Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BERTHOLD TECHNOLOGIES Uni-Probe LB 490

- Page 1 Process Control Level Measurement Uni-Probe LB 490 With All Supplements User’s Manual ID no. 38477BA2B Rev. no.: 05 25.5.09 Embedded Soft. Rev. 100 Device Description 03 HART Device Description 01 PA Device Description 02 FF...

- Page 3 Volume 1: Safety Manuals Volume 2: Uni-Probe Installation ® Volume 3: HART Communicator User Interface ™ Volume 4: PACTware User Interface FDT/DTM ® Volume 5: SIMATIC PDM User Interface HART Volume 6: SIMATIC PDM User Interface Profibus PA ™ Volume 7: FOUNDATION Fieldbus User Interface...

- Page 4 General Information Thank you very much for purchasing the level gauging system Dear customers Uni-Probe LB 490 made by BERTHOLD TECHNOLOGIES GmbH & Co. KG. The scope of supply also includes this User’s Manual. Be sure to have this User’s Manual always to hand.

-

Page 5: Table Of Contents

9.1 Scope of Application ..........1 – 61 9.2 Use and Function............1 – 63 9.3 Safety Function............1 – 64 9.4 Safety Requirement ..........1 – 64 9.5 Project Planning............1 – 65 Uni-Probe LB 490 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 6 Contents Volume 1-7 9.6 Getting Started............1 – 67 9.7 Behavior during Operation and during Malfunctions . 1 – 69 9.8 Recurrent Performance Test ........1 – 70 9.9 Safety-Technical Data..........1 – 71 9.10 Certificate Functional Safety ........1 – 73 Safety Instructions for the Types of Protection ATEX / FM / CSA ...............

- Page 7 1.5 Technical Data ............2 – 130 1.6 Detector Codes ............2 – 133 1.7 Uni-Probe LB 490 Nomenclature ......2 – 134 1.8 LB 490 Super-Sens Nomenclature ......2 – 135 1.9 LB 490 Tower-Sens Nomenclature ......2 – 136 Installation ..............

- Page 8 Contents Volume 1-7 4.9 Replacing the Plastic Scintillator ......2 – 229 4.10 Replacing the Digital Board........2 – 231 4.11 Replacing the Power Supply Unit ......2 – 234 4.12 Replacing Fuses ............2 – 236 4.13 Updating the Embedded Software in the Uni-Probe 2 – 237 4.14 Check Detector ............

- Page 9 ........3 – 327 2.31 S ERVICE ..............3 – 328 2.32 T ALCULATION ..........3 – 329 2.33 I/O T ............. 3 – 329 2.34 S TATUS NPUT ..........3 – 330 Uni-Probe LB 490 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 10 Contents Volume 1-7 2.35 D UTPUT ..........3 – 330 2.36 C URRENT UTPUT ..........3 – 331 2.37 P ROBE ETTINGS ..........3 – 332 2.38 HV S ETTINGS ............3 – 334 2.39 P LATEAU ............... 3 – 335 2.40 HART I NTERFACE ..........

- Page 11 PC Connection to the Uni-Probe ........4 – 407 Installing and Working with DTM ........4 – 409 2.1 Requirements ............4 – 409 2.2 FDT Container ............4 – 409 2.3 DTM Communication Software....... 4 – 411 Uni-Probe LB 490 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 12 3.1 How to Get Started ..........5 – 427 3.2 Installing SIMATIC PDM .......... 5 – 427 3.3 Installing the Uni-Probe LB 490 Device Description.. 5 – 432 3.4 Project Setup ............5 – 434 3.5 Start SIMATIC PDM..........5 – 438 Menu Overview ..............

- Page 13 9.3 Corrective Action............ 5 – 545 9.4 Reset ..............5 – 546 9.5 Operation Modes during Measurement ....5 – 547 9.6 Error Reset.............. 5 – 547 9.7 Fault Current ............5 – 548 Uni-Probe LB 490 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 14 Contents Volume 1-7 Volume 6 SIMATIC PDM User Interface Profibus PA Process Operation ............6 – 555 1.1 Important Information on the Profibus PA Operation............... 6 – 555 ® 1.2 Alternative Operation via HART ......6 – 555 1.3 System Overview ............ 6 – 556 Installation / Program Start..........

- Page 15 Installation / Program Start ..........7 – 663 2.1 Installing the Device Description......7 – 663 2.2 Addressing the Uni-Probe LB 490 Level System ..7 – 663 Parameter Overview ............7 – 665 3.1 Parameters for the Function Block Resource.... 7 – 665 3.2 Parameters for the Function Block Transducer ..

- Page 16 Contents Volume 1-7 Error Handling ..............7 – 715 7.1 Device Response in Case of Error ......7 – 715 7.2 Error Handling Modes..........7 – 716 7.3 Operation Modes during Measurement ....7 – 716 7.4 Corrective Action............ 7 – 717 7.5 Reset ..............

- Page 17 Volume 1 Safety Manuals...

- Page 18 Volume 1 38477BA2B 1 – 18 25.5.09...

-

Page 19: About This User's Manual

SMALL CAPS indicate commands or menu items. The term BERTHOLD TECHNOLOGIES in this User’s Manual stands for the company BERTHOLD TECHNOLOGIES GmbH & Co. KG. Please observe the warnings and safety instructions given in this User’s Manual to rule out physical injury and property damage. -

Page 20: Further Symbols

1 About this User’s Manual Volume 1 Further Symbols Warning sign: Never step under hovering loads Warning sign: Nuclear radiation Warning sign: Explosion protection Warning sign: Risk of crushing Instruction: Disconnect from mains supply Instruction: Wear hard hat Instruction: Wear safety shoes 38477BA2B 1 –... -

Page 21: General Instructions

– the characteristic data, limit values and the information on the operating and environmental conditions on the type labels and data sheets – the signs on the devices Uni-Probe LB 490 1 – 21 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 22 1 About this User’s Manual Volume 1 38477BA2B 1 – 22 25.5.09...

-

Page 23: Use And Function

2 Use and Function Use and Function The Uni-Probe LB 490 has been designed as a level gauging system and may be used only for this purpose. If it is used in any manner not described in this User’s Manual, the protection of the device is impaired and all warranty claims are voided. - Page 24 Explosion hazard! Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service staff or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, you have to replace the complete detector or return it to the man- ufacturer for repair.

-

Page 25: Qualification Of Personnel

IMPORTANT At least specialized persons are required for all work on and with the Uni-Probe LB 490, under the guidance of a qualified or autho- rized person. Specialized Persons Specialized persons are e.g. technicians or welders who can carry out various tasks in transportation, assembly and installation of the Uni-Probe LB 490 under the supervision of an authorized person. -

Page 26: Qualified Persons

Authorized persons are persons, who are foreseen for certain activ- ities as a consequence of statutory provisions, or who have been approved by BERTHOLD TECHNOLOGIES for carrying out certain activities. The Radiation Safety Officer has to be involved whenever radioactive substances are being handled. -

Page 27: Transport And Assembly

Uni-Probe cannot be used any more in ex-protected areas. If the Uni-Probe housing receives a mechan- ical blow, e.g. because it is dropped, then you have to return the Uni-Probe to BERTHOLD TECHNOLOGIES GmbH & Co. KG for inspection. Uni-Probe LB 490 1 –... - Page 28 4 Transport and Assembly Volume 1 38477BA2B 1 – 28 25.5.09...

-

Page 29: Electrical Installation

If the housing is open, you may get in contact with live parts if the power supply is turned on. During installation and servicing on the hardware of the Level Gauge Uni-Probe LB 490 you have to discon- nect the system, possibly connected relay contacts and all in- and outputs from power to avoid getting in contact with live parts. - Page 30 When you open the instrument: Please take precautions when working with printed circuit boards (ESD). Dis- charge yourself before touching the components by touching a grounding point. Please contact BERTHOLD TECHNOLOGIES if you need any further information. 38477BA2B 1 – 30...

-

Page 31: Radiation Protection

The total sum of the radiation dose absorbed by a body is deter- mined by three factors. On the basis of these factors, certain fun- damental radiation protection rules can be derived: Uni-Probe LB 490 1 – 31 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 32 6 Radiation Protection Volume 1 This means the distance between the radioactive source and the Distance human body. The radiation intensity (dose rate) decreases - like light - in proportion to the square of the distance; this means, dou- bling the distance to the source will reduce the dose rate to one quarter.

-

Page 33: General Radiation Protection Instructions

Installation, dismantling, relocation, maintenance, testing involving the radioactive source, or its shielding shall ONLY be performed under the supervision of the Radiation Safety Officer. Please contact BERTHOLD TECHNOLOGIES if you need any further information. Uni-Probe LB 490 1 – 33... -

Page 34: Mounting The Shielding

6 Radiation Protection Volume 1 Mounting the Shielding 6.3.1 Safety Instructions To keep the radiation exposure of the assembling personnel as low as possible, only licensed personnel who have been trained on how to handle radioactive substances are allowed to assemble or disas- semble the shielding with the source. - Page 35 30: 350MBq 0.35μSv m 0.5h × × × 8.2μSv ------------------------------------------------------------------------------------------- - 0.5m h MBq × × × Uni-Probe LB 490 1 – 35 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 36 6 Radiation Protection Volume 1 6.3.4 Testing the Shutter Mechanism This procedure ensures that the shutter mechanism is operating correctly and that the shutter is closed and the source is completely shielded when CLOSED is indicated by the device handle or cylin- der.

