Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Festo DHTG-A Series

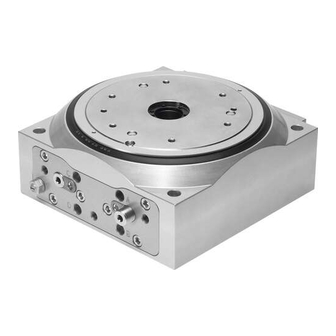

- Page 1 Rotary indexing table DHTG-…-A Repair instructions (en) 7DHTGb_en...

- Page 2 Imprint Version: 7DHTGb_en (11.2011) Copyright: ©Festo AG & Co. KG P.O. Box D-73726 Esslingen Editorial team: SC-S Tel.: +49 (0) 711/347-0 E-mail: service_international@festo.com Internet: http://www.festo.com The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without explicit authorisation is prohibited.

-

Page 3: Festo 7Dhtgb_En

These repair instructions have been prepared with care. Festo AG & Co. KG does not, however, accept liability for any errors in these repair instructions or their consequences. Likewise, no liability is accepted for direct or consequential damage resulting from improper use of the products. -

Page 4: Table Of Contents

4.2.4 Assembling the plate (DHTG-65 and DHTG-90) 4.2.5 Assembling the plate (DHTG-140) 4.2.6 Assembling the plate (DHTG-220) 4.2.7 Installing the plate Maintenance Cleaning and lubricating the rotary indexing table Inspection interval for the shock absorber Tools Standard tools Liability 4 / 46 Festo 7DHTGb_en... -

Page 5: Important Information

Can be maintenance tools, etc. (aids for The rotary indexing table DHTG-…-A is found on the Festo website assembly and maintenance). Can fully repairable. The costs of carrying (www.Festo.com). be found in the online spare parts... -

Page 6: General Safety Information

Repairs must only be carried out in conjunction with these repair instructions as well as the respective operating instructions for the device. Note Instead of carrying out the repair yourself, your local Festo sales office offers the option of having the repair carried out by Festo. Environment Components and equipment replaced as part of a repair must be disposed of in accordance with the locally valid envi- ronmental protection regulations. -

Page 7: Types And Part Numbers

The complete overview of features, accessories, type codes, Type Part number technical data and dimensions for the rotary indexing tables DHTG-65-2-A 548076 DHTG-… -A can be found in the product catalogue or on the DHTG-65-3-A 555448 Festo website (www.Festo.com). DHTG-65-4-A 548077 DHTG-65-6-A 548078 DHTG-65-8-A 548079 DHTG-65-12-A 548080... -

Page 8: Component Overview

47 48 49 50 51 This diagram is intended only to provide an overview of the individual components. To order spare and wearing parts, please use the online spare parts catalogue on the Festo website (spareparts.Festo.com). 8 / 46 Festo 7DHTGb_en... - Page 9 DIN 912-M4×16 Tightening torque 2.9 Nm Stop screw M8×12 Clamping component Tightening torque 0.8 Nm Sealing ring Blanking plug Tightening torque 1.5 Nm Blanking plug module Stop screw M8×1×… Hollow bolt Tightening torque 1.5 Nm Festo 7DHTGb_en 9 / 46...

-

Page 10: Dhtg-90

DHTG-90-…-A 51 52 This diagram is intended only to provide an overview of the individual components. To order spare and wearing parts, please use the online spare parts catalogue on the Festo website (spareparts.Festo.com). 10 / 46 Festo 7DHTGb_en... - Page 11 Tightening torque 2.9 Nm Stop screw M8×12 Clamping component Tightening torque 0.8 Nm Sealing ring DIN 913-M5×5 Blanking plug Tightening torque 1.5 Nm Blanking plug module Stop screw M8×1×… Hollow bolt Tightening torque 1.5 Nm Festo 7DHTGb_en 11 / 46...

-

Page 12: Dhtg-140

DHTG-140-…-A 55 56 This diagram is intended only to provide an overview of the individual components. To order spare and wearing parts, please use the online spare parts catalogue on the Festo website (spareparts.Festo.com). 12 / 46 Festo 7DHTGb_en... - Page 13 DIN 912-M6×16 Tightening torque 9.9 Nm Stop screw Clamping component Tightening torque 2.5 Nm Sealing ring DIN 913-M8×8 Blanking plug Tightening torque 0.5 Nm Blanking plug module Stop screw Hollow bolt Tightening torque 5.5 Nm Festo 7DHTGb_en 13 / 46...

