Subscribe to Our Youtube Channel

Summary of Contents for Evoqua WALLACE & TIERNAN DEPOLOX 400 M

- Page 1 ® WALLACE & TIERNAN DISINFECTION ANALYZER ® DEPOLOX 400 M Version 1.00 and later OPERATING MANUAL...

- Page 2 ® DEPOLOX 400 M Please note Original operating manual! WT.050.700.000.DE.IM.0319...

-

Page 3: Table Of Contents

DEPOLOX 400 M ® Contents Contents Introduction Documentation Conventions Safety Intended use General safety instructions Sample water monitoring Specific operating phases Warranty conditions Exclusion of liability Description General Versions Optional accessories Electronic module Flow cell modules DEPOLOX® 5 C Flow cell module VariaSens C Y-style flow-through assembly Sensors Technical data... -

Page 4: Table Of Contents

DEPOLOX 400 M ® Contents Operation Display and control elements Menus System menu Web visualization Firmware update Calibration Faults and remedies Maintenance Maintenance intervals Sample water monitoring Checking for leaks Servicing the flow cell module DEPOLOX® 5 C Cleaning the flow rate monitor and check valve Cleaning or replacing the optional strainer Cleaning Replacing the fuses on the CPU board... -

Page 5: Introduction

® DEPOLOX 400 M Introduction 1. Introduction Documentation 1.1.1 Target groups This operating manual provides the information required for installation, operating and maintenance personnel for the installation, operation and ® maintenance of the disinfection analyzer DEPOLOX 400 M. All personnel working with and on the disinfection analyzer must have read and understood the operating manual, particularly the safety instructions. -

Page 6: Conventions

® DEPOLOX 400 M Introduction Conventions Please note This operating manual contains a number of notes with different priorities that are labeled with pictograms. Pictogram Note Meaning Danger! Immediate danger to life and limb! If the situation is not corrected, death or serious injury will result. -

Page 7: Safety

® DEPOLOX 400 M Safety 2. Safety Intended use ® The disinfection analyzer DEPOLOX 400 M with installed sensors is designed exclusively for measurement of the parameters free chlorine, total chlorine, chlorine dioxide, ozone, potassium permanganate, pH value, fluoride and temperature in drinking water. ®... - Page 8 ® DEPOLOX 400 M Safety State-of-the-art technology The disinfection analyzer has been constructed in accordance with the technological state-of-the-art and the accepted rules of safety engineer- ing. However, if the disinfection analyzer is used by persons who have not been adequately instructed, danger to the life and limb of such persons or third parties and damage to the unit itself or to other property cannot be ruled out.

-

Page 9: Sample Water Monitoring

® DEPOLOX 400 M Safety Sample water monitoring Danger! Risk of injury or death If there is a shortage of sample water or the flow rate is too low, there is a risk of uncontrolled dosing of chemicals. To ensure safe operation and prevent injury, the sample water monitoring must never be disabled. -

Page 10: Warranty Conditions

® DEPOLOX 400 M Safety Warranty conditions The following must be observed for compliance with warranty conditions: • Installation and commissioning by the manufacturer or trained and authorized specialist personnel, e.g. from contracted companies • Intended use • Observation of the operational parameters and settings •... -

Page 11: Description

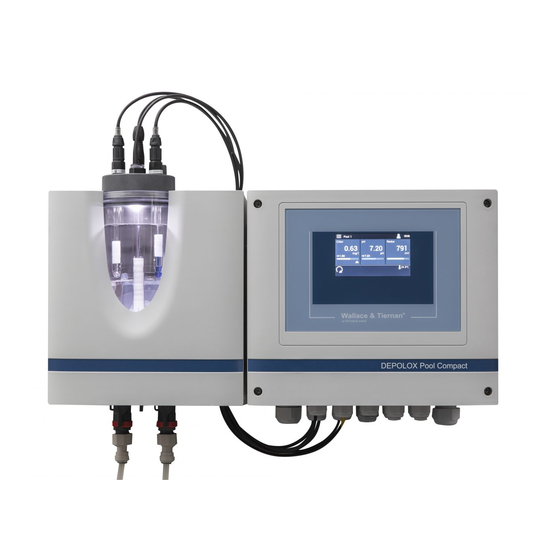

® DEPOLOX 400 M Description 3. Description General ® The disinfection analyzer DEPOLOX 400 M has a modular design structure and comprises an electronic module (Module name E02), a ® flow cell module (Module name D02) DEPOLOX 5 C or VariaSens C or a Y-style flow-through assembly and sensors. -

Page 12: Versions

® DEPOLOX 400 M Description Versions The following modules are available: Part No. Name Electronic module 400 M (Module name E02) W3T441932 Electronic module 400 M with 2-channel disinfection analyzer and 4-way mA output module (factory installed) Flow cell module (Module name D02) ®... - Page 13 ® DEPOLOX 400 M Description Configuration options The following configuration options are possible: Name F E D F E D E D C A 3-Electrode cell A Fluoride sensor (only on (free chlorine) non-pressurized version) B Blind plug B Membrane sensors TC3, C Fluoride sensor (only on FC2, CD7, OZ7 non-pressurized version)

-

Page 14: Optional Accessories

® DEPOLOX 400 M Description Optional accessories The following optional accessories are available. For part numbers, see Chapter 8. “Spare parts, Accessories and retrofit kits”. • Mounting plate with accessories For simple mounting of the flow cell and electronic module and the strainer. -

Page 15: Electronic Module

® DEPOLOX 400 M Description Electronic module 3.4.1 Design The electronic module 400 M (Module name E02) comprises: • Plastic housing with removable housing cover • Motherboard with power supply, terminal strips, electronic compo- nents and relays • Touchscreen • Cable glands Image 2 Electronic module 400 M A Touchscreen/display... - Page 16 ® DEPOLOX 400 M Description The color touchscreen shows the following: • Measurements with bar graph display • Operation mode and switching states • Display of limit values • Setpoint (if applicable) • Customer-specific measurement designation • Messages and errors •...