-

Page 37: Safety Measures

In the event that radioactive substances are lost, the Radiation Safety Manager and the regulatory authority have to be notified immediately. In case of theft, the police must be informed as well. Uni-Probe LB 490 1 – 37 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 38: Accidents, Loss, Damage, Fire, Theft

• Limit access to the area. • Report the incident to BERTHOLD TECHNOLOGIES; who will advise what further immediate precautions to take and arrange for quick support from a licensed person. In case of loss or theft, notify the regulatory authority. - Page 39 In case of an accident or malfunction or any other event which affects the safety, the regulatory authority has to be informed and also, if necessary, the authority in charge of public safety. Please contact BERTHOLD TECHNOLOGIES if you need any further infor- mation. Uni-Probe LB 490 1 –...

-

Page 40: Shielding And Source

6 Radiation Protection Volume 1 Shielding and Source Shieldings do not include any wearing parts or mechanically mov- ing parts that under normal operating conditions require mainte- nance. For safety reasons, however, it should be possible any time to lock the useful beam. A function check has to be performed in appropriate intervals of max. - Page 41 (here: November) and the third the year the source was manufactured (here: 1994). It is included on the identity plate of the shielding and also on the seal certificate that comes with every source. Uni-Probe LB 490 1 – 41 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 42: Leak Test

6 Radiation Protection Volume 1 Leak Test Depending on the regulatory authority responsible for the sources employed in their territory, regularly recurring leak tests have to be carried out. These tests have to be carried out by authorized tech- nical experts. The appropriate documents on the source have to be provided in order to carry out this test. - Page 43 The alternative test area is the visible part on the head of the For point source shieldings with shielding cylinder. rotary shutter Alternative test area Figure 6-4 Alternative test area on point source shieldings Uni-Probe LB 490 1 – 43 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 44 6 Radiation Protection Volume 1 38477BA2B 1 – 44 25.5.09...

-

Page 45: Source Replacement

• Allan keys in the required sizes. • 2 pairs of pliers to take hold of source and source holder. Uni-Probe LB 490 1 – 45 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 46 7 Source Replacement Volume 1 Cordon off an area consistent with the activity of the source. Pre- vent persons from approaching. If sufficient space is available, the source can be replaced in the shielding installed at the measuring site. To this end, bring the new source in its transport shielding close to the measuring site.

- Page 47 IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES' Source Trans- port Manager. This completes the point source replacement. Uni-Probe LB 490 1 –...

-

Page 48: Rod Source Replacement

7 Source Replacement Volume 1 Rod Source Replacement This section describes how to replace rod source in the following shieldings: – Type 80 – Type 100 – Type 120 – Type 150 – Type 200 – Type 270 Radioactive sources may be replaced only by competent and licensed persons, taking into account official regulations. -

Page 49: Shielding1

7-3 on page 1–50). With multi-part sources, the rings on the rod source indicate the installation order and position. It is important to observe these instructions when replacing a source. Uni-Probe LB 490 1 – 49 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 50 7 Source Replacement Volume 1 Shielding Rod sources Top: 1 ring Bottom: 2 rings Figure 7-3 Markings on multi-part sources and shieldings 7.2.1 Procedure for Source Replacement Figure 7-4 Dismounting rod source shielding Unscrew the head flange (1) using a suitable Allan key. ...

- Page 51 IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES' Source Trans- port Manager. This completes the source replacement. Uni-Probe LB 490 1 – 51...

- Page 52 7 Source Replacement Volume 1 Point Source Replacement on Rotary Cylinder Shielding This section describes how to replace point sources in the following shieldings: – Type 80 – Type 100 – Type 120 – Type 150 – Type 200 – Type 270 When replacing a source, you have to work with the unshielded source for a short time.

- Page 53 Do not push the pipe wrench tight too much to prevent damage to the source. Hold the source far Uni-Probe LB 490 1 – 53 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 54 IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES' Source Trans- port Manager. This completes the source replacement. 38477BA2B 1 – 54...

-

Page 55: Radiation Exposure During Source Replacement

If the above assumptions do not apply, the calculations have to be corrected accordingly. Actually, it can only be another working time which has a proportional effect on the result of the calculated dose rate. Uni-Probe LB 490 1 – 55 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 56 7 Source Replacement Volume 1 38477BA2B 1 – 56 25.5.09...

-

Page 57: Source Disposal

• Radioactive material can be returned only after you have received permission from BERTHOLD TECHNOLOGIES. We would be happy to send you a quotation on the disposal costs to be expected. Uni-Probe LB 490 1 –... - Page 58 8 Source Disposal Volume 1 • The radioactive material has to be shipped to Wildbad carriage paid. BERTHOLD TECHNOLOGIES does not take over any costs for customs clearance or transport. • BERTHOLD TECHNOLOGIES has to be informed in advance about the return transport. Radioactive material that is shipped to Berthold without prior notice will not be accepted by BERTHOLD TECHNOLOGIES.

- Page 59 Telephone no.: Town / Postal code Country: Activity Source No. Isotope Source will be returned for disposal Other instructions (please complete) ........................................................... Shielding may be disposed off Uni-Probe LB 490 1 – 59 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 60 8 Source Disposal Volume 1 New sources to be inserted in the shielding(s) according to sender's order no.: ....../ our order confirmation no. Shielding to be returned empty to sender Shielding to be returned to sender after repair Sender's repair order no.: ....../ our order confirmation no. Return of a shielding on loan from sender Sender's order no.: ....../ our order confirmation no.

-

Page 61: Functional Safety

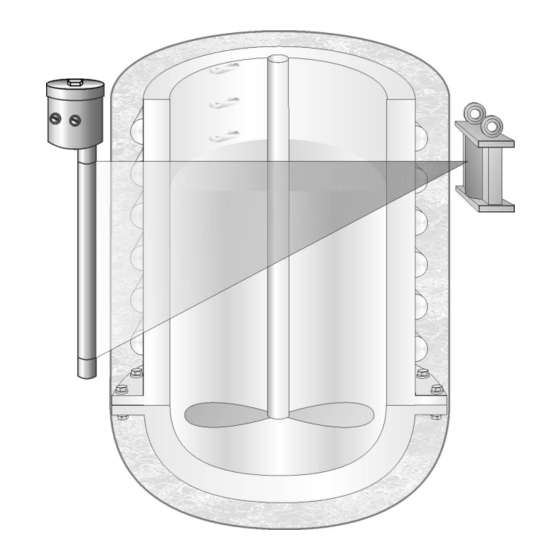

Shielded source Uni-Probe LB 490 Current output - Co-60 4–20mA - Cs-137 with mechanical locking mechanism Figure 9-1 Overview measuring system with Uni-Probe LB 490 The information applies to the following device versions: DEVICE Description Hardware Software revision revision Level... - Page 62 9 Functional Safety Volume 1 The software revision can be viewed on the Device Description menu, menu item REVIEW The hardware revision (Device Rev.) is indicated on the outside of the housing and inside the connection box. 38477BA2B 1 – 62 25.5.09...

-

Page 63: Use And Function

Volume 1 9 Functional Safety Use and Function The Level Gauge Uni-Probe LB 490 is employed for continuous level measurement and monitoring and for the detection of limit levels of liquids and bulk material in and pipelines. Source Measuring system LB 490... -

Page 64: Safety Function

9 Functional Safety Volume 1 Safety Function The safety function of the measuring system comprises the mea- surement and detection of levels caused by the presence of product being measured in the measuring path between radiation source and measuring system. Safety Requirement Safety integrity level Operating mode with low... -

Page 65: Project Planning

(MTTR = 8h). • In the operating mode with low demand rate the reaction time of the LB 490 to dangerous detected faults is max. 15 minutes. Uni-Probe LB 490 1 – 65 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 66 9 Functional Safety Volume 1 • In the operating mode with high demand rate the reaction time of the LB 490 to dangerous apparent faults is max. 1 day. If the demand rate is not more than once a year, the measuring device may be operated as a safety-relevant sub-system in the operating mode with low demand rate (IEC 61508-4, 3.5.12).

-

Page 67: Getting Started

User’s Manual. See Volume 3, chapter "4.3.2 Empty Cali- bration". Full calibration The level must be above the measuring range. If this is not possible, you may also close the source shielding. If only the Uni-Probe LB 490 1 – 67 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 68 Make sure that the absorption of the closed shielding nearly corresponds to the absorption of the product. If in doubt, please contact BERTHOLD TECHNOLOGIES or your local repre- sentative. – Full calibration has to be carried out as described in the User’s Manual.