-

Page 14: Dhtg-220

55 56 43 44 This diagram is intended only to provide an overview of the individual components. To order spare and wearing parts, please use the online spare parts catalogue on the Festo website (spareparts.Festo.com). 14 / 46 Festo 7DHTGb_en... - Page 15 Socket head screw DIN 912-M6×25-10.9 Tightening torque 9.9 Nm Stop screw Clamping component Tightening torque 2.5 Nm Sealing ring Blanking plug Tightening torque 0.5 Nm Blanking plug module Stop screw Hollow bolt Tightening torque 5.5 Nm Festo 7DHTGb_en 15 / 46...

-

Page 16: Repair Steps

(if necessary with the help of a second person or by securing the rotary indexing table). • Check the plate seal on the clamping ring for wear and replace it as follows if necessary: • Remove the plate seal from the clamping ring. 16 / 46 Festo 7DHTGb_en... -

Page 17: Dismantling The Plate (Dhtg-65 And Dhtg-90)

Loosen the countersunk screws in the index plate and steadily unscrew them. • To loosen the index plate, steadily screw the countersunk screws into the threaded holes of the index plate and lift it without twisting it. Festo 7DHTGb_en 17 / 46... - Page 18 Lever the two rails of the guide segments out of the housing. Note If only individual components of the plate need to be repaired, you can con- tinue with section 4.2.4 “Assembling the plate (DHTG-65 and DHTG-90)”. 18 / 46 Festo 7DHTGb_en...

-

Page 19: Dismantling The Plate (Dhtg-140)

To loosen the index plate, steadily screw the three countersunk screws into the threaded holes of the index plate and lift it without twisting it. • Remove the index plate from the plate. • Remove the ring gear from the plate. Festo 7DHTGb_en 19 / 46... - Page 20 Lever the two rails of the guide segments out of the housing. Note If only individual components of the plate need to be repaired, you can con- tinue with section 4.2.5 “Assembling the plate (DHTG-140)”. 20 / 46 Festo 7DHTGb_en...

-

Page 21: Dismantling The Plate (Dhtg-220)

To loosen the index plate, steadily screw the three countersunk screws into the threaded holes of the index plate and lift it without twisting it. • Remove the index plate from the plate. • Remove the ring gear from the plate. Festo 7DHTGb_en 21 / 46... - Page 22 Lever the two rails of the guide segments out of the housing. Note If only individual components of the plate need to be repaired, you can con- tinue with section 4.2.6 “Assembling the plate (DHTG-220)”. 22 / 46 Festo 7DHTGb_en...

-

Page 23: Removing The Gear Racks

Take care of the compression spring at the rear when removing the stop plate, as it can easily be lost. • Remove the impact plate from the housing. • Pull the compression spring out of the impact plate. Festo 7DHTGb_en 23 / 46... - Page 24 Unscrew the two stop screws from the impact plate. • Remove the clamping components from the impact plate. • Remove the retaining ring of the shock absorber. • Pull the shock absorber out of the gear rack. 24 / 46 Festo 7DHTGb_en...

- Page 25 This O-ring is not present in the impact plate of the DHTG-65. • Loosen the countersunk head screws in the stop plate at the rear of the housing and unscrew them. Type Number of countersunk head screws DHTG-65-…-A DHTG-90-…-A DHTG-140-…-A DHTG-220-…-A • Remove the stop plate. Festo 7DHTGb_en 25 / 46...

- Page 26 Loosen the four socket head screws in the flange on the underside of the housing and unscrew them. • Place the housing on two suitable supports so that there is a clearance of at least 15 mm for driving out the flange. min. 15 mm 26 / 46 Festo 7DHTGb_en...

- Page 27 • Push the two covers out from their guides. • Remove the retaining ring of the pinion. • Pull the pinion out of the housing. • Slide the two gear racks out of the housing. Festo 7DHTGb_en 27 / 46...

-

Page 28: Removing The Bolts

Remove the retaining ring from both covers. • Carefully drive the bolts out of the bolt guide, e.g. using a wooden slat and a plastic hammer. 4.1.7 Dismantling the bolts • Pull the cover off the two bolts. 28 / 46 Festo 7DHTGb_en... - Page 29 Carefully tap the bolts on both sides over a soft surface to catch the lock bolts from the bolt. • Lever the piston seals off the two bolts. • Lever the wiper seal (arrow) out of the two covers. • Lever the O-ring off the two covers. Festo 7DHTGb_en 29 / 46...

-

Page 30: Assembling The Rotary Indexing Table

Press the new wiper seals into their holder using your finger or a suitable blunt object. Note The open side of the piston seal must face the outside of the bolt. • Insert the new piston seals (arrow) into position on both bolts. 30 / 46 Festo 7DHTGb_en... - Page 31 Insert the new stop pins into the bolts on both sides and tighten them. • Press the new O-rings (arrow) into position on both covers. Note The open side of the wiper seal must face away from the taper. • Insert the new wiper seals into the covers. Festo 7DHTGb_en 31 / 46...