- Page 17 ® DEPOLOX 400 M Description 3.4.5 Alarms The electronic module supports up to eight freely configurable alarms. The alarms can be assigned to a relay contact and noted on the color display. At the same time, a message is displayed in the message window and the message system is displayed.

- Page 18 ® DEPOLOX 400 M Description Latched alarm with reset • In the event of an alarm, the alarm symbol and the message symbol acknowledgment option flash and the relay is active until acknowledged. • The alarm symbol and the message go out even if the conditions still apply when the alarm is acknowledged.

- Page 19 ® DEPOLOX 400 M Description 3.4.6 Safety functions The electronic module is equipped with various integrated safety func- tions to ensure system safety and minimize the risk of accidents. The fol- lowing safety functions are integrated: • safety deactivation if the sample water flow is too low and/or if the dosing tank signals that it is empty (depending on the configuration of the digital inputs) •...

-

Page 20: Relay Outputs

® DEPOLOX 400 M Description 3.4.8 Relay outputs The electronic module has six relays, each with a changeover contact. These switches are assigned various switching tasks depending on the respective application. The corresponding diagrams are defined in Chap- ter 9. “Wiring diagrams”. In order to switch larger capacitive loads, we recommend installing an additional switching element such as a contac- tor or load relay to guarantee longer service life for the contacts. - Page 21 ® DEPOLOX 400 M Description ® Flow cell modules DEPOLOX ® The flow cell module DEPOLOX 5 C (Module name D02) has a 3-elec- trode cell and is available in a pressure-free or pressurized version. The versions also differ in the number and layout of the sensors that can be installed and in the design of the sample water outlet.

- Page 22 ® DEPOLOX 400 M Description 3.5.2 Function Please note ® The flow cell module DEPOLOX 5 C (Module name D02) can be used for the measurement of free chlorine, ozone, potassium permanganate and chlorine dioxide. It must be ensured that only one of these disinfec- tion agents is present in the water.

- Page 23 ® DEPOLOX 400 M Description The adjustable cell voltage Upot is output via the potentiostatic control loop. The cell current (µA signal) is proportional to the concentration of disinfection agent in the sample water and is evaluated with the elec- tronic module.

-

Page 24: Flow Cell Module Variasens C

® DEPOLOX 400 M Description Flow cell module VariaSens C The flow cell module VariaSens C (Module name D02) is available in a pressure-free or pressurized version. The versions also differ in the num- ber and layout of the sensors that can be installed and in the design of the sample water outlet. - Page 25 ® DEPOLOX 400 M Description 3.6.2 Function Please note The flow cell module VariaSens C (Module name D02) can be used in combination with membrane sensors for the measurement of free chlorine, total chlorine, ozone and chlorine dioxide. It must be ensured that only one of these disinfection agents is present in the water and that the cross-sensitivity of the sensors is allowed for.

- Page 26 ® DEPOLOX 400 M Description Sample water outlet On the pressurized version, the sample water supply is connected on the output side via the G 1/2” connection on the ball valve. At this point, a maximum back pressure of 1.5 bar is permitted. On the non-pressurized version, the sample water runs off via a drain connection for hoses with an internal diameter of 6 mm directly via the cell body outlet at the top.

-

Page 27: Y-Style Flow-Through Assembly

® DEPOLOX 400 M Description Y-style flow-through assembly The Y-style flow-through assembly is available in a non-pressurized version and can be fitted with a pH or fluoride sensor. 3.7.1 Design The structure of the Y-style flow-through assembly is as follows: Image 10 Y-style flow-through assembly A Sensor holder B Outlet (open) -

Page 28: Sensors

® DEPOLOX 400 M Description Sensors The sensors are screwed into the cell body cover of the flow cell module and connected to the electronic module. The pH and fluoride sensor can also be installed via the Y-style flow- through assembly and connected to the flow cell module. ®... - Page 29 ® DEPOLOX 400 M Description 3.8.3 Fluoride sensor Fluoride measurement using a fluoride-ion-selective electrode is used for continuous identification of fluoride ions in the solution. To obtain a cor- rect reading, the pH value of the measured medium must be within a range from pH 5 to pH 8.

-

Page 30: Technical Data

® DEPOLOX 400 M Description 3.8.6 Membrane sensor OZ7 (ozone) Membrane sensor OZ7 allows selective measurement of the chlorine dioxide content in all types of water, including ultrapure water (LF > 1µS/ cm), without cross-sensitivity to chlorine, bromine and hydrogen perox- ide, but cross-sensitive to chlorine dioxide and peracetic acid. - Page 31 ® DEPOLOX 400 M Description Measurement inputs • 3-electrode sensor (measuring range 0 to max. 20 mg/l, end value can be set) or membrane sensor • pH value (measuring range pH 0 to pH14, initial and end value can be set) or fluoride (measuring range 0 to 20 mg/l) •...

- Page 32 ® DEPOLOX 400 M Description ® 3.9.2 Flow cell module DEPOLOX 5 C (Module name D02) Please note The pH sensor can be installed in the pressure-free and pressurized ver- ® sion of the flow cell module DEPOLOX 5 C. The fluoride sensor can be installed in the non-pressurized version.

- Page 33 ® DEPOLOX 400 M Description 3.9.3 Flow cell module VariaSens C (Module name D02) Please note The pH sensor and the membrane sensors FC2, TC3, CD7 and OZ7 can be installed in the pressure-free and pressurized version of the flow cell module VariaSens C.

- Page 34 ® DEPOLOX 400 M Description 3.9.7 Membrane sensors TC3 (total chlorine) FC2 (free chlorine) Measured value Total chlorine (= free chlorine + Free chlorine combined chlorine) Range 0.05 to 20.00 mg/l (ppm) 0.05 to 20.00 mg/l (ppm) Area of application Swimming pool, drinking and pro- Swimming pool and drinking water cess water...

