Eurotherm Invensys Mini8 Engineering Manual

Multi-loop controllers

Hide thumbs

Also See for Invensys Mini8:

- User manual (343 pages) ,

- Installation and wiring instructions (2 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for Eurotherm Invensys Mini8

- Page 1 Mini8™ Multi-loop Controllers Engineering Manual...

- Page 2 The information in this document is given in good faith, but is intended for guidance only. Eurotherm Limited will accept no responsibility for any losses arising from errors in this document.

-

Page 3: Table Of Contents

Mini8 Controller Engineering Handbook Mini8 controller – Multi-Loop Process Controller CHAPTER 1 INSTALLATION AND OPERATION............8 What Instrument Do I Have? ....................8 Mini8 Controller Ordering Code ................... 9 How to Install the Controller....................10 1.3.1 Dimensions......................................10 1.3.2 To Install the Controller................................10 1.3.3 Environmental Requirements .............................. - Page 4 Engineering Handbook Mini8 Controller Graphical Wiring Editor....................... 48 3.6.1 Graphical Wiring Toolbar ................................49 3.6.2 Function Block....................................49 3.6.3 Wire ........................................49 3.6.4 Block Execution Order ...................................49 3.6.5 Using Function Blocks ..................................49 3.6.6 Tooltips .......................................50 3.6.7 Function Block State..................................51 3.6.8 Using Wires......................................52 3.6.9 Using Comments....................................53 3.6.10 Using Monitors ...................................54...

- Page 5 Mini8 Controller Engineering Handbook CHAPTER 8 ALARMS ..................88 Further Alarm Definitions....................88 Analogue Alarms........................89 8.2.1 Analogue Alarm Types................................... 89 Digital Alarms ........................90 8.3.1 Digital Alarm Types..................................90 Alarm Outputs ........................90 8.4.1 How Alarms are Indicated ................................90 8.4.2 To Acknowledge an Alarm ................................90 Alarm Parameters ........................91 8.5.1 Example: To Configure Alarm 1..............................

- Page 6 Engineering Handbook Mini8 Controller CHAPTER 11 COUNTERS, TIMERS, TOTALISERS, RT CLOCK ......126 11.1 Counters..........................126 11.1.1 Counter Parameters................................127 11.2 Timers ..........................128 11.2.1 Timer Types ....................................128 11.2.2 On Pulse Timer Mode ................................128 11.2.3 On Delay Timer Mode................................129 11.2.4 One Shot Timer Mode ................................

- Page 7 Mini8 Controller Engineering Handbook CHAPTER 17 CONTROL LOOP SET UP............... 162 17.1 What is a Control Loop? ....................162 17.2 Loop Parameters - Main.....................163 17.3 Loop Set up........................163 17.3.1 Types of Control Loop................................164 17.4 PID Control ........................164 17.4.1 Proportional Term .................................. 165 17.4.2 Integral Term....................................

- Page 8 Engineering Handbook Mini8 Controller 18.4 Output Events ........................197 18.4.1 Digital Events.................................... 197 18.4.2 PV Event & User Value................................198 18.4.3 Time Event ....................................198 18.5 Holdback ........................... 201 18.5.1 Guaranteed Soak..................................201 18.6 PID Select.......................... 202 18.7 Program Cycles ......................... 202 18.7.1 Servo......................................

- Page 9 Mini8 Controller Engineering Handbook 23.5 Step 3 – Activate OEM Security ..................231 23.6 Step 4 – Deactivate OEM Security ..................232 23.7 Erasing Memory .........................232 APPENDIX A MODBUS SCADA TABLE............... 233 24.1 Comms Table ........................233 24.2 SCADA Table........................233 24.2.1 Version 2.xx Programmer Addresses - Decimal......................257 24.2.2 Version 2.xx Programmer Addresses - Hexadecimal....................

-

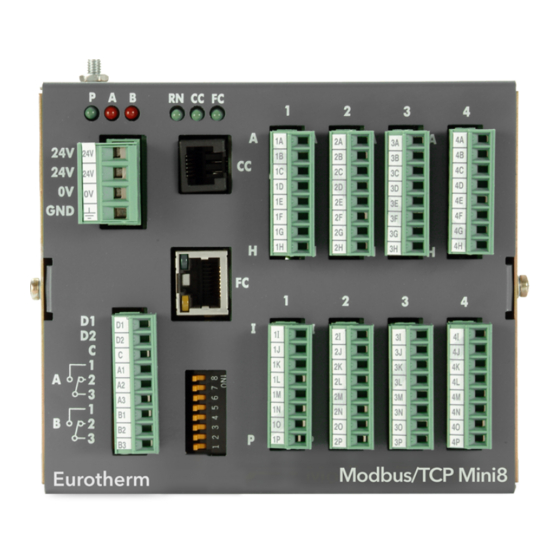

Page 10: Chapter 1 Installation And Operation

The Mini8 controller is pre-assembled in the factory to give the I/O required for the application as specified in the order code. With standard applications the Mini8 controller is also supplied configured. Alternatively, the Mini8 controller is configured using Eurotherm’s iTools configuration suite running on a personal computer. All Safety & EMC information is in Appendix E. -

Page 11: Mini8 Controller Ordering Code

Mini8 Controller Engineering Handbook Mini8 Controller Ordering Code Mini8 Loops Programs Comms Units controller Slot1 Slot2 Slot3 Slot4 12 . Application Recipe Wires Manual Config 7-10 IO Slots 1-4 MINI8 CONTROLLER Mini 8 controller No module fitted Control Loops 4 Channel TC Input IO Acquisition only 8 Channel TC Input 4 Control loops... -

Page 12: How To Install The Controller

Engineering Handbook Mini8 Controller How to Install the Controller This instrument is intended for permanent installation, for indoor use only, and to be enclosed in an electrical panel. Select a location where minimum vibrations are present and the ambient temperature is within 0 and 50 C (32 and 122 Please read the safety information, Appendix E at the end of this manual, before proceeding and refer to the... -

Page 13: Electrical Connections

Mini8 Controller Engineering Handbook Electrical Connections The Mini8 controller is intended for operation at safe low voltage levels, except the RL8 relay module. Voltages in excess of 42 volts must not be applied to any terminals other than the RL8 relay module. A protective earth connection is required. -

Page 14: Fixed Io Connections

The configuration port (Modbus) is on an RJ11 socket, just to the right of the power supply connections. It is a point to point RS232 connection. Eurotherm supply a standard cable to connect a serial COM port on a computer to the RJ11 socket, part no. SubMin8/cable/config. - Page 15 1200m. 31 instruments and one master may be connected. To use RS485, buffer the RS232 port of the PC with a suitable RS232/RS485 converter. The Eurotherm Controls KD485 Communications Adapter unit is recommended for this purpose. The use of a RS485 board built into the computer is not recommended since this board may not be isolated, which may cause noise problems or damage to the computer, and the RX terminals may not be biased correctly for this application.

-

Page 16: Devicenet / Canopen

Engineering Handbook Mini8 Controller 1.4.6 DeviceNet / CANopen This instrument supports DeviceNet CAN interface, CANopen V4.02 CAN interface and Enhanced DeviceNet DeviceNet and CANopen both use a 5 way, 5.08mm pitch, connector/screw terminal. The DeviceNet bus is powered (24V) from the system network, not from the instrument. The Mini8 controller requirement is a load of around 100mA. -

Page 17: Enhanced Devicenet Interface

This version of DeviceNet has been added for use in the Semiconductor industry. Configuration for both versions is the same and is described in the DeviceNet Handbook HA027506 which can be downloaded from www.eurotherm.com. The Enhanced DeviceNet interface uses a different connector, as described below, but cabling, cable specification and termination are the same as described in sections 1.4.6 and 1.4.8. -

Page 18: Typical Devicenet / Canopen Wiring Diagram

Engineering Handbook Mini8 Controller 1.4.8 Typical DeviceNet / CANopen Wiring Diagram Mini8 V+ 5 CAN-H 4 CAN-H Drain 3 Drain CAN-L CAN-L 2 V- 1 (SLAVE) Address 11 MASTER Mini8 CAN-H Drain CAN-L (SLAVE) Supply Address 12 24Vdc (+/- 1%) 250mV p-p Ripple Mini8 CAN-H... -

Page 19: Profibus Dp

Mini8 Controller Engineering Handbook 1.4.9 Profibus DP Two Profibus communications board options are available for the Mini8 controller. Standard Profibus 3 wire RS485 9 pin D connector intended for installation using standard Profibus cabling. Note that in this arrangement line terminations must be catered for in the cabling. Profibus 3 wire RS485 via 2 paralleled RJ45 sockets. -

Page 20: Ethernet (Modbus Tcp)

Engineering Handbook Mini8 Controller 1.4.10 Ethernet (Modbus TCP) The Ethernet connection uses standard Cat5E patch cables (RJ45). These would be used with a 10BaseT hub to create a network. A crossover patch cable may be used ‘point-to-point’ i.e. to connect a single instrument directly to a PC. Connector: RJ45: Function Network traffic activity is displayed on indicators built into the connector, yellow indicates network activity and... -