-

Page 69: Behavior During Operation And During Malfunctions

Replacement of the measuring system is rather simple; it is described in the User’s Manual. • If parts are replaced as a result of a detected failure, please inform BERTHOLD TECHNOLOGIES accordingly (including fail- ure description). • If modifications in the product, the gas pressure, or the con- struction of the tank in the area of the radiation path are car- ried out, the measurement has to be calibrated again. -

Page 70: Recurrent Performance Test

9 Functional Safety Volume 1 Recurrent Performance Test The recurrent performance test is used to check the safety function to uncover possibly undetected dangerous failure. The operational capability of the measuring system has to be checked in adequate intervals. It is in the responsibility of the operator to select the type of test and the proof test interval. -

Page 71: Safety-Technical Data

= 2 years <0.064 x 10 Proof = 5 years <0.160 x 10 Proof HFT = 1 (Hardware Fault Tolerance) Two-channel architecture 1002 Shielding with source 2 Uni-Probes Tank Uni-Probe LB 490 1 – 71 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 72 9 Functional Safety Volume 1 1. For common cause ß = 2% = (PFD + ß x PFD 1002 1001 1001 = 1 year <6.5 x 10 Proof = 2 years <13.2 x 10 Proof = 5 years <34.5 x 10 Proof 2.

-

Page 73: Certificate Functional Safety

Volume 1 9 Functional Safety 9.10 Certificate Functional Safety Uni-Probe LB 490 1 – 73 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 74 9 Functional Safety Volume 1 38477BA2B 1 – 74 25.5.09...

- Page 75 Volume 1 9 Functional Safety Uni-Probe LB 490 1 – 75 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 76 9 Functional Safety Volume 1 38477BA2B 1 – 76 25.5.09...

- Page 77 Volume 1 9 Functional Safety Uni-Probe LB 490 1 – 77 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 78 9 Functional Safety Volume 1 38477BA2B 1 – 78 25.5.09...

- Page 79 Volume 1 9 Functional Safety Uni-Probe LB 490 1 – 79 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 80 9 Functional Safety Volume 1 38477BA2B 1 – 80 25.5.09...

- Page 81 Volume 1 9 Functional Safety Uni-Probe LB 490 1 – 81 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 82 9 Functional Safety Volume 1 38477BA2B 1 – 82 25.5.09...

-

Page 83: Safety Instructions For The Types Of Protection Atex / Fm / Csa

BERTHOLD TECHNOLOGIES. Prerequisite for working in these areas is that the personnel knows all applicable rules and regulations. Users have to keep in mind: –... - Page 84 Spare parts for measuring devices used in the ex-area may only be Repair and spare part exchange installed by the BERTHOLD TECHNOLOGIES service or by service engineers authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be returned to the manufac- turer for repair.

-

Page 85: Overview Ex-Versions

IP66 T80°C IP66 T80°C Signal output intrinsically safe Ex temp. range -40 … +60°C -20 … +50°C -20 … +60°C -40 … +60°C -20 … +60°C -40 … +60°C Uni-Probe LB 490 1 – 85 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 86 10 Safety instructions ATEX/FM/CSA Volume 1 Ex temp. range -40 … +80°C -20 … +50°C -20 … +60°C -40 … +80°C -20 … +60°C -40 … +80°C Operat. temp. -40 … +50°C -20 … +50°C -20 … +50°C -40 … +50°C -20 …...

-

Page 87: Type Of Protection Atex

The tightening torques for the screwed cable glands supplied by BERTHOLD TECHNOLOGIES are listed in the technical documents in chapter 5, page 2–247. Uni-Probe LB 490 1 –... -

Page 88: Type Of Protection Fm/Csa

10 Safety instructions ATEX/FM/CSA Volume 1 Armoured cables Special screwed cable glands are needed for armoured cables. How to install these cables is described in the installation instructions for the cable conduits used. 10.2.1 Characteristic Features of Versions with Intrin- sically Safe Current Output •... -

Page 89: Certificates

Volume 1 11 Certificates Certificates 11.1 ATEX Certificate Uni-Probe LB 490 1 – 89 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 90 11 Certificates Volume 1 38477BA2B 1 – 90 25.5.09...

- Page 91 Volume 1 11 Certificates Uni-Probe LB 490 1 – 91 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 92 11 Certificates Volume 1 38477BA2B 1 – 92 25.5.09...

- Page 93 Volume 1 11 Certificates Uni-Probe LB 490 1 – 93 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 94 11 Certificates Volume 1 38477BA2B 1 – 94 25.5.09...

- Page 95 Volume 1 11 Certificates Uni-Probe LB 490 1 – 95 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 96 11 Certificates Volume 1 38477BA2B 1 – 96 25.5.09...

- Page 97 Volume 1 11 Certificates Uni-Probe LB 490 1 – 97 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 98 11 Certificates Volume 1 38477BA2B 1 – 98 25.5.09...

- Page 99 Volume 1 11 Certificates Uni-Probe LB 490 1 – 99 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 100 11 Certificates Volume 1 38477BA2B 1 – 100 25.5.09...

- Page 101 Volume 1 11 Certificates Uni-Probe LB 490 1 – 101 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 102 11 Certificates Volume 1 38477BA2B 1 – 102 25.5.09...

- Page 103 Volume 1 11 Certificates Uni-Probe LB 490 1 – 103 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 104 11 Certificates Volume 1 38477BA2B 1 – 104 25.5.09...

- Page 105 Volume 1 11 Certificates Uni-Probe LB 490 1 – 105 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 106 11 Certificates Volume 1 38477BA2B 1 – 106 25.5.09...

- Page 107 Volume 1 11 Certificates Uni-Probe LB 490 1 – 107 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 108: Fm Certificate

11 Certificates Volume 1 11.2 FM Certificate 38477BA2B 1 – 108 25.5.09... - Page 109 Volume 1 11 Certificates Uni-Probe LB 490 1 – 109 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 110: Csa Certificate

Master Contract: 215040 Project: 1876850 Date Issued: 2007/02/09 Issued to: Berthold Technologies GMBH & CO KG Calmbacher Str 22 Bad Wildbad, 75323 Germany Attention: Francisco Silva The products listed below are eligible to bear the CSA Mark shown David Wood... - Page 111 Volume 1 11 Certificates Uni-Probe LB 490 1 – 111 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 112: Eg Declaration Of Conformity

11 Certificates Volume 1 11.4 EG Declaration of Conformity 38477BA2B 1 – 112 25.5.09... -

Page 113: Material Safety Data Sheet For Lubricant Oks

Volume 1 11 Certificates 11.5 Material Safety Data Sheet for Lubri- cant OKS 217 Uni-Probe LB 490 1 – 113 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 114 11 Certificates Volume 1 38477BA2B 1 – 114 25.5.09...

- Page 115 Volume 1 Notes: Uni-Probe LB 490 1 – 115 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 116 Subject to change in the course of further technical development. © BERTHOLD TECHNOLOGIES GmbH & Co. KG 2009 Language: English Printed in Germany 05/2009 Rev. no.: 05 BERTHOLD TECHNOLOGIES GmbH & Co. KG Calmbacher Str. 22 D-75323 Bad Wildbad Germany www.Berthold.com...

- Page 117 Volume 2 Uni-Probe Installation...

- Page 118 Volume 2 38477BA2B 2 – 118 25.5.09...

-

Page 119: System Description

Measuring System 1.1.1 Basic Measuring Configuration Uni-Probe LB 490 is a level gauging system consisting of scintilla- tion detector and evaluation unit in one housing. The Uni-Probe LB 490 utilizes the radiometric measuring method, i.e. the absorption of Gamma radiation passing through the product being measured. - Page 120 Volume 5: SIMATIC PDM User Interface HART 1.1.3 Measuring Geometries The hardware and software of the Uni-Probe LB 490 system makes it easy to adapt the system to different measuring geometries and measuring tasks. Therefore, the settings and parameters of the measuring device have to be defined with care for the particular measuring task.

- Page 121 Auxiliary Unit into the Main Unit. As an alternative to the multi-detector mode, you may also use the Tower-Sens version which allows measurement ranges up to 8m. Uni-Probe LB 490 2 – 121 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 122 1 System Description Volume 2 Assignment of activities Main Unit / Auxiliary Unit Main Unit Auxiliary Unit Creation of Auxiliary Unit raw data Creation of Auxiliary Unit raw data Consistency check of Main Unit Consistency check of Auxiliary Unit raw data raw data Query, sum or averaging of all raw Provision of raw data for the Main...

-

Page 123: Uni-Probe Hardware

Volume 2 1 System Description Uni-Probe Hardware 1.2.1 Probe The Uni-Probe LB 490 Level Gauge comprises one detector and one evaluation unit which are accommodated in one housing. 3/4" NPT conduits Power supply Preamplifier & HV generation Photomultiplier Scintillator Evaluation electronics ®... - Page 124 The user defines in a multi-detector system which Uni-Probe is a Main or an Auxiliary Unit. ® HART The Uni-Probe LB 490 uses the protocol to communicate. Device communication Configuration, parameter setting and calibration of the Uni-Probe, as well as the output and display of the digital units of measure are carried out either: ®...

