Summary of Contents for BERTHOLD TECHNOLOGIES LB 480

- Page 1 Process Control SENSseries LB 480 LB 480 Level measurement User’s Manual Id. No. 54733-10BA2L Rev. No.: 03 02.2017 Embedded Soft. from Rev. 1.00.00 Device Description from Rev. 01...

- Page 3 Volume 1: Safety Manual Volume 2: Installing SENSseries ® Volume 3: Operation with HART Communicator...

- Page 4 General Information Thank you for purchasing the measuring system SENSseries Dear customer LB 480 by BERTHOLD TECHNOLOGIES. The scope of supply also includes this User’s Manual. Keep this User’s Manual on hand for reference at any time. Please observe the warnings and safety instructions given in this User’s Manual to rule out personal injury and property damage.

-

Page 5: Table Of Contents

5.8 Maintenance and Visual Inspection ......1 – 49 5.9 ATEX Certificate ............1 – 55 5.10 IECEx Certificate ............1 – 65 5.11 FM Certificate............1 – 81 SENSseries LB 480 Level measurement 1 – 5 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 6 7.8 Commissioning............1 – 101 7.9 Periodic Inspections ..........1 – 102 7.10 Repair..............1 – 103 7.11 Functional Safety Data Sheet LB 480....... 1 – 104 7.12 Attachments............1 – 106 7.13 Functional Safety Certificate ........1 – 108 Visual Inspection.............

- Page 7 1.4 Measuring Arrangements ........2 – 158 1.5 Technical Data ............2 – 162 1.6 Detector Codes ............2 – 166 1.7 Nomenclature of the SENSseries LB 480....2 – 167 Installation ..............2 – 171 2.1 Transport to the Installation Site ......2 – 173 2.2 Source Detector Arrangements .......

- Page 8 Table of Contents Volume 1-3 Volume 3 Operation with ® HART Communicator ® HART Communication ..........3 – 301 1.1 HART® Protocol ............. 3 – 301 1.2 General Information on the ® HART Communicator ........... 3 – 301 1.3 Connection, Power On and Power Off of the ®...

- Page 9 Getting Started via the HART Communicator ....3 – 389 3.1 Steps for Getting Started ........3 – 389 Quick Guide to Calibration..........3 – 391 SENSseries LB 480 Level measurement 1 – 9 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 10 Table of Contents Volume 1-3 Calibration..............3 – 393 5.1 Preparing Calibration..........3 – 394 5.2 Calibration with Quick Start........3 – 396 5.3 Ensuring the Function of the Measurement .... 3 – 402 Functional Processes ............3 – 405 6.1 Multidetector Operation .........

- Page 11 Volume 1 Safety Manual...

- Page 12 Volume 1 54733-10BA2L 1 – 12 02.2017...

-

Page 13: About This User's Manual

The term BERTHOLD TECHNOLOGIES is used in this User’s Manual for the company BERTHOLD TECHNOLOGIES GmbH & Co. KG. Please observe the warnings and safety instructions given in this User’s Manual to rule out personal injury and property damage. -

Page 14: Meaning Of Other Symbols Used In This Documentation

1 About this User’s Manual Volume 1 Meaning of Other Symbols Used in this Documentation Warning: Do not step or stand under a suspended load. Warning: Radiation Warning: Ex-protection Warning: Risk of crushing Requirement: Switch off power Requirement: Wear a hardhat Requirement: Wear safety shoes Meaning of Warning Signs on Detectors and Source Shieldings... -

Page 15: Terms Used In This User's Manual

Volume 1 1 About this User’s Manual Terms Used in this User’s Manual Standard point detector version in the SENSseries LB 480. CrystalSENS Standard rod detector version in the SENSseries LB 480. UniSENS Highly sensitive detector with large volume polymer scintillator 150 SuperSENS x 150 mm for large pipe or tank diameter. -

Page 16: General Information

1 About this User’s Manual Volume 1 Canadian Standard Association: sets norms and standards that are important for Canada (and America), among other things, the Directive for Explosion Protection and Low Voltage. Photomultiplier or only multiplier: converts the flashes of light gen- erated by the radiation in the detector into electrical signals. -

Page 17: Proper Use

BERTHOLD TECHNOLOGIES only accepts liability for / guarantees the correspondence of the systems of the SENSseries LB 480 to its published specifications. The detectors of the SENSseries may only be installed in an undamaged, dry and clean condition. Alterations and modifications to the system components are not allowed. - Page 18 Operation without the safety precautions provided by the man- ufacturer. – Manipulating or bypassing existing safety installations. The measuring system of the SENSseries LB 480 may only be Maintenance installed, serviced and repaired by trained persons (see chapter 3.2, page 1-20).

-

Page 19: Qualification Of Personnel

SENSseries LB 480 under the guidance of an authorized person. This can also refer to construction site personnel. The persons in question must have experience in the transportation and assembly of heavy com- ponent parts. -

Page 20: Experts

Authorized persons are those who are either designated for the cor- responding task due to legal regulations or those who haven been authorized by BERTHOLD TECHNOLOGIES for particular tasks. When dealing with radioactive materials, a Radiation Safety Officer must also be consulted. -

Page 21: Transport And Assembly

– System components must be mounted vibration-free. – Hold housing cover to prevent falling of housing cover when opening and closing the terminal compartment. SENSseries LB 480 Level measurement 1 – 21 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 22 4 Transport and Assembly Volume 1 54733-10BA2L 1 – 22 02.2017...

-

Page 23: Explosion Protection

Volume 1 5 Explosion Protection Explosion Protection SENSseries LB 480 - .. 1A LB 480 - .. 2A LB 480 - .. 1B LB 480 - .. 2B LB 480 - .. 3B LB 480 - .. 4B LB 480 - .. FA LB 480 - .. - Page 24 5 Explosion Protection Volume 1 (bg) Инструкции за безопасност за употреба в (it) Istruzioni per l’impiego in ambienti a rischio di потенциално експлозивни райони. Това deflagrazione. Il presente manuale contiene le ръководство за безопасност е и на disposizioni di sicurezza ed è disponibile in разположение...

-

Page 25: Declaration Of Conformity

Volume 1 5 Explosion Protection Declaration of Conformity SENSseries LB 480 1 – 25 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 26: General Information

• The repair of detectors that are used in explosion hazardous areas by persons who were not authorized by BERTHOLD TECHNOLOGIES. • Using the device in a damaged or corroded condition. • Operation with open or inadequately closed cover. -

Page 27: Safety Instructions

TECHNOLOGIES service or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, you must replace the entire detector or return it to the manufacturer for repair. SENSseries LB 480 1 – 27 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 28: Application Range And Technical Data

5 Explosion Protection Volume 1 Application Range and Technical Data 5.5.1 Ex-protection and temperature limits Test certificates: PTB 11 ATEX 1032 X IECEx PTB 12.0038X CSA 70009819 Protection type: IP66 / IP68 according to IEC 60529 IP69K according to ISO 20653 NEMA Type 4X Air pressure: 80 kPa (0.8 bar) to 110 kPa (1.1 bar) - Page 29 AEx tb IIIC AEx tb [ia] IIIC IIIC Protection principle Ex-d/ -e/ -t Ex-d/ -e/ -i/ -t Ex-d/ -e/ -t Ex-d/ -e/ -i/ -t 1) Internal IP30 protection cover SENSseries LB 480 1 – 29 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 30 5 Explosion Protection Volume 1 5.5.3 Detector Versions and Application Range for Divisions according NEC/CEC Design LB 480-1x-xx-... CrystelSENS (point detector) LB 480-2x-xx-... CrystelSENS (rod detector) LB 480-3x-xx-... SuperSENS LB 480-4x-xx-... PowerSENS Protection concept LB 480-xx-Fx-... LB 480-xx-Gx-... Signal circuit...

- Page 31 The max. ambient temperature decreases when the detector is not mounted freestanding; the maximum surface temperature must not be exceeded. SENSseries LB 480 1 – 31 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 32 5 Explosion Protection Volume 1 5.5.5 Electrical safety characteristics of the associ- ated equipment Signal circuits LB 480-...-3B (Sink) LB 480-...-4B (Source) ® Current output HART / 4 ... 20mA (Terminals 17, 18) linear characteristic curve max. output voltage = 25,2V max.

- Page 33 Volume 1 5 Explosion Protection In gas atmospheres, when selecting group IIB or IIC for the intrin- sically safe circuits, all intrinsically safe circuits and the LB 480 detector must be operated completely in the selected group IIB or IIC.

-

Page 34: Installation

5 Explosion Protection Volume 1 Installation • Observe the installation and safety instructions in the operating manual. • Install according to manufacturer's instructions and applicable standards and regulations. • Do not operate device outside of the electrical, thermal and mechanical characteristics. •... - Page 35 Only screwed fittings are permitted for ambient temperatures between -20° C and +40° C that technically meet at least the standard listed on the cover page of LB 480 EC type-examina- tion certificate. Only screwed fittings which have been approved by BERTHOLD TECHNOLOGIES may be used outside this temperature range.