Page 21: Thermocouple Input Tc4 And Tc8

Mini8 Controller Engineering Handbook 1.4.11 Thermocouple Input TC4 and TC8 The TC8 thermocouple module takes 8 thermocouples; the TC4 module takes 4 thermocouples. They may be placed in any slot in the Mini8 controller. Up to 4 may be fitted in a Mini8 controller. Each input can be configured to any thermocouple type or a linear mV input. -

Page 22: Rtd / Pt100 Input Rt4

Engineering Handbook Mini8 Controller 1.4.12 RTD / PT100 Input RT4 The RT4 module provides 4 RTD inputs for 2, 3 or 4 wire connections. Up to 4 modules may be fitted in a Mini8 controller and they may be placed in any slot. Each input can be configured for any resistive sensor up to 600 ohms. -

Page 23: Logic Input Di8

Mini8 Controller Engineering Handbook 1.4.13 Logic Input DI8 The DI8 module provides 8 logic inputs. They may be placed in any slot in the Mini8 controller. Up to 4 may be fitted in a Mini8 controller. Ø D1 + +24V Ø... -

Page 24: Logic Output Do8

Engineering Handbook Mini8 Controller 1.4.14 Logic Output DO8 The DO8 module provides 8 logic outputs. They may be placed in any slot in the Mini8 controller. Up to 4 may be fitted in a Mini8 controller. Each output can be configured to Time Proportioning or On/Off. Ø... -

Page 25: Relay Output Rl8

Mini8 Controller Engineering Handbook 1.4.15 Relay Output RL8 The RL8 module provides 8 relay outputs. Up to 2 modules may be fitted and in slots 2 and/or 3 only RLY1 A Ø RLY1 B Ø RLY2 A Ø RLY2 B Ø... -

Page 26: Analogue Output Ao4 And Ao8

Engineering Handbook Mini8 Controller 1.4.16 Analogue Output AO4 and AO8 The AO8 modules provides 8 analogue outputs and the AO4 provides 4 analogue outputs. Each output is configurable within 0 to 20 mA , max load 360 ohm. The AO4 offers OP1 to OP4 on terminals A to H. Only one module may be fitted and in slot 4 only. -

Page 27: Current Transformer Input Module Ct3

Mini8 Controller Engineering Handbook 1.4.17 Current Transformer input Module CT3 This provides inputs for 3 current transformers. The heater load cables are threaded through the transformers. Each input is 50mA max into 5 ohms. Ø Reserved Ø Reserved Ø Reserved Ø... -

Page 28: Adding Or Replacing An Io Module

Engineering Handbook Mini8 Controller Adding or replacing an IO module. Modules contain static sensitive electronic devices. Take full antistatic protection when replacing modules by working on an earthed mat with an earthed wrist strap. Avoiding touching components, keep fingers on the green connectors or the edge of the printed circuit boards. Remove screw →... -

Page 29: Mini 8 Led Indicators

Mini8 Controller Engineering Handbook Mini 8 LED Indicators Two sets of 3 LEDs on the front panel indicate the power, the state of the output relays, the status of the Mini8 controller and communications activity. Legend Green Function Indicates 24V Relay A state Relay B state No power... -

Page 30: Status Indication For Enhanced Devicenet

Engineering Handbook Mini8 Controller 1.6.1 Status Indication for Enhanced DeviceNet If an Enhanced DeviceNet module is fitted (section 1.4.7), two bi-colour LEDs are NET MOD used to indicate Module and Network status. These two LEDs replace the single LED shown as FC on other modules. See previous section. -

Page 31: Chapter 2 Using The Mini8 Controller

OPCLink. In this situation the user would not have to know any of the parameter addresses, and would just select a parameter by browsing through the namespace. e.g. Eurotherm.ModbusServer.1.COM1.ID001-Mini8.Loop.1.Main.PV Modbus, single register, SCADA addressing The key parameters of the Mini8 controller are available at a fixed single 16 bit register address, independent of its configuration. -

Page 32: Modbus (Floating Point)

Engineering Handbook Mini8 Controller Modbus (Floating Point) If the application requires the extra resolution, the Commstab folder also offers an alternative solution where a parameter can be indirectly addressed and communicated either as a floating point or as a double integer value –... -

Page 33: The Itools Operator Interface

The iTools handbook, part no. HA026179, provides further step by step instructions on the general operation of iTools. This and the iTools software may be downloaded from www.eurotherm.co.uk. When an instrument is found on the network it will be shown as, for example ‘COM1.ID001-Min8’... - Page 34 Engineering Handbook Mini8 Controller To view or change a parameter: Highlight the folder Press to get the parameter window or open up the parameter list by clicking on the required folder. Right click in the parameter list to reveal or hide columns. To change the value of a parameter, click the parameter value, write in the new value.

-

Page 35: Recipe Editor

Mini8 Controller Engineering Handbook Recipe Editor Press for this feature. Up to 8 recipes can be stored. They can also be named by the user. Recipes allow the operator to change the operating values of up to 24 parameters in an instrument for different batch items/processes by simply selecting a particular recipe to load. -

Page 36: Opcscope

Excel. With iTools open OPC Scope can be started using the icon But it can also be started on its own using the Windows Start/Programs/Eurotherm iTools/OPC Scope Select Server/Connect or click the icon and the OPC server will start up (if it is not running) and will display the active ports on the computer. -

Page 37: Opc Scope List Window Context Menu

If you have iTools Open (not iTools Standard) then OPC Scope can run on a remote networked computer. Enter the name of the server computer (attached to the instruments) the ‘Computer’ window and browse for the ‘Eurotherm.ModbusServer1’. 2.9.2 OPC Scope Chart Window Click the Chart tab at the bottom of the display window and select Chart Control Panel. - Page 38 Engineering Handbook Mini8 Controller iTools Trend Graph showing Loop1 SP and PV icon allows the chart to occupy all the window space. Part No HA028581 Issue 7.0 Dec-09...

-

Page 39: Opc Server

OPC Server ITools and OPC Scope all use the Eurotherm OPC Server to provide the connection between the instruments and the computer displays. When you ‘scan’ for instruments on iTools it is in fact the OPC Server that is actually doing the work in background (the window is not usually displayed). -

Page 40: Chapter 3 Configuration Using Itools

RJ11 port connecting to a serial port on the PC. Alternatively a Configuration Clip is available from Eurotherm that can be fitted into the rear of the controller. The benefit of using this arrangement is that it is not necessary to power the controller, since the clip provides the power to the internal memory of the controller. -

Page 41: Cloning

Mini8 Controller Engineering Handbook Cloning Saving a Clone File On the iTools menu ‘File – Save to File’ allows the clone file of the attached Mini8 controller to be saved to disc as <user name>.UIC file. This can be loaded into another Mini8 controller. Note that after synchronization iTools using uses a ‘quick’... -

Page 42: Configuring The Mini8 Controller

Engineering Handbook Mini8 Controller Configuring the Mini8 Controller Once iTools is successfully connected to a Mini8 controller, it can be configured for the application in hand. Configuration involves selection of the required elements of functionality called ‘function blocks’ and setting their parameters to the correct values. -

Page 43: Soft Wiring

Mini8 Controller Engineering Handbook 3.4.2 Soft Wiring Soft Wiring (sometimes known as User Wiring) refers to the connections that are made in software between function blocks. Soft wiring, which will generally be referred to as ‘Wiring’ from now on is created during the instrument configuration using the iTools configuration package. -

Page 44: Simple Worked Example

Engineering Handbook Mini8 Controller Simple Worked Example Using function blocks and wiring the following sections will show a blank Mini8 controller being configured to have one PID loop. 3.5.1 The I/O With the Mini8 controller successfully connected to iTools configuration can begin. ☺... - Page 45 Mini8 Controller Engineering Handbook Figure 3-4: Thermocouple Input Select the I/O type, linearisation, units, resolution etc. required. Parameter details are in Section 7.5. The other thermocouple channels can be found by using the 2, 3, 4…7, 8 tabs on the top of the parameter window.

- Page 46 Engineering Handbook Mini8 Controller Example 2: RTD Input Configuration In the IO list ModIDs select the type of module. RTD modules are 4 input modules [RT4Mod (173)]. Figure 3-6: Mini8 Controller IO Module1 Defined as RTD RTDs can be defined as 2-wire [RTD2 (32)], 3-wire [RTD3 (33)] or 4-wire [RTD4 (34)] in the module definition list. It is important that the ‘IO Type’...

- Page 47 Mini8 Controller Engineering Handbook 3.5.2 Wiring The IO that has been configured now needs to be wired to PID loops and other function blocks. Select (GWE) to create and edit instrument wiring. The Graphical Wiring Editor window To add a function block drag it from the list and drop it on this editor.

- Page 48 Engineering Handbook Mini8 Controller Use drag and drop to select the first thermocouple from IOMod 1, the Cool output from IOMod 17 and the Heat output from IOMod 25 and drop them on the wiring window. Finally take the first PID block from Loop/Loop 1 and drop it on the wiring window. Note that as each block is used it greys out on the list.

- Page 49 Mini8 Controller Engineering Handbook Figure 3-10: PID Function Block This enables the PID function block to be set up to suit the required application. See Chapter 17 for details. Click on the instrument button to download the application: Once downloaded the dotted lines around the function blocks and the wires will become solid to show that the application is now in the Mini8 controller.

