Subscribe to Our Youtube Channel

Summary of Contents for NCT MSL-200

- Page 1 MSL-200 CNC LATHE MAINTENANCE MANUAL MSL-200 CNC LATHE MAINTENANCE MANUAL NCT Ipari Elektronikai Kft. 1 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu...

-

Page 2: Table Of Contents

Handling method ....................... 19 3.1.1 Handling of machine in crate ................19 3.1.2 Handling of machine without a crate ..............19 NCT Ipari Elektronikai Kft. 2 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300... - Page 3 MAINTENANCE AND SERVICING ................32 Daily maintenance ..................... 32 Weekly maintenance ....................32 Semi-annual maintenance ..................32 Annual maintenance ....................32 NCT Ipari Elektronikai Kft. 3 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300...

-

Page 4: Machine Safety Guidelines

Any obstacles on the walking path should be removed. People should keep away from the machine before the machine can be hoisted or handled to avoid damage or inju- NCT Ipari Elektronikai Kft. 4 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 5: Electrical Safety

Fig. 2, the grounding im- pedance is 100 Ω. Prohibit serial connection of several equipment items to grounding terminals, as shown in Fig. 3. NCT Ipari Elektronikai Kft. 5 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 6: Environmental Conditions

Turn on no-fuse switch of main circuit to “ON” or “1” (the power lamp lights on) Press the green “ON” power knob on NC power operation panel Turn on emergency switch Turn on exterior air pressure system switch. NCT Ipari Elektronikai Kft. 6 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 7: Routine Inspection

2. Damaged and defective cutting tools will damage the work piece, so they should be re- placed before machining operation. NCT Ipari Elektronikai Kft. 7 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 8: Operation

1. In machining process, do not open the protective doors of all machine parts. 2. In heavy machining process, make sure to prevent excessive accumulation of iron scraps, which may cause rising temperature and result in a fire inside the machine. NCT Ipari Elektronikai Kft. 8 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 9: Interruption Of Machining Process

1. Before maintenance, make sure to turn off the power source in the factory, the special switch for this machine and no-fuse switch of machine’s main circuit, and put up signs of “UNDER MAINTENANCE – DO NOT TURN ON POWER” at the switches or at NCT Ipari Elektronikai Kft. 9 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 10: Subsequent Jobs After Maintenance

The operator and maintenance personnel should ensure their operation is within the range of movement. NCT Ipari Elektronikai Kft. 10 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 11: Warning Signs

MSL-200 CNC LATHE MAINTENANCE MANUAL Warning signs NCT Ipari Elektronikai Kft. 11 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 12: Illustration Of Safety Positions

1 Front door safety switch 2 Side door safety switch (right) 3 Emergency stop knob 4 Emergency stop knob Machine nameplate NCT Ipari Elektronikai Kft. 12 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300... -

Page 13: Illustration Of Operator's Position

MSL-200 CNC LATHE MAINTENANCE MANUAL Illustration of operator’s position NCT Ipari Elektronikai Kft. 13 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 14: Machine Introduction

Do not try to oper- ate without due authorization. The following is a detailed description of the operation of all components of this machine. NCT Ipari Elektronikai Kft. 14 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 15: Specification Table

Factors that actually affect expo- sure grade of work piece include the time when the noise was sustained (e.g., level in the vi- NCT Ipari Elektronikai Kft. 15 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

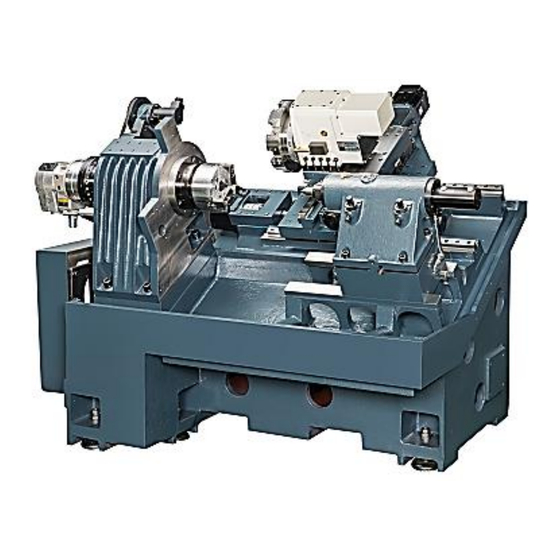

Page 16: Description Of Main Parts

1 Spindle head 5 Saddle 2 Chuck, spindle 6 Base 3 Turret 7 Tailstock 4 Slide way 8 Spindle motor NCT Ipari Elektronikai Kft. 16 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 17: Machine Dimension

