Table of Contents

Advertisement

ALIB-320-C

Rada 320

Installation and Maintenance

Water Temperature Controls

Groups of Fixtures

Thermostatic

This Rada 320 Valve has been supplied for this application based upon information provided

to Armstrong at the time the order was placed.

This Rada 320 Valve is configured for use in a "dead-leg" piping configuration as indicated in

the drawing on Page 5.

This Rada 320 Valve has not been configured for use in a central pumped re-circulation

system.

This Rada 320 Valve has not been designed to deliver tepid water to Emergency Fixtures.

For further information, please call our technical department Toll Free at 1-888-HOT-HOSE.

Model No.

Rada 320

Rada 320D

Rada 320DC

1017

Serial No.

Ship Date

B125

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Armstrong Rada 320

- Page 1 This Rada 320 Valve has been supplied for this application based upon information provided to Armstrong at the time the order was placed. This Rada 320 Valve is configured for use in a “dead-leg” piping configuration as indicated in the drawing on Page 5.

-

Page 2: Operational Specifications

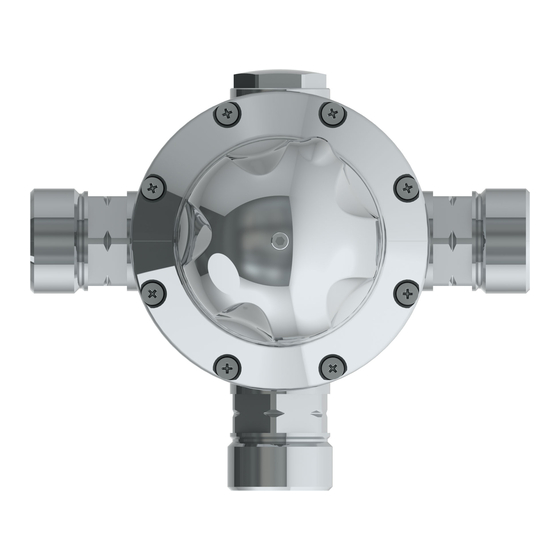

Rada 320 Rada Thermostatic Mixing Valve of “sealed for life” disposable cartridge construction. Compact design with top and/or bottom blended water outlet makes Rada 320 ideal for recessed enclosure, plumbing chase and utility/mechanical room installation. Complete operating mechanism of valve is enclosed in a durable polymer cartridge for ease of field maintenance. - Page 3 Water Temperature Control - Groups of Fixtures Thermostatic Rada 320D A derivative assembly of the standard Rada 320 Thermostatic Mixing Valve of “sealed for life” disposable cartridge construction. Compact design with top and/or bottom blended water outlet makes Rada 320D ideal for recessed enclosure, plumbing chase and utility/mechanical room installation.

-

Page 4: Safety Warnings

Mixing Valve at such elevated temperatures is not recommended. ** Under laboratory test conditions Rada 320 has displayed a repeatable capability to blend to within 5°F (2°C) of each inlet supply temperature. 21°F (12°C) is the optimum published differential required to achieve full thermal... - Page 5 4. Be sure to thoroughly flush the pipework before fitting the Rada 320. 5. Be sure to “make up” all “sweat” or “soldered” fittings ahead of time. Do not expose Rada 320 or any of its fittings to extreme temperatures (such as an acetylene or propane torch).

- Page 6 The maximum blend temperature obtainable through the mixing valve should be limited to prevent selection of a system temperature that is too hot. Rada 320 is fully performance tested and the maximum temperature is pre-set to approximately 110°F (43°C) under ideal installation conditions at the factory.

- Page 7 5. Refit the temperature knob. Make sure that the indicator points to 6 o’clock. Rada 320 Servicing and Maintenance (Refer to Figures 8-1 and 8-2) Rada 320 Thermostatic Mixing Valves should be inspected annually, or more frequently where acknowledged site conditions such as high mineral content water dictate.

- Page 8 Wrench Figure 8-2 Step 1 Step 2 The Rada 320 Mixing Unit features a single “sealed for life” disposable internal cartridge. With an allen key (3 mm) to remove the handle retaining screw and a phillips head screwdriver to remove the 6 cartridge retaining screws, the entire mixing unit can be serviced and/or replaced in approximately 10 minutes.

- Page 9 Rada 320/320R/320D Common Spare Parts Part No. Description D33382 Body, Model 320 (less connector) D33383 Temperature Indicating Ring D33384 Cartridge Assembly D33385 Hub Pack D33386 Inlet/Outlet Adapter, 3/4” Female D33387 Seal Pack - Includes “A” Components D33388 Screw Pack - Includes “B” Components D33389 Backplate Kit - Includes “C” Components D33390 Knob Pack with Screw...

-

Page 10: Fault Diagnosis

Fault Diagnosis Symptom Cause Action Check-Rectify. Tip: check rear of valve under polymer mounting plate for raised “H” (hot)on appropriate inlet. If sight evaluation is not possible a. Inlet supplies reversed (i.e.: hot to cold or vice- consult factory Technical Support for additional versa) diagnositc tips. - Page 11 Notes...

-

Page 12: Limited Warranty And Remedy

Armstrong products, notice of any warranty or other claim relating to the products must be given in writing to Armstrong: (i) within 30 days of last day of the applicable warranty period, or (ii) within 30 days of the date of the manifestation of the condition or occurrence giving rise to the claim, whichever is earlier.

Need help?

Do you have a question about the Rada 320 and is the answer not in the manual?

Questions and answers