-

Page 125: Measuring Principle

For this reason, the radiometric measur- ing principle ensures high reliability and low maintenance. Source Detector Figure 1-4 Measuring Principle Uni-Probe LB 490 2 – 125 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 126: Measuring Arrangements

The respective selections are made during the planning stage and must be observed during assembly and commissioning. The following scintillator types are available for the level gauge Uni-Probe LB 490: ID no. Size Description 38477-X1X, 47678-X1X, 500XX-X1X... - Page 127 - detector distance or for very thick vessel walls, one can choose an arrangement with rod source and rod detector to reduce the source activity (see Figure 1-7). In this Uni-Probe LB 490 2 – 127 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 128 1 System Description Volume 2 case, the lengths of source and detector have to be adjusted to the size of the measuring range to be covered. The non-linearities obtained in the upper range of the characteristic curve are compensated for by means of a correction line adjusted to the measuring site and stored in the evaluation electronics.

- Page 129 The arrangement shown in Figure 1-9 is used for limit switches, e.g. to rule out overflowing when filling a vessel. Level Source Detector Detector signal Figure 1-9 Point source / Point detector arrangement for limit switches Uni-Probe LB 490 2 – 129 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 130: Technical Data

1 System Description Volume 2 Technical Data If you are working under different operating conditions, please con- tact BERTHOLD TECHNOLOGIES. for non ex-applications: Operating temperature range Operation: -40 … +50°C Storage: -50 … +55°C according to ATEX: Ex-protection DMT 02 ATEX E 132 II 2 GD Ex d IIB/IIC T6 (Gas Ex, Zone 1&2) - Page 131 250V / 5A or 24V 5A non-inductive Voltages larger than 150V must be grounded. Relay contacts are not protected by fuses. Relay 1: Error messages Uni-Probe LB 490 2 – 131 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 132 1 System Description Volume 2 Relays 2 to 4 are also available for the following functions: – Min / Max – Halt – Detector temperature – Radiation interference 0.5 to 1.5mm Terminal cross-section: 3/4" NPT, 4 each, closed by dummy plugs Cable conduits: The cable cross-section is dependent on the cable screws used (see Cable cross-section...

-

Page 133: Detector Codes

38477-X7X 1500mm 47678-X7X 500XX-X7X 38477-X9X 2000mm 47678-X9X 500XX-X9X Super-Sens 53214-XXX 150x150mm Tower-Sens 50250-XXX 1000mm 50250-XXX 2000mm 50250-XXX 3000mm 50250-XXX 4000mm 50250-XXX 5000mm 50250-XXX 6000mm 50250-XXX 7000mm 50250-XXX 8000mm Uni-Probe LB 490 2 – 133 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 134: Uni-Probe Lb 490 Nomenclature

1 System Description Volume 2 Uni-Probe LB 490 Nomenclature The first part of the ID no. describes the device version with respect to interfaces and explosion protection, the second part the variants of cooling, scintillator and mains supply. The type of com- munication and the signal output can also be identified via the LB numerical code. -

Page 135: Lb 490 Super-Sens Nomenclature

Volume 2 1 System Description LB 490 Super-Sens Nomenclature With the Uni-Probe LB 490 Super-Sens, the ID no. describes the device version, especially the last three digits. ID no. Communication Ex approvals Power supply Collimator Water cooling ® 53214-001 HART... -

Page 136: Lb 490 Tower-Sens Nomenclature

1 System Description Volume 2 LB 490 Tower-Sens Nomenclature With the Uni-Probe LB 490 Tower-Sens, the ID no. describes the device version, especially the last three digits. ID no. Communication Ex approvals Power supply Collimator Water cooling length ® 50250-001... - Page 137 1000mm with Fieldbus ™ 50250-036 FOUNDATION Ex-i/ATEX 2000mm with Fieldbus ™ 50250-038 FOUNDATION Ex-i/ATEX - 240V 1000mm with Fieldbus ™ 50250-040 FOUNDATION Ex-i/ATEX - 240V 2000mm with Fieldbus Uni-Probe LB 490 2 – 137 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 138 1 System Description Volume 2 38477BA2B 2 – 138 25.5.09...

-

Page 139: Installation

Take the shielding out of the box just prior to installation. Up to that time, store the shielding with the radioactive source in a location that is guarded against unauthorized access, see chapter "2.1.4 Installation Sites" on page 2–142. Uni-Probe LB 490 2 – 139 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 140 If the Uni-Probe housing receives a mechan- ical blow, e.g. because it is dropped, then you have to return the Uni-Probe to BERTHOLD TECHNOLOGIES for inspection. Carefully install the mounting brackets and fixtures using the draw- ings of the shielding and taking into account the circumstances at the measuring site.

-

Page 141: Transport To The Installation Site

The operator has to take suitable provisions for temporary storage of sources at the place of installation between the period from source delivery to the start of the installation work. Uni-Probe LB 490 2 – 141 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 142 The exact position for your sys- tem parts is stated on the calculation documents and the technical information prepared by BERTHOLD TECHNOLOGIES. 2.1.5 Unpacking and Cleaning System Parts After unpacking, compare all parts with the packing list and check if the shipment is complete and shows any sign of damage.

-

Page 143: Source-Detector Arrangements

Volume 2 2 Installation Source-Detector Arrangements BERTHOLD TECHNOLOGIES offers a number of solutions for your applications. The schematic drawings below show examples of dif- ferent arrangements and refer you to the respective installation instructions. Since other arrangement than those shown here are possible, the installation of the detector side and the source side will be explained separately. - Page 144 2 Installation Volume 2 IMPORTANT If a suitable arrangement example should be missing for your spe- cial application, you will receive special documents in advance. Please contact us if you did not receive these documents. Please let us know the source number (you find it on the shielding) and we will provide you with the required information on this measuring point.

-

Page 145: Detector Protection

The ambient temperature must not exceed the values specified in the technical data (see Volume 2, "1.5 Technical Data", page 2– 130). The Uni-Probe LB 490 with water cooling jackets has to be used if temperatures exceeding 50° C are expected. The cooling water cycle has to remain in operation even when the instrument is turned off, if the temperature is likely to exceed 50°C. - Page 146 2 Installation Volume 2 2.3.2 Sun Protection If the Uni-Probe LB 490 is installed outdoors, it has to be protected against exposure to direct sunlight by a cover. Figure 2-1 Sun protection 2.3.3 Heavy-Duty Environments When selecting the installation site, keep in mind that the Uni-Probe LB 490 should not be affected by mechanical stress or heavy vibrations, in order not to restrict its service life.

-

Page 147: Detector Installation

100mm. The clamps have to be arranged so that no heat is transferred to the detector. Uni-Probe LB 490 2 – 147 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 148 2 Installation Volume 2 Point sources top fixing clamp 134 mm bottom fixing clamp » 100 mm Figure 2-2 Rod detector installation, example with point source Rod detector with detector shielding (collimator), with and with- out water cooling Due to the weight of the collimator, a mounting foot has to be used which will carry the detector with collimator.

- Page 149 The Tower-Sens detector supports a detector length of up to 8m. If needed, the Tower-Sens can be extended in several parts. The basic module for the Tower-Sens detector is always arranged at the Uni-Probe LB 490 2 – 149 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 150 2 Installation Volume 2 bottom (connection and evaluation unit also at the bottom) (see Figure 2-5). End cap Source 1 Installation Fixing clamp base Source 2 Connection clamp Detector mounting base Electronics housing Figure 2-5 Tower-Sens arrangement, example with basic module and two extension modules Up to three extension modules with 2m length each can be put on top of the two possible basic modules of 1m or 2m length.

- Page 151 20cm and secure it with the fixing clamp. If this is the only extension module, you have to install the end cap first, see page 2–154. IMPORTANT Protect the module ends against humidity and dirt. Uni-Probe LB 490 2 – 151 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 152 2 Installation Volume 2 End cap Connection clamp Fixing clamp Connection clamp Mounting plate Mounting bracket Extension module Basic module All dimensions in mm for 1m basic module (2m basic module) Figure 2-6 Structure of a Tower-Sens detector Take off the plastic protection cap from the extension module and then from the basic module.

- Page 153 Pull off the protective foils from the basic module and on the bottom of the extension module (Figure 2-8f). Place the guide sleeve on the basic module (Figure 2-9g). Uni-Probe LB 490 2 – 153 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 154 2 Installation Volume 2 Figure 2-9 Installation of an extension module Open the fixing clamp of the extension module, push the exten- sion module into the guide sleeve and carefully push the mod- ule down until you reach the basic module (Figure 2-8h and i). ...

- Page 155 The combination of point detector and point source is typically used for two different types of application: for measurement of a limit level (Figure 2-11) or for continuous level measurement (Figure 2-12). Uni-Probe LB 490 2 – 155 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 156 2 Installation Volume 2 Bracket provided by customer Uni-Probe Bracket provided by customer Point Detector Figure 2-11 Limit level measurement Installation kit Anti-tipping device provided with clamps, by customer optional Rod source shielding Bracket by cus- tomer Mounting base provided by customer Figure 2-12 Continuous level measurement As shown in Figure 2-12, the size of the measurement range for...