MSL-200 CNC LATHE MAINTENANCE MANUAL Machine dimension NCT Ipari Elektronikai Kft. 17 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 18: Illustration Of Cutting Tool Interference

MSL-200 CNC LATHE MAINTENANCE MANUAL Illustration of cutting tool interference NCT Ipari Elektronikai Kft. 18 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 19: Machine Handling And Installation

4. When the forks lift up the machine, make sure of the lifted height. Do not lift it too high, or it may swing due to too high a centre of gravity, and result in an accident. NCT Ipari Elektronikai Kft. 19 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 20: Preparation Before Installation

2. Grout concrete, making sure spaces for foundation bolt channels are reserved according to the foundation drawing. 3. After the concrete is set, spread flat plates onto the reserved foundation bolt channels. NCT Ipari Elektronikai Kft. 20 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. - Page 21 Wait seven to ten days until the concrete has com- pletely set, then you may calibrate the level precision of the machine. Foundation layout plan NCT Ipari Elektronikai Kft. 21 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7.

-

Page 22: Environmental Requirement

4. Please make sure every levelling bolts to touch foundation when adjust it. 5. Please lock every screw nut of levelling bolts after adjustment. 6. Mechanical levelling adjustment standard precision value: NCT Ipari Elektronikai Kft. 22 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 23: Installation Of Machine Power

MAINTENANCE MANUAL Levelling precision:0.04 mm/1000 mm Saddle and level angle precision:1 Grad=0.02 mm/1000 mm Installation of machine power NCT Ipari Elektronikai Kft. 23 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300... -

Page 24: Machine Mechanisms And Adjustment

1 Axial servo motor 5 End bracket 2 Coupling 6 Motor bracket 3 Ball screw 7 Saddle 4 Slide NCT Ipari Elektronikai Kft. 24 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 25: Z Axis Driving Mechanism

The method of adjusting runout as following: Rotating the spindle to max. runout valve (highest position) Then follow lock direction to lock screw nut. NCT Ipari Elektronikai Kft. 25 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 26: Adjustment Of Belt Tension

Adjustment of belt tension Please loose screw nut A first, then adjust screw bolt to move motor bracket up or down. Please lock screw nut A after adjusted belt tension to best condition. NCT Ipari Elektronikai Kft. 26 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 27: Hydraulic System

MSL-200 CNC LATHE MAINTENANCE MANUAL HYDRAULIC SYSTEM Hydraulic system diagram NCT Ipari Elektronikai Kft. 27 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 28: Hydraulic Tank Part Diagram

During adjustment, you can confirm the value from the pressure scale. (The total pressure setting is 28 kgf/cm before shipping. ) Note: Please don’t adjust pressure source to avoid any issue. NCT Ipari Elektronikai Kft. 28 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 29: Lubrication

In case the grease deteriorates, the bearing must be disassembled and cleaned before it is reinstalled. Please contact our company so our professionals may execute servicing and ad- justment. NCT Ipari Elektronikai Kft. 29 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 30: Lubrication Of Hydraulic System

Lubrication position Auto lubrication pump install on machine right side, please make sure quantity of oil enough or not, if the quantity not enough, please add oil. NCT Ipari Elektronikai Kft. 30 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. -

Page 31: Table Of Characteristics Of Oil On All Parts

3. CASTROL 3. Castrol 3. SHELL MAGNA BD68 CLEAREDGE V4 Tellus oil 4. Shell TONNA T68 4. Esso KUTWELL 40 NCT Ipari Elektronikai Kft. 31 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7. Phone: +36 1 467 6300 www.nct.hu... -

Page 32: Maintenance And Servicing

7. Use a vacuum cleaner to clean dust in the strong current box, and use alcohol to wipe it clean. 8. Clean cutting fluid box and filter net, and replace cutting fluid NCT Ipari Elektronikai Kft. 32 / 32 10 September 2018 H-1148 Budapest, Fogarasi út 7.

Need help?

Do you have a question about the MSL-200 and is the answer not in the manual?

Questions and answers