- Page 35 ® DEPOLOX 400 M Description CD7 (chlorine dioxide) OZ7 (ozone) Measured value Chlorine dioxide, selective toward Ozone, selective toward Cl , Br , Br , cross-sensitivity to , cross-sensitivity to ClO , peracetic acid peracetic acid Power supply Unipolar +12 – 15 VDC, 11 mA Typical output signal approx.

- Page 36 ® DEPOLOX 400 M Description WT.050.700.000.DE.IM.0319...

-

Page 37: Interfaces

® DEPOLOX 400 M Interfaces 4. Interfaces USB interface The electronic module is equipped internally with a USB interface. It is used to update the firmware via USB stick (see Chapter 6.5 “Firmware update”) or for use as a data logger via USB stick. If a W2T866279 memory stick is permanently installed in the USB port, monthly archive files are saved in CSV format. -

Page 38: Rs485 Interface

® DEPOLOX 400 M Interfaces RS485 interface The RS485 interface is used for data transfer to higher-level control sys- tems such as the Process Monitoring system or other systems that sup- port the Wallace & Tiernan RS485 protocol. For more detailed information, please refer to the operating manual “RS485 interface.”... -

Page 39: Ethernet Interface

® DEPOLOX 400 M Interfaces Ethernet interface The electronic module has two integrated Ethernet interfaces (ETH 1 and ETH 2). They are connected internally via an Ethernet switch. The device has an MAC address. The MAC address is displayed in the menu “Set- tings”... - Page 40 ® DEPOLOX 400 M Interfaces The Ethernet connection is designed in accordance with IEEE 802.3. There are two I8P8C sockets (often referred to as RJ45 sockets) (green) (yellow) installed. Connection to the HUB or switch can be realized with a 1:1-wire and screened patch cable.

- Page 41 ® DEPOLOX 400 M Interfaces 7 Enter the IP address of the electronic module, e.g. “http:// 192.168.200.11/“ (in the factory setting). After successful connection, the start screen of the electronic module appears. Depending on the size of the operating device, the measurement windows are dis- played side by side or one below the other.

- Page 42 ® DEPOLOX 400 M Interfaces Example: Electronic module Laptop or PC IP address 192.168.200.11 192.168.200.1 (factory setting) Network mask 255.255.255.0 255.255.255.0 (factory setting) Gateway 0.0.0.0 (factory setting) 4.3.3 Network setting under Windows 10 Windows 10 automatically establishes a network connection as soon as a network card is detected in the PC or laptop computer.

- Page 43 ® DEPOLOX 400 M Interfaces Windows 10 with static (fixed) IP address Windows 10 with static ( With the setting, a fixed IP address is always assigned to the PC or laptop fixed) IP address computer. Proceed as follows: 1 Under “Connections,” click “Ethernet” (see red marking in the illustra- tion).

-

Page 44: Modbus Tcp Interface

® DEPOLOX 400 M Interfaces Windows 10 with an alternative configuration Windows 10 with an alter- With Windows 10, it is also possible to set an alternative configuration. native configuration Proceed as follows: 1 Carry out steps 1 to 4 as described under “Windows 10 with static (fixed) IP address”... - Page 45 ® DEPOLOX 400 M Interfaces The reference tables have the following structure: Column Description Modbus register Modbus register address E-byte Byte address input data A-byte Byte address output data Module name Profibus Name of the module in the GSD file Name Name of the data point Length...

- Page 46 ® DEPOLOX 400 M Interfaces For the byte sequence in which the various data types are saved in the memory or transferred, see the following figures. Data type INT8 / UINT8 Example using the figure 50 (32 hex): Data type INT16 / UINT16 Example using the figure 12589 (312D hex): Data type INT32 / UINT32 Example using the figure 1212117675 (483F72AB hex):...

- Page 47 ® DEPOLOX 400 M Interfaces 4.4.2 Reference list The following reference list contains all available data points and values that can be read and written via Modbus TCP. It must be noted that write commands should not be set to variables or the Modbus register cycli- cally or repeatedly set to the same values.

- Page 48 ® DEPOLOX 400 M Interfaces Name Type Access Max. Min. Description register byte 400156 400158 (Ch.5) Temperature 400160 Measured value FLOAT 400162 Measurement unit ASCII °C 400167 Range start FLOAT 400169 Range end FLOAT 400171 400173 [400300-400399] Status messages (read only) 400300 Alarm states UINT16 2...

- Page 49 ® DEPOLOX 400 M Interfaces Name Type Access Max. Min. Description register byte 400318 400322 400326 Error code tempera- UINT32 4 Bit coding as for error code chlorine ture (Ch.5) [401000-401049] Controller parameters (read and write) (Ch.1) Disinfection 401000 Setpoint (W) FLOAT Upper Lower...

- Page 50 ® DEPOLOX 400 M Interfaces Name Type Access Max. Min. Description register byte 401074 401076 401078 401080 401082 401084 401086 401088 401090 401092 401094 401096 (Ch.5) Temperature 401098 Min. value 1 FLOAT Max. value Lower °C range 401100 Max. value 1 FLOAT Upper Min.