-

Page 50: Graphical Wiring Editor

Engineering Handbook Mini8 Controller Graphical Wiring Editor Select (GWE) to view and edit instrument wiring. You can also add comments and monitor parameter values. Drag and drop required function blocks into the graphical wiring from the list in the left pane Click on parameter to be wired from and drag the wire to the parameter to be wired to (do not hold mouse button down) Right click to edit parameter values... -

Page 51: Graphical Wiring Toolbar

Mini8 Controller Engineering Handbook 3.6.1 Graphical Wiring Toolbar Download Grab & Pan Pan Drawing Delete, Undo & Redo Copy a Diagram Fragment to a File Copy Paste a Diagram Fragment to a File Create a Compound IO Setup Select Zoom Drawing Grid on/off Paste 3.6.2... -

Page 52: Tooltips

Engineering Handbook Mini8 Controller 3.6.5.1 Function Block Context Menu Right clicking displays the context menu with the following entries. Function Block Brings up an iTools parameter list which shows all the parameters in the function block. If the block has View…... -

Page 53: Function Block State

Mini8 Controller Engineering Handbook 3.6.7 Function Block State The blocks are enabled by dragging the block onto the diagram, wiring it up, and downloading it to the instrument When the block is initially dropped onto the diagram it is drawn with dashed lines. When in this state the parameter list for the block is enabled but the block itself is not executed by the instrument. -

Page 54: Using Wires

Engineering Handbook Mini8 Controller 3.6.8 Using Wires 3.6.8.1 Making A Wire Between Two Blocks • Drag two blocks onto the diagram from the function block tree. • Start a wire by either clicking on a recommended output or clicking on the icon at the bottom right corner of the block to bring up the connection dialog. -

Page 55: Using Comments

Mini8 Controller Engineering Handbook 3.6.8.3 Wire Colours Wires can be the following colours: Black Normal functioning wire. The wire is connected to an input which is not alterable when the instrument is in operator mode and so values which travel along that wire will be rejected by the receiving block Blue The mouse is hovering over the wire, or the block to which it is connected it selected. -

Page 56: Using Monitors

Engineering Handbook Mini8 Controller 3.6.10 Using Monitors Drag a monitor onto the diagram and connect it to a block input or output or a wire as described in ‘Using Comments’. The current value (updated at the iTools parameter list update rate) will be shown in the monitor. By default the name of the parameter is shown, double click or use the context menu to not show the parameter name. -

Page 57: Colours

Mini8 Controller Engineering Handbook 3.6.13 Colours Items on the diagram are coloured as follows: Function blocks, comments and monitors which partially obscure or are partially obscured by other items are drawn red. If a large function block like the loop is covering a small one like a math2 the loop will be drawn red to show that it is covering another function block. -

Page 58: Wiring Floats With Status Information

Engineering Handbook Mini8 Controller 3.6.15 Wiring Floats with Status Information There is a subset of float values which may be derived from an input which may become faulty for some reason, e.g. sensor break, over-range, etc. These values have been provided with an associated status which is automatically inherited through the wiring. -

Page 59: Edge Wires

Mini8 Controller Engineering Handbook 4: Up Scale The measurement will be forced to adopt its high limit. This is like having a resistive pull up on an input circuit. In addition the status of the measured value will be set to ‘BAD’, such that any function block using this measurement can operate its own fallback strategy. -

Page 60: Chapter 4 Mini8 Controller Overview

Engineering Handbook Mini8 Controller Chapter 4 Mini8 controller Overview Input and output parameters of function blocks are wired together using software wiring to form a particular control strategy within the Mini8 controller. An overview of all the available functions and where to get more detail is shown below. -

Page 61: Complete List Of Function Blocks

If a particular block or blocks do not appear in your instrument then the option has not been ordered. Check the order code of your instrument and contact Eurotherm. Examples of features that may not have been enabled are: Loops... -

Page 62: Chapter 5 Access Folder

Engineering Handbook Mini8 Controller Chapter 5 Access Folder Folder: Access Sub-folder: none Name Parameter Value Default Access Description Level Disabled ClearMemory Cold start the Conf Mini8 controller memory reset but comms and instrument linearisation tables retained LinTables Custom Linearisation tables are deleted InitComms Comms ports reset to default configurations Wires... -

Page 63: Chapter 6 Instrument Folder

Mini8 Controller Engineering Handbook Chapter 6 Instrument Folder Instrument / Enables The following table lists the options that can be enabled in the instrument. Enable flags are one bit for each item – i.e.Bit (0=1) enables item 1, Bit 1 (=2) item 2, Bit(3=4) item 3 and so on to Bit7(=128) enables Item 8. -

Page 64: Instrument Options

Engineering Handbook Mini8 Controller Folder: Instrument Sub-folder: Enables Name Parameter Description Value Default Access Level Poly En Polynomial linearisation Poly Linearisation 1 and 2 0 (none) to 3 (both) Conf block Enable Flags Prog En Programmer Enable Flags 0 = off, 1 to 8 0 (none) to 255 (all 8) Conf RTClock En... -

Page 65: Instrument / Diagnostics

Mini8 Controller Engineering Handbook Instrument / Diagnostics This list provides fault finding diagnostic information as follows:- Folder: Sub-folder: Diagnostics Instrument Name Parameter Description CPUFree This is the amount of free CPU Time left. It shows the percentage of the tasks ticks that are idle. MinCPUFree A benchmark of the lowest reached value of the CPU free percentage. - Page 66 Engineering Handbook Mini8 Controller Folder: Sub-folder: Diagnostics Instrument Name Parameter Description CommsStack Comms Stack Free Space (words) The number of words of un-used stack for the comms task IdleStack Idle Stack Free Space (words) The number of words of un-used stack for the idle (background) task. Max segments Max number of setpoint programmer segments available MaxSegsPerProg...

-

Page 67: Chapter 7 I/O Folder

Mini8 Controller Engineering Handbook Chapter 7 I/O Folder This lists the modules fitted into the instruments, all the IO channels, the fixed IO and the current monitoring. The IO folder lists all the channels of each of the IO boards in the 4 available slots. Each board has up to 8 inputs or outputs making a maximum of 32 channels. -

Page 68: Logic Input

Engineering Handbook Mini8 Controller Logic Input Each DI8 card provides 8 logic input channels (voltage controlled) to the system. These can be wired to provide digital inputs to any function block within the system. 7.2.1 Logic Input Parameters Folder – IO Sub-folder Mod.1 to .32 Name Parameter Description... -

Page 69: Logic Output

Mini8 Controller Engineering Handbook Logic Output If a slot is fitted with a DO8 board then 8 channels will be available to be configured and connected to Loop outputs, alarms or other logic signals. 7.3.1 Logic Out Parameters Folder – IO Sub-folder Mod.1 to .32 Name Parameter Description... -

Page 70: Logic Output Scaling

Engineering Handbook Mini8 Controller 7.3.2 Logic Output Scaling If the output is configured for time proportioning control, it can be scaled such that a lower and upper level of PID demand signal can limit the operation of the output value. By default, the output will be fully off for 0% power demand, fully on for 100% power demand and equal on/off times at 50% power demand. -

Page 71: Relay Output

Mini8 Controller Engineering Handbook Relay Output If slot 2 and/or 3 is fitted with a RL8 board then 8 channels will be available to be configured and connected to Loop outputs, alarms or other logic signals. 7.4.1 Relay Parameters Folder – IO Sub-folder Mod.9 to .24 Name Parameter Description... -

Page 72: Thermocouple Input

Engineering Handbook Mini8 Controller Thermocouple Input A TC4 offers 4 channels and the TC8 board offers 8 channels which may be configured as thermocouple inputs or mV inputs. 7.5.1 Thermocouple Input Parameters Folder – IO Sub-headers: Mod .1 to .32 Name Parameter Description Value... - Page 73 Mini8 Controller Engineering Handbook Folder – IO Sub-headers: Mod .1 to .32 Name Parameter Description Value Default Access Level Fallback PV Fallback value Instrument range Conf See also section 7.5.5. Filter Time Input filter time. Off to 500:00 (hhh:mm) 1s600ms Oper Constant An input filter provides damping of the...

