Summary of Contents for Fronius KD Supply 2500

- Page 1 / Perfect Charging / Perfect Welding / Solar Energy Operating Instructions KD Supply 2500 Spare parts list System extension 42,0426,0049,EN 001-16012019...

- Page 3 Thank you for the trust you have placed in our company and congratulations on buying this high-quality Fronius product. These instructions will help you familiarise yourself with the product. Reading the instructions carefully will enable you to learn about the many different features it has to offer.

-

Page 5: Table Of Contents

General remarks ..........................Fitting the KD Supply 2500 to the base of the trolley................Connecting the KD Supply 2500 to the cooling unit and power source ............. Safety..............................Connecting the KD Supply 2500 to the cooling unit and power source .......... -

Page 7: General

KD Supply 2500 Safety symbols The KD Supply 2500 has safety symbols on the rating plate. The safety symbols must NOT on the rating plate be removed or painted over. The symbols warn against operating the equipment incorrect- ly, which can cause serious injury and damage. -

Page 8: Warning Notices Affixed To The Machine

Warning notices Machines destined for the USA have additional warning notices. The warning notices must affixed to the ma- NOT be removed or painted over. chine US machine with additional warning notices... -

Page 9: Controls, Connections And Mechanical Components

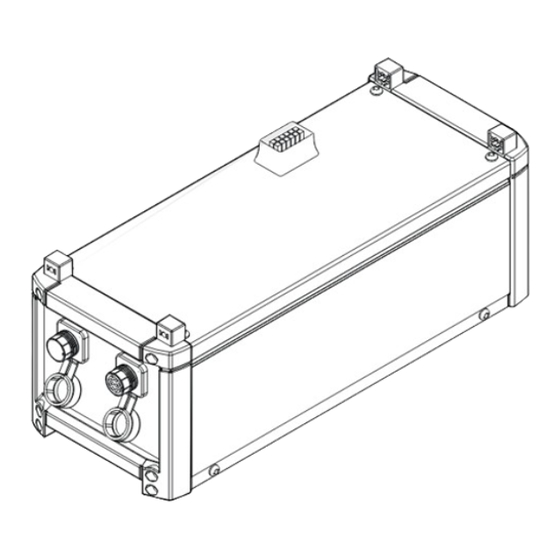

Do not use the functions described here until you have read and completely understood all of the following documents: ► these Operating Instructions ► all the Operating Instructions for the system components, especially the safety regula- tions KD Supply 2500 - LocalNet X9.1 interface front Standard connection socket for the power source LocalNet X9.2 interface... -

Page 10: Fitting The Kd Supply 2500 To The Trolley

If the welding system is not equipped with an auto-transformer or a cooling unit, the KD Supply 2500 must be installed right at the bottom. ► If a cooling unit is present, fit it right at the bottom and place the KD Supply on top of it. -

Page 11: Connecting The Kd Supply 2500 To The Cooling Unit And Power Source

Establish connection between KD Sup- ply 2500 and cooling unit CAUTION! Risk of short circuit from kinked or damaged cables. ► When positioning the KD Supply 2500, ensure that the cables are not kinked. Carefully place the KD Supply 2500 on the cooling unit... -

Page 12: Establishing A Localnet Connection Between The Kd Supply 2500 And The Power Source

Using two „Extrude-Tite“ screws, fasten the KD Supply to the fastening bars (2) on the front and back of the cooling unit Position the power source over the KD Supply 2500 using a suitable hoisting device Pull the power source connector as far as possible through the opening on the under-... -

Page 13: Connecting The Kd Supply 2500 To The Cold Wire Feeder, Commissioning

LocalNet X9.2 interface (front) or LocalNet X9.3 interface (rear) Commissioning Power for the KD Supply 2500 is supplied by the power source Connect the power source and the cold wire feeder using the interconnecting hose- pack Connect the welding torch... -

Page 14: Care, Maintenance And Disposal

Care, maintenance and disposal General remarks Under normal operating conditions the KD Supply 2500 requires only a minimum of care and maintenance. However, it is vital to observe some important points to ensure the weld- ing system remains in a usable condition for many years. -

Page 15: Technical Data

Technical data KD Supply 2500 Mains voltage 230 / 460 V Mains frequency 50 / 60 Hz Primary current I 2,4 / 1,3 A Secondary voltage U 55 V Secondary current I Protection IP 23 Measurements l x w x h 625 x 240 x 225 mm 24.61 x 9.45 x 8.86 in. -

Page 17: Appendix

Appendix... -

Page 18: Spare Parts List: Kd Supply 2500

Spare parts list: KD Supply 2500... - Page 20 FRONIUS INTERNATIONAL GMBH Froniusplatz 1, A-4600 Wels, Austria Tel: +43 (0)7242 241-0, Fax: +43 (0)7242 241-3940 E-Mail: sales@fronius.com www.fronius.com www.fronius.com/addresses Under http://www.fronius.com/addresses you will find all addresses of our Sales & service partners and Locations...

Need help?

Do you have a question about the KD Supply 2500 and is the answer not in the manual?

Questions and answers