- Page 36 5 Explosion Protection Volume 1 • Permissible wire cross-section: Terminals – with ferrules 0.5 - 1.5 mm (AWG 21 - 16 flexible) – without ferrules 0.5 - 2.5 mm² (AWG 21 - 14 flexible or solid) • Both stranded leads as well as solid wires are permitted. •...

- Page 37 • Devices with intrinsically safe circuits must not be connected to intrinsically safe circuits any more if they have not been used intrinsically safe before. SENSseries LB 480 1 – 37 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 38 5 Explosion Protection Volume 1 5.6.3 Explosion Proof (XP) The paragraph "Terminals" in chapter 5.6.1 is also valid in this chapter. • The threads (cable entries 1/2" NPT and housing cover) must be protected against damage. • The threads (cable entries 1/2" NPT and housing cover) must be protected against moisture and corrosion.

- Page 39 Please proceed as described in chapter 5.2.4 if the non-intrinsi- cally safe part of the terminal compartment is to be opened. Waiting time before opening the Ex-e cover after turning off the power supply: 2 minutes. SENSseries LB 480 1 – 39 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 40: Ex - Concept

Volume 1 Ex – Concept 5.7.1 Ex-e – Concept LB 480-xx-1A LB 480-xx-2A Fig. 5-1 Ex-e - Concept LB 480-xx-1A, LB 480-xx-2A LB 480-xx-1B LB 480-xx-2B Fig. 5-2 Ex-e - Concept LB 480-xx-1B, LB 480-xx-2B 54733BA26 1 – 40 02.2017... - Page 41 LB 480-xx-3B LB 480-xx-4B Master Terminal Compartment semicircular cover for Ex-e compartment with IP30 protection type Bild 5-3 Ex-i - Concept LB 480-xx-3B, LB 480-xx-4B SENSseries LB 480 1 – 41 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 42 5 Explosion Protection Volume 1 LB 480-xx-FX LB 480-xx-GX Fig. 5-4 XP - Concept LB 480-xx-FX, LB 480-xx-GX 54733BA26 1 – 42 02.2017...

- Page 43 Power Supply Zone 0 or Zone 1 100 ... 240 VAC 24 VDC RS 485 for Multi Detector Sytsem Pt100 Equipotential bonding Fig. 5-5 Installation plan type of protection SENSseries LB 480 1 – 43 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 44 5.7.4.1 Power supply Terminal Labeling Type DC supply Supply + Ue = 24 V LB 480 - .. - .. - 11 max. 12 W Supply - Supply + To forward the supply to the next slave Supply - Type AC supply Supply L Ue = 100 ...

- Page 45 5.7.4.2 Power Supply Terminal Labeling Type DC supply Supply + Ue = 24 V LB 480 - .. - .. - 11 max. 12 W Supply - Supply + To forward the supply to the next slave Supply - Type AC supply Supply L Ue = 100 ...

- Page 46 RS 4 8 5 A In Power supply Terminal Labeling Type DC supply Supply + Ue = 24 V LB 480 - .. - .. - 01 max. 12 W Supply - Supply + To forward the supply to the next slave Supply -...

- Page 47 10 Nm IP66 / IP 68 / IP69K Silicone (9 - 13 mm internal) 56103 12 - 20 mm 30 mm 10 Nm Silicone (10 - 15 mm internal) SENSseries LB 480 1 – 47 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 48 5 Explosion Protection Volume 1 Plugs M20 x 1.5 Material ID No. Ex labeling / Protection type Torque 56093 PTB 09 ATEX 1002 X 22 mm 10 Nm IP66 / IP68 / IP69K Silicone 59031 LCIE08 ATEX 6085 X 23 mm 6 Nm IP66 / IP68 / IP69K Neoprene...

-

Page 49: Maintenance And Visual Inspection

For detectors that are used in hazardous areas, the detector hous- ing (Bild 5-6) and thus the pressure-proof enclosure of the electron- ics may be opened only by the BERTHOLD TECHNOLOGIES service or by persons authorized by BERTHOLD TECHNOLOGIES. Housing cover... - Page 50 5 Explosion Protection Volume 1 Carry out regular visual inspections of the SENSseries measuring Visual inspection system, at least once every three years. To do this, use the visual inspection plan in chapter 5.8.1. Take appropriate actions immedi- ately if you detect damage in the course of the visual inspection; if necessary, disconnect the detector from power supply immediately.

- Page 51 EC type-examination certificate or are screwed fittings used that have been approved for use in the LB 480 by BERTHOLD TECHNOLOGIES? Is the permissible temperature range of the screwed fittings suitable for the tempera-...

- Page 52 5 Explosion Protection Volume 1 Measures Date: ..........Name:..........Test of screwed fittings (cable glands, adapters, sealing plugs), continue Is more than one adapter (reduction or extension piece) used? Is the total length of the cable glands plus any possibly used adapters less than 10 cm? Are the cable diameters of the cables used permitted for the cable glands?

- Page 53 Are all the wires of a fine-wire strand cov- ered by the terminal and clamped? Is the grounding conductor properly installed? Is the screened cable properly insulated electrically up to the terminal (e.g. with shrink tubing)? SENSseries LB 480 1 – 53 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 54 5 Explosion Protection Volume 1 Measures Date: ..........Name:..........Applies only to detectors with intrinsically safe installation (Ex-i) Does the semicircular lid cover the terminal compartment (Ex-e)? Are the screws for the semicircular lid tight- ened? Has it been ensured that no wires are trapped between the semicircular cover and the underlying holder? Have both screws (flat head screw ISO...

-

Page 55: Atex Certificate

Volume 1 5 Explosion Protection ATEX Certificate SENSseries LB 480 1 – 55 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 56 5 Explosion Protection Volume 1 54733BA26 1 – 56 02.2017...

- Page 57 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 57 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 58 5 Explosion Protection Volume 1 54733BA26 1 – 58 02.2017...

- Page 59 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 59 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 60 5 Explosion Protection Volume 1 54733BA26 1 – 60 02.2017...

- Page 61 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 61 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 62 5 Explosion Protection Volume 1 54733BA26 1 – 62 02.2017...

- Page 63 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 63 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 64 5 Explosion Protection Volume 1 54733BA26 1 – 64 02.2017...

-

Page 65: Iecex Certificate

Volume 1 5 Explosion Protection 5.10 IECEx Certificate SENSseries LB 480 1 – 65 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 66 5 Explosion Protection Volume 1 54733BA26 1 – 66 02.2017...

- Page 67 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 67 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 68 5 Explosion Protection Volume 1 54733BA26 1 – 68 02.2017...

- Page 69 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 69 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 70 5 Explosion Protection Volume 1 54733BA26 1 – 70 02.2017...

- Page 71 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 71 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 72 5 Explosion Protection Volume 1 54733BA26 1 – 72 02.2017...

- Page 73 Volume 1 5 Explosion Protection SENSseries LB 480 1 – 73 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 74 70009819 (215040) Master Contract: 215040 Project: 70066628 Date Issued: 2016-03-07 Issued to: Berthold Technologies GMBH & CO KG Calmbacher Str 22 Bad Wildbad, 75323 GERMANY Attention: Juergen Betzelt The products listed below are eligible to bear the CSA Mark shown with adjacent indicators 'C' and 'US' for Canada and US or with adjacent indicator 'US' for US only or without either indicator for Canada only.

- Page 75 The second numeric character distinguishes between different kinds of terminal compartments. Version x1: Flame Proof Enclosure type terminal compartment. Version x2: Increased Safety type terminal compartment. DQD 507 Rev. 2012-05-22 Page 2 SENSseries LB 480 1 – 75 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 76 Volume 1 Certificate: 70009819 Master Contract: 215040 70066628 Date Issued: 2016-03-07 Project: LB 480 - . - ..- -. Version Description Point Detector 50x50 Point Detector 50x50 + Water Point Detector … Rod Detector 500 mm Rod Detector 500 mm + Water...

- Page 77 Maximum permissible external values for common effective reactance’s (C is not considered) (mH) (µF) 0.107 0.078 0.061 Single reactance’s to table A.2 and figure A.4 or A.6 of 60079-11 DQD 507 Rev. 2012-05-22 Page 4 SENSseries LB 480 1 – 77 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 78 RS485 circuit. 2) In gas atmospheres for the choice of Group IIB or IIC for the intrinsically safe circuits, all intrinsically safe circuits and the scintillation meter LB 480 series shall be fully operated in the selected Group IIB or IIC.

- Page 79 “!” symbol: SEE SAFETY MANUAL FOR FURTHER INFORMATION “!” symbol: IN AN EXPLOSIVE ATMOSPHERE, DE-ENERGIZE AND WAIT 2 MINUTES BEFORE OPENING" “!” symbol: SEAL WITHIN 50mm OF ENCLOSURE" DQD 507 Rev. 2012-05-22 Page 6 SENSseries LB 480 1 – 79 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 80 46031 #08 and correction to entity parameters. 70009819 2015-11-25 New North American Certification for Scintillation Measuring Equipment, Model Series LB 480, for C1Z1, Ex d e [ia] T-Code T1-T6, and Class II, Zone 21 based upon IECEx Certification. DQD 507 Rev. 2012-05-22 Page 1 54733BA26 1 –...