- Page 157 The radiation window of the Super-Sens detector has to be aligned toward the source. For more information on the fixtures please see the technical draw- ings in section 6.3.7 on page 2–267. Uni-Probe LB 490 2 – 157 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 158 2 Installation Volume 2 Figure 2-13 Super-Sens with frontal irradiation IMPORTANT Please observe the alignment of the radiation window, see dimen- sional drawing of the detector (page 2–264). Side view Beam path View from above Figure 2-14 Detector installation 38477BA2B 2 –...

- Page 159 Figure 2-15 Super-Sens with radial (lateral) irradiation Anti-tipping device provided by customer Super-Sens Mounting base Rod source provided by shielding customer Mounting base provided by customer Figure 2-16 Super-Sens and rod source Uni-Probe LB 490 2 – 159 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 160: Mounting The Shielding

2 Installation Volume 2 Mounting the Shielding Shielding, source type, isotope and activity for each measurement configuration will be selected together with the customer to ensure compliance with the locally permitted dose rate limits. Co-60 or Cs-137 point sources are used which are tightly welded into a sturdy stainless steel capsule. - Page 161 (6) is firmly connected with a lever (4). The positions OPEN and CLOSED and the removal of the sources by unauthorized persons are secured by a padlock (3). Uni-Probe LB 490 2 – 161 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 162 2 Installation Volume 2 1 Shielding 2 Source fixture 3 Padlock 4 Locking bolt 5 Point sources 6 Locking core 7 Beam path 8 Cover plate, front Figure 2-20 Cross-section drawing and photo of the point source shielding, beam path open Turning the lever (4) will also rotate the locking core and open the radiation exit channel towards the detector.

- Page 163 During installation, the shielding and thus the useful beam must be aligned such that they face the detector. Side view max. 45° Top view Figure 2-22 Point source shielding 45° Uni-Probe LB 490 2 – 163 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 164 Install shielding 45° determine the background for rod detectors (see Volume 3, section 4.3.1 on page 3–351). Point source shielding Uni-Probe LB 490 Mounting Marking groove bracket Figure 2-23 Point source with rod detector The standard arrangement (Figure 2-23) shows the mounting posi- tion of the shielding with point source;...

- Page 165 2 base with an elongated hole allows the alignment of the source at the detector Figure 2-25 Installation proposal shielding; size B see section 6.6 on page 2–281 Uni-Probe LB 490 2 – 165 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 166 2 Installation Volume 2 Eyebolts Direction of rotation for opening Order-related commission number Transportation safety device Do not remove the transpor- Designation of measuring tation safety device before system (option) completing the installation Type label of shielding with Borehole for lever model name and serial num- Source type label with information on source and...

- Page 167 Depending on the size of the measuring range, this arrangement can be realized with one or several detectors. Source 1 Uni-Probe LB 490 Marking grooves Source 2 Figure 2-27 Multi-source arrangement Uni-Probe LB 490 2 – 167 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 168 2 Installation Volume 2 2.5.4 Rod Sources Increased radiation dose due to open beam path! A too high dose of radiation may be harmful to your health. A source may be transported only in its shielding. The shielding must be closed during transportation and installation. For rod sources, cylinder-shaped shieldings having the length of Rod source shielding the source are used which are provided with a radiation exit slit...

- Page 169 ("G") and the center of the detector are on a horizontal line, which defines the upper point of the measuring range (Max). Rod source Figure 2-30 Rod source arrangement, see also next table Uni-Probe LB 490 2 – 169 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 170 2 Installation Volume 2 Diameter of shielding (in mm) G (in mm) The installation height of the supporting structure to be provided by the customer has to be measured using the dimensional drawings of the shielding. The size and stability of the supporting structure or another suit- able mounting device for the shielding has to match the size and total weight of the shielding.

- Page 171 As an option, rod source shieldings may be supplied with a pneu- Pneumatic actuator matic actuator. You find the technical data in section Uni-Probe LB 490 2 – 171 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 172 2 Installation Volume 2 "6.8 Pneumatic for Rod and Point Source Shieldings" on page 2– 284. Risk of crushing! The cylinder rotates automatically! Fingers may get jammed on the strap or on the locking piece. Never change the factory-adjusted setting for attenuation of the pneumatic actuator.

- Page 173 This position can now be locked again with the padlock to prevent inadvertent closing of the beam path during operation. If locking with the lock should not be permitted, you may also fix the position with the supplied screw. Uni-Probe LB 490 2 – 173 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 174 2 Installation Volume 2 2.5.6 Flange Shieldings in the Dip Tube Increased radiation dose due to open beam path! A too high dose of radiation may be harmful to your health. A source may be transported only in its shielding. The shielding must be closed during transportation and installation.

- Page 175 Uni-Probe LB 490 2 – 175 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 176 2 Installation Volume 2 Shielding with source Pressure control Protection gas Vessel wall Detector Dip tube Protective tube Figure 2-35 Dip tube installation with rod source and rod detector One or up to five rod sources can be installed in a shielding, depending on type (see section 6.10 on page 2–286).

- Page 177 Operating a flange shielding with steel cable A steel cable for positioning of the rod source is supplied for each source. Uni-Probe LB 490 2 – 177 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 178 2 Installation Volume 2 Caution: Source may fall into the dip tube. If the source drops into the dip tube during applications where the flange shielding has been installed onto the vessel from above, it can be recovered again only with a lot of work and under the super- vision of the Radiation Safety Officer.

- Page 179 The eyebolts can also be used as anti-tipping devices in the assembled state Engage latch in clutch Source locking Latch engaged in clutch mechanism Figure 2-37 Flange shielding with steel cable Uni-Probe LB 490 2 – 179 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 180 2 Installation Volume 2 Pull the source back into the shielding using the steel cables or Move source again to the shielding the shaft core. position Fix the source with the clamping screw at the head piece. If the shielding contains several sources, then the order in which the sources are pulled back into the shielding is important to rule out that the cables get twisted: ...

- Page 181 Open the fixing screw at the head piece. Figure 2-41 Open fixing screw Open the source shielding. Figure 2-42 Open source shielding Push the shaft core in up to the limit stop. Uni-Probe LB 490 2 – 181 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 182 2 Installation Volume 2 Figure 2-43 Push the shaft core in Fix the position with the fixing screw at the head piece. Attach the covering cap again. Secure the lock with a padlock or the safety screw. The source is now installed.

-

Page 183: Electrical Installation

For the supply line we recommend a backup fuse of 1A slow-blow. Backup fuse This fuse allows you to turn off the Uni-Probe, if necessary, and also to monitor the supply line to the Uni-Probe. Uni-Probe LB 490 2 – 183 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 184: Conduits

3 Electrical Installation Volume 2 Conduits The Uni-Probe housing is provided with ¾" NPT conduits through which the electrical cables are installed according to regulations. Cable pipes or screwed cable glands can be screwed into the con- duits. They have to be licensed for the respective type of protection and have to be installed carefully in accordance with regulations! Make sure that the thread turns are clean and apply the supplied lubricant OKS 217 completely onto the NPT thread to be screwed... - Page 185 The tightening torques for the screwed cable glands supplied by BERTHOLD TECHNOLOGIES are listed in the technical documents in chapter 5, page 2–247. Armored cables Special screwed cable glands are needed for armored cables.

- Page 186 3 Electrical Installation Volume 2 If intrinsically safe signal lines are passed through areas with Installing intrinsically safe signal potentially explosive dust atmosphere or through zone 0, then they lines must be protected against electrostatic charge. 3.1.2 Please keep in mind for FM connection type A conduit seal has to be installed on each conduit used directly behind the Uni-Probe housing.

-

Page 187: Terminals

REL 1 Dig IN 1 Digital input 1 Error Halt REL 2 Alarm REL 3 Alarm REL 4 RS -232 interface Alarm (for software update) Figure 3-2 Terminals Uni-Probe LB 490 2 – 187 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 188 Max. cable length with Berthold cable # 32024: – 3300m at 120Ohm – 1600m at 250Ohm – 800m at 500Ohm We recommend using a screened cable, The BERTHOLD TECHNOLOGIES cable #32024 is shielded. 53 - 54 Not used 55 - 56 Not used 57 - 60 RS-485 for multi-detector mode.

-

Page 189: Switch Setting

Ω at the current output. ON OFF 120 Ohm / RS-485 4–20mA active passive with complete electronics Figure 3-3 Digital board Uni-Probe LB 490 2 – 189 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 190 3 Electrical Installation Volume 2 1. Capacitor-buffered real-time clock 2. Slide switch for current output With this slide switch you can choose whether power is gener- ated by the current output or supplied by an external source. Move slide switch to the left: current output is passive Move slide switch to the right: current output is active Versions with intrinsically safe current output may not be switched over, since the connected buffer amplifier serves as current output to the...

- Page 191 3 Electrical Installation Only a screened cable with twisted wires may be used as cable for Multi-detector mode wiring the RS485, e.g. the BERTHOLD TECHNOLOGIES cable, ID no. 32024. Connect the cable screen on both sides to the grounding bolt.