-

Page 51: Installation

® DEPOLOX 400 M Installation 5. Installation Scope of delivery The scope of delivery includes the following, depending on the version selected (see Chapter 3.2 “Versions”): • Electronic module (Module name E02) • Flow cell module (Module name D02): ® •... -

Page 52: Transport And Storage

® DEPOLOX 400 M Installation Transport and storage Transport The disinfection analyzer is shipped in standard packaging. During trans- port, the packaged disinfection analyzer must be handled carefully and should not be exposed to wet weather or moisture. Check that the transport packaging is undamaged. In the event of dam- age, please inform the transport company immediately, as your rights to compensation will otherwise be lost. -

Page 53: Mechanical Installation

® DEPOLOX 400 M Installation Mechanical installation Warning! Risk of injury or damage to the installation! Only authorized and qualified electricians are permitted to install the disinfection analyzer. All electrical work on the disinfection analyzer must be carried out by authorized and qualified electricians. Modifications to the device other than those described in this operating manual are not permissible. - Page 54 ® DEPOLOX 400 M Installation 5.4.1 Installing the flow cell module The following mounting variants are available for the installation of the ® electronic module 400 M and the flow cell modules DEPOLOX 5 C and VariaSens C: • with DIN rail •...

- Page 55 ® DEPOLOX 400 M Installation Mechanical installation without DIN rail Instead of on a DIN rail, the disinfection analyzer can be hooked onto the top clips on suitable tallow-drop screws. Please note The dimensions for the drilling pattern can be found on the back of the plastic housing.

- Page 56 ® DEPOLOX 400 M Installation Dimension drawing Flow cell module (pressurized version) and electronic module (example) WT.050.700.000.DE.IM.0319...

- Page 57 ® DEPOLOX 400 M Installation 5.4.2 Installing the Y-style flow-through assembly Proceed as follows: 1 Using mounting clamps (not included in the scope of delivery), screw the Y-style flow-through assembly to the solid wall below the elec- tronic module.

- Page 58 ® DEPOLOX 400 M Installation 5.4.3 Removing and fitting the housing cover 1 Remove the housing cover of the flow cell module. To do this, press both unlocking buttons on the top of the housing and carefully remove the cover toward the front. 2 Fit and engage the housing cover of the flow cell module.

- Page 59 ® DEPOLOX 400 M Installation The following two options are possible for the sample water inlet: • with tubing connection • with rigid pipework Sample water inlet with tubing connection Attention! The water-tightness of the hose screw connection is only guaranteed if the following installation instructions are followed! Proceed as follows: 1 Release union nut (A) on the hose screw connection.

- Page 60 ® DEPOLOX 400 M Installation 5.4.5 Installing the optional strainer To install the optional strainer with ball valve (W3T158721) and pipe clamp in the sample water supply line, proceed as follows: 1 Release the screw joint on the sample water inlet with ball valve (A) (threaded connection G 1/2”...

- Page 61 ® DEPOLOX 400 M Installation ® 5.4.7 DEPOLOX 5 C Removing the felt ring ® In order to keep the diaphragm in the flow cell module DEPOLOX moist and prevent crystallization of the electrolyte solution during stor- age, a moist felt ring is inserted in the space between the electrolyte stor- age tank and electrode.

- Page 62 ® DEPOLOX 400 M Installation ® 5.4.8 DEPOLOX 5 C Removing and replacing the transport plug Please note ® Before commissioning the flow cell module DEPOLOX 5 C, the trans- port plug must be removed from the electrolyte storage tank and replaced with the stopper provided.

- Page 63 ® DEPOLOX 400 M Installation ® 5.4.9 DEPOLOX 5 C Add electrode cleaning sand To insert the electrode cleaning sand (W3T158743) into the cell body of ® the flow cell module DEPOLOX 5 C, proceed as follows: 1 Close the ball valve on the sample water inlet. 2 Close the ball valve on the sample water outlet on the pressurized version.

- Page 64 ® DEPOLOX 400 M Installation 5.4.10 VariaSens C Installing the fine filter Please note A fine filter must only be installed when membrane sensors are em- ployed. The fine filter must be installed in the flow cell module VariaSens C; proceed as follows: 1 Release both knurled nuts (B).

- Page 65 ® DEPOLOX 400 M Installation 5.4.11 Installing sensors in the flow cell module Please note The sensors are inserted or screwed into the location hole in the cell body cover. With the pressurized version, the sensors must be screwed in or secured to prevent them from being pushed out.

- Page 66 ® DEPOLOX 400 M Installation 5.4.12 Fitting calibration aids ® The flow cell modules DEPOLOX 5 C and VariaSens C have two cali- bration clips in the housing cover. They are pushed into the side of the basic housing at the back. The clip with the plastic insert for the sensor is pushed into the top catch (A).

-

Page 67: Connecting Sensors

® DEPOLOX 400 M Installation 5.4.14 Connecting sensors Please note The sensor cable glands on the electronic module are special cable glands and are already fitted with special sealing inserts at the factory. Threaded locking bolts are fitted in the cable glands at the factory. These must be removed during installation in order to install the corresponding sensor cables. - Page 68 ® DEPOLOX 400 M Installation 4 Connect the sensor cable of the 3-electrode cell or the membrane sensor to the electronic module as shown in the wiring diagrams. ® The sensor cable of the DEPOLOX 5 C 3-electrode cell is already pre-wired.

-

Page 69: Electrical Installation

® DEPOLOX 400 M Installation Electrical installation Danger! Risk of injury or death! External voltages may still be connected even if the operating voltage is switched off. The electronic module must be de-energized before open- ing it. Warning! Risk of injury or damage to the device! Only authorized and qualified electricians are permitted to install the dis- infection analyzer and open the housing. - Page 70 ® DEPOLOX 400 M Installation Please note The electronic module is not suitable for electrical connection with per- manently installed cable conduits. If the cable glands do not meet local installation rules and regulations, these glands must be replaced with suitable ones.

-

Page 71: Initial Commissioning

® DEPOLOX 400 M Installation Initial commissioning Danger! Risk of injury or death! The disinfection analyzer must not be operated with flammable liquids. Attention! Risk of injury or damage to the device! To ensure safe and correct commissioning, knowledge of the operation, connected electrical load, measurement signals, cable assignment and fuse protection of the connected devices and machines and the relevant safety regulations is required. - Page 72 ® DEPOLOX 400 M Installation Procedure Following complete mechanical and electrical installation of the disinfec- tion analyzer, initial commissioning can be carried out in accordance with the table below. Please check that the following conditions are met: • The electronic module is wired in accordance with the wiring diagram (circuit diagram) and local regulations.

