Advertisement

Quick Links

Version of May, 2009

User Manual

Quattroflow-20k Series

4-Piston Diaphragm Pump

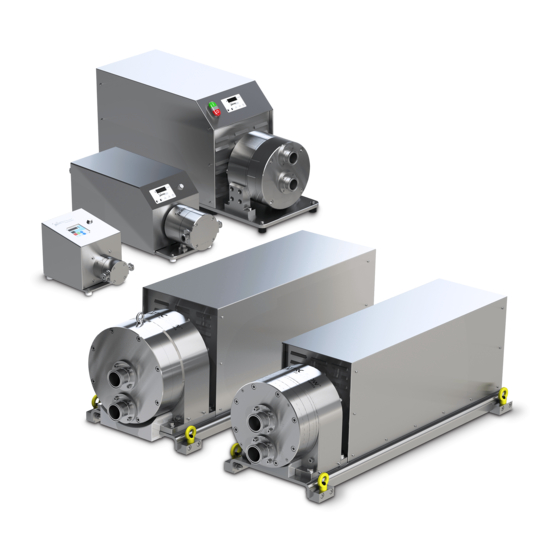

Pictures of Quattroflow 20k Pump (other designs are optional available)

Safety

These operating instructions contain precautions to be observed during installation,

operation and maintenance. Therefore, prior to mounting and commissioning, these

operating instructions must be read by the user and must always be available at the place

of installation.

Performance Data

The exact performance data applying to the pump are to be taken from the order data

sheet.

These Operating and Maintenance instructions contain information from the pump

manufacturer. They may need to be supplemented by instructions of the operator company

for its personnel.

ALMATEC Maschinenbau GmbH is constantly working on improvements of the pump.

Modifications of the design or materials might be done without prior notice.

Page 1 of 17

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Dover Almatec Quattroflow-20k Series

- Page 1 Version of May, 2009 User Manual Quattroflow-20k Series 4-Piston Diaphragm Pump Pictures of Quattroflow 20k Pump (other designs are optional available) Safety These operating instructions contain precautions to be observed during installation, operation and maintenance. Therefore, prior to mounting and commissioning, these operating instructions must be read by the user and must always be available at the place of installation.

- Page 2 Version of May, 2009 1. General Appropriate Specification Labelling of the Pump 2. Safety Marking of precautions in the operating instructions Personnel qualification and personnel training Responsible working Dangers in case of non-compliance with the safety precautions Safety precautions fort the user and/or operator Safety precautions for maintenance, inspection and mounting operations Arbitrary reconstruction and spare part production Attention! Warning precautions!

-

Page 3: Labelling Of The Pump

Version of May, 2009 1. General: 1.1 Appropriate specification This User Manual is valid for the Quattroflow Q20k pump No liability will be undertaken for any damages caused by non-compliance with the operating instructions and service conditions! Original spare parts serve safety purposes. The use of other parts may cancel the liability for the consequences resulting there from. - Page 4 Version of May, 2009 2. Safety The operating instructions are recommended to be followed during installation, operation and maintenance. Prior to mounting and commissioning, the operating instructions must be followed by authorized personnel. The manual should be kept with the pump for future reference. The general safety warnings in Section 2 “Safety”...

- Page 5 Version of May, 2009 2.4 Non-compliance of safety warnings Failure to follow safety precautions may cause danger to personnel, equipment and environment. Such as: Failure of the proper function of the pump/system. Danger to personnel by electrical, mechanical, chemical, biological impacts. ...

- Page 6 Version of May, 2009 2.9 Attention! Warning precautions! These warning precautions are to prevent the user from an inadmissible mode of operation. These warning precautions are to be strictly followed to avoid any damage of the pump and/or any danger to personnel. Diaphragm pumps are positive displacement pumps and can theoretically generate an infinitely high pressure.

- Page 7 Version of May, 2009 2.10 Attention! Safety Precautions! The following safety precautions notify you of the potential of bodily harm or life danger of the user/operators! Please read and follow the safety precautions and warnings to avoid any risk of bodily harm, life danger and/or the damage of equipment.

- Page 8 Version of May, 2009 3. Description of the Quattroflow 20k pump 3.1 Application and range of utilization of the Quattroflow 20k pump The Quattroflow 20k is a 4-piston Diaphragm pump, which is mainly used to pump water-like fluids that are typically handled in research, pilot plant or production facilities of the pharmaceutical, biotech, food or cosmetic research centres or plants.

- Page 9 Version of May, 2009 3.4 Start-Up Prior to leaving our factory all pumps are subjected to a leakage and performance test. Only properly operating pumps leave the factory achieving the performances assured by us. It is possible that there will be a few milliliters of water inside the pump. Prior to each use we recommend flushing the pump with a proper fluid (i.e.

- Page 10 Version of May, 2009 4. Maintenance/Servicing of the Quattroflow 20k pump Due to the robust construction the Quattroflow 20k pump requires only little and easy- to-do maintenance. The ball bearings do not need any extra lubrication. The diaphragm and the valves are wear parts. These should be checked and if needed be changed once the performance of the pump decreases.

- Page 11 Version of May, 2009 4.1 Dismounting of the pump chamber and changing seals and diaphragms: The changing of the diaphragm and the valves can be done by the user. Please follow the schematic drawings “Dismounting of the pump chamber” and “Mounting of the pump chamber”...

- Page 12 Version of May, 2009 Page 12 of 17...

- Page 13 Version of May, 2009 4.2 Mounting of the pump chamber: Page 13 of 17...

- Page 14 Version of May, 2009 4.3 Changing of the shaft–bearing–cap unit The changing of the shaft-bearing unit can be done by the user by using the spare parts PSKITWLC20: 6. Mounting in reverse order Page 14 of 17...

-

Page 15: Operating Troubles

Version of May, 2009 5. Operating troubles, causes and remedial action Causes and remedial Operating troubles action Delivery The 4-piston diaphragm pump Pump Pump is not Pressure Irreg- Pump Motor Display operates trouble-free at any time Pump does does head is ular oper- gets... - Page 16 Version of May, 2009 6. Performance chart of the Quattroflow 20k pump Performance Diagram Quattroflow 20k Pump Test media: Water at ambient temperature Discharge pressure: 0 to 6 bar 6.1 Diagram 1: Approximate flow rate as function of pump rpm. Please note, if motor is directly coupled to pump: Pump rpm = motor rpm If reducer gear drives are used: Pump rpm = motor rpm x reduction ratio Kennlinie Quattroflow -20k...

- Page 17 Version of May, 2009 7. Technical data of the Quattroflow 20k pump 4-piston-diaphragm pump: Eccentric shaft: 7° Flow rate max: appr. 23000 L/h at 0 bar appr. 20000 L/h at 4 bar Flow rate min 5°: appr. 750 L/h at 0 bar appr.

Need help?

Do you have a question about the Almatec Quattroflow-20k Series and is the answer not in the manual?

Questions and answers