-

Page 74: Linearisation Types And Ranges

Engineering Handbook Mini8 Controller 7.5.2 Linearisation Types and Ranges Input Type Min Range Max Range Units Min Range Max Range Units Thermocouple type J -210 1200 -238 2192 Thermocouple type K -200 1372 -238 2498 Thermocouple type L -200 -238 1652 Thermocouple type R 1700... -

Page 75: Sensor Break Value

Mini8 Controller Engineering Handbook 7.5.3.4 Isothermal Systems The thermocouple junctions being referenced are contained in a block which is heavily thermally insulated. The junctions are allowed to follow the mean ambient temperature, which varies slowly. This variation is accurately sensed by electronic means, and a signal is produced for the associated instrumentation. The high reliability factor of this method has favoured its use for long term monitoring. -

Page 76: User Calibration (Two Point)

Engineering Handbook Mini8 Controller 7.5.6 User Calibration (Two Point) All ranges of the controller have been calibrated against traceable reference standards. However in a particular application it may be necessary to adjust the displayed reading to overcome other effects within the process. A two point calibration is offered allowing offset and slope adjustment. -

Page 77: Using Tc4 Or Tc8 Channel As A Mv Input

Mini8 Controller Engineering Handbook 7.5.8 Using TC4 or TC8 channel as a mV input Example – a pressure sensor provides 0 to 33mV for 0 to 200 bar. Set IO type as mV Set the Linearisation Type as Linear Set DisplayHigh to 200 (bar) Set DisplayLow to 0 (bar) Set RangeHigh to 33 mV Set RangeLow to 0 mV... -

Page 78: Resistance Thermometer Input

Engineering Handbook Mini8 Controller Resistance Thermometer Input The RT4 module offers 4 resistance inputs which can be linear or PT100. 7.6.1 RT Input Parameters Folder – IO Sub-headers: Mod .1 to .32 Name Parameter Description Value Default Access Level Ident Channel Ident RTinput Read Only... -

Page 79: Linearisation Types And Ranges

Mini8 Controller Engineering Handbook Folder – IO Sub-headers: Mod .1 to .32 Name Parameter Description Value Default Access Level Offset Used to add a constant offset to the PV Instrument range Oper see section 7.5.7 SBrk Value Sensor break Value Used for diagnostics only, and displays the sensor break trip value Cal State... -

Page 80: Analogue Output

Engineering Handbook Mini8 Controller Analogue Output The AO4 offers 4 channels and the AO8 module 8 channels which maybe configured as mA outputs. An AO4 or AO8 may only be fitted in Slot 4. Folder – IO Sub-folder: Mod.25 to Mod.32 Name Parameter Description Value... -

Page 81: Fixed Io

Mini8 Controller Engineering Handbook Fixed IO There are two digital inputs, designated D1 and D2. Folder: IO Sub-folder: Fixed IO.D1 and .D2 Name Parameter Value Default Access Description Level Ident Channel Ident LogicIn LogicIn Read Only IO Type IO Type Input Input Read... -

Page 82: Current Monitor

Engineering Handbook Mini8 Controller Current Monitor The Mini8 controller, with a CT3 card, has the capability of detecting failures of up to 16 heater loads by measuring the current flowing through them via 3 current transformer inputs. The failures that can be detected are: SSR Fault If current is detected flowing through the heater when the controller is requesting it to be off then this indicates... -

Page 83: Single Phase Configurations

Mini8 Controller Engineering Handbook 7.9.2 Single Phase Configurations 7.9.2.1 Single SSR triggering With this configuration, failures of individual heater loads can be detected. For example, if the current detected flowing through Heater 3 is less than its PLF threshold then this will be indicated as Load3PLF Example1 –... - Page 84 Engineering Handbook Mini8 Controller 7.9.2.2 Multiple SSR triggering With this configuration, failure of a set of heater loads can be detected. For example, if the current detected flowing through Heater Set 1 is less than Load1’s PLF threshold then this will be indicated as Load1PLF. Further investigation will then be required to determine which heater within Set 1 has failed.

-

Page 85: Three Phase Configuration

Mini8 Controller Engineering Handbook 7.9.3 Three Phase Configuration Configuration for Three Phase supply applications is similar to that for Single phase using three CT inputs All currents passed through an individual CT must come from the same MINI8 phase controller Star with neutral or delta N/Ph2 connection is possible... -

Page 86: Parameter Configuration

Engineering Handbook Mini8 Controller 7.9.4 Parameter Configuration If Current Monitor is enabled in the folder Instrument/Options/Current Monitor then the current monitor configuration folder appears as a subfolder in IO. Folder: IO Sub-folder: CurrentMonitor/Config Name Parameter Value Default Access Description Level See section 7.9.5 Commission Commission CT... -

Page 87: Commissioning

Mini8 Controller Engineering Handbook 7.9.5 Commissioning 7.9.5.1 Auto Commission Auto commissioning of the Current Monitor is a feature that automatically detects which time proportioning outputs drive individual heaters (or heater sets), detects which CT input individual heaters are associated with and determines the Partial Load and Over Current thresholds using a 1:8 ratio. - Page 88 Engineering Handbook Mini8 Controller 7.9.5.2 Manual Commission Manual Commissioning is also available and is intended for those users who want to commission the Current Monitor off-line or do not want to accept auto commissioned settings. How to Manual Commission Set Commission to Manual. CommissionStatus will display Commissioning and Load1 configuration parameters will become available Set Load1DrivenBy to the IO Module that is connected to the heater load.

-

Page 89: Calibration

Mini8 Controller Engineering Handbook 7.9.6 Calibration A Mini8 controller supplied from factory with the CT3 card already installed the CT inputs will have been factory calibrated. If the CT3 card is installed at a later date then default calibration values are automatically loaded into the instrument. -

Page 90: Chapter 8 Alarms

Engineering Handbook Mini8 Controller Chapter 8 Alarms Alarms are used to alert the system when a pre-set level has been exceeded or a particular condition has changed state. As the Mini8 controller has no display to show alarms the alarm flags are all available over communications in status words See Alarm Summary (Section 8.7). -

Page 91: Analogue Alarms

Mini8 Controller Engineering Handbook Analogue Alarms Analogue alarms operate on variables such as PV, output levels, etc. They can be soft wired to these variables to suit the process. 8.2.1 Analogue Alarm Types Absolute High - an alarm occurs when the PV exceeds a set high threshold. Absolute Low - an alarm occurs when the PV exceeds a set low threshold. -

Page 92: Digital Alarms

Engineering Handbook Mini8 Controller Digital Alarms Digital alarms operate on Boolean variables. They can be soft wired to any suitable Boolean parameter such as digital inputs or outputs. 8.3.1 Digital Alarm Types Pos Edge The alarm will trigger when the input changes from a low to high condition Neg Edge The alarm will trigger when the input changes from a high to low condition Edge... -

Page 93: Alarm Parameters

Mini8 Controller Engineering Handbook Alarm Parameters Four groups of eight analogue alarms are available. The following table shows the parameters to set up and configure alarms. Folder: Alarm Sub-folders: 1 to 32 Name Parameter Description Value Default Access Level Type Selects the type of alarm None Alarm not configured... -

Page 94: Example: To Configure Alarm 1

Engineering Handbook Mini8 Controller 8.5.1 Example: To Configure Alarm 1 Change Access level to configuration. In this example the high alarm will be detected when the measured value exceeds 100.00. The current measured value is 27.79 as measured by the ‘Input’ parameter. This parameter will normally be wired to an internal source such as a thermocouple input. -

Page 95: Digital Alarm Parameters

Mini8 Controller Engineering Handbook Digital Alarm Parameters Four groups of eight digital alarms are available. The following table shows the parameters to set up and configure alarms. Folder: DigAlarm Sub-folders: 1 to 32 Name Parameter Description Value Default Access Level Type Selects the type of alarm None... -

Page 96: Alarm Summary

Engineering Handbook Mini8 Controller Alarm Summary This is a summary of all the alarms in the Mini8 controller. It provides global alarm and acknowledge flags as well as 16 bit status words which can be read over communications by the supervisory system. Folder: AlmSummary Sub-folders: General Name... - Page 97 Mini8 Controller Engineering Handbook Folder: AlmSummary Sub-folders: General Name Parameter Description Value Default Access Level DigAlarmStatus1 16 bit word for digital alarms 1 to 8 Bit 0 Alarm 1 active Bit 1 Alarm 1 not ack’d Bit 2 Alarm 2 active Bit 3 Alarm 2 not ack’d Bit 4...

-

Page 98: Alarm Log

Engineering Handbook Mini8 Controller Folder: AlmSummary Sub-folders: General Name Parameter Description Value Default Access Level CTAlarmStatus2 16 bit word for CT alarms 6 to 10 Bit 0 Load6 SSR fail Bit 1 Load6 PLF Bit 2 Load6 OCF Bit 3 Load7 SSR fail Bit 4 Load7 PLF... -

Page 99: Chapter 9 Bcd Input

Mini8 Controller Engineering Handbook Chapter 9 BCD Input The Binary Coded Decimal (BCD) input function block uses a number of digital inputs and combines them to make a numeric value. A very common use for this feature is to select a setpoint program number from panel mounted BCD decade switches. -

Page 100: Example: To Wire A Bcd Input

Engineering Handbook Mini8 Controller In 1 In 2 In 3 In 4 In 5 In 6 In 7 In 8 Units Tens 9.1.1 Example: To wire a BCD Input The BCD digital input parameters may be wired to digital input terminals of the controller. A DI8 module may be used and there are also two standard digital input terminals in FixedIO, D1 and D2. -

Page 101: Chapter 10 Digital Communications

The configuration port is on an RJ11 socket, just to the right of the power supply connections. This will normally be connected to a personal computer running iTools. Eurotherm supply a standard cable to connect a serial COM port on a computer to the RJ11 socket, part no. SubMini8/cable/config. -

Page 102: Field Communications Port

Engineering Handbook Mini8 Controller When connecting to iTools the instrument on this port will be found at address 255. iTools will also optimise the baud rate to suit the conditions. This port can be used as a ‘permanent’ connection but it is limited to one instrument, it is a RS232 point to point connection. -