-

Page 73: Shut-Down

® DEPOLOX 400 M Installation Shut-down Danger! Risk of injury or death! External voltages may still be connected even if the operating voltage is switched off. To shut down, proceed as follows: 1 Disconnect the electronic module from the power supply. 2 Drain the sample water supply line and drainage line. - Page 74 ® DEPOLOX 400 M Installation WT.050.700.000.DE.IM.0319...

-

Page 75: Operation

® DEPOLOX 400 M Operation 6. Operation Display and control elements 6.1.1 General information The colored graphic display with capacitive touchscreen is the display and control element. It is used by means of direct entry on the display, i.e. by touching using your finger or a pen (PDA pen) for capacitive touch- screens. - Page 76 ® DEPOLOX 400 M Operation Please note The Home screen view depends on the sensors that are fitted. If the disinfection analyzer is equipped with two sensors, the menu fields “Measurement with the current measured value” are shown wider on the screen.

- Page 77 ® DEPOLOX 400 M Operation Symbols Meaning Message/error active Tap the symbol to open the message window. Yellow symbol = alarm that cannot be acknowledged is active Red symbol = alarm that can be acknowledged is active or error message is active Orange symbol = maintenance or calibration interval expired Data logger symbol USB memory stick...

-

Page 78: Menus

® DEPOLOX 400 M Operation Menus 6.2.1 Menu structure The following menu selections are available in the Home screen: • System menu • Messages • Logout/Login level • Menu field Measurement (depends on the sensors that are fitted) • Operation mode From the main menu, you can call up the system settings, the measured values menus and the controller menus. - Page 79 ® DEPOLOX 400 M Operation 6.2.3 Menu “Settings” Home screen Menu field Measurement To access the “Settings” menu for a specific measurement, proceed as HLORINE FREE follows: 1 Call up the Home menu. 2 Select the desired measurement (e.g. Chlorine free). The menu “Measurement”...

- Page 80 ® DEPOLOX 400 M Operation Chlorine measurement The following parameters are possible for chlorine measurement: Measurement Range Range end 1.00 / 2.00 / 5.00 / 10.00 / 20.00 mg/l or ppm 200 / 500 µg/l or ppd Unit µg/l / mg/l / ppb / ppm Sensor type O3sel(M) / ClO2sel(M) / Cl-tot(M) / Cl2 free(M) / KMnO4 / O3 / Cl02 / Cl2 free / Cl2++...

- Page 81 ® DEPOLOX 400 M Operation pH measurement The following parameter settings are possible for pH measurement: Measurement Range Range end pH 0.00 to pH 14.00 Range start pH 0.00 to pH 14.00 Measurement filter off/low/middle/strong Limits Limit values I Within range Within range Hysteresis 1 to 25...

- Page 82 ® DEPOLOX 400 M Operation Fluoride measurement The following parameter settings are possible for fluoride measurement: Measurement Range Range end 2.00 / 5.00 / 20.00 mg/l Measurement filter off/low/middle/strong Limits Limit values I Within range Within range Hysteresis 1 to 25 Limit values II Within range Within range...

-

Page 83: System Menu

® DEPOLOX 400 M Operation System menu Access to the operating and configuration level of the electronic module is possible via the System menu. All setting parameters not relating to measured values, for example, Alarms, I/O inputs and outputs, interface parameters etc., are parametrized via the System menu. - Page 84 ® DEPOLOX 400 M Operation 6.3.1 Menu “Operation mode” Please note This function is only available if the parameter “Disinfection controller = On” is set in the menu “Settings – Setup.” The disinfection controller is only suitable for constant flow applications. The device offers two options for changing the operation mode.

- Page 85 ® DEPOLOX 400 M Operation System menu Home screen Symbol “Settings menu” To perform calibration via the System menu, proceed as follows: YSTEM MENU 1 Call up the Home menu. 2 Tap the symbol. 3 Press the menu Calibration. 4 Tap the desired measurement (chlorine, pH, fluoride or temperature). The menu “Measurement”...

- Page 86 ® DEPOLOX 400 M Operation Calibration selection The following calibration selections are available, depending on the selected measurement: Chlorine Zero point Calibration of the zero point current of the chlorine measuring cell (only with extended calibration view) DPD calibration of the chlorine measurement cell pH7 calibration with buffer solution (only with extended calibration view) Span calibration of the pH sensor with buffer solution (only with extended calibration view)

- Page 87 ® DEPOLOX 400 M Operation 6.3.3 Menu “Inputs and outputs” The digital inputs and the mA outputs are configured in the “Inputs and outputs” menu. Home screen Symbol “System menu” Menu “Inputs / Outputs” Proceed as follows: NPUTS OUTPUTS 1 Call up the Home menu. 2 Tap the symbol.

- Page 88 ® DEPOLOX 400 M Operation 6.3.4 Menu “Alarm configuration” Alarms 1 to 8 are configured in the “Alarm Configuration” menu. The disinfection analyzer offers the option of setting various alarm configura- tions. It is not necessary to assign a relay switching function to every alarm.

- Page 89 ® DEPOLOX 400 M Operation 6.3.5 Menu “Login” Log in on the desired user level in the “Login” menu. Home screen Symbol “System menu” Menu “Login” To access the Login menu, proceed as follows: OGIN 1 Call up the Home menu. 2 Tap the symbol.

- Page 90 ® DEPOLOX 400 M Operation System Setup Controller Disinfection controller On/Off Enables or disables the disinfection controller (only to be used for constant flow application) Measurement Disinfection On/Off Enables or disables pH measurement and controller pH/fluoride Off/pH/fluoride Enables or disables pH or fluoride measurement General information System name Freely definable...