-

Page 81: Fm Certificate

CERTIFICATE OF CONFORMITY HAZARDOUS (CLASSIFIED) LOCATION ELECTRICAL EQUIPMENT PER US REQUIREMENTS Certificate No: FM16US0282X Equipment: LB 480 Series Scintillation Measurement Equipment (Type Reference and Name) Name of Listing Company: Berthold Technologies GmbH & Co. KG Address of Listing Company: Calmbacher Strasse 22... - Page 82 Type 4X Description of Equipment: General - The LB 480 Series Scintillation Measurement Equipment is used as part of a measuring system for monitoring industrial processes. The equipment is used for continuously measuring the level or weight per unit area, in tanks or bins, of liquid, granular, viscous or encrustation-forming media and for measuring conveyor belt charges as well as the density of liquids, suspensions, slurries and bulk solids.

- Page 83 FM Approvals LLC. 1151 Boston-Providence Turnpike, Norwood, MA 02062 USA T: +1 (1) 781 762 4300 F: +1 (1) 781 762 9375 E-mail: information@fmapprovals.com www.fmapprovals.com F 347 (Mar 16) Page 3 of 3 SENSseries LB 480 1 – 83 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 84 CERTIFICATE OF CONFORMITY HAZARDOUS LOCATION ELECTRICAL EQUIPMENT PER CANADIAN REQUIREMENTS Certificate No: FM16CA0144X Equipment: LB 480 Series Scintillation Measurement Equipment (Type Reference and Name) Name of Listing Company: Berthold Technologies GmbH & Co. KG Address of Listing Company: Calmbacher Strasse 22...

- Page 85 Type 4X Description of Equipment: General - The LB 480 Series Scintillation Measurement Equipment is used as part of a measuring system for monitoring industrial processes. The equipment is used for continuously measuring the level or weight per unit area, in tanks or bins, of liquid, granular, viscous or encrustation-forming media and for measuring conveyor belt charges as well as the density of liquids, suspensions, slurries and bulk solids.

- Page 86 5 Explosion Protection Volume 1 SCHEDULE Canadian Certificate Of Conformity No: FM16CA0144X Test and Assessment Procedure and Conditions: This Certificate has been issued in accordance with FM Approvals Canadian Certification Scheme. Schedule Drawings A copy of the technical documentation has been kept by FM Approvals. Certificate History Details of the supplements to this certificate are described below: Date...

-

Page 87: Electrical Installation

Please note that only one adapter per cable entry may be used. It is not permitted to screw together several adapters. The total length of the cable glands, including any adapter must not exceed 10 cm. SENSseries LB 480 Level measurement 1 – 87 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 88 In case of doubt, we recommend using screw fittings, dummy plugs or adapters by BERTHOLD TECHNOLOGIES. Only use cables with diameters that are permitted for each cable Cables and wires gland.

- Page 89 The SENSseries detectors may only be operated with fully closed housing. • Cleaning corroded threads at the cable glands or cable conduits using abrasives or a wire brush is not allowed. SENSseries LB 480 Level measurement 1 – 89 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 90 6 Electrical Installation Volume 1 • The use of the detectors is not permitted if: – cable fittings are corroded or damaged; – threads on the housing are corroded or damaged; – dummy plugs are badly corroded or damaged; – the housing of the detector is badly corroded or damaged;...

-

Page 91: Functional Safety

Scope This safety manual applies for radiometric measurement systems consisting of a radiation source and the measuring system of the SENSseries LB 480. The measuring system can be used in the fol- lowing applications: • Level measurement (also cascaded in a master-slave arrange- ment) •... -

Page 92: Use

7 Functional Safety Volume 1 The measuring device LB 480 may only be used as intended. Per- missible measuring arrangements as well as the intended use are described in the operating manual. For use in safety-related systems (Functional safety according to IEC 61508:2010 / 61511:2003) all information in this manual has to be considered. -

Page 93: Other Applicable Documents And Records

Level measurement LB 480 Level measurement ID No. 54733-10BA1L German ID No. 54733-10BA2L English Limit level measurement LB 480 Limit level measurement ID No. 54733-20BA1S German ID No. 54733-20BA2S English Density measurement LB 480 Density measurement ID No. 54733-30BA1D German ID No. -

Page 94: Project Planning

Project Planning 7.5.1 Safety Function The measuring system SENSseries LB 480 is used for non-contact measurement of level, density or concentration. A gamma radiation source (Co-60 and Cs-137) generates a radiation field which is attenuated or absorbed by the product to be measured and is detected by the scintillation detector LB 480. - Page 95 Detector Product below Container Container the beam path The level change from 0 ... 100% is represented by the analog cur- rent output 4 ... 20mA. SENSseries LB 480 Level measurement 1 – 95 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 96 7 Functional Safety Volume 1 Density measurement 7.5.1.3 The measuring system consists of a detector and a radiation source. These are mechanically positioned such that the beam path runs through the product in order to detect the product density. The safety function is to monitor the fill level of the product to be mon- itored within a defined density measuring range.

- Page 97 The following types of detectors can only be used when all count rates within the measuring range are above 1000 cps. – LB 480-13 (CrystalSENS 40/35) – LB 480-14 (CrystalSENS 40/35 with water cooling) – LB 480-15 (CrystalSENS 25/25) – LB 480-16 (CrystalSENS 25/25 with water cooling) These detectors can be operated only with detector code "0".

- Page 98 In the other case detector code "0" can be used. – LB 480-11 (CrystalSENS 50/50) – LB 480-12 (CrystalSENS 50/50 with water cooling) • The error current (Loop Alarm Type) has following setup options: – High: >21mA –...

- Page 99 2.5 • Continuous operating temperature 70 … 80° C (158...176°F) by a factor of 4.5 Similar factors apply when frequent temperature fluctuations are expected. SENSseries LB 480 Level measurement 1 – 99 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 100: Device Behavior During Operation

Overfilling or underfilling cannot be detected during this time. Even if the LB 480 is very sensitive when it comes to the detection of interference, one cannot rule out ultimately that spe- cially low interference radiation influences may not be detected and the measured value is falsified. -

Page 101: Commissioning

• HART -Communicator • The PC-based control software LB 480-PC. For commissioning, you should be familiar with the operating instructions (Level, Limit Level, or Density). Carry out the following steps for commissioning: 1. Calibration (see User's Manual Volume 3, Chapter 5) 2. -

Page 102: Periodic Inspections

7 Functional Safety Volume 1 Periodic Inspections The periodic performance test is used to check the safety function in order to detect possible non-recognizable dangerous errors and thus to test the operational capability of the measuring system at appropriate intervals. It is the responsibility of the operator to select the type of inspection. -

Page 103: Repair

>30% of the measur- ing range. 7.10 Repair Repairs of the SENSseries LB 480 may be carried out at the manu- facturer's works only. 7.10.1 Software Update A software update must be carried out only by personnel authorized by BERTHOLD TECHNOLOGIES. -

Page 104: Functional Safety Data Sheet Lb 480

SIL 2 in System Architecture 1oo1 (1-channel) Parameter Value Protective function - Limit level measurement - Level measurement - Density measurement SIL 2 with one detector LB 480 (SIL2 SC3 FT0) Device type MTTR, MRT 0 FIT 0 FIT ... - Page 105 SIL 3 in System Architecture 1oo2 (2-channels) Parameter Value Protective function - Limit level measurement - Level measurement - Density measurement SIL 3 with two detectors LB 480 (SIL3 SC3 FT1) Device type MTTR, MRT Beta PFDg for T1 = 1 year <5.6E-05 PFDg for T1 = 2 years <1.0E-04...

-

Page 106: Attachments

7 Functional Safety Volume 1 7.12 Attachments 7.12.1 Test Log Identification Company/Auditor Date Measuring point Product Order no. Isotope, source no., activity Detector type, detector size High voltage Date of last function test Device parameters of the safety function Operating mode ... - Page 107 Rate for dangerous detected failure Rate for dangerous undetected failure Diagnostic Coverage Proof Test Interval MTBF Mean Time Between Failure MTTR Mean Time To Repair Commissioning SENSseries LB 480 Level measurement 1 – 107 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 108: Functional Safety Certificate

7 Functional Safety Volume 1 7.13 Functional Safety Certificate 54733-10BA2L 1 – 108 02.2017... - Page 109 Volume 1 7 Functional Safety SENSseries LB 480 Level measurement 1 – 109 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 110 7 Functional Safety Volume 1 54733-10BA2L 1 – 110 02.2017...

-

Page 111: Visual Inspection

Please use the visual inspection plan (Vol- ume 1) on page 1-51 and the plan for checking the terminal com- partment on page 1-53. SENSseries LB 480 Level measurement 1 – 111 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 112 8 Visual Inspection Volume 1 54733-10BA2L 1 – 112 02.2017...

-

Page 113: Radiation Protection

The total sum of the radiation dose absorbed by a body is deter- mined by three factors. On the basis of these factors, certain fun- damental radiation protection rules can be derived: Distance, time and shielding. SENSseries LB 480 Level measurement 1 – 113 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 114 Installation, dismantling, relocation, maintenance, testing involving During use the radioactive source and its shielding shall ONLY be performed under the supervision of the Radiation Safety Officer. For more information please contact BERTHOLD TECHNOLOGIES. 54733-10BA2L 1 – 114 02.2017...