-

Page 32: Installing The Bolts

10 mm DHTG-90-…-A 24 mm 15 mm DHTG-140-…-A 29 mm 18 mm DHTG-220-…-A 39 mm 24 mm • Insert the new retaining rings into the guides. Note Check that the retaining rings are correctly positioned. 32 / 46 Festo 7DHTGb_en... -

Page 33: Installing The Gear Racks

Note (DHTG-140 only) The gear rack that lies next to the impact plate must be moved inwards by one tooth, as otherwise correct functioning of the rotary indexing table cannot be guaranteed. Festo 7DHTGb_en 33 / 46... - Page 34 • Screw the socket head screws into the housing through the flange and tighten them using the appropriate torque (see table). Type Torque DHTG-65-…-A 1.2 Nm DHTG-90-…-A 2.9 Nm DHTG-140-…-A 5.9 Nm DHTG-220-…-A 9.9 Nm 34 / 46 Festo 7DHTGb_en...

- Page 35 Note The O-rings must be positioned correctly to ensure that there is no leakage. You can apply a light coat of grease to the O-rings to prevent them from pop- ping out of the seats. Festo 7DHTGb_en 35 / 46...

- Page 36 Push the shock absorber into the gear rack based on the notes you made during removal. • Insert the new retaining ring into the gear rack. Note Check that the retaining ring is correctly positioned. • Insert the clamping components into the impact plate. 36 / 46 Festo 7DHTGb_en...

- Page 37 Tightening the socket head screws on one side can result in twisting of the impact plate. • Steadily screw the socket head screws into the impact plate, but do not tighten them yet. Type Number of socket head screws DHTG-65-…-A DHTG-90-…-A DHTG-140-…-A DHTG-220-…-A Festo 7DHTGb_en 37 / 46...

-

Page 38: Assembling The Plate (Dhtg-65 And Dhtg-90)

5.5 Nm 4.2.4 Assembling the plate (DHTG-65 and DHTG-90) • Push the rail of the guide segments onto the plate. • Press the new O-ring into position on the inside of the hole in the plate. 38 / 46 Festo 7DHTGb_en... -

Page 39: Assembling The Plate (Dhtg-140)

Push the rail of the guide segments onto the plate. • Place the compression springs and the sleeves in the guides in the plate. • Place the ring gear on the sleeves with the countersinks facing downwards. Festo 7DHTGb_en 39 / 46... -

Page 40: Assembling The Plate (Dhtg-220)

DHTG-140-…-A 4 Nm 4.2.6 Assembling the plate (DHTG-220) • Push the rail of the guide segments onto the plate. • Press the new O-ring into position on the inside of the hole in the plate. 40 / 46 Festo 7DHTGb_en... - Page 41 Note the position of the centring bolts in the plate when placing the index plate. Note The ring gear is equipped with overload protection. It has spring tensioning and can twist when the countersunk screws are tightened on one side. Festo 7DHTGb_en 41 / 46...

-

Page 42: Installing The Plate

The sealing rim of the plate seal must face the underside of the clamping ring. • Press the new plate seal into the groove on the edge of the clamping ring. • Place the two rails of the guide segments in the housing. 42 / 46 Festo 7DHTGb_en... - Page 43 (arrow) is level with the screw hole and the clamping ring is flush with the plate surface. For design reasons, sizes DHTG-65 and DHTG-90 must have two screw holes. The correct pretension is achieved with the hole noted during removal. Festo 7DHTGb_en 43 / 46...

-

Page 44: Maintenance

A detailed description of the steps for care and maintenance can be found in the operating instructions. Additional infor- mation on assembly aids and lubricants can be found on the Festo website (www.Festo.com). Cleaning and lubricating the rotary indexing table Clean the rotary indexing table using a soft cloth and a gentle detergent if necessary. -

Page 45: Tools

A/F 9 and A/F 12 Hole profile or other suitable – lever tool Liability The General Terms and Conditions of Festo AG & Co. KG, which can be viewed on the Festo website (www.Festo.com) apply. Festo 7DHTGb_en 45 / 46... -

Page 46: Festo 7Dhtgb_En

Festo shall have the correspond- status as the last printed edition. and 2 completely to a third party. The third ing rights of use. Festo permits the user to party must be made explicitly aware of these 2. Furthermore, Festo cannot be held liable use the electronic documentation under the conditions of use.

Need help?

Do you have a question about the DHTG-A Series and is the answer not in the manual?

Questions and answers