Page 103: Communications Parameters

Mini8 Controller Engineering Handbook 10.3.2 Communications Parameters The following table shows the parameters available. Folder – Comms Sub-folder: FC (Field Communications Name Parameter Description Value Default Access Level Ident Comms Module Identity Modbus / DeviceNet/CANopen/Profibus/ Modbus Ethernet Protocol Digital communications protocol MODBUS / DeviceNet/CANopen/Profibus/ MODBUS Conf... -

Page 104: Modbus Address Switch

Engineering Handbook Mini8 Controller 10.3.4 Modbus Address Switch On a network of instruments an address is used to specify a particular instrument. Each instrument on a network MUST have a unique address. Address 255 is reserved for configuration using the configuration port or the configuration clip The switch is situated at the bottom of the Comms module. -

Page 105: Modbus Broadcast Master Communications

Before using this facility, check that the instrument to which you wish to send values can accept continuous writes. Note that in common with many third party lower cost units, the Eurotherm 2200 series and the 3200 series prior to version V1.10 do not accept continuous writes to the temperature setpoint. Damage to the internal non-volatile memory could result from the use of this function. -

Page 106: Wiring Connections

Engineering Handbook Mini8 Controller 10.4.2 Wiring Connections The Digital Communications module for the master must be the Field Comms and is only RS485/RS422. RS232 is not available. The Digital Communications module for the slave can be the Config port (RS232 only) or the Field Comms port (Not RS232). -

Page 107: Devicenet

Mini8 Controller Engineering Handbook 10.5 DeviceNet Only 2 parameters have to be set on the Mini8 controller for use with DeviceNet, baud rate and address. Both can be set on the hardware address switch situated under the DeviceNet connector. Each Mini8 controller must have a unique address on the DeviceNet network and all units must be set to the same Baud rate. -

Page 108: Canopen

Engineering Handbook Mini8 Controller 10.8 CANopen Note: from July 09 CANopen option has been discontinued. 10.8.1 Instrument setup Up to 127 Nodes can be connected to a standard CANopen Network, for nodes 1 – 31 the address can be set via the comms DIP switches. -

Page 109: Communication Interface

Mini8 Controller Engineering Handbook 10.8.3 Communication Interface CANopen is based on communication profiles, which specifies the basic communication mechanisms (PDOs, SDOs and NMT messages) and an object directory that specifies device parameters and functions. 10.8.3.1 Object Dictionary The object dictionary is divided into a section containing general device information (device identification, manufacturer name etc), communication parameters, and a section that describes the specific device data/functionality whether by a device profile (part of CANopen specifications) or manufacturer specified. -

Page 110: Network Management (Nmt)

Engineering Handbook Mini8 Controller 10.8.4 Network Management (NMT) CANopen slave nodes include the following state machine, which allows the slaves to be in different operating states. Initialisation Boot Up FC LED: Off Pre-operational SDO communications Emergency Heartbeat/Node Guard Sync FC LED: blinking Stopped Heartbeat/Node Guard FC LED: Off... -

Page 111: Device Profile Ds-404

IO etc to be associated with different channels. The Mini8 controller is classed as a Generic Device as its CANopen application objects have been specified by Eurotherm using the range from 2000h. 10.8.6 Default PDOs Transmit PDOs are typically used to transmit critical instrument data to other nodes on the network, for example, alarm status’. - Page 112 Engineering Handbook Mini8 Controller 10.8.6.2 Transmit PDO1 This contains the Analogue Alarm Status words. As default it is Enabled and configured to transmit when any of the status word values change. Object Sub Index Parameter Data Type Index 1A00h Number of Supported Entries [4] Unsigned8 AlmSummary.AnAlarmStatus1 Integer16...

- Page 113 Mini8 Controller Engineering Handbook 10.8.6.6 Receive PDO1 This contains control loop Operational parameters, the loop number must be specified in order for the Mini8 controller to set the correct loop instance parameters. Object Sub Index Parameter Data Type Index 1600h Number of Supported Entries [4] Unsigned8 Loop Number [0.…15 corresponding to n=1….16]...

-

Page 114: Enabling And Disabling Pdo Communications

Engineering Handbook Mini8 Controller 10.8.7 Enabling and Disabling PDO Communications The Mini8 controller is supplied with all 8 PDOs enabled. Every PDO has a mapping object and a communication object as shown. The PDO is enabled by resetting the appropriate bit and disabled by setting the appropriate bit. This is done using SDO communications. Mapping Object Communication PDO Enable... - Page 115 Mini8 Controller Engineering Handbook 10.8.8.1 Commstab Example 1 Remap Receive PDO 1 with UsrVal.1-4.Vals: Receive PDO1 from the Object pick list in Appendix C is shown below Object Parameter Data Type SCADA Index Index Address 2000h Receive PDO1 Note: Sub indices 02h – 04h are letter boxed via sub index 01h. Loop Number (Comms.InstNum1) Integer16 15816...

- Page 116 Engineering Handbook Mini8 Controller Enter 15843 as the Modbus Destination, and pick Loop.1.Main.AutoMan for the Source and set LetterBox to Yes. CommsTab Source Modbus Address Pick List Tx PDO 3 Loop.1.Main.AutoMan 15843 2000h 1Ch 1A02h 04h 10.8.8.3 Commstab Example 3 Remap Transmit PDO 3 sub index 04h with UsrVal.3.Val, not using letter boxing so that no matter what the loop instance UsrVal.3.Val will be transmitted: CommsTab Source...

-

Page 117: Remapping Over The Network

Mini8 Controller Engineering Handbook 10.8.9 Remapping over the network 10.8.9.1 Using SDO communications It is possible to remap any of the PDOs with entries from the Pick List using SDO communications. The following procedure must be followed: Disable PDO by setting bit 31 sub index 1 of the PDOs communication object. Deactivate PDO mapping object by writing ‘0’... - Page 118 Engineering Handbook Mini8 Controller 10.8.9.2 Using Device Configuration Software. This shows one step of the example above using configuration software. From the CANopen parameter tables in Appendix C UserVal 1 to 4 have sub-ibex C3h to C6h, or 195 to 198 so delete the existing elements in the Mapped Objects and add elements 195 to 198.

-

Page 119: Enabling & Disabling Pdo Change Of State Transmission

Mini8 Controller Engineering Handbook 10.8.10 Enabling & Disabling PDO Change of State transmission. It is possible to change the way a transmit PDO works – either cyclically or on change of state (COS), or both. Object Index 2002h allows COS transmission of PDOs to be enabled or disabled. Object Index Sub Index Parameter... -

Page 120: Error Register

Engineering Handbook Mini8 Controller 10.8.13 Error Register Index Sub Index Description Value (U32) Bit set = error 1001h Generic Error: Mandatory Bit set = ANY error Current: not supported Voltage: not supported Temperature: not supported Communication Error: Bit set = error Device Profile Defined not supported Error:... - Page 121 Mini8 Controller Engineering Handbook 10.8.14.2 Manufacturer Software Version This will indicate the software version of the instrument firmware. Index Sub Index Description Value (String) 100Ah Formal Release (n: Phase m: Minor Revision) Vn.mm Engineering Release (n: Phase m: Minor Revision) En.mm 10.8.14.3 Store &...

- Page 122 Engineering Handbook Mini8 Controller In order to avoid saving parameters by mistake, saving is only executed when a specific signature is written to sub-index 01h. The signature is “save”: ASCII: Hex: Or Using the IXXAT Node Manager, select ASCII Data and write ‘save’ It should be noted that whilst in the process of saving the parameter data to non-volatile memory it is not possible to write to the parameters that are currently being saved.

- Page 123 Product Code = E800 Revision Number = Bits Description 0 – 15 Minor Revision Number (Initially: 0001h) 16 – 31 Major Revision Number (Initially: 0001h) Serial Number (32-bit interface board number entered by Eurotherm) Part No HA028581 Issue 7.0 Dec-09...

-

Page 124: Profibus

Engineering Handbook Mini8 Controller 10.9 Profibus Up to 127 Nodes can be connected to a Profibus Network and the address is set via the comms DIP switches. The Baud Rate is auto-detected and set by the master. Not Used Address 64 Example shows an address 68 Address 32 Address 16... -

Page 125: Ethernet

Mini8 Controller Engineering Handbook 10.10 Ethernet 10.10.1 Instrument setup It is recommended that you setup the communications settings for each instrument before connecting it to any Ethernet network. This is not essential but network conflicts may occur if the default settings interfere with equipment already on the network. -

Page 126: Itools Setup

Engineering Handbook Mini8 Controller 10.10.3.3 Default Gateway The "Comms" tab also includes configuration settings for "Default Gateway", these parameters will be set automatically when Dynamic IP Addressing is used. When fixed IP addressing is used these settings are only required if the instrument needs to communicate wider than the local area network i.e. over the internet. 10.10.3.4 Preferred Master The "Comms"... -

Page 127: Ethernet Parameters

Mini8 Controller Engineering Handbook 10.10.5 Ethernet Parameters Folder - Comms Sub-folder: FC Name Parameter Description Value Default Access Level Ident Identifies that the comms None No module fitted module is fitted. Comms Communications module fitted Protocol Digital communications protocol MODBUS; Profibus; DeviceNet; Conf Ethernet,CANopen Address... -

Page 128: Counters

Engineering Handbook Mini8 Controller Chapter 11 Counters, Timers, Totalisers, RT Clock A series of function blocks are available which are based on time/date information. These may be used as part of the control process. 11.1 Counters Up to two counters are available. They provide a synchronous edge triggered event counter. Direction Enable Count... -