-

Page 115: Mounting The Shielding

BERTHOLD TECHNOLOGIES. Depending on the operation conditions, the function check has to be repeated at appropriate intervals, at least once a year. SENSseries LB 480 Level measurement 1 – 115 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 116 9 Radiation Protection Volume 1 9.2.2 Radiation Exposure during Installation of the Shielding The shieldings of measuring systems are usually designed such that the limit of the control area is in a given distance (in most cases less than one meter) around the shielding, and it does not matter whether point or rod sources are being used and how high their activity is.

- Page 117 30: 350MBq x 0.35µSv x m x 0.5h Dose D = = 8.2µSv (0.5m) x h x MBq x 30 SENSseries LB 480 Level measurement 1 – 117 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 118: Testing The Shutter Mechanism

the locking mechanism does not get jammed at any point in the range of rotation the beam path can be closed completely If you notice a failure or you have doubts, please contact the BERTHOLD TECHNOLOGIES service department. 54733-10BA2L 1 – 118 02.2017... -

Page 119: Safety Measures

In the event that radioactive substances are lost, the Radiation Safety Manager and the regulatory authority have to be notified immediately. In case of theft, the police must be informed as well. SENSseries LB 480 Level measurement 1 – 119 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 120: Accidents, Loss, Damage, Fire, Theft

• Limit access to the area • Report the incident to the authorities. • Inform BERTHOLD TECHNOLOGIES. Proper handling and disposal of possibly leaking radioactive sources or contaminated parts of the equipment must be coordinated with the supervisory authority. 9.6.1... - Page 121 In case of an accident or malfunction or any other event which affects the safety, the regulatory authority has to be informed and also, if necessary, the authority in charge of public safety. Please contact BERTHOLD TECHNOLOGIES if you need any further infor- mation. SENSseries LB 480 Level measurement 1 –...

-

Page 122: Shielding And Source

9 Radiation Protection Volume 1 Shielding and Source Shieldings do not include any wearing parts or mechanically moving parts that under normal operating conditions require maintenance. For safety reasons, however, it should be possible any time to lock the useful beam. A functional check has to be performed in appro- priate intervals of max. -

Page 123: Leak Test

• Certificate on an acceptance test by the manufacturer. SENSseries LB 480 Level measurement 1 – 123 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 124 9 Radiation Protection Volume 1 For point source shieldings with rotary shutter: Alternative test areas Alternative test area Fig. 9-2 Alternative test area on point source shieldings: The alternative test area is the visible part on the head of the shielding cylinder.

- Page 125 Alternative test area Fig. 9-3 Alternative test area on rod source shieldings The alternative test area is the visible part on the head of the shield- ing cylinder. SENSseries LB 480 Level measurement 1 – 125 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 126 9 Radiation Protection Volume 1 For point source shieldings with rotary shutter: Alternative test area Fig. 9-4 Alternative test area on point source shieldings: The alternative test area is the visible part on the head of the shield- ing cylinder. 54733-10BA2L 1 –...

- Page 127 The alternative test area is the head of the visible edge of the source holder. If the cover is also accessible then you have to wipe there as well. SENSseries LB 480 Level measurement 1 – 127 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 128 9 Radiation Protection Volume 1 54733-10BA2L 1 – 128 02.2017...

-

Page 129: Source Replacement

Using a pocket dosimeter with direct reading, measure the accu- rate radiation exposure during this work, even if the radiation exposure lies below the detection limit of dosimeters. SENSseries LB 480 Level measurement 1 – 129 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 130 10 Source Replacement Volume 1 A single part rod source with an activity of 400 MBq (approx. Calculation example 11 mCi) has to be replaced. Using the above assumptions concern- ing distance and time and the above equation, we get the following result: D = 400 x 0.15 = 60µSv The radiation exposure in the vicinity of the shielding was previously...

-

Page 131: Point Source Replacement On Rotary Cylinder Shielding

Radioactive Substances” states whether you are in possession of such a license. Prerequisite for this work is detailed knowledge of the design of the shielding; appropriate drawings must therefore be available. SENSseries LB 480 Level measurement 1 – 131 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 132 10 Source Replacement Volume 1 All necessary work has to be prepared well so that it can be carried Preparation out quickly to keep exposure to the unshielded source to a mini- mum. Using a drawing of the shielding, you should plan the best procedure and have the following tools handy: •...

- Page 133 Unscrew the source holder (3) with the source (4) from the shielding. Use a size 12 socket wrench. SENSseries LB 480 Level measurement 1 – 133 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 134 IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES's Source Trans- port Manager. This completes the source replacement. 54733-10BA2L 1 – 134...

-

Page 135: Rod Source Replacement

Radioactive Substances” states whether you are in possession of such a license. Prerequisite for this work is detailed knowledge of the design of the shielding; appropriate drawings must therefore be available. SENSseries LB 480 Level measurement 1 – 135 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 136 10 Source Replacement Volume 1 All necessary work has to be prepared well so that it can be carried Preparation out quickly to keep exposure to the unshielded source to a mini- mum. Using a drawing of the shielding, you should plan the best procedure and have the following tools handy: •...

- Page 137 Rod source Top: 1 ring Bottom: 2 Top: 2 rings Bottom: 3 Top: 2 rings Bottom: 4 rings Fig. 10-3 Markings on multi-part sources and shieldings SENSseries LB 480 Level measurement 1 – 137 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 138 10 Source Replacement Volume 1 10.3.1 Source Replacement Procedure Fig. 10-4 Dismounting rod source shielding Unscrew the head flange (1) using a suitable Allen key. Open the locking cover (2). Health hazards due to radiation! Do not remove the source from the shielding! Do not touch the source to prevent a high partial body dose.

- Page 139 IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES's Source Trans- port Manager. This completes the rod source replacement. SENSseries LB 480 Level measurement 1 –...

-

Page 140: Point Source Replacement On Lb 744X Shieldings

10 Source Replacement Volume 1 10.4 Point Source Replacement on LB 744x Shieldings In this chapter we will describe how to replace point sources on the following shieldings: – LB 7440 – LB 7442 – LB 7444 – LB 7445 –... - Page 141 Pull the knob (3) and turn the lever (4) by 90° to the right to the center position between OPEN and CLOSED Now the hex screw head of the source holder is visible. SENSseries LB 480 Level measurement 1 – 141 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 142 10 Source Replacement Volume 1 rotate by 90° Fig. 10-5 Point source shielding, beam path closed Fig. 10-6 Sectional drawing of source holder, beam path open 54733-10BA2L 1 – 142 02.2017...

- Page 143 (torque: 44Nm). Check the proper ON/OFF function. Carefully close the transport shielding again, after you have put the old source into the transport shielding. SENSseries LB 480 Level measurement 1 – 143 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 144 Calibrate the system new (see Volume 3) IMPORTANT The special regulations regarding labeling and transport of the shielding back to the manufacturer have to be observed. If in doubt, please contact BERTHOLD TECHNOLOGIES's Source Trans- port Manager. This completes the point source replacement. 54733-10BA2L 1 –...

-

Page 145: Source Disposal

In many countries the transport of radioactive materials is subject to approval by the authorities. The source may be returned only after prior order confirmation and release confirmation by BERTHOLD TECHNOLOGIES. SENSseries LB 480 Level measurement 1 – 145 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 146 • BERTHOLD TECHNOLOGIES has to be informed in advance about the return transport. Radioactive material that is shipped to BERTHOLD TECHNOLOGIES without prior notice will not be accepted by BERTHOLD TECHNOLOGIES. Any warehouse expenses will be charged to the supplier.

- Page 147 Volume 1 Notes: SENSseries LB 480 Level measurement 1 – 147 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 148 Subject to change in the course of further technical development. © BERTHOLD TECHNOLOGIES GmbH & Co. KG 2009 Language: English Printed in Germany 02.2017 Rev. No.: 03 BERTHOLD TECHNOLOGIES GmbH & Co. KG Calmbacher Str. 22 D-75323 Bad Wildbad Germany www.Berthold.com...

- Page 149 Volume 2 Installing SENSseries...

- Page 150 Volume 2 54733-10BA2L 2 – 150 02.2017...

-

Page 151: System Description

Volume 2 1 System Description System Description Measuring System 1.1.1 Basic Measuring Configuration The measuring system SENSseries LB 480 is a detector which, depending on its design, can be used for different measurement tasks: – Level measurement – Monitoring limit values –... - Page 152 Source in shielding Process control with SIMATIC PDM ® HART Communicator Con- SENSseries tainer LB 480 Tank connected notebook Fig. 1-1 Basic measuring configuration 1.1.2 Detector communication The communication with display, evaluation and control devices Communication with the PCS ®...

- Page 153 Measuring Geometries The hardware and software of the measuring system SENSseries LB 480 allow for an easy adaptation of the system to different mea- suring geometries and measuring tasks. Therefore, the settings and parameters of the measuring device have to be defined with care during commissioning for the particular measuring task.