- Page 91 ® DEPOLOX 400 M Operation Max. dosing time 00:00 ... 10:00 h This parameter defines a monitoring time which specifies the maximum time the controllers may require before the measured value reaches the setpoint minus monitoring hysteresis. If one of the controllers does not reach the set- point within the defined maximum dosing time, the corresponding controller is switched off and a message is displayed.

- Page 92 ® DEPOLOX 400 M Operation Connections Network IP address Enter a fixed IP address (contact network administrator) Subnet mask Enter the subnet mask (contact network administrator) Gateway Gateway setting DHCP On/Off In the setting “DHCP = On,” the network configuration is automatically defined by the DHCP server and cannot be configured manually.

- Page 93 ® DEPOLOX 400 M Operation 6.3.7 Menu “Information” Various system information, e.g. the installed software version, is described in the menu Information. 6.3.8 Menu “User administration” The electronic module offers the option of using up to three user levels. Different rights are assigned to each user level. The colored user symbol in the Home screen shows on what level the user is logged in.

- Page 94 ® DEPOLOX 400 M Operation Login Proceed as follows to log in: Home screen Symbol “System menu” Menu “Login” 1 Call up the Home menu. OGIN 2 Press the symbol. 3 Tap the menu Login. 4 Enter locking code or password. See Chapter 6.3.3 “Menu “Inputs and outputs””.

- Page 95 ® DEPOLOX 400 M Operation 7 Press the desired parameter Level 1/Level 2 or Level 3 to enable or change the desired Level, 1, 2 or 3. The display changes to the set- tings menu for the corresponding level (Example: Level 1). The parameter Level 1/Level 2 or Level 3 is used to enable or disable user level 1,2 and 3.

- Page 96 ® DEPOLOX 400 M Operation 6.3.9 User administration web visualization User administration via web visualization comprises two levels. At the factory, these two user levels are disabled and preset to “0.” For security reasons, the user levels must be enabled during commissioning. The padlock symbol in the menu bar shows whether the user is logged in.

-

Page 97: Web Visualization

® DEPOLOX 400 M Operation Web visualization The web views integrated in the disinfection analyzer allow you to visual- ize the measurements and setting parameters via a standard browser and Internet-capable devices. ® Image 2 Example, web view, DEPOLOX 400 M Please note If alarms or errors are active, a yellow or red message symbol is dis- played in the menu bar. - Page 98 ® DEPOLOX 400 M Operation Parameter Temperature Limit value Max 1 Within range Limit value Min 1 Within range Limit value Max 2 Within range Limit value Min 2 Within range System System name Customizable, customer-specific device name Date Date setting Time 00:00 ...

-

Page 99: Firmware Update

“Bootload.ini” must be copied to the USB stick. Do not use subdirectories. Please note A firmware update can be downloaded free of charge from the homepage of Evoqua Water Technologies GmbH. Warning! Risk of injury or damage to the device! Only authorized and qualified electricians are permitted to connect the electronic module electrically and to open the housing. - Page 100 ® DEPOLOX 400 M Operation 9 Close the housing cover of the electronic module again. Place the housing cover carefully on the basic housing. Tighten the four hous- ing screws by hand (to a maximum torque of 0.7 Nm ± 0.15 Nm). 10 Switch the device on.

-

Page 101: Calibration

® DEPOLOX 400 M Operation Calibration When calibrating the measurements, variations in the calibration solu- tions, buffer solutions or comparative measurements are adjusted. Cali- bration is performed for new devices (first commissioning) and to recalibrate existing measuring instruments in accordance with mainte- nance regulations. - Page 102 ® DEPOLOX 400 M Operation 5 To enable the calibration check interval, set the parameter “Mes- sage” to “On” under the heading Calibration and, under “Interval,” enter the number of days after which you wish to receive a reminder to carry out sensor calibration. When the set interval expires, the disinfection analyzer generates an orange message reminding you to carry out sensor calibration.

- Page 103 ® DEPOLOX 400 M Operation 7 Wait until the displayed value no longer changes. 8 Press the “Calibration” button. An input field opens. 9 Press "Enter" to save the zero point. 10 Open the ball valve on the sample water inlet. Measuring value calibra- 11 After zero point calibration, wait at least 2 minutes.

- Page 104 ® DEPOLOX 400 M Operation 9 Dip the pH sensor through the top clip at least 2 cm deep into the buffer solution and move slightly until the indicated pH value remains constant. 10 Press the “Calibration” button. An input field opens. 11 Use the input field to enter the value to be calibrated for the buffer solution.

- Page 105 ® DEPOLOX 400 M Operation 4 Press the parameter “Offset.” 5 Use the keypad to enter the value from the comparative measure- ment. 6 Press "Enter" to save the entry. This concludes the pH offset. Please note The offset calibration is deleted each time a new pH-7 alignment or span alignment is performed with the pH buffer solution.

- Page 106 ® DEPOLOX 400 M Operation 10 Press the “Calibration” button. An input field opens. 11 Use the input field to enter the value to be calibrated for the calibra- tion solution. 12 Press "Enter" to save the entry. Calibrate upper value 13 Remove the calibration solution from the bottom clip.

-

Page 107: Faults And Remedies

® DEPOLOX 400 M Operation 6.6.5 Temperature calibration multi-sensor System menu Calibration Proceed as follows: EMPERATURE MEASURE MENT MENU 1 Press the symbol. 2 Press the menu Calibration. 3 Tap the measurement “Temperature.” 4 Press the parameter “Cal. value.” 5 Perform comparative temperature measurement. 6 Use the keypad to enter the value to be calibrated. - Page 108 ® DEPOLOX 400 M Operation Non-acknowledgeable messages and errors Error messages are displayed in red in the message window and can only be rectified by eliminating the cause. Error message Cause Remedy Measured value dis- Measured value is outside the mea- Check measurement range and play flashes surement range.