Page 129: Counter Parameters

Mini8 Controller Engineering Handbook Count = Count = Count = 0 Target -1 Target Clock RippleCarry Overflow Figure 11-3: Timing Diagram for an Up Counter 11.1.1 Counter Parameters Folder - Counter Sub-folders: 1 to 2 Name Parameter Description Value Default Access Level Enable... -

Page 130: Timers

Engineering Handbook Mini8 Controller 11.2 Timers Up to eight timers can be configured. Each one can be configured to a different type and can operate independently of one another. 11.2.1 Timer Types Each timer block can be configured to operate in four different modes. These modes are explained below 11.2.2 On Pulse Timer Mode This timer is used to generate a fixed length pulse from an edge trigger. -

Page 131: On Delay Timer Mode

Mini8 Controller Engineering Handbook 11.2.3 On Delay Timer Mode This timer provides a delay between the trigger event and the Timer output. If the input pulse is less than the set delay time there is no output pulse. The Output is set to Off when the Input changes from Off to On. •... -

Page 132: One Shot Timer Mode

Engineering Handbook Mini8 Controller 11.2.4 One Shot Timer Mode This timer behaves like a simple oven timer. When the Time is edited to a non-zero value the Output is set to On • The Time value is decremented until it reaches zero. The Output is then cleared to Off •... -

Page 133: Minimum On Timer Or Compressor Mode

Mini8 Controller Engineering Handbook 11.2.5 Minimum On Timer or Compressor Mode This timer has been targeted at guaranteeing that the output remains On for a duration after the input signal has been removed. It may be used, for example, to ensure that a compressor is not cycled excessively. The output will be set to On when the Input changes from Off to On. -

Page 134: Timer Parameters

Engineering Handbook Mini8 Controller 11.2.6 Timer Parameters Folder – Timer Sub-folders: 1 to 4 Name Parameter Description Value Default Access Level Type Timer type Conf Timer not configured On Pulse Generates a fixed length pulse from an edge trigger Off Delay Provides a delay between input trigger event and timer putput One Shot... -

Page 135: Totalisers

Mini8 Controller Engineering Handbook 11.3 Totalisers There are two totaliser function blocks which are used to measure the total quantity of a measurement integrated over time. A totaliser can, by soft wiring, be connected to any measured value. The outputs from the totaliser are its integrated value and an alarm state. -

Page 136: Totaliser Parameters

Engineering Handbook Mini8 Controller 11.3.1 Totaliser Parameters Folder – Total Sub-Folders: 1 to 2 Name Parameter Description Value Default Access Level TotalOut The totalised value ±9,999,999,999 The value to be totalised Oper -9999.9 to 9999.9. Note:- the totaliser stops accumulating if the input is ‘Bad’. -

Page 137: Real Time Clock

Mini8 Controller Engineering Handbook 11.4 Real Time Clock A real time clock (day of week and time only) is used to provide a daily and weekly scheduling facility and provides two corresponding outputs. The configuration for an output is an On-Day and an On-Time and an Off- Day and an Off-Time. -

Page 138: Chapter 12 Applications

Engineering Handbook Mini8 Controller Chapter 12 Applications 12.1 Humidity 12.1.1 Overview Humidity (and altitude) control is a standard feature of the Mini8 controller. In these applications the controller may be configured to generate a setpoint profile (see Section 18 ‘Setpoint Programmer’). Also the controller may be configured to measure humidity using either the traditional Wet/Dry bulb method or it may be interfaced to a solid state sensor. -

Page 139: Humidity Parameters

Mini8 Controller Engineering Handbook 12.1.4 Humidity Parameters List Folder – Humidity Sub-folder: None Name Parameter Description Value Default Access Level Resolution Resolution of the relative XXXXX Conf humidity XXXX.X XXX.XX XX.XXX X.XXXX Psychro Const The psychrometric constant at a 0.0 to 10.0 6.66 Oper given pressure (6.66E-4 at... -

Page 140: Zirconia (Carbon Potential) Control

Engineering Handbook Mini8 Controller 12.2 Zirconia (Carbon Potential) Control A Mini8 Controller has a Zirconia function block which may be used to control Carbon potential. The controller is often a programmer which generates carbon potential profiles. In this section it is assumed that a programmer is used. -

Page 141: Zirconia Parameters

Mini8 Controller Engineering Handbook 12.2.8 Zirconia Parameters Folder - Zirconia Sub-folders: None Name Parameter Description Value Default Access Level Probe Type Configures the type of probe to be used Drayton Drayton Accucarb Accucarb MacDhui MacDhui Oxygen LogO2 Log Oxygen BoschO2 Bosch Oxygen ZircoDew Dewpoint. - Page 142 Engineering Handbook Mini8 Controller Folder - Zirconia Sub-folders: None Name Parameter Description Value Default Access Level PvFrozen This is a Boolean which freezes the PV during a purging cycle. It may have been wired, for example, to disable control output during purging CleanValve Enable the clean valve.

-

Page 143: Chapter 13 Input Monitor

Mini8 Controller Engineering Handbook Chapter 13 Input Monitor 13.1 Description There are two Input monitors. Each input monitor may be wired to any variable in the controller. It then provides three functions:- Maximum detect Minimum detect Time above threshold 13.1.1 Maximum Detect This function continuously monitors the input value. -

Page 144: Input Monitor Parameters

Engineering Handbook Mini8 Controller 13.2 Input Monitor Parameters Folder - IPMonitor Sub-Folders: 1 or 2 Name Parameter Description Value Default Access Level The input value to be monitored May be wired to an input source. The range will Oper depend on the source R/O if wired M a x... -

Page 145: Chapter 14 Logic And Maths Operators

Mini8 Controller Engineering Handbook Chapter 14 Logic and Maths Operators. 14.1 Logic Operators Logic Operators allow the controller to perform logical calculations on two input values. These values can be sourced from any available parameter including Analogue Values, User Values and Digital Values. The parameters to use, the type of calculation to be performed, input value inversion and ‘fallback’... -

Page 146: Input Logic Operations

Engineering Handbook Mini8 Controller 14.1.2 2 input Logic Operations The following calculations can be performed: Oper Operator description Input 1 Input 2 Output Invert = 0: OFF The selected logic operator is turned off None 1: AND The output result is ON when both Input 1 and Input 2 are ON 2: OR The output result is ON when either Input... -

Page 147: Logic Operator Parameters

Mini8 Controller Engineering Handbook 14.1.3 Logic Operator Parameters Folder – Lgc2 (2 Input Operators) Sub-Folders: 1 to 24 Name Parameter Description Value Default Access Level Oper To select the type of operator See previous table None Conf Input 1 Normally wired to a logic, analogue or user value. OPER May be set to a constant value if not wired. -

Page 148: Eight Input Logic Operators

Engineering Handbook Mini8 Controller 14.2 Eight Input Logic Operators The eight input logic operator may be used to perform the following operations on eight inputs. Oper Operator description 0: OFF The selected logic operator is turned off 1: AND The output result is ON when ALL eight inputs are ON 2: OR The output result is ON when one or more of the 8 inputs are ON 3: XOR... -

Page 149: Maths Operators

Mini8 Controller Engineering Handbook 14.3 Maths Operators Maths Operators (sometimes known as Analogue Operators) allow the controller to perform mathematical operations on two input values. These values can be sourced from any available parameter including Analogue Values, User Values and Digital Values. Each input value can be scaled using a multiplying factor or scalar. The parameters to use, the type of calculation to be performed and the acceptable limits of the calculation are determined in Configuration level. -

Page 150: Math Operations

Engineering Handbook Mini8 Controller 14.3.1 Math Operations The following operations can be performed: 0: Off The selected analogue operator is turned off 1: Add The output result is the addition of Input 1 and Input 2 2: Subtract (Sub) The output result is the difference between Input 1 and Input 2 where Input 1 >... -

Page 151: Math Operator Parameters

Mini8 Controller Engineering Handbook 14.3.2 Math Operator Parameters Folder – Math2 (2 Input Operators) Sub-Folders: 1 to 24 Name Parameter Description Value Default Access Level Oper To select the type of operator See previous table None Conf In1Mul Scaling factor on input 1 Limited to max float * Oper In2 Mul... -

Page 152: Sample And Hold Operation

Engineering Handbook Mini8 Controller 14.3.3 Sample and Hold Operation The diagram below shows the operation of the sample and hold feature. True False Result Figure 14-4: Sample and Hold Part No HA028581 Issue 7.0 Dec-09... -

Page 153: Multiple Input Operator Block

Mini8 Controller Engineering Handbook 14.4 Multiple Input Operator Block The Multiple Input Operator Block simultaneously outputs the Sum, Average, Minimum and Maximum values of up to 8 valid inputs. The outputs will be clipped to user-defined limits or be replaced by a fallback value based on the selected fallback strategy. -

Page 154: Cascaded Operation

Engineering Handbook Mini8 Controller 14.4.1 Cascaded operation Multiple input operator blocks may be cascaded to allow operations on more than eight inputs (33 max for four instances of the block). shows how two blocks should be configured to find the average of more than eight inputs. -