-

Page 154: Sensseries Hardware

1 System Description Volume 2 SENSseries Hardware 1.2.1 Detector The measuring system SENSseries LB 480 comprises one detector and the evaluation unit, both accommodated in a sturdy stainless steel housing. Cable entries M20 or ½“ NPT ® 4–20mA + HART... - Page 155 The 4-20 mA measuring signal is passed through a 2-wire cable to the PCS (terminals 15 and 16). ® HART The measuring system SENSseries LB 480 uses the proto- Detector Communication col for communication. Configuration, parameter setting and cali-...

- Page 156 1 System Description Volume 2 1.2.2 Sources Sources are not part of the SENSseries LB 480 measuring system. They can be purchased separately through BERTHOLD together with the respective shieldings and TECHNOLOGIES holding devices. Radioactive sources for industrial applications are always "encapsu- lated radioactive substances"...

-

Page 157: Measuring Principle

For this reason, the radiometric measur- ing principle ensures high reliability and low maintenance. Source Detector Fig. 1-4 Measuring Principle SENSseries LB 480 Level measurement 2 – 157 BERTHOLD TECHNOLOGIES GmbH & Co. KG... -

Page 158: Measuring Arrangements

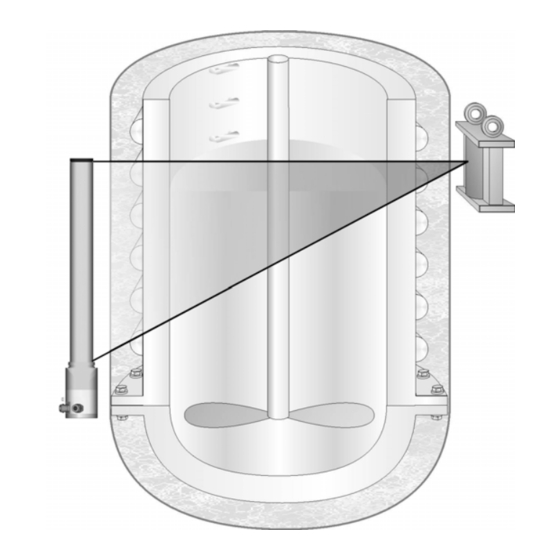

1 System Description Volume 2 Measuring Arrangements To be able to cover a certain measuring range continuously, a mea- suring arrangement must be realized where the dimensions of source and detector form a geometry, which covers a measuring field of equal size. The different options that are available will be described below. - Page 159 The required tag-specific calculations will be provided by BERTHOLD TECHNOLOGIES. Level Detector Point source Detector signal Fig. 1-6 Rod detector arrangement SENSseries LB 480 Level measurement 2 – 159 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 160 1 System Description Volume 2 1.4.3 Rod Source / Rod Detector Arrangement For measuring geometries with an unfavorable ratio between mea- suring range and the source - detector distance or with very thick container walls, one can choose an arrangement with rod source and rod detector to reduce the source activity (see Fig.

- Page 161 The arrangement shown in Fig. 1-9 is used for limit measurements, for example to avoid overflowing when filling a container. Level Source Detector Detector signal Fig. 1-9 Point source / Point detector arrangement for limit switches SENSseries LB 480 Level measurement 2 – 161 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 162: Technical Data

1 System Description Volume 2 Technical Data If you are working under different operating conditions, please con- tact BERTHOLD TECHNOLOGIES. Ambient temperature for "non-Ex" areas Operating temperature Storage temperature uncooled with water cooling CrystalSENS -40 to +60° C to +100° C -40 to +60°... - Page 163 2-290. The screw fittings supplied by BERTHOLD TECHNOLOGIES match Cable glands the protection type IP66, IP68 and IP69K. The permitted cable cross-section of the screw fittings is listed in our offer or our order confirmation.

- Page 164 1 System Description Volume 2 The cable cross-section is dependent on the cable glands used. Cable cross-section 0.5mm to 2.5mm ; stripped length 10mm Wire cross-section for spring-type terminals Scintillators Type Scintillator Dose Rate (typic) Tempera- Weight in kg Weight in kg for CS-137 in μSv/h ture stabil- with water cool-...

- Page 165 Standard BELL-202 FSK. – measurable temperature range -30° C ... 180° C Pt100 – monitored temp limits – Accuracy: +/-0.2° C – maximum connectable cable length: 30m SENSseries LB 480 Level measurement 2 – 165 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 166: Detector Codes

They only have to be checked or adapted when the elec- tronics has been exchanged. Detector type LB-No. Scintillator Detector code Restrictions CrystalSENS LB 480-11 50x50 NaI with count rates in the mea- suring range of >1000cps LB 480-12 LB 480-11 50x50 NaI with count rates in the mea- suring range of <1000cps... -

Page 167: Nomenclature Of The Sensseries Lb 480

Volume 2 1 System Description Nomenclature of the SENSseries LB 480 LB480 - 1 1 - - 1 1 - r 1 - 0 0 0 Scintillator CrystalSENS 50/50 CrystalSENS 50/50 + WK CrystalSENS 40/35 CrystalSENS 40/35 + WK CrystalSENS 25/25... - Page 168 1 System Description Volume 2 LB480 - 1 1 - - 1 1 - r 1 - 0 0 0 Power supply 100V to 240V Collimator without axial laterally positioned or laterally 66° for SuperSENS axial 316L lateral 316L Housing material 1.4301 (Standard) 316L I/O extensions...

- Page 169 R RID LK4 G SWITCH SPEEDSTAR LK4 H SWITCH SPEEDSTAR LK5 J LEVEL SPEEDSTAR LK4 P LEVEL SPEEDSTAR LK5 K DENSITY SPEEDSTAR LK5 (LK = License Key) SENSseries LB 480 Level measurement 2 – 169 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 170 1 System Description Volume 2 54733-10BA2L 2 – 170 02.2017...

-

Page 171: Installation

Please be sure to comply with the Radiation Protection Guidelines applicable in your country and observe the Radi- ation Protection Instructions in chapter 9, page 1-113. SENSseries LB 480 Level measurement 2 – 171 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 172 2 Installation Volume 2 The shielding with the radioactive source is delivered in a box in Storing the shieldings compliance with the regulations concerning the transportation of radioactive substances. Risk of injury! The weight of the source shielding may be up to several 100kg, depending on the version.

-

Page 173: Transport To The Installation Site

If the system parts are provided with eyebolts for transportation, they have to be used for lifting, unless the system parts are transported in their original packaging. SENSseries LB 480 Level measurement 2 – 173 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 174 The exact position for your sys- tem parts is stated on the calculation documents and the technical information prepared by BERTHOLD TECHNOLOGIES. 2.1.5 Unpacking and Cleaning System Parts After unpacking, compare all parts with the packing list and check if the shipment is complete and shows any sign of damage.

-

Page 175: Source Detector Arrangements

Volume 2 2 Installation Source Detector Arrangements BERTHOLD TECHNOLOGIES offers a large number of options for your particular measurement setup. The schematic drawings below show examples of different arrangements which will guide you to the respective installation instructions. Since other arrangements are also possible, the installation of the detector side and the source side will be explained separately. - Page 176 2 Installation Volume 2 IMPORTANT If a suitable arrangement example should be missing for your spe- cial application, you will receive special documents in advance. Please contact us if you did not receive these documents. By means of the source number which you find on the shielding it is easily possible to provide you with the suitable information on this mea- suring site.

-

Page 177: Detector Protection

40° C, you could switch off the detector on exceeding a temperature limit of e.g. 50° C prematurely to protect the detector against overtemperature. SENSseries LB 480 Level measurement 2 – 177 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 178 2 Installation Volume 2 The required amount of cooling water is dependent on the possible Cooling water curves heat transmission, the cooling water temperature and the detector type. You find the cooling water curves and further information in the technical specifications on page 2-241. Water is always supplied from the bottom to prevent air pockets Connecting the water cooling that can drastically reduce the cooling effect.

- Page 179 The detector may be cleaned with water or gaso- line. Remove coarse deposits with a wire brush. Grinding, filing or chipping away at deposits with the hammer is not permitted. SENSseries LB 480 Level measurement 2 – 179 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 180: Detector Assembly

2 Installation Volume 2 Detector Assembly Make sure that – the detector or the source fixtures do not obstruct the beam path. – there are no pipes, flanges, stirrers or other installations in the beam path. Only installations that have already been taken into account in plan- ning the measurement configuration are permitted. - Page 181 91mm Mounting platform Fig. 2-3 Installation proposal for rod detector with collimator For details on how to position the collimator please see the techni- cal drawings. SENSseries LB 480 Level measurement 2 – 181 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 182 Seitenansicht 1. + 2. Rod detector Stabdetektor Fig. 2-4 Multi-detector arrangement For installation details see the technical drawing (see page 2-241). 2.4.2 TowerSENS See chapter 5.2, "TI LB 480 TowerSENS" on page 2-276. 54733-10BA2L 2 – 182 02.2017...

- Page 183 The installation situation is illustrated in the project drawings, sketches and descriptions. SENSseries LB 480 Level measurement 2 – 183 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 184 2 Installation Volume 2 IMPORTANT When installing the CrystalSENS, please pay attention to the cor- rect alignment relative to the source. The lateral opening (beam window) in the collimator releases the sensitive area of the detec- tor and must be directed at the source. Terminal compartment Collimator Cable gland...

