Summary of Contents for Pentair Myers ME40 Series

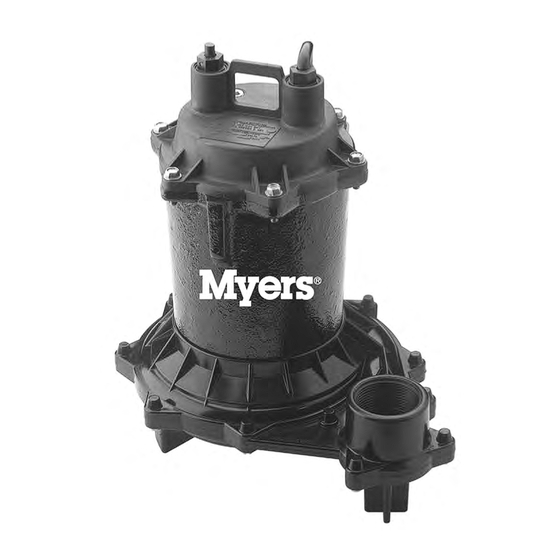

- Page 1 ME40/ME40AG SERIES Submersible Sump, Effluent & Sewage Pumps Installation and Service Manual Automatic and manual models. Single phase power only — 115 or 230 volt. 23833A245 (Rev. 7/30/10)

-

Page 2: Description And Application

DESCRIPTION AND APPLICATION Each pump is packaged separately in a carton marked ME40 with a catalog number and Myers engineering number. Myers ME40 Series Pumps are single seal units, automatic or manual, designed for use in effluent Catalog Engineering Cord dosing. -

Page 3: Installation

DESIGN OF PRESSURE SEWER SYSTEMS CAUTION: Never enter pump chamber after sewage or effluent has been in basin. Sewage Myers has available complete computer software for water can give off methane, hydrogen sulfide, and designing PRESSURE SEWER SYSTEMS. This other gasses which are highly poisonous. For this gives pipe sizes to use and gives exact flow from reason, Myers recommends installing effluent pumps any pump or group of pumps in the system when... - Page 4 ME40 TYPICAL INSTALLATION 23833A245...

- Page 5 DIMENSIONS [Dimensions in mm] 1½” NPT Discharge 9.19” ME40 [233] 12.44” Level Control 3.75” [316] 3.89” 5.66” [99] [144] 11.68” [297] ME40AG Suction Screen ME40AG PERFORMANCE CURVE ME40 PERFORMANCE CURVE 8.00 115 V OLT AMPS 7.00 6.00 5.00 230 VOLT AMPS 4.00 3.00 60HZ PERFORMANCE...

-

Page 6: Trouble Check List

TROUBLE CHECK LIST CONDITION PROBABLE CAUSE Pump does not run or start when 1. Check for blown fuse or tripped circuit breaker. water is up in tank. 2. Check for defective level switch. 3. Where control panel is used be sure H-O-A switch is in the AUTO position. - Page 7 TO REPLACE POWER CORD OR 7. Remove the seal from the package being careful not to touch the carbon or ceramic faces with AUTOMATIC CONTROL FLOAT fingers or anything dirty. Add a film of oil to the 1. Use a wrench to loosen and remove thermoplastic perimeter of the rubber cup holding the ceramic nut from the cap socket.

-

Page 8: Wiring Diagram

5. Lay pump on its side. Place a flat screwdriver 12. Check that the impeller turns freely. in the slot in the bottom of the shaft and turn the impeller counterclockwise to remove it from the 13. Guide the four motor wires up through a common shaft. - Page 9 TYPICAL SECTION DRAWING FOR ME40 SERIES Shaded Pole Motor 23833A245...

- Page 10 TYPICAL SECTION DRAWING FOR ME40AG SERIES PSC Motor 23833A245...

- Page 11 PARTS LIST ME40/ME40AG Ref. Part Ref. Part Description Req’d Numbers Description Req’d Numbers Seal, shaft 21607A015 Plug, nut 24448A000 (manual only) Screw, machine, flat head 07597A030 Washer 05030A213 (manual only) Plug, connector 24449A000 Case, volute, upper half 25306D000 (manual only) Cord, electric See Chart Screws, self tap #10 x 3/4...

-

Page 12: Limited Warranty

LIMITED WARRANTY F.E. MYERS warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from defects in material and workmanship for the Warranty Period shown below. Product Warranty Period Sump/Sewage/Effluent Products 24 months from date of manufacture Fibrewound Tanks 5 years from date of original installation...

Need help?

Do you have a question about the Myers ME40 Series and is the answer not in the manual?

Questions and answers