Page 155: Multiple Input Operator Block Parameters

Mini8 Controller Engineering Handbook 14.4.3 Multiple Input Operator Block Parameters Folder – MultiOper (Multi Operator) Sub-folders: 1 to 4 Name Parameter Description Value Default Access Level NumIn Number of inputs selected to 2 to 8 Config use. CascNumIn Number of cascaded inputs from 0 to 255 the previous block CascIn... -

Page 156: Eight Input Analog Multiplexers

Engineering Handbook Mini8 Controller 14.5 Eight Input Analog Multiplexers The eight Input analogue multiplexers may be used to switch one of eight inputs to an output. It is usual to wire inputs to a source within the controller that selects that input at the appropriate time or event. 14.5.1 Multiple Input Operator Parameters Folder –... -

Page 157: Chapter 15 Input Characterisation

Mini8 Controller Engineering Handbook Chapter 15 Input Characterisation 15.1 Input Linearisation The Lin16 function block converts an input signal into an output PV using a series of up to 15 straight lines to characterise the conversion. The function block provides the following behaviour. The Input values must be monotonic and constantly rising. -

Page 158: Compensation For Sensor Non-Linearities

Engineering Handbook Mini8 Controller Out Low If the input value is outside the translated range then the output status will indicate Bad, Note: and the value will be limited to Out Low > Out the nearest output limit. High The units and resolution parameters will be used for the output values. -

Page 159: Input Linearisation Parameters

Mini8 Controller Engineering Handbook 15.1.2 Input Linearisation Parameters List Folder – Lin16 Sub-folders: 1 to 2 Name Parameter Description Value Default Access Level Units Units of the linearised output None Conf AbsTemp V, mV, A, mA, PH, mmHg, psi, Bar, mBar, %RH, %, mmWG, inWG, inWW, Ohms, PSIG, %O2, PPM, %CO2, %CP, %/sec, RelTemp... -

Page 160: Polynomial

Engineering Handbook Mini8 Controller 15.2 Polynomial Folder – Poly Sub-Folders: 1 to 2 Name Parameter Description Value Default Access Level LinType To select the input type. J , K, L, R, B, N, T, S, PL2, C, PT100, Conf The linearisation type selects which of the Linear, SqRoot instruments linearisation curves is applied to the input signal. - Page 161 Mini8 Controller Engineering Handbook Folder – Poly Sub-Folders: 1 to 2 Name Parameter Description Value Default Access Level Status Indicates the status of the linearised output: Good Good indicates the value is within range and the input is not in sensor break. Indicates the Value is out of range or the input is in...

-

Page 162: Chapter 16 Load

Engineering Handbook Mini8 Controller Chapter 16 Load The load simulation block provides styles of load which can be used to allow an instrument configuration to be tested before connection to the process plant. In the current issue of firmware the simulated loads available are Oven and Furnace. - Page 163 Mini8 Controller Engineering Handbook Folder – Load Sub-Folders: None Name Parameter Description Value Default Access Level LoopOutCh2 Loop output channel 2 input. Oper The output of the loop as wired to the load simulation, this is the power requested of the load.

-

Page 164: Chapter 17 Control Loop Set Up

Engineering Handbook Mini8 Controller Chapter 17 Control Loop Set Up The Mini8 controller has up to 16 loops of control. Each Loop has two outputs, Channel 1 and Channel 2, each of which can be configured for PID or On/Off. The control function block is divided into a number of sections the parameters of which are all listed under the Folder ‘Loop’. -

Page 165: Loop Parameters - Main

Mini8 Controller Engineering Handbook 17.2 Loop Parameters - Main Folder – Loop.1 to Loop.16 Sub-Folder: Main Name Parameter Description Value Default Access Level AutoMan To select Auto or Manual operation. Auto Automatic (closed loop) Auto Oper operation Manual (output power adjusted by the user) operation The process variable input value. -

Page 166: Types Of Control Loop

Engineering Handbook Mini8 Controller 17.3.1 Types of Control Loop 17.3.1.1 On/Off Control On/Off control simply turns heating power on when the PV is below setpoint and off when it is above setpoint. If cooling is used, cooling power is turned on when the PV is above setpoint and off when it is below. The outputs of such a controller will normally be connected to relays –... -

Page 167: Proportional Term

Mini8 Controller Engineering Handbook 17.4.1 Proportional Term The proportional term, or gain, delivers an output which is proportional to the size of the error signal. It is the range over which the output power is continuously adjustable in a linear fashion from 0% to 100% (for a heat only controller). -

Page 168: Derivative Term

Engineering Handbook Mini8 Controller 17.4.3 Derivative Term Derivative action, or rate, provides a sudden shift in output as a result of a rapid change in error, whether or not this is caused by PV alone (derivative on PV) or on SP changes as well (derivative on error selection). If the measured value falls quickly derivative provides a large change in output in an attempt to correct the perturbation before it goes too far. -

Page 169: High And Low Cutback

Mini8 Controller Engineering Handbook 17.4.4 High and Low Cutback Cutback high ‘CBH’ and Cutback low ‘CBL’ are values that modify the amount of overshoot, or undershoot, that occurs during large step changes in PV (for example, under start-up conditions). They are independent of the PID terms which means that the PID terms can be set for optimal steady state response and the cutback parameters used to modify any overshoot which may be present. -

Page 170: Loop Break

Engineering Handbook Mini8 Controller 17.4.7 Loop Break The loop is considered to be broken if the PV does not respond to a change in the output in a given time. Since the time of response will vary from process to process the Loop Break Time (LBT – PID list) parameter allows a time to be set before a Loop Break Alarm (Lp Break - Diag list) is initiated. -

Page 171: Gain Scheduling

Mini8 Controller Engineering Handbook 17.4.9 Gain Scheduling Gain scheduling is the automatic transfer of control between one set of PID values and another. It may be used in very non-linear systems where the control process exhibits large changes in response time or sensitivity, see diagram below. -

Page 172: Pid Parameters

Engineering Handbook Mini8 Controller 17.4.10 PID Parameters Control loops must be specifically ordered – Order Code MINI8 – 4LP, 8LP or 16LP. To enable a loop place one of the Loop function blocks on the graphical wiring page. Folder – Loop Sub-folders: Loop1.PID to Loop16.PID Name Parameter Description... -

Page 173: Tuning Function Block

Mini8 Controller Engineering Handbook 17.5 Tuning Function Block Tuning involves setting the following parameters. Proportional Band ‘PB’, Integral Time ‘Ti’, Derivative Time ‘Td’, Cutback High ‘CBH’, Cutback Low ‘CBL’, and Relative Cool Gain ‘R2G’ (applicable to heat/cool systems only). The controller is shipped with these parameters set to default values. In many cases the default values will give adequate stable straight line control, however, the response of the loop may not be ideal. -

Page 174: Multi-Zone Applications

Engineering Handbook Mini8 Controller Heat/Cool Deadband. In controllers fitted with a second (cool) channel a parameter ‘Ch2 DeadBand’ is also available in the Loop OP folder, section 17.7, which sets the distance between the heat and cool proportional bands. The default value is 0% which means that heating will turn off at the same time as cooling turns on. The deadband may be set to ensure that there is no possibility of the heat and cool channels being on together, particularly when cycling output stages are installed. -

Page 175: Automatic Tuning

Mini8 Controller Engineering Handbook 17.5.4 Automatic Tuning Auto Tune automatically sets the following parameters:- Proportional Band ‘PB’ If ‘Ti’ and/or ‘Td’ is set to OFF, because you wish to use PI, PD or P only control, Integral Time ‘Ti’ these terms will remain off after an autotune. Derivative Time ‘Td’... -

Page 176: Tune Parameters

Engineering Handbook Mini8 Controller 17.5.5 Tune Parameters Folder – Loop.Loop.1 to Loop.16 Sub-folder: Tune Name Parameter Description Value Default Access Level AutoTune To start self tuning Stop Stop Oper Enable Start OutputHigh Set this to limit the maximum Between Low Output and 100.0 !00.0 Oper Limit... -

Page 177: Autotune And Sensor Break

Mini8 Controller Engineering Handbook a. Select the loop to be tuned, b. Set AutoTune Enable to On A One-shot Tune can be performed at any time, but normally it is performed only once during the initial commissioning of the process. However, if the process under control subsequently becomes unstable (because its characteristics have changed), it may be necessary to tune again for the new conditions. -

Page 178: Autotune From Below Sp – Heat/Cool

Engineering Handbook Mini8 Controller 17.5.11 Autotune from Below SP – Heat/Cool The point at which Automatic tuning is performed (Tune Control Point) is designed to operate just below the setpoint at which the process is normally expected to operate (Target Setpoint). This is to ensure that the process is not significantly overheated or overcooled. -

Page 179: Autotune From Below Sp – Heat Only

Mini8 Controller Engineering Handbook 17.5.12 Autotune From Below SP – Heat Only The sequence of operation for a heat only loop is the same as that previously described for a heat/cool loop except that the sequence ends at ‘F’ since there is no need to calculate ‘R2G’. At ‘F’... -

Page 180: Autotune At Setpoint – Heat/Cool

Engineering Handbook Mini8 Controller 17.5.13 Autotune at Setpoint – Heat/Cool It is sometimes necessary to tune at the actual setpoint being used. This is allowable in Mini8 Controller and the sequence of operation is described below. Pk to Pk Hysteresis Target Setpoint High Output Zero Output... -