-

Page 192: Connecting The Uni-Probe

3 Electrical Installation Volume 2 Connecting the Uni-Probe If cables have already been connected to the Uni-Probe, then please keep in mind: Danger, electric shock! Open the housing cover of the Uni-Probe only after the device, pos- sibly connected relay contacts and all in- and outputs have been disconnected from power. - Page 193 "5 Screw Fittings and Accessories" on page 2–247. For conduits in the hazardous area: Seal the conduit seal behind the cable ducts using a suitable filling material. Uni-Probe LB 490 2 – 193 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 194 3 Electrical Installation Volume 2 Do not remove the lubricant on the housing cover. If the thread is dry, you have to apply lubricant once more. Use only the lubricant OKS 217. Apply the lubricant evenly on the thread turns such that the thread turns are completely covered.

-

Page 195: Uni-Probe With Ex I Current Output

If 20m cable are not enough to reach the next distribution cabinet, you may use an intrinsically safe terminal box (ID no. 49546) to extend the cable. See also "3.5.3 Terminal Box" on page 2–198. Uni-Probe LB 490 2 – 195 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 196 3 Electrical Installation Volume 2 3.5.2 Uni-ProbeConnection Box Covering cap Isolating repeater Fuses for Isolating repeater (only for version LB 49x-11) Figure 3-6 Uni-Probe open The isolating repeater is mounted on the side in the connection box on a top hat rail. To ensure intrinsic safety, please do not: •...

- Page 197 The current output of the isolating repeater cannot be switched over between active and passive. The table on page 2–199 shows which type of isolating repeater is used in your device. Uni-Probe LB 490 2 – 197 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 198 3 Electrical Installation Volume 2 3.5.3 Terminal Box Figure 3-8 Terminal box Use the terminal box (ID no. 49546) in order to extend the fac- tory-mounted 20m long current signal cable to the next distribu- tion point. The current output signal and the screen have to be looped via the terminal box.

- Page 199 -20°C … +50°C R.steel (passive) ID no. 47678-XXX IP66 T80°C Type 9164/13-22-09 LB 490 Super-Sens Ci=3.36nF; Li=13.65µH ID no. 53214-009 … -016 LB 490 Tower-Sens ID no. 50250-009 … -016 Uni-Probe LB 490 2 – 199 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 200 3 Electrical Installation Volume 2 see chapter 1.5 Storage temperature Fuses for power supply 24 VAC/DC and 230 VAC: Fuses 2 ea. 1.25A breaking capacity 1500A Type Littelfuse Berthold ID no. 46719 Littelfuse order number: 215 1.25 Fuses for isolating repeater: Explosion hazard! If this fuse fails, the complete Uni-Probe has to be returned to the manufacturer for inspection, since the intrinsic safety is no longer...

- Page 201 Uni-Probe LB 490 2 – 201 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 202 3 Electrical Installation Volume 2 I.S. Isolators mA - Isolating Repeater Type 9164 Intrinsically safe input (I.S.) or ● increased safety protection Ex e version Bi-directional HART ● transmission 4 ... 20 mA Suitable for 4-wire transmitter ● 1 channel ●...

- Page 203 ... 260 (AC-Impedance HART) (AC-Impedance HART) Communication signal HART transmission bi-directional; HART transmission bi-directional; 0,5 kHz ... 5 kHz 0,5 kHz ... 5 kHz Polarity reversal protection yes 10.11.2004 Uni-Probe LB 490 2 – 203 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 204 3 Electrical Installation Volume 2 mA - Isolating Repeater Type 9164 Technical Data 9164/13-22-08 (I.S. Input) 9164/13-22-09 (Ex e Input) I.S. output Version passive (current sink up) passive (current sink up) Signal output 3.6 mA ... 21 mA with HART 3.6 mA ...

- Page 205 Dimension drawing (all dimensions in mm) - subject to alterations 0932E00 We reserve the right to make alterations to the technical data, weights, dimensions, designs and products available without notice. The illustrations cannot be considered binding. 10.11.2004 Uni-Probe LB 490 2 – 205 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 206: Uni-Probe With Signal Output Profibus Pa / Foundation

3 Electrical Installation Volume 2 Uni-Probe with Signal Output ™ Profibus PA / FOUNDATION Fieldbus (not intrinsically safe) The following special information is valid for the devices: • Profibus PA – LB 490 Uni-Probe ID no. 50035-XXX – LB 490 Super-Sens ID no. 53214-049 -056 …... - Page 207 This module is installed on the digital board of the Uni-Probe (see Figure 3-11). 1: + Terminals for Fieldbus communication 2: - Digital board Fieldbus module Figure 3-11 Digital board with field bus module Uni-Probe LB 490 2 – 207 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 208 3 Electrical Installation Volume 2 3/4" NPT conduit Power supply 3/4" NPT conduit Equipotential bonding Fuses Power Digital Equipotential bonding supply board busbar provided by customer 3/4" NPT conduit RS -232 3/4" NPT conduit Figure 3-12 Connection box with field bus module ...

-

Page 209: Uni-Probe With Intrinsically Safe Signal Output Profibus Pa / Foundation

If 20 m cable are not enough to reach the next distribution cabinet, you may use an intrinsically safe terminal box (ID no. 49546) to extend the cable. See also "3.5.3 Terminal Box" on page 2–198. Uni-Probe LB 490 2 – 209 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 210 3 Electrical Installation Volume 2 Danger, electric shock! If the housing is open, you may get in contact with live parts if the power supply is turned on. Before turning on the power supply, carefully close the housing with the housing cover. Screw the housing cover completely onto the housing and pull it tight using a torque of 25Nm (reference value).

- Page 211 Uni-Probe is negligible. However, the cable data of the 20m firmly connected cable has to be taken into account for interconnection. The cable data of the 20m cable length are as follows: Capacity: 2.84nF Inductivity: 0.013mH Uni-Probe LB 490 2 – 211 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 212 3 Electrical Installation Volume 2 The bus cable (ID no. 46413, UNITRONIC BUS PA FC (BU) 1x2xAWG18/1) supplied by Berthold Technologies has the following properties: Capacity (1kHz conductor/conductor) 50nF/km Capacity (1kHz conductor/screen) 92nF/km Inductivity (31.25kHz) 0.65mH/km … Ambient temperature range -20°C...

-

Page 213: Repair, Maintenance And Service

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 214 4 Repair, Maintenance and Service Volume 2 Danger of explosion when opening the housing in an explosive atmosphere! Please wait 30 minutes after you have turned off the power supply before you open the housing. The cooling-off time of 30 minutes ensures that possibly overheated components have enough time to cool off and cannot ignite the explosive atmosphere.

- Page 215 Uni-Probe housing cover. Please use the visual inspection schedule on page 2–216 and the plan for checking the connection room on page 2–217. Uni-Probe LB 490 2 – 215 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 216: Visual Inspection Of The Uni-Probe

4 Repair, Maintenance and Service Volume 2 Visual Inspection of the Uni-Probe If you answer one of the following questions with “No”, you have to record the action you have taken to remedy this deficiency in the last column. Make sure before you take the device into operation again that the provisions you have taken are correct by consulting with the person in charge of explosion protection. -

Page 217: Checking The Connection Box

Is the sealing inside the screw fitting OK? Is the O-ring for the sealing of the cover OK? (the O- ring is visisble from the outside at the edge of the cover) Uni-Probe LB 490 2 – 217 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 218: Trouble Shooting

4 Repair, Maintenance and Service Volume 2 Trouble Shooting Problem Probable cause Potential solution No signal System out of work Check power supply check fuses; is LED 1 on the digital board flashing? Count rate too Shielding not or not cor- Check lock and secure it in rectly opened position OPEN... - Page 219 (software update) – LED off: CPU malfunction, or no power supply 2. Communication LEDs ® If a communication via fieldbus or HART exists, both LEDs (TxD, RxD) are flashing. Uni-Probe LB 490 2 – 219 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 220: Replacing The Complete Uni-Probe

4 Repair, Maintenance and Service Volume 2 Replacing the Complete Uni-Probe Devices that are used in non-hazardous areas may not be used any more in hazardous areas. Intrinsically safe devices whose intrinsically safe signals are con- nected to non-intrinsically safe electric circuits may also not be connected to intrinsically safe electric circuits any more. - Page 221 Volume 2 4 Repair, Maintenance and Service Carry out a new empty calibration (see the respective software description). Then the Uni-Probe is operational again. Uni-Probe LB 490 2 – 221 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 222: Replacing The Electronics Module

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 223 You find the device numbers on white labels with a two, three or four-digit number. The inscription reads: “Dev. ID XXXX”. Establish the power supply to the Uni-Probe again. Uni-Probe LB 490 2 – 223 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 224 4 Repair, Maintenance and Service Volume 2 Set the software parameters again using the list you have noted down earlier. See also Volume 3 on page 3–295. Separate User’s Manuals are available for user interfaces such ™ as SIMATIC PDM or FOUNDATION Fieldbus.

-

Page 225: Replacing The Crystal-Multiplier Assembly (For Point Detector)

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 226 4 Repair, Maintenance and Service Volume 2 IMPORTANT Replacement of the multiplier requires a new setting of detector code and HV parameters. Please see Volume 2, "1.6 Detector Codes", page 2–133, and Volume 3, "2.38 HV S ", page 3– ETTINGS 334.