- Page 109 ® DEPOLOX 400 M Operation Error message Cause Remedy Setpoint ? Due to modification of the measure- Reset the controller setpoint or adjust ment range, the controller setpoint is the measurement range. outside the range. Limit value ? Due to modification of the measure- Reset the limit value or adjust the mea- ment range, the limit value is outside surement range.

- Page 110 ® DEPOLOX 400 M Operation 6.7.2 Messages Message Cause Remedy Cl2 free Calibration check interval Calibrate the measurement, reset main- Maintenance! Sensor Time expired tenance interval after calibration and calibration acknowledge message. Fluoride Calibration check interval Calibrate the measurement, reset main- Maintenance! Sensor Time expired tenance interval after calibration and...

-

Page 111: Maintenance

® DEPOLOX 400 M Maintenance 7. Maintenance Danger! Risk of injury or death! External voltages may still be connected even if the operating voltage is switched off. Please note Liability for defects can only be accepted if maintenance work is per- formed as specified. - Page 112 ® DEPOLOX 400 M Maintenance Activity Period/Interval Chapter Sample water monitoring regularly Check the flow cell module, including all screw connec- daily tions, for leakage. Comparative measurement of chlorine, pH and fluoride in accordance with standard or Carry out calibration. local regulations Check the electrode cleaning sand.

-

Page 113: Checking For Leaks

® DEPOLOX 400 M Maintenance Checking for leaks Check the entire flow cell module every day, including all screw connec- tions, for leakage. Repair any leaks immediately. Please note Ascending air bubbles in the cell body influence the measuring accuracy. The cause must be determined and remedied. -

Page 114: Cleaning The Flow Rate Monitor And Check Valve

® DEPOLOX 400 M Maintenance Cleaning the flow rate monitor and check valve Proceed as follows: 1 Close the ball valves on the sample water supply and drainage line. 2 Remove the housing cover of the flow cell module. 3 Release both knurled nuts. Take out the filter unit toward the front. 4 Carefully pull the complete check valve housing (A) down and out. -

Page 115: Cleaning Or Replacing The Optional Strainer

® DEPOLOX 400 M Maintenance Cleaning or replacing the optional strainer The optional strainer must be cleaned or replaced regularly to avoid con- tamination or blockages. The frequency of cleaning or replacement depends on the degree of contamination caused by the sample water. Proceed as follows: 1 Close the ball valve on the sample water supply line in front of the strainer. -

Page 116: Replacing The Fuses On The Cpu Board

® DEPOLOX 400 M Maintenance Replacing the fuses on the CPU board Danger! Risk of injury or death! External voltages may still be connected even if the operating voltage is switched off. Warning! Only authorized and qualified electricians are permitted to open the hous- ing. -

Page 117: Replacing The Battery

® DEPOLOX 400 M Maintenance Replacing the battery Danger! Risk of injury or death! External voltages may still be connected even if the operating voltage is switched off. Warning! Risk of injury! Only authorized and qualified electricians are permitted to open the hous- ing. - Page 118 ® DEPOLOX 400 M Maintenance WT.050.700.000.DE.IM.0319...

-

Page 119: Spare Parts, Accessories And Retrofit Kits

® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8. Spare parts, Accessories and retrofit kits Please note For reasons of safety, only use original spare parts. Please contact our customer service if you need any spare parts. Spare parts 8.1.1 Electronic module 400 M (Module name E02) - W3T441932 Pos. - Page 120 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits Electronic module 400 M (Module name E02) - W3T441932 WT.050.700.000.DE.IM.0319...

- Page 121 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits ® 8.1.2 Flow cell module DEPOLOX 5 C (Module name D02) non-pressurized version - W3T389205...

- Page 122 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits ® Flow cell module DEPOLOX 5 C (Module name D02) - W3T389205 non-pressurized version Item Part No. Designation Item Part No. Designation W3T247776 Basic housing W3T435413 Hose W3T247777 Housing cover W2T505093 Angle-reducing connector W3T166170...

- Page 123 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits ® 8.1.3 Flow cell module DEPOLOX 5 C (Module name D02) pressurized version - W3T389210...

- Page 124 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits ® Flow cell module DEPOLOX 5 C (Module name D02) pressurized version - W3T389210 Item Part No. Designation Item Part No. Designation W3T247776 Basic housing W3T438413 Hose W3T247777 Housing cover W2T505093 Angle-reducing connector W3T166170...

- Page 125 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.1.4 Flow cell module VariaSens C (Module name D02) non-pressurized version - W3T440600...

- Page 126 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits Flow cell module VariaSens C (Module name D02) non-pressurized version - W3T440600 Item Part No. Designation Item Part No. Designation W3T247776 Basic housing W3T158739 Flow body W3T247777 Housing cover W3T166169 Retaining clip, coated W3T166170 Shut-off valve...

- Page 127 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.1.5 Flow cell module VariaSens C (Module name D02) pressurized version - W3T440611...

- Page 128 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits Flow cell module VariaSens C (Module name D02) pressurized version - W3T440611 Item Part No. Designation Item Part No. Designation W3T247776 Basic housing W3T167941 O-ring W3T247777 Housing cover W3T158739 Flow body W3T166170 Shut-off valve W3T171788...

- Page 129 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits ® 8.1.6 Cell body cover, flow cell module DEPOLOX W3T322432 W3T322435 W3T166171 W3T158603 W3T163739 Cell body, complete, Cell body, complete, Drain valve Non-return unit Spherical seat, complete with float PVC/EPDM non-pressurized version Pressurized version Unit...

- Page 130 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits Pre-installed assembly Part no. Designation groups W3T322432 Cell body, fully non-pressurized version W3T322435 Cell body, fully pressurized version W3T166171 Flow cell drain valve W3T158603 Back pressure unit with float W3T163739 Spherical seat cpl.