- Page 185 Volume 2 2 Installation Fig. 2-9 Alternative installations The technical drawings for CrystalSENS and its accessories can be found in chapter 5, "Technical Information", on page 2-241. SENSseries LB 480 Level measurement 2 – 185 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 186 2. Mount the bracket either directly on the container or on a stable support. 3. Mount the detector with the clamps on the bracket (see chapter 5.1, "TI LB 480 Level"). 2.4.5 Installation Procedure with Mounting Kit A robust stainless steel holder is available instead of the clamps.

-

Page 187: Water Cooling

Screws (about 30mm long) Fig. 2-11 Mounting screws for collimator 2. Slide the cooling jacket over the detector. Water cooling Detector Fig. 2-12 Detector with water cooling SENSseries LB 480 Level measurement 2 – 187 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 188 2 Installation Volume 2 3. Remove the plastic ring from the collimator by opening the screws on the side of the collimator. Screws Plastic ring Screws Fig. 2-13 Collimator for detector 4. Slide the collimator over the water cooling system, so that the beam window is facing the source.

-

Page 189: Shielding

4 Shielding material 5 Type of shielding 6 Shielding manufacturer 7 Dose rate in 1m distance 8 Effective shielding thickness 9 Activity Fig. 2-15 Identity plate SENSseries LB 480 Level measurement 2 – 189 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 190 2 Installation Volume 2 Please observe the safety instructions in Volume 1 on page 1-113. A source may be transported only in its shielding. Keep the source shielding closed during storage, transportation and installation. The arrangement of the sources is defined during the planning stage and entered in a drawing or defined in writing.

- Page 191 Side view max. 45° Top view Fig. 2-17 Point source shielding 45° SENSseries LB 480 Level measurement 2 – 191 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 192 Mounting Marking groove bracket SENSseries LB 480 Fig. 2-18 Point source with rod detector The standard arrangement (Fig. 2-18) shows the mounting position of the shielding with point source; H indicates the topmost point of the measuring range that can be covered. The shielding must be...

- Page 193 The bracket has to be mounted in the appropriate height, if possible, directly on the ves- sel or on another supporting structure. SENSseries LB 480 Level measurement 2 – 193 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 194 2 Installation Volume 2 Shielding 45° with point source Mounting base 1 Mounting base 2 This version is easier to The version of the mount- make than version 2 ing base with an elongated hole allows the alignment of the source at the detec- tor.

- Page 195 Following installation of the shielding, the function of the locking mechanism has to be tested. The function check has to be carried out every six months and recorded. SENSseries LB 480 Level measurement 2 – 195 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 196 2 Installation Volume 2 Open shielding After the shielding has been installed, it may be opened only for commissioning. Open the transportation safety device and open the lock. Now use the lever fixed to the base with adhesive tapes and plug it into the borehole for the locking mechanism. Open the beam channel by turning the lever to the right up to the right limit stop.

- Page 197 Depending on the size of the measuring range, this arrangement can be realized with one or several detectors. Source 1 Marking grooves Source 2 SENSseries LB 480 Fig. 2-22 Multi-detector arrangement SENSseries LB 480 Level measurement 2 – 197 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 198 2 Installation Volume 2 2.6.3 Rod source Increased radiation dose due to open beam channel! A too high dose of radiation may be harmful to your health. A source may be transported only in its shielding. The shielding must be closed during transportation and installation. For rod sources, cylinder-shaped shieldings having the length of Rod source shielding the source are used which are provided with a source exit channel...

- Page 199 (Max). Rod source Fig. 2-25 Rod source arrangement, see also next table SENSseries LB 480 Level measurement 2 – 199 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 200 2 Installation Volume 2 Shielding diameter (in mm) G (in mm) The installation height of the supporting structure that is to be pro- vided by the customer has to be measured using the dimensional drawings of the shielding. The size and stability of the supporting structure or another suit- able mounting device for the shielding has to match the size and total weight of the shielding.

- Page 201 Following installation of the shielding, the function of the locking mechanism has to be tested. The function check has to be carried out every six months and recorded. SENSseries LB 480 Level measurement 2 – 201 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 202 2 Installation Volume 2 Open shielding After the shielding has been installed, it may be opened only for commissioning. Open the transportation safety device and open the lock. Now use the lever fixed to the base with adhesive tapes and plug it into the borehole for the locking mechanism. Open the beam channel by turning the lever to the right up to the right limit stop.

- Page 203 Following installation of the shielding, the function of the locking mechanism has to be tested. The function check has to be carried out every six months and recorded. SENSseries LB 480 Level measurement 2 – 203 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 204 2 Installation Volume 2 Anti-tipping device installed by the installa- tion contractor. Strap e.g. welded to the vessel or the sup- porting structure. The anti-tipping device must be installed on both sides and on each shielding. Mounting base installed by the installation contractor.

- Page 205 Fig. 2-29 Flange shieldings for rod source and point source SENSseries LB 480 Level measurement 2 – 205 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 206 2 Installation Volume 2 – Rod source with steel cable, one-part or multi-part Versions for flange shieldings – Rod source with shaft core, one-part or multi-part – Point source with steel cable, one-part – Point source with shaft core, one-part Multi-part rod source flange shieldings can be designed such that they can be loaded with up to 5 rod sources.

- Page 207 The shieldings can be adapted to your vessel flange using various flange adapters. SENSseries LB 480 Level measurement 2 – 207 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 208 2 Installation Volume 2 Shielding with source Pressure control Protection gas Vessel wall Protection tube Dip tube Detector Fig. 2-31 Dip tube installation with point source and point detector If the shieldings are employed in aggressive atmospheres, the steel cable or the shaft core and the latch mechanism have to be checked for corrosion in regular intervals.

- Page 209 Therefore, never close the source locking mechanism as long as not all rod sources are again in the shielding. Otherwise, the steel cable may be kinked or even cut. SENSseries LB 480 Level measurement 2 – 209 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 210 2 Installation Volume 2 Source end piece (inactive) Steel cable latch, must be latched into the source end piece Positioning screw Clamping screw Steel cable for source positioning Source end piece with clutch Steel cable with Shielding head latch for clutch A source type label is attached on the shielding for Eyebolt...

- Page 211 Connect the shaft core with the source end piece. Shaft core with latch for clutch Source end piece with clutch Fig. 2-34 Shaft core and source end piece SENSseries LB 480 Level measurement 2 – 211 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 212 2 Installation Volume 2 Fig. 2-35 Connect shaft core and source end piece Open the fixing screw at the head piece. Fig. 2-36 Open fixing screw Open the source shielding. Fig. 2-37 Open source shielding Push the shaft core in up to the limit stop. 54733-10BA2L 2 –...

- Page 213 Fix the position with the fixing screw at the head piece. Attach the covering cap again. Secure the lock with a padlock or the safety screw. The source is now installed. SENSseries LB 480 Level measurement 2 – 213 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 214 2 Installation Volume 2 2.6.6 Point Source Shielding LB744X The radiation warning sign identi- fies the start of the controlled area, provided the controlled area is out- side the shielding. If the controlled area is inside the shielding, then the radiation warning sign attached on the shielding suffices.

- Page 215 Therefore, install the fixture on a vibration-free support or attenu- ate possible vibrations using vibration absorbers. Prevent heat transfer by using suitable insulating materials. SENSseries LB 480 Level measurement 2 – 215 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 216 2 Installation Volume 2 The shielding can either be installed on a bracket or on a flange. Installing the shielding Size and position of the measuring range to be covered are deter- mined in the projection phase for the measuring site and defined by drawings, sketches or details in writing.

-

Page 217: Electrical Installation

Equipotential busbar provided by customer Signal line Fig. 3-1 Detector housing open - top view Cable entries that are not used must have dummy plugs installed. SENSseries LB 480 Level measurement 2 – 217 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 218 3 Electrical Installation Volume 2 3.1.1 Multi-detector Operation Refer to the connection diagram for the multi-detector operation in the Technical Information on page 2-241. 3.1.2 ATEX Connection Type Follow the safety instructions in chapter 5, "Explosion Protection", Volume 1. 3.1.3 FM/CSA Connection Type A stopping box (conduit seal) has to be installed on each cable entry used directly behind the detector housing.

-

Page 219: Terminals

(loop through) the supply voltage to the next slave (only permitted for supply of 24 V 5 - 6 RS-485: for Multi-detector operation, connection for slave detector, service interface and software update SENSseries LB 480 Level measurement 2 – 219 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 220 3 Electrical Installation Volume 2 Terminals Master ® HART 11 - 12 Open collector signal output with reverse voltage protection ALARM: no current flowing NORMAL: Current flowing The supply voltage for the open collector must be between 5 and 36V. The maximum current that may flow through the open col- lector is 100mA.

- Page 221 Connect the last slave to terminal 9 Connect the last slave to terminal 10 9 - 10 RS 485: Connection to the next slave detector SENSseries LB 480 Level measurement 2 – 221 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 222 3 Electrical Installation Volume 2 We recommend using a screened cable for the signal lines. Signal cable with shielding The screen has to be connected to the detector on the PE terminal in the terminal compartment of the detector, or better, to suitable EMC cable glands.