-

Page 227: Replacing The Multiplier (For Rod Detector)

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. -

Page 228: Fieldbus (Not Intrinsically Safe)

4 Repair, Maintenance and Service Volume 2 Check the level indication empty and full . If you detect any deviations, please carry out a new calibration, see Volume 3, "4 Calibration", on page 3–341. Separate User’s Manuals are available for user interfaces such ™... -

Page 229: Replacing The Plastic Scintillator

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 230 4 Repair, Maintenance and Service Volume 2 dow (Berthold ID no. 18844) to establish the optical connection between both parts. Install the electronics module in the Uni-Probe as described on page 2–223. Check the level indication empty and full . If you detect any deviations, please carry out a new calibration, see Volume 3, "4 Calibration", on page 3–341.

-

Page 231: Replacing The Digital Board

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 232 4 Repair, Maintenance and Service Volume 2 Dismantled digital board Figure 4-6 Digital board There are three versions of digital boards. The current version is Digital board versions described in detail in this User's Manual and is called digital board The digital boards can be exchanged against each other;...

- Page 233 Uni-Probe housing. IMPORTANT After installation of a new software, carry out a “Factory Reset” (Volume 3, "7.4 Reset", on page 3–397); otherwise a correct func- tion cannot be ensured. Uni-Probe LB 490 2 – 233 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 234: Replacing The Power Supply Unit

Spare parts for detectors used in hazardous areas may only be installed by BERTHOLD TECHNOLOGIES service personnel or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, the complete detector has to be replaced or returned to the manufacturer for repair. - Page 235 Install the new digital board in reverse order. Install the electronics module in the Uni-Probe as described on page 2–223. This completes the replacement of the power supply. Uni-Probe LB 490 2 – 235 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 236: Replacing Fuses

4 Repair, Maintenance and Service Volume 2 4.12 Replacing Fuses Two fuses (16) are located on the power supply board (14). Position Power supply board 24V AC/DC Power supply board 90 - 240V AC/DC Figure 4-8 Position of power supply board and fuses in the device Type of fuse: Berthold part #46719. -

Page 237: Updating The Embedded Software In The Uni-Probe

The cooling-off time of 30 minutes ensures that possibly overheated components have enough time to cool off and cannot ignite the explosive atmosphere. Unscrew the housing cover (M32 screw wrench). Uni-Probe LB 490 2 – 237 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 238 4 Repair, Maintenance and Service Volume 2 Connect the RS-232 interface of your PC via the null modem cable to the RS-232 interface (17) of the Uni-Probe. Figure 4-9 Position of RS-232 interface in the open device Danger, electric shock! The update has to be carried out with open housing cover.

- Page 239 Select the respective update file. Click on FILE LOAD BINARY FILE Select in the directory the update file (in our example LB490.RUN Click on to start the update. PROGRAM Uni-Probe LB 490 2 – 239 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 240 4 Repair, Maintenance and Service Volume 2 The flash memory is checked and this check shows that the flash memory is not empty. Confirm the update by clicking on . The ERASE AND PROGRAM download is now carried out. This may take several minutes. The progress bar shows that the Uni-Probe programming is running.

- Page 241 See also Volume 3 on page 3–295. Separate User’s Manuals are available for user interfaces such ™ as SIMATIC PDM or FOUNDATION Fieldbus. The Uni-Probe is again ready for use. Uni-Probe LB 490 2 – 241 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 242: Check Detector

4 Repair, Maintenance and Service Volume 2 4.14 Check Detector Scintillation counters do not include any wearing parts and their service life is not limited, provided they are used under normal operating conditions. Malfunctions in the scintillation detector can only be caused by excessive mechanical or thermal stress. See also Volume 2, sections 2.5 and 7. - Page 243 While you are doing this, make sure that the multiplier is not exposed to bright sunlight. Magnetic shielding (Mu metal) Crystal Multiplier Optical connection Figure 4-12 Crystal-multiplier assembly Uni-Probe LB 490 2 – 243 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 244 4 Repair, Maintenance and Service Volume 2 The crystal must be perfectly clear inside and not show any cracks or dull areas. The normal coloring is slightly greenish. A yellowish to brownish coloring is a sign of thermal overload and indicates that the crystal must be replaced.

-

Page 245: Customer Service

– Measuring device, e.g. level, rod source with rod detector • Parameter listing • Source number and / or Berthold commission number • Contact person and phone number Uni-Probe LB 490 2 – 245 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 246: Returning Repairs

Your order number (if necessary) • Preferred mode of transportation (if necessary) • Customs value (for cross-border shipment) BERTHOLD TECHNOLOGIES delivery address: BERTHOLD TECHNOLOGIES GmbH & Co. KG Service Department Calmbacher Str. 22 D-75323 Bad Wildbad 38477BA2B 2 – 246... -

Page 247: Screw Fittings And Accessories

Three sealing kits enclosed: 3–8mm, 7–12mm, 11.5–15mm To obtain better sealing capabilities against penetrating liquid, the Sealing against humidity screw threads of the screwed cable glands, the adapter and the Uni-Probe LB 490 2 – 247 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 248 5 Screw Fittings and Accessories Volume 2 dummy plugs have to be greased with the lubricant OKS 217. Apply the lubricant evenly on the threads such that the threads are completely covered. Remove excess lubricant. 5.1.2 Nickel-Plated Screwed Cable Gland Brass This type of screwed cable glands are suitable for zones 1 and 2.

-

Page 249: Atex-Adapter (Ex D Iic) For Screwed Cable Glands

Corrosion protection and sealing for NPT thread Adapter and dummy plug include NPT external screw threads. NPT screw threads must NOT be sealed with Teflon tape. For NPT screw Uni-Probe LB 490 2 – 249 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 250 5 Screw Fittings and Accessories Volume 2 threads you have to use the lubricant OKS 217 as corrosion protec- tion, which at the same time has a sealing effect. A sufficient amount of lubricant OKS 217 is enclosed with each Uni-Probe. Apply the lubricant evenly on the threads such that the threads are completely covered.

-

Page 251: Technical Drawings

Technical Drawings Point Detector Type Crystal Collimator Weight (kg) Total length 38477-X10 radial 22.5 without water cooling 38477-X20 axial 50/50 38477-X11 radial with water cooling 38477-X21 axial 24.5 Uni-Probe LB 490 2 – 251 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 252 6 Technical Drawings Volume 2 6.1.1 Point Detector Mounting Clamps 76 mm (without water cooling) 90 mm (with water cooling, plastic ring not needed) Mounting clamps for ID no. Point detector without water cooling 39246 Point detector with water cooling 39247 38477BA2B 2 –...

- Page 253 Volume 2 6 Technical Drawings 6.1.2 Holding Device Mounted on Detector 6.1.3 Installation on vessel Uni-Probe LB 490 2 – 253 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 254: Rod Detector

6 Technical Drawings Volume 2 Rod Detector 38477BA2B 2 – 254 25.5.09... - Page 255 Rod Detector without Water Cooling Type Sensitive scintillator Weight length (mm) (mm) (mm) (kg) (mm) 38477-X30 14,5 38477-X50 1000 1404 1174 38477-X70 1500 1904 1674 38477-X90 2000 2404 2174 26.5 Uni-Probe LB 490 2 – 255 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 256 6 Technical Drawings Volume 2 6.2.2 Rod Detector with Water Cooling Type Sensitive scintilla- Weight Weight tor length (mm) (mm) (mm) without water with water (mm) (kg) (kg) 38477-X31 18.5 19.5 38477-X51 1000 1404 1174 28,5 38477-X71 1500 1904 1674 38477-X91 2000 2404...

- Page 257 Sensitive length Marking Position of clamps EPDM profile A set of clamps (2 each) ID no. (mm) For Uni-Probe without water cooling 39983 For Uni-Probe with water cooling 31347 Uni-Probe LB 490 2 – 257 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 258 6 Technical Drawings Volume 2 6.2.4 Shielding for Rod Detector without Water Cooling Mounting foot top/bottom Ø 11 Ø 75 Length scintillator Length rod detector Length shielding Dismantling ID no. Weight (mm) (mm) (mm) from above approx. (kg) 1000 42744-050 1000 1400 1120...

- Page 259 (mm) from above approx. (kg) 1000 42131-050 1000 1400 1120 1155 1090 1500 42131-100 1500 1900 1620 1655 1590 2100 42131-150 2000 2400 2120 2155 2090 2600 42131-200 Uni-Probe LB 490 2 – 259 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 260 6 Technical Drawings Volume 2 6.2.6 Collimator Details for Rod Detectors Cross-section View from above View from the front Collimator alignment to Clamping screw for Lead filling source rod detector 6.2.7 Installation Instructions for Collimator with Rod Detector We recommend using an installation/ deinstallation room for swiveling out Boreholes for installation of of the mounting foot...

- Page 261 Distance to the vessel wall approx. 100mm Mounting platform Installed by the installation con- tractor, e.g. welded to the vessel or the supporting structure. Uni-Probe LB 490 2 – 261 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 262 6 Technical Drawings Volume 2 6.2.9 Terminal Position for Rod Detector (with and without Water Cooling) 2000 All dimensions in mm 1500 1000 6.2.10 Position of the Fixtures for Rod Detector Shieldings (with and without Water Cooling) 2000 All dimensions in mm 1500 1000 38477BA2B...