Page 181: Failure Modes

Mini8 Controller Engineering Handbook 17.5.14 Failure Modes The conditions for performing an autotune are monitored by the parameter ‘State’ (Tune folder). If autotune is not successful error conditions are read by this parameter as follows:- Timeout This will occur if any one stage is not completed within one hour. It could be due to the loop being open or not responding to the demands from the controller. -

Page 182: Manual Tuning

Engineering Handbook Mini8 Controller 17.5.15 Manual Tuning If for any reason automatic tuning gives unsatisfactory results, you can tune the controller manually. There are a number of standard methods for manual tuning. The one described here is the Ziegler-Nichols method. Adjust the setpoint to its normal running conditions (it is assumed this will be above the PV so that heat only is applied) Set the Integral Time ‘Ti’... -

Page 183: Manually Setting The Cutback Values

Mini8 Controller Engineering Handbook 17.5.17 Manually Setting the Cutback Values Enter the PID terms calculated from the table in section 17.5.15 before setting cutback values. The above procedure sets up the parameters for optimum steady state control. If unacceptable levels of overshoot or undershoot occur during start-up, or for large step changes in PV, then manually set the cutback parameters. -

Page 184: Setpoint Function Block

Engineering Handbook Mini8 Controller 17.6 Setpoint Function Block For each of the 16 loops, the controller setpoint is the Working Setpoint that may come from a number of alternative sources. This is the value ultimately used to control the process variable in each loop. The working setpoint may be derived from:- SP1 or SP2, both of which are individually set, can be selected by an external signal or via the SPSelect parameter over communications. -

Page 185: Sp Tracking

Mini8 Controller Engineering Handbook 17.6.2 SP Tracking When setpoint tracking is enabled and the local setpoint is selected, the local setpoint is copied to ‘TrackSP’. Tracking now ensures that the alternate SP follows or tracks this value. When the alternate setpoint is selected it initially takes on the tracked value thus ensuring that no bump takes place. - Page 186 Engineering Handbook Mini8 Controller Folder – Loop.1 to Loop.16 Sub-folder: SP Name Parameter Description Value Default Access Level RateDone Flag which indicates when the setpoint is Setpoint changing changing or completed Complete Rate Disable Setpoint rate disable Enabled Oper Disabled SP Trim Trim is an offset added to the setpoint.

-

Page 187: Setpoint Limits

Mini8 Controller Engineering Handbook 17.6.6 Setpoint Limits The setpoint generator provides limits for each of the setpoint sources as well as an overall set of limits for the loop. These are summarised in the diagram below. Range High SPTrim SP HighLimit HighLimit LoopAlm TgtSP... -

Page 188: Setpoint Tracking

Engineering Handbook Mini8 Controller 17.6.8 Setpoint Tracking The setpoint used by the controller may be derived from a number of sources. For example:- Local setpoints SP1 and SP2. These may be selected using the parameter ‘SP Select’ in the SP folder, through digital communications or by configuring a digital input which selects either SP1 or SP2. -

Page 189: Output Function Block

Mini8 Controller Engineering Handbook 17.7 Output Function Block The output function block allows you to set up output conditions from the control block, such as output limits, hysteresis, output feedforward, behaviour in sensor break, etc. Folder – Loop.1 to Loop.16 Sub-folder: OP Name Parameter Description... - Page 190 Engineering Handbook Mini8 Controller Folder – Loop.1 to Loop.16 Sub-folder: OP Name Parameter Description Value Default Access Level Step On transition to manual the output will be the manual op value as last set by the operator ManualOutVal The output when the loop is in manual. Between output Hi and Output Lo Note: In manual mode the controller will still limit the maximum power to the power...

-

Page 191: Output Limits

Mini8 Controller Engineering Handbook 17.7.1 Output Limits The diagram shows where output limits are applied. PID List Including Gain Scheduling output limits OPHi +100 Diag List OPLo -100 OPHi2 +100 Output SchedOPHi Level 3 SchedOPLo Diagnostics Writable NOT Wireable Read only OPLo2 -100 OPHi3 +100 Writable NOT... -

Page 192: Output Rate Limit

Engineering Handbook Mini8 Controller 17.7.2 Output Rate Limit The output rate limiter is a simple rate of change limiter which will prevent the control algorithm demanding step changes in output power. It may be set in percent per second. The rate limit is performed by determining the direction in which the output is changing, and then incrementing or decrementing the Working Output (‘ActiveOut’... -

Page 193: Feedforward

Mini8 Controller Engineering Handbook 17.7.5 Feedforward Feedforward is a value, which is scaled and added to the PID output, before any limiting. It can be used for the implementation of cascade loops or constant head control. Feedforward is implemented such that the PID output is limited to trim limits and acts as a trim on a FeedForward Value. -

Page 194: Effect Of Control Action, Hysteresis And Deadband

Engineering Handbook Mini8 Controller 17.7.6 Effect of Control Action, Hysteresis and Deadband For temperature control ‘Loop.1.Control Action’ will be set to ‘ ’. For a PID controller this means that Reverse the heater power decreases as the PV increases. For an on/off controller output 1 (usually heat) will be on (100%) when PV is below the setpoint and output 2 (usually cool) will be on when PV is above the setpoint Hysteresis applies to on/off control only. -

Page 195: Time To Target Programmer

Mini8 Controller Engineering Handbook Chapter 18 Setpoint Programmer In a setpoint programmer you can set up a profile in the controller in which the setpoint varies in a pre- determined way over a period of time. Temperature is a very common application where it is required to ‘ramp’ the process value from one level to another over a set period of time. -

Page 196: Ramp Rate Programmer

Engineering Handbook Mini8 Controller 18.1.2 Ramp Rate Programmer A ramp rate programmer specifies it's ramp segments as maximum setpoint changes per time unit. Each segment can be specified by the operator as Ramp Rate, Dwell or Step. 1. Ramp Rate – the setpoint changes at a rate in units/time 2. -

Page 197: Segment Types

Mini8 Controller Engineering Handbook 18.3 Segment Types Depending on the type of program configured, a segment may be set as:- 18.3.1 Rate A Ramp segment provides a controlled change of setpoint from an original to a target setpoint. The duration of the ramp is determined by the rate of change specified. Two styles of ramp are possible in the range, Ramp-Rate or Time-To-Target. -

Page 198: Wait

Engineering Handbook Mini8 Controller 18.3.6 Wait Wait specifies the criterion for which a segment cannot proceed to the next segment. Any segment can be defined as ‘Wait’ in the ‘Program Edit’ page. The next parameter is then ‘Wait For’ and here you define the criterion. -

Page 199: Output Events

Mini8 Controller Engineering Handbook 18.4 Output Events Program segments have configurable events. ‘Wait’ ‘GoBack’ and ‘End’ segments do not have events. There are up to 8 digital events, PV Events and Time Events. 18.4.1 Digital Events These are digital flags which can be set on or off for each of the segments. These are enabled by setting Programmer.n.Setup.MaxEvents to the required maximum number of events (>0 and <=8). -

Page 200: Pv Event & User Value

Engineering Handbook Mini8 Controller 18.4.2 PV Event & User Value PV Events are essentially a simplified analogue alarm per segment based on the programmer PV input. For this feature the Programmer.n.Setup.EnablePVEvent must be set to ‘Yes’. The PV Event Output (PVEventOP) may be used to trigger the required response. - Page 201 Mini8 Controller Engineering Handbook The following example of a timed event in segment 3 shows that Programmer.n.Setup.EventOut1 will be on for 10 minutes during segment 3 starting 10 minutes after segment 3 begins. Editing of the Time Events follows a number of simple rules to make programming easier for the operator - these are shown in the 3 diagrams below: Segment TimeEvent = Event1...

- Page 202 Engineering Handbook Mini8 Controller Segment TimeEvent = Event1 TimeEvent = On OffTime >0 OffTime OffTime * = 0 Event Output OnTime=0 OnTime Time Event = Event1 Time Event = Off OffTime Event Output OnTime = 0 Time Event = Event1 TimeEvent = Off OffTime Error : OffTime >...

-

Page 203: Holdback

Mini8 Controller Engineering Handbook 18.5 Holdback Holdback freezes the program if the process value (PV) does not track the setpoint (SP) by more than a user defined amount. The programmer will remain in HOLDBACK until the PV returns to within the requested deviation from setpoint. -

Page 204: Pid Select

Engineering Handbook Mini8 Controller 18.6 PID Select It is possible to set up three sets of PID values, see section 17.4.9. Any one of these sets may be activated in any segment of the program, except if the segment is configures as Wait, Goback or End. For this feature Programmer.n.Setup.EnablePIDSched must be set to ‘Yes’. -

Page 205: Power Fail Recovery

Mini8 Controller Engineering Handbook 18.8 Power Fail Recovery In the event of power fail to the Mini8 controller, a strategy may be set in configuration level, which defines how the controller behaves on restoration of the power. The action on power failure is selecte3d using Programmer.n.Setup.PowerFailAct and offers: Ramp This will servo the program setpoint to the measured value (the PV Input parameter value), then return to the target setpoint at the current (or previous) ramp rate. -