R41, R42, R45, R46 R39, R40, R43, Resistor, chip, 22.6 kΩ, 1/10−W, 1% R47, R49, R51, Resistor, chip, 124 kΩ, 1/10−W, 1% R48, R50, R53,...

-

Page 26: Important Notice

TI product or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements. Following are URLs where you can obtain information on other Texas Instruments products and application solutions:...

Need help?

Do you have a question about the TPS40090EVM-002 and is the answer not in the manual?

Questions and answers