- Page 263 6 Technical Drawings 6.2.11 Terminal Position for Multi-detector Arrangement All dimensions in mm 100% 6.2.12 Position of the Fixture for Multi-detector Arrangement with Collimators All dimensions in mm Uni-Probe LB 490 2 – 263 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 264: Super-Sens

6 Technical Drawings Volume 2 Super-Sens 6.3.1 Super-Sens with Frontal Irradiation Weight approx. 60kg 6.3.2 Super-Sens with Frontal Irradiation and Water Cooling Weight approx. 65kg Connection seal for water cooling: ø 10mm /R ¼" 38477BA2B 2 – 264 25.5.09... - Page 265 Weight approx. 45kg 6.3.4 Super-Sens with Radial Irradiation and Water Cooling Radial heat protection Radial heat protection Weight approx. 50kg Connection seal for water cooling: ø 10mm /R ¼" Uni-Probe LB 490 2 – 265 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 266 6 Technical Drawings Volume 2 6.3.5 Water Cooling with Horizontal Installation Outlet Inlet With horizontal installation of the detector, the water inlet is con- nected directly to the end of the pipeline on the side of the cable entries. 6.3.6 Water Cooling with Vertical Installation Outlet Inlet...

- Page 267 Side view Top view Radiation window Section for radiation window Radiation path Bracket Ø18 With installed Super-Sens detector Radiation window Section for radiation window Radiation path Bracket Uni-Probe LB 490 2 – 267 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 268: Tower-Sens

6 Technical Drawings Volume 2 Tower-Sens 6.4.1 Basic Module without Water Cooling (0.59) (4.33) (6.02) (5.12) (8.00) (8.46) Mounting plate 100...170 (4...6.7) Clamp position Mounting plate 180° 135° Dimensions in mm (inch) Housing material stainless steel 1.4301 45° 0° (2.91) 4 cable conduits 3/4NPT internal screw threads (4.33) Type... - Page 269 4 cable conduits 3/4NPT internal screw threads (4.33) Type Sensitive length L1 Length L Length L2 Weight approx. (mm) (mm) (mm) (kg) 1000 mm 1385 2000 mm 1990 2385 1833 Uni-Probe LB 490 2 – 269 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 270 6 Technical Drawings Volume 2 6.4.3 Extension Module without Water Cooling Sealing 100...400 (4...16) Window Clamp position Dimensions in mm (inch) EPDM profile Type Sensitive length L1 Length L Weight approx. (mm) (mm) (kg) 2000 mm 2000 2021 38477BA2B 2 – 270 25.5.09...

- Page 271 Sealing (3.34) (72.9) (3.34) Window Clamp position Dimensions in mm (inch) EPDM profile Type Sensitive length L1 Length L Weight approx. (mm) (mm) (kg) 2000 mm 2000 2021 Uni-Probe LB 490 2 – 271 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 272 6 Technical Drawings Volume 2 6.4.5 Installation Proposal for Tower-Sens Base The mounting base has to be provided by the customer. ~200 ~110 (~7.9) (~4.3) (8.66) Ø18 (Ø0.71) Ø112 (Ø4.41) Dimensions in mm (inch) (5.67) 38477BA2B 2 – 272 25.5.09...

-

Page 273: Point Source Shielding Lb 744X

LB 7440 DE CR LB 7442 F CR LB 7442 D CR ND 200, PN 6 LB 7442 FE CR LB 7442 DE CR ND 200, LB 7444 CR PN 6 Uni-Probe LB 490 2 – 273 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 274 6 Technical Drawings Volume 2 6.5.1 Installation Proposal for Point Source Shielding LB 744X The shielding vessel is consisting of a stable casting cabinet filled with lead. A rotary shutter is installed to close the radiation exit channel. Operation is made from behind by a T-handle, which is secured by a padlock in open as well as in closed position.

- Page 275 2 proximity switches for intrinsically safe supply ID no. Description 36119 Pneumatic actuator with limit switch IP 65 80919 Pneumatic actuator with limit switch Ex de IIC T6 Uni-Probe LB 490 2 – 275 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 276 6 Technical Drawings Volume 2 Parts of the pneumatic actuator Return spring (FAIL-SAFE) with Pneumatic actuator pneumatic actuator Adjustable cams Square neck for position indication or possible hand actuating Limit switch for position OPEN Point source Limit switch for position shielding LB 744X CLOSED Cable gland...

- Page 277 Move revolving wings to the opposite stop position. Com- pressed air is needed for single-acting swivel drives with spring lock unit. Proceed accordingly with the second trip cam. Uni-Probe LB 490 2 – 277 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 278 6 Technical Drawings Volume 2 Technical Specification / Electrical Wiring … 2 micro push-buttons BARTEC 07-1501-6120-63 (closer) for drive size 02/03 BARTEC 07-1501-6130-63 (changer) for drive size 05-14 Volt Load (A) Resistor inductive (max.) up to 12 up to 24 up to 48 0.06 up to 250...

- Page 279 Ø50 Installation according to factory norm After connecting, tighten the stuffing box fitting. IMPORTANT Make sure that the cover sealing is inserted in its groove! Uni-Probe LB 490 2 – 279 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 280 6 Technical Drawings Volume 2 Slightly grease the housing cover in the shaft duct with MoS grease, attach the cover and tighten the cover screws. Correction of the switching points Direct installation for drives with pre-assembled Unscrew the cover of the supplied limit-switch box and pull it limit-switch box off, as shown in the illustration, while pushing down the limit-switch shaft.

-

Page 281: Point Source Shielding For Rod Detectors

Volume 2 6 Technical Drawings Point Source Shielding for Rod Detectors Point source Radiation exit Padlock Position Open Position Closed Type plate Type Weight (kg) Uni-Probe LB 490 2 – 281 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 282: Rod Source Shielding

6 Technical Drawings Volume 2 Rod Source Shielding Point source Radiation exit Padlock Position Open Position Closed Type plate Type approx. Kg/m approx. 204.5 11.5 224.5 11.5 11.5 222. 38477BA2B 2 – 282 25.5.09... - Page 283 The required individual types of shieldings are labeled with Roman numbers. Shielding ∅ Drawing no. 21157.000-000 21159.000-000 21160.000-000 21161.000-000 Uni-Probe LB 490 2 – 283 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 284: Pneumatic For Rod And Point Source Shieldings

6 Technical Drawings Volume 2 Pneumatic for Rod and Point Source Shieldings Pneumatic drive for point source shieldings with spring reset: 40085 Type 100 40084 Type 100, limit switch (Ex) 41689 Type 150 41690 Type 150, limit switch (Ex) 412681 Type 200 41691 Type 200, limit switch (Ex) -

Page 285: Pneumatic, Design And Electrical Data For Limit Switch

Position marked by a milled-in red line 0.06 0.06 0.25 0.03 0.25 0,05 0.025 Return spring (FAIL-SAFE) with pneumatic actuator Shielding type 80 … 270 Uni-Probe LB 490 2 – 285 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 286: Shielding For Rod Source On Dip Tube

6 Technical Drawings Volume 2 6.10 Shielding for Rod Source on Dip Tube 38477BA2B 2 – 286 25.5.09... -

Page 287: Flange Adapter For Rod Source Shieldings

Volume 2 6 Technical Drawings 6.11 Flange Adapter for Rod Source Shield- ings Uni-Probe LB 490 2 – 287 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 288 6 Technical Drawings Volume 2 38477BA2B 2 – 288 25.5.09...

-

Page 289: Cooling Water Curves

Ambient temperature in ºC Rod Detector Cooling water curves for rod detector 500 mm Cooling water curves for rod detector 500 mm Cooling water input temperature Ambient temperature in ºC Uni-Probe LB 490 2 – 289 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 290 7 Cooling Water Curves Volume 2 Cooling water curves for rod detector 1000 mm Cooling water curves for rod detector 1000 mm Cooling water input temperature Ambient temperature in ºC Cooling water curves for rod detector 1500 mm Cooling water curves for rod detector 1500 mm Cooling water input temperature Ambient temperature in ºC Cooling water curves...

-

Page 291: Super-Sens

Ambient temperature in ºC Tower-Sens Cooling water curves for Tower-Sens detector 40 °C Cooling water input temperature Cooling water input temperature 30 °C 20 °C 10 °C Ambient temperature in ºC Uni-Probe LB 490 2 – 291 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 292 7 Cooling Water Curves Volume 2 38477BA2B 2 – 292 25.5.09...

- Page 293 Volume 2 Notes: Uni-Probe LB 490 2 – 293 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 294 Subject to change in the course of further technical development. © BERTHOLD TECHNOLOGIES GmbH & Co. KG 2009 Language: English Printed in Germany 05/2009 Rev. no.: 05 BERTHOLD TECHNOLOGIES GmbH & Co. KG Calmbacher Str. 22 D-75323 Bad Wildbad Germany www.Berthold.com...

- Page 295 Volume 3 ® HART Communicator User Interface...