Summary of Contents for York YLCD Series

- Page 1 Air-condensed water coolers and centrifugal heat pumps YLCD/YLHD 40 to 70 User manual Ref.: N-40412_EN 0112...

-

Page 2: Table Of Contents

Index Index User manual..........................1 General information........................2 1.1.1 Product nomenclature......................2 1.1.2 General description of the unit....................2 1.1.3 Models available and capacities....................3 1.1.4 Features and advantages......................4 1.1.5 Technical specifications......................4 Safety instructions........................7 Icons used in this document.....................8 Instructions for storage, transport, loading and unloading of the unit........8 1.4.1 Inspection..........................9 1.4.2... -

Page 3: User Manual

User manual... -

Page 4: General Information

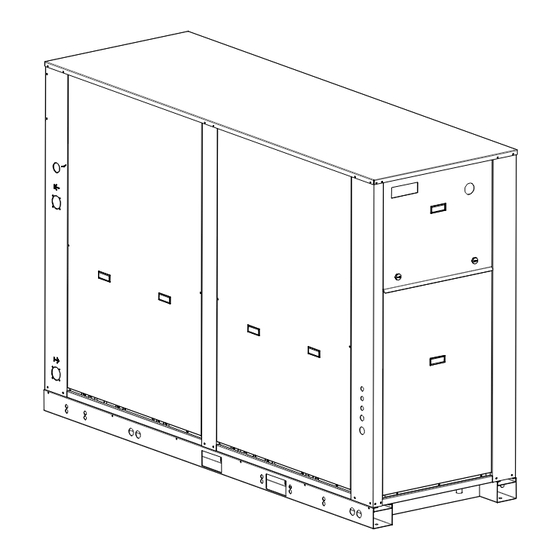

User manual General information 1.1 General information 1.1.1 Product nomenclature Air-water cooler with centrifugal fans / Air-water heat pump with centrifugal fans Nominal cooling capacity in kW Voltage T: Three-phase (400.3.50) -: Hydro kit (pack) not included P: Hydro kit (pack) included C: Water circulation pump included YLCD / YLHD 1.1.2 General description of the unit... -

Page 5: Models Available And Capacities

User manual General information 1.1.3 Models available and capacities Cool-only YLCD 25 YLCD 40 YLCD 70 YLCD 100 YLCD 120 YLCD 150 model Cooling 24,6 39,8 69,5 98,4 118,5 144,5 capacity Cooling capacity Net cooling capacities in kW for 7 °C of water inlet/outlet temperature and 35 °C of ambient temperature according to the EUROVENT EN14511:2011 certification Gross cooling capacities in kW for 7 °C of water inlet/outlet temperature and 35 °C of ambient temperature ac‐... -

Page 6: Features And Advantages

User manual General information 1.1.4 Features and advantages Features • R-410A coolant • Factory-tested equipment. • Accessibility • Main switch • Microprocessor for control and alarms • Manufactured to ISO 9001 • Hydro kit • Connection for communications Advantages • Does not harm the ozone layer •... - Page 7 User manual General information The standard air outlet is horizontal, although there is an option of modifying it to a vertical air outlet. • The 100, 120 and 150 units are fitted with radial centrifugal fans with a directly coupled, electronically controlled (EC) three-phase motor.

- Page 8 User manual General information Water filter A T T E N T I O N The warranty of the unit will not be valid if a water filter has not been installed. Supplied as a standard element on units including the hydro kit. Stainless steel mesh with 1 mm. diameter perforations.

-

Page 9: Safety Instructions

User manual Safety instructions Antivibration supports Whenever necessary to reduce vibrations and noise produced by the unit to a maximum, a set of steel spring antivibratory supports can be used. These should be installed between the chassis support of the unit and the base or floor on which it is to sit. -

Page 10: Icons Used In This Document

User manual Icons used in this document 1.3 Icons used in this document D A N G E R • The text following this symbol contains information and instructions relating directly to your safety and physical well-being. • Not taking these instructions into account could lead to serious, very serious or even fatal injuries to you and others in the proximities of the unit. -

Page 11: Inspection

User manual Operating instructions Loading and unloading the unit from a truck or trailer should be on flat, solid ground using an appropriate crane with sufficient capacity. 1.4.1 Inspection Upon reception, inspect the goods and notify the carrier and the insurance company, in writing, of any possible damage during transportation. - Page 12 User manual Operating instructions • Alarm device • Heaters STANDARD COMPONENTS Base control module for the system and the first compressor. This is the central nucleus that processes the signals coming from the probes and protection elements of the entire system to control its active elements: compressors and fans, four-way valve, water circulating pump, alarm relay and antifreeze heater.

- Page 13 User manual Operating instructions General diagram YLCD 40 and 70 Water outlet temperature probe (Antifreeze pro‐ Compressor 2 tection) Pump Outdoor temperature probe (Dynamic set point) Ratiometric pressure probe (Fan speed and de‐ Heater frost control) Compressor 1 Phase detector/General stop Alarm Water flow switch 230 / 24 transformer...

- Page 14 User manual Operating instructions Symbols on the display The display has three figures in green, plus the sign and one decimal. It also shows the symbols of the functions selected in orange (the alarm symbol is red). Meaning Button Colour LED permanently lit LED flashing Compressor operating *...

