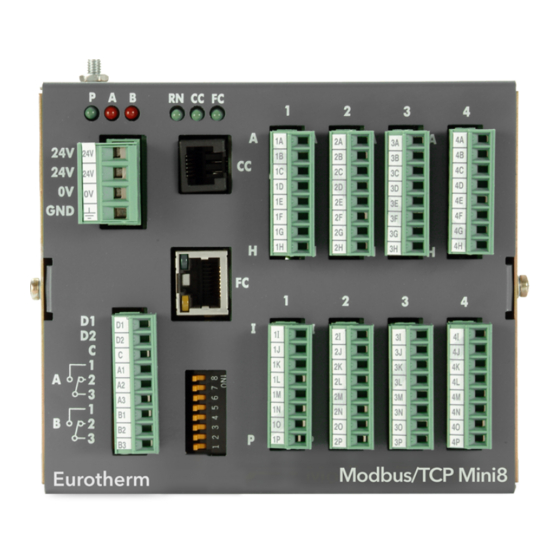

Eurotherm Invensys Mini8 Manuals

Manuals and User Guides for Eurotherm Invensys Mini8. We have 3 Eurotherm Invensys Mini8 manuals available for free PDF download: User Manual, Engineering Manual, Installation And Wiring Instructions

Eurotherm Invensys Mini8 User Manual (343 pages)

Multi-loop Process Controller

Brand: Eurotherm

|

Category: Controller

|

Size: 7 MB

Table of Contents

-

-

-

-

-

-

Soft Wiring50

-

-

Wire58

-

Tooltips59

-

Using Wires61

-

Downloading63

-

Selections63

-

Colours64

-

Edge Wires66

-

-

Module ID

74-

Modules74

-

-

Logic Input

75 -

Logic Output

76 -

Relay Output

78 -

Fixed IO

88

-

-

-

Alarm Parameters

100 -

Alarm Summary

103 -

Alarm Log

105

-

-

Modbus

110-

Baud Rate110

-

Parity110

-

RX/TX Delay Time110

-

Devicenet

113 -

-

Address Switch113

-

Baud Switch113

-

-

Canopen

115-

Instrument Setup115

-

Default Pdos118

-

-

Profibus

131 -

-

Instrument Setup132

-

Unit Identity132

-

Itools Setup133

-

Ethernet/Ip135

-

Feature Switch135

-

-

-

Installation139

-

Run Mode147

-

-

Ethercat

151 -

-

Precautions155

-

Trademark

156

-

-

Counters

157 -

Timers

159 -

Totalisers

164 -

Real Time Clock

166

-

-

-

Humidity

167 -

-

Sooting Alarm169

-

Clean Probe169

-

Probe Status169

-

-

-

Description

172-

Maximum Detect172

-

Minimum Detect172

-

-

-

-

Logic Operators

174-

Logic 8174

-

-

Maths Operators

178

-

-

Chapter 17 Load

191-

Load Parameters

191

-

-

-

Loop Set up

194 -

PID Control

195-

Integral Term196

-

Derivative Term197

-

Loop Break199

-

Gain Scheduling200

-

PID Parameters201

-

Loop Response202

-

Initial Settings202

-

Automatic Tuning204

-

Tune Parameters205

-

Failure Modes210

-

Manual Tuning211

-

-

SP Tracking214

-

Manual Tracking214

-

Rate Limit214

-

Setpoint Limits216

-

Manual Tracking217

-

-

-

Introduction

225 -

Segment Types

227 -

Output Events

229-

Digital Events229

-

Time Event231

-

-

Holdback

233-

Guaranteed Soak233

-

-

PID Select

234 -

Program Cycles

234-

Servo234

-

-

-

Run236

-

Reset236

-

Hold236

-

Skip Segment236

-

Advance Segment237

-

Fast237

-

-

PV Start

237 -

Program Editor

242-

Analog View243

-

Digital View245

-

-

-

-

Load Cell

252 -

-

Parameter Notes254

-

Tare Calibration254

-

Load Cell255

-

-

-

-

Set up257

-

Zero Calibration257

-

CJC Calibration257

-

-

-

Set up258

-

Calibration258

-

-

-

-

Recipes

334 -

Toolkit Blocks

335 -

Process Alarms

335

-

Parameter Index

336

Advertisement

Eurotherm Invensys Mini8 Engineering Manual (310 pages)

Multi-loop Controllers

Brand: Eurotherm

|

Category: Controller

|

Size: 6 MB

Table of Contents

-

-

-

Logic Input

68 -

Logic Output

69 -

Relay Output

71 -

Fixed IO

81

-

-

-

Devicenet

107 -

Canopen

108 -

Profibus

124 -

Ethernet

125-

Itools Setup126

-

-

Counters

128 -

Timers

130 -

Totalisers

135 -

Real Time Clock

137

-

-

Maths Operators

149

-

Chapter 16 Load

162 -

-

-

Derivative Term168

-

Loop Break170

-

Gain Scheduling171

-

PID Parameters172

-

-

SP Tracking185

-

Setpoint Limits187

-

-

Segment Types

197-

Wait198

-

-

Output Events

199 -

Holdback

203 -

PID Select

204 -

-

Analog View212

-

Digital View214

-

-

-

Load Cell

221-

Parameter Notes223

-

Load Cell224

-

-

-

Parameter Index

300

Eurotherm Invensys Mini8 Installation And Wiring Instructions (2 pages)

Brand: Eurotherm

|

Category: Controller

|

Size: 1 MB

Advertisement