- Page 131 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.1.9 Y-style flow-through assembly non-pressurized version - W3T167442 Pos. Part no. Designation Pos. Part no. Designation W2T505181 Union W3T170970 Electrode support W2T507048 Laboratory ball cock W3T167237 Washer W2T507158 W3T163413 Clamping nut W2T507134 Elbow W3T168861...

- Page 132 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits Sensors ® 8.2.1 3-electrode cell (DEPOLOX 5 C) Part No. Designation W3T164482 KCl tank with stand and 5 ml KCl solution W3T160410 Electrolyte solution 3 mol/l KCl, bottle 250 ml W3T158743 Electrode cleaning sand QJ W3T158600...

- Page 133 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.2.3 Fluoride sensor Part No. Designation W2T840142 Fluoride sensor (manufacturer VanLondon) W3T161789 Calibration solution, fluoride 0.2 mg/l, 500 ml W3T161845 Calibration solution, fluoride 2 mg/l, 500 ml W3T161884 Calibration solution, fluoride 100 mg/l, 500 ml W3T158600 Measuring beaker (5 pcs) W3T173161...

- Page 134 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.2.5 Membrane sensor FC2 Part No. Designation W3T365498 Membrane sensor FC2 W3T172017 Sensor cable W3T365500 Membrane cap, incl. lapping paper W3T168101 Electrolyte ECS2/gel, 100 ml bottle W3T365601 Maintenance parts kit, comprising: membrane cap, lapping paper, electrolyte ECS2/gel, O-ring and elas- tomer seal W3T164339...

-

Page 135: Accessories

® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.2.7 Membrane sensor OZ7 Part No. Designation W3T164494 Membrane sensor OZ7 W3T172017 Sensor cable W3T168106 Membrane cap, incl. lapping paper W3T168105 Electrolyte OZ7, 100 ml bottle W3T168107 Maintenance parts kit, comprising: membrane cap, lapping paper, electrolyte ECS2/gel, O-ring and elas- tomer seal W3T164519... - Page 136 ® DEPOLOX 400 M Spare parts, Accessories and retrofit kits 8.3.5 Tubing to tubing connection PVC tubing, fabric-reinforced ø 4 x 3 ø 6 x 3 ø 10 x 3 (internal diameter x wall thickness) Tubing W2T505524 W2T505525 W2T505334 PVC hose connecting parts W3T167626 W3T167518 W3T167590...

-

Page 137: Wiring Diagrams

® DEPOLOX 400 M Wiring diagrams 9. Wiring diagrams... - Page 138 ® DEPOLOX 400 M Wiring diagrams WT.050.700.000.DE.IM.0319...

- Page 139 ® DEPOLOX 400 M Wiring diagrams...

- Page 140 ® DEPOLOX 400 M Wiring diagrams WT.050.700.000.DE.IM.0319...

-

Page 141: Explanations And Certificates

® DEPOLOX 400 M Explanations and Certificates 10.Explanations and Certificates 10.1 Declaration of Conformity... - Page 142 ® DEPOLOX 400 M Explanations and Certificates WT.050.700.000.DE.IM.0319...

- Page 143 ® DEPOLOX 400 M Explanations and Certificates 10.1.1 CSA certificate...

- Page 144 ® DEPOLOX 400 M Explanations and Certificates WT.050.700.000.DE.IM.0319...

- Page 145 ® DEPOLOX 400 M Explanations and Certificates...

- Page 146 ® DEPOLOX 400 M Explanations and Certificates WT.050.700.000.DE.IM.0319...

-

Page 147: Index

DEPOLOX 400 M ® Index 11.Index Data type Accessories 119 ASCII 46 Acknowledgment options FLOAT 46 Alarms 17 INT16 / UINT16 46 Alarm INT32 / UINT32 46 Acknowledgment with reset 18 INT8 / UINT8 46 Latched with confirmation 18 Declaration of Conformity 141 Latched with reset acknowledgment option DEPOLOX®... -

Page 148: Wt.050.700.000.De.im

DEPOLOX 400 M ® Index Electronic module 400 M Spare parts 119 General information 11 Error messages 107 Electronic module 15 Acknowledgeable 107 Y-style flow-through assembly 27 Non-acknowledgeable 108 General safety instructions 7 Ethernet configuration 40 Ethernet interface 39 Exclusion of liability 10 Home screen 75 Housing cover Fitting 58... - Page 149 DEPOLOX 400 M ® Index Measurement pH sensor Chlorine 80 Description 28 Fluoride 82 Technical data 33 Menu 78 pH value pH 81 Calibration 103 Temperature 82 Plugging in the Membrane sensor CD7 Multi-sensor 67 Description 29 Process measurements 15 Membrane sensor FC2 Description 29 Membrane sensor OZ7...

- Page 150 DEPOLOX 400 M ® Index Servicing Transport plug DEPOLOX® 5 C 113 Non-pressurized version DEPOLOX® 5 C Settings Menu 79, 89 Pressurized version DEPOLOX® 5 C 62 Setup 90 Shut-down 52 Spare parts 119 Specific operating phases 9 USB interface 37 Start-up 71 User administration 91 Storage 52...

- Page 151 ® ® Wallace & Tiernan Products worldwide Australia Canada China +61 3 8720 6597 +1 905 944 2800 +86 10 57076305 info.au@evoqua.com canadainfo@evoqua.com sales.cn@evoqua.com France Germany Singapore +33 1 41 15 92 20 +49 8221 9040 +65 6830 7165 wtfra@evoqua.com wtger@evoqua.com...

- Page 152 Evoqua assumes no responsibility for the completeness of this information. Users are responsible for making sure that the product is suitable for specific applications. Evoqua assumes no liability for specific or indirect damage or consequential damage arising from the sale, resale or misuse of its products.

Need help?

Do you have a question about the WALLACE & TIERNAN DEPOLOX 400 M and is the answer not in the manual?

Questions and answers