-

Page 223: Connecting The Detector

For detectors that are used in hazardous areas, the detector hous- ing (Fig. 3-4) and thus the pressure-proof enclosure of the elec- tronics may be opened only by the BERTHOLD TECHNOLOGIES ser- vice or by persons authorized by BERTHOLD TECHNOLOGIES. - Page 224 3 Electrical Installation Volume 2 Housing cover Connection head Do not unscrew the 6 screws connecting the detector housing to the connection head. Detector housing Fig. 3-4 Detector housing with connection head Unscrew the housing cover (M5 and M8 Allen wrench). Connecting cables ...

- Page 225 To do this, put the housing cover with the sealing on the housing and tighten the Allen screws using the specified torque: depending on the version, M5 with 4 Nm or M8 with 17 Nm (standard values). SENSseries LB 480 Level measurement 2 – 225 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 226 3 Electrical Installation Volume 2 Create cable loops with the connected lines in front of the hous- ing entrance and provide for an appropriate strain relief of the connected cables. If there is a danger that the cable may be used as a stepladder, then the cables must be installed pro- tected, for example in conduits.

-

Page 227: Repair, Maintenance And Upkeep

– the detector housing BERTHOLD TECHNOLOGIES recommends to have detectors repaired solely by the BERTHOLD TECHNOLOGIES service or by per- sons authorized by BERTHOLD TECHNOLOGIES. Only original spare parts by BERTHOLD TECHNOLOGIES may be used. Please follow the instructions in the Safety Manual (Volume 1) and the instructions in chapter 3, "Electrical Installation", page 2-217. -

Page 228: Safety Instructions

Repair and maintenance work on the detectors must be performed by competent personnel, see Volume 1, chapter 3, "Qualification of Personnel", page 1-19. If in doubt, return the entire detector for repair to BERTHOLD TECHNOLOGIES. Also note the following points: •... -

Page 229: Replacing The Complete Detector

Allen screws using the specified torque: depending on the version, M5 with 4 Nm or M8 with 17 Nm (standard val- ues). Turn on power. SENSseries LB 480 Level measurement 2 – 229 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 230 4 Repair, Maintenance and Upkeep Volume 2 Enter the previously documented parameters of the detector ® with the exception of the parameter HV-Default via the HART Communicator or an alternative user interface. Perform a new calibration (see Volume 3, chapter 5). Now the detector is ready for operation again.

-

Page 231: Replacing The Electronics Module

Explosion hazard! For detectors used in the Ex-area, the electronics module must be replaced solely by the BERTHOLD TECHNOLOGIES service or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, you must replace the entire detector or return it to the manufacturer for repair. - Page 232 4 Repair, Maintenance and Upkeep Volume 2 Risk of fatal injury due to electric shock! When the housing is open, you may come into contact with live parts if the power supply is connected. Make sure when you open the cover that no supply voltage is applied to the terminals.

- Page 233 See also Volume 3 on page 3- 299. Separate User’s Manuals are available for user interfaces such ™ as SIMATIC PDM or FOUNDATION Fieldbus. This completes the replacement of the electronics module. SENSseries LB 480 Level measurement 2 – 233 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 234: Replacing The Crystal-Multiplier Assembly (For Crystalsens)

For detectors used in the Ex-area, the crystal-multiplier assembly must be replaced solely by the BERTHOLD TECHNOLOGIES service or by persons authorized by BERTHOLD TECHNOLOGIES. If this is not possible, you must replace the entire detector or return it to the manufacturer for repair. -

Page 235: Checking The Detector

Photo cathode Fig. 4-2 Scintillation detector The point detector CrystalSENS uses a 50/50 NaI crystal as a scin- tillator, the SuperSENS detector uses a 150/150 scintillator. SENSseries LB 480 Level measurement 2 – 235 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 236 4 Repair, Maintenance and Upkeep Volume 2 4.5.1 Checking the NaI Point Detector (CrystalSENS) Malfunctions of the scintillation counter are not always indicated by a missing pulse rate; it is also possible that the specific Gamma sen- sitivity appears to have changed or obvious instabilities are appar- ent.

- Page 237 Using the adhesive tape, replace the Mu-metal screen, making sure that it is only under light tension. SENSseries LB 480 Level measurement 2 – 237 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 238: Customer Service

+49 (0) 7081 177-339 (fax) +49 (0) 7081 177-0 (switchboard)) e-mail: Service@Berthold.com To get efficient help you have to provide the following information: • Detector type or "LB" number, e.g. LB 480 • Information on the error • Information on the application –... -

Page 239: Repair, Return Shipping

Repair, Return Shipping 4.7.1 Electronics, Detector If you intend to return parts or complete detectors for repair, please provide the following information: • Detector type or "LB" number, e.g. LB 480 • Information on the error • Delivery address •... - Page 240 4 Repair, Maintenance and Upkeep Volume 2 54733-10BA2L 2 – 240 02.2017...

-

Page 241: Technical Information

Volume 2 5 Technical Information Technical Information TI LB 480 Level SENSseries LB 480 Level measurement 2 – 241 BERTHOLD TECHNOLOGIES GmbH & Co. KG... - Page 242 5 Technical Information Volume 2 Technical Information Level LB 480 Level Gauge Füllstandmessung Field mounted components Messstellen-Komponenten 54733-10BA2L 2 – 242 02.2017...

- Page 243 25.0 25.5 LB 480-2F 1433 1000 32.0 33.0 LB 480-2J 1933 1500 39.5 40.0 LB 480-2L 2433 2000 48.0 50.0 * WC/WK = Water Cooling / Wasserkühlung SENSseries LB 480 Füllstandsmessung 2 – 243 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 244 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 1.2 Examples for Measurement Arrangements with Rod Detector Beispiele für Messanordnungen mit Stabdetektor 54733-10BA2L 2 – 244 02.2017...

- Page 245 2573 2090 2600 60085-050 1077 1100 60085-100 1000 1120 1155 1577 1090 1600 60085-150 1500 1620 1655 2077 1590 2100 60085-200 2000 2120 2155 2577 2090 2600 SENSseries LB 480 Füllstandsmessung 2 – 245 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 246 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 1.4 Examples for Mounting Devices and the Installation at the Collimator Beispiele für die Halterung und Montage des Kollimators Detector locking screws with Stabilizer against tilting, installed by customer.

- Page 247 Die Zeichnungen auf dieser Seite sind gültig für Detektoren mit und ohne Wasserkühlung. 2000 1500 1000 1.7 Clamping Position for Multi Detector Arrangement 1.8 Mounting Position for Rod Detector Shieldings Klemmenposition für Multidetektor-Anordnung Klemmenposition für Stabdetektorabschirmungen SENSseries LB 480 Füllstandsmessung 2 – 247 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 248 LB 480 Abmessungen in mm 2.0 CrystalSENS (Version f. Zone 1/2) LB 480-1.-0. LB 480-1.-1. LB 480-1.-2. LB 480-1.-Z. LB 480-1.-.. -..-r.- LB 480-1.-.. -..-0.- with water cooling mit Wasserkühlung 2.1 CrystalSENS (Version f. Divisions 1/2) LB 480-1.-F. LB 480-1.-G.

- Page 249 Abmessungen in mm 2.3 Point Detector Installation Examples Punktdetektor Installationsbeispiele Application with multipart rod source shielding Application with dip pipe Anordnung mit mehrteiliger Stabstrahler-Abschirmung Anordnung mit Tauchrohr SENSseries LB 480 Füllstandsmessung 2 – 249 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 250 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 2.4 Mounting Clamps for Detector Befestigungsschellen für Detektor for Detectors without water cooling for Detectors with water cooling für Detektoren ohne Wasserkühlung für Detektoren mit Wasserkühlung Material 316Ti 1.4571...

- Page 251 Auch die Aufheizung des Detektors durch Wärmeabstrahlung vom Behälter kann durch ein dünnes Wärmeableitblech gemildert werden. Für jeden Detektor steht auch eine geeignete Wasserkühlung (Option) zur Verfügung. SENSseries LB 480 Füllstandsmessung 2 – 251 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 252 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 2.7 CrystalSENS Water Cooling Jacket and Adaptor Fittings CrystalSENS Wasserkühlung und Adapter Anschlussstücke tube connection diameter Ø 10 mm Schlaucholive Ø 10 Thread connection R ¼" Gewindeanschluss R ¼"...

- Page 253 Damit sich die Wasserkühlung vollständig mit Wasser füllt, muss der Wasserzufluss von unten erfolgen. bottom 2.9 Detector Cooling Water Demand Detektor Kühlwasserbedarf SENSseries LB 480 Füllstandsmessung 2 – 253 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 254 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 54733-10BA2L 2 – 254 02.2017...

- Page 255 3.1 with Side Irradiation mit seitlicher Einstrahlung LB 480-31-..-..-r. Weight/Gewicht 52 kg 3.2 with Side Irradiation and Water Cooling mit seitlicher Einstrahlung und Wasserkühlung LB 480-32-..-..-r. Weight/Gewicht 59 kg SENSseries LB 480 Füllstandsmessung 2 – 255 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 256 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 3.3 with Axial Irradiation mit frontaler Einstrahlung LB 480-31-..-..-a. Weight/Gewicht 62 kg 3.4 with Axial Irradiation and Water Cooling mit frontaler Einstrahlung und Wasserkühlung LB 480-32-..-..-a. Weight/Gewicht 69 kg 3.5 SuperSENS (Version f.

- Page 257 Stabstrahler radiation channel Strahlenaustritt pad lock Vorhängeschloss position open Stellung auf position closed Stellung zu name plate Typenschild Type kg/m approx 204.5 11.5 224.5 11.5 11.5 222.5 SENSseries LB 480 Füllstandsmessung 2 – 257 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 258 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 4.1 Multipart Installation of Rod Source Shieldings Mehrteilige Installation von Stabstrahler-Abschirmungen Distance shielding to vessel surface: approx. 100mm Abstand Abschirmung zur Behälter-Oberfläche: ca 100mm Tilt protection installed by customer.

- Page 259 Anordnung mit 3 Abschirmungen: II + III + IV Anordnung mit 4 Abschirmungen: II + III + III + IV etc. Shielding / Abschirmung drawing no. Ø Zeichnungs-Nr. 21156.000-000 21157.000-000 21158.000-000 21159.000-000 21160.000-000 21161.000-000 SENSseries LB 480 Füllstandsmessung 2 – 259 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 260 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 5. Shielding for Point Source Abschirmungen für Punkt Strahler r r r r The shielding are marked with BOTTOM to rule out any side-inverted installation. Die Abschirmungen sind markiert mit UNTEN um eine seitenverkehrte Installation auszuschließen.

- Page 261 Der Montagesockel 1 ist leichter Die Ausführung 2 des Montagesockels mit herzustellen. dem Langloch, ermöglicht die Ausrichtung des Strahlers auf den Detektor. SENSseries LB 480 Füllstandsmessung 2 – 261 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 262 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 6. Pneumatic Actuator for Rod and Point Source Shielding (Type 80 … 270) Pneumatik für Stab- und Punktstrahler-Abschirmungen (Typ 80 … 270) Pneumatic actuator for rod source shielding Pneumatischer Antrieb für Stabstrahler-Abschirmung...

- Page 263 Square neck for position control or for pneumatic actuator. manual operation Rückstellfeder (Fail-Save) mit pneumatischem Antrieb Außenvierkant zur Stellungsanzeige, oder manueller Betätigung Shielding Type 80 … 270 Abschirmung Typ 80 … 270 SENSseries LB 480 Level measurement 2 – 263 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 264 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 7. Flange Shielding for Rod Source on Dip Pipe Abschirmungen für Stabstrahler am Tauchrohr 54733-10BA2L 2 – 264 02.2017...

- Page 265 Verschluss erst öffnen wenn der Strahler in das Tauchrohr gefahren werden soll und das Stahlseil, bzw. die Wellenseele eingeklinkt ist. SENSseries LB 480 Level measurement 2 – 265 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 266 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 7.2 Flange Adaptors for Rod Source Shieldings Flanschadapter für Stabstrahler-Abschirmungen 54733-10BA2L 2 – 266 02.2017...

- Page 267 Carbon Steel St 37 ND 200 LB 7444-CR Dimensions in drawing / Abmessungen in Zeichnung 6° PN 6 Radiation Angle of the Shielding / Abstrahlwinkel der Abschirmung SENSseries LB 480 Level measurement 2 – 267 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 268 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 8.1 Mounting Proposal for Source Shielding LB 744x Montagevorschlag für Abschirmbehälter LB 744x Source Shielding LB 744x Abschirmbehälter LB 744x ~ 30 mm Flange Installation Flanschinstallation Pedestal Installation...

- Page 269 Gehäuseschutzart: EEx e II T6 Option III: 2 Proximity switches EEx ia IIC T6, for intrinsically safe power supply 2 Näherungsinitiatoren EEx ia IIC T6, für eigensichere Speisung SENSseries LB 480 Level measurement 2 – 269 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 270 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 8.3 Components for Pneumatic Actuator Einzelteile für Pneumatischen Verschlussantrieb Pneumatic Actuator Return Spring Pneumatischer Antrieb Rückstellfeder male square spin-type handle as position indicator, or for manual operation Außenvierkant zur Stel-...

- Page 271 ND 125 PN 6 LB 8030-02 10° LB 8040-01 30° ND 200 1014 PN 6 LB 8040-02 10° Radiation Angle of the Shielding / Abstrahlwinkel der Abschirmung SENSseries LB 480 Level measurement 2 – 271 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 272 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 10. Point Source Flange Shielding LB 81xx for Dip Pipe Installations Punktstrahler-Flansch-Abschirmbehälter LB 81xx für Tauchrohr-Applikationen Type/Typ LB 8115 + LB 8120 Version for 2 Sources LB 81xx-20 Version für 2 Strahler LB 81xx-20...

- Page 273 Klinke in Kupplung einklinken A steel rope or flexible shaft can be used to position the source. Zur Positionierung kann ein Stahlseil oder eine Wellenseele genutzt werden. SENSseries LB 480 Level measurement 2 – 273 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 274 5 Technical Information Volume 2 Dimensions in mm LB 480 Abmessungen in mm 11. Terminal Connection for Single Detector Elektrischer Anschlussplan für Einzeldetektor 54733-10BA2L 2 – 274 02.2017...

- Page 275 11.1 Multi Detector Connection Diagram Multidetektor-Anschlussplan Up to 16 slaves can be connected at one master. Bis zu 16 Slaves können an einen Master angeschlossen werden. SENSseries LB 480 Level measurement 2 – 275 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 276: Ti Lb 480 Towersens

5 Technical Information Volume 2 TI LB 480 TowerSENS 54733-10BA2L 2 – 276 02.2017... - Page 277 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 277 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 278 5 Technical Information Volume 2 54733-10BA2L 2 – 278 02.2017...

- Page 279 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 279 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 280 5 Technical Information Volume 2 54733-10BA2L 2 – 280 02.2017...

- Page 281 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 281 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 282 5 Technical Information Volume 2 54733-10BA2L 2 – 282 02.2017...

- Page 283 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 283 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 284 5 Technical Information Volume 2 54733-10BA2L 2 – 284 02.2017...

- Page 285 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 285 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 286 5 Technical Information Volume 2 54733-10BA2L 2 – 286 02.2017...

- Page 287 Volume 2 5 Technical Information SENSseries LB 480 Level measurement 2 – 287 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 288 5 Technical Information Volume 2 54733-10BA2L 2 – 288 02.2017...

-

Page 289: Accessories

Remove the sealing rings from the screwed fitting to adapt them to the cable diameter used. A list of screwed fittings available from BERTHOLD TECHNOLOGIES can be found in the manual for explosion protection on page 1-47. The following is an example for a M20 cable gland with additional sealing ring for small cable diameters, that must be removed for cables with larger diameter. - Page 290 6 Accessories Volume 2 Assembly instructions for ID No. 56091 blueglobe TRI ® – Montageanleitung blueglobe TRI ® – Assembly Instruction Übersicht Bestandteile Schritt 1 – Vorbereitung der Montage Overview components Step 1 – Prepare installation Doppelnippel (A), Feder (B), Globe-Dichteinsatz (C), Druckschraube (D) Leitung abmanteln, Geflecht mit Isolierband schützen Double nipple (A), spring (B), globe-sealing insert (C), pressure screw (D) Dismantle wire, protect braid...

- Page 291 Double nipple Article LA/mm X/mm Torque 1/Nm Torque 2/Nm Adapter [min] für/for für/for Adapter 220bg220msAC13 220bg225msAC15 225bg225msAC17 232bg232msAC23 232bg240msAC27 240bg240msAC31 250bg250msAC36 250bg250msAC40 263bg263msAC46 263bg263msAC51 275bg275msAC61 285bg285msAC70 285bg285msAC78 SENSseries LB 480 Level measurement 2 – 291 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 292: Limit Switches For Pneumatics

6 Accessories Volume 2 Limit Switches for Pneumatics Installation and setup instructions for limit-switch box by KINETROL … -003U Ex ed IIC T6 and IMPORTANT If the limit-switch box … -003U is delivered separately, it has to be … -004U stored in a plastic bag until it will be installed. - Page 293 Standard dimensions according to DIN41635 Volt Load (A) Resistor inductive (max.) Lamps up to 12 up to 24 up to 48 0.06 up to 250 0.25 0.03 0.025 SENSseries LB 480 Level measurement 2 – 293 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

-

Page 294: Volume 2

6 Accessories Volume 2 … … Material: -3U and KINETROL …-3U KINETROL …-4U Housing Zinc die casting Coating Epoxy resin, burned in Sealing O-rings (Nitril) Temperature range -25° C to +60° C -20° C to +80° C Weight 1,4 kg Cable inputs M20x1.5 M20x1,5;... - Page 295 Make sure that the cover sealing is inserted in its groove! Slightly grease the housing cover in the shaft duct with MoS grease, attach it and tighten cover screws. SENSseries LB 480 Level measurement 2 – 295 BERTHOLD TECHNOLOGIES GmbH & Co. KG...

- Page 296 6 Accessories Volume 2 Correction of the switching points Direct installation for drive with pre-assembled Unscrew the cover of the supplied limit-switch box and pull it limit-switch box off, as shown in the illustration, while pushing down the limit-switch shaft. Caution: Do not lose the cover sealing! Push ...