- Page 15 User manual Operating instructions Location of controls (YLCD 40 and 70) Low-pressure switch Temperature probe (B3) (LP) Compressor 1 Flow switch (FS) Compressor 2 NTC water outlet probe High-pressure switch (B2) (HP) Outdoor heat exchang‐ Indoor heat exchanger NTC water inlet probe (B1) Pressure sensor (B4) Pump Parameter tables...

- Page 16 User manual Operating instructions Parameters relating to probes Parameters relating to probes Display Description Level Unit Max. Min. Value NTC B1 probe (water inlet): 0= Absent (function not available) 1 (R/W) 1= Present NTC B2 probe (water outlet): 0=Always ON (function not available) 2 (R/W) 1= Present NTC B3 probe:...

- Page 17 User manual Operating instructions Operating graphics Min. operating time of a compressor Signal Compressor Min. stoppage time of a compressor Signal Compressor Min. time between compressor start-ups Signal Compressor...

- Page 18 User manual Operating instructions Min. time between start-up of two compressors Signal 1 Compressor 1 Signal 2 Compressor 2 Time between stoppage of two compressors Signal 1 Compressor 1 Signal 2 Compressor 2 Compressor / pump stoppage delays Compressor Pump...

- Page 19 User manual Operating instructions Pump / compressor start-up delays Pump Compressor...

- Page 20 User manual Operating instructions Parameters relating to fans Parameters relating to fans Parameters Description Level Unit Max. Min. Value Fan outlet: 0= Absent (function not available) 10 (R/W) 1= Present Operating mode: 0=Always ON (function not available) 1= In parallel with compressor 48 (R/W) 2=ON/OFF operation (function not avail‐...

- Page 21 User manual Operating instructions Antifreeze control configuration parameters Antifreeze control configuration parameters Parameters Description Level Unit Max. Min. Value Antifreeze control set point temperature 11 (R/W) °C Antifreeze reset differential 12 (R/W) °K Antifreeze alarm bypass time 22 (R/W) Seconds Antifreeze heater activation temperature 13 (R/W) °C...

- Page 22 User manual Operating instructions Unit configuration parameters Unit configuration parameters Display Description Level Unit Max. Min. Value Unit model: 2= Water cooler 54 (R/W) 3= Air-water heat pump Number of ventilation circuits (do not modify this pa‐ 12 (R/W) rameter) No.

- Page 23 User manual Operating instructions Alarm configuration parameters Alarm configuration parameters Parameters Description Level Unit Max. Min. Value Alarm delay by flow switch at start-up. 63 (R/W) Seconds Alarm delay by flow switch with unit in operation. 64 (R/W) Seconds Alarm delay by low-pressure switch at start-up. 65 (R/W) Seconds Alarm reset...

- Page 24 User manual Operating instructions Controller configuration parameters Controller configuration parameters Display Description Level Unit Max. Min. Value Cool cycle set point temperature 41 (R/W) °C Cool set point temperature differential 42 (R/W) °C Compressor rotation 0= Disabled 78 (R/W) 1= FIFO type 2= Per operating hours Type of regulation 0= Proportional.

- Page 25 User manual Operating instructions Alarm table Alarm table Display Alarm type Reset Antifreeze alarm Manual High temperature at start-up (if activated, P20=1) Automatic Low temperature at start-up (if activated, P20=1) Automatic B1 probe Automatic B2 probe Automatic B3 probe Automatic B4 probe Automatic Low voltage power supply...

- Page 26 User manual Operating instructions Functions Alarm reset Pressing the UP and DOWN keys for 5 seconds cancels alarms present in the memory. At the same time, the alarm message disappears from the display and the alarm relay is deactivated. Clearing hour counters While reading compressor or pump (c10, c11 and c15) operating hours, said counters can be cleared by pressing the UP and DOWN keys simultaneously.

-

Page 27: Operating Instructions Μc2 (Ylhd 40 And 70)

User manual Operating instructions 1.5.2 Operating instructions µC2 (YLHD 40 and 70) DESCRIPTION OF THE CONTROL UNIT This is a multipurpose controller specially programmed for use with air-water coolers and heat pumps equipped with a tandem compressor, two power stages and a single cooling circuit. Main functions •... - Page 28 User manual Operating instructions Direct Level Accessible without password. Allows for reading of the values detected by the probes, as well as other system values. Can be used by the user without affecting unit operation. General Modification of the parameters that affect basic unit configuration should be made with the controller in Standby position.

- Page 29 User manual Operating instructions General diagram YLHD 40 and 70 A B C D µchiller Neutral µchiller (expansion) Phase Four-way valve Water inlet temperature probe (Control set point) Water outlet temperature probe (Antifreeze pro‐ Pump tection) Heater Outdoor temperature probe (Dynamic set point) Ratiometric pressure probe (Fan speed and de‐...

- Page 30 User manual Operating instructions Symbols on the display The display has three figures in green, plus the sign and one decimal. It also shows the symbols of the functions selected in orange (the alarm symbol is red). Meaning Button Colour LED permanently lit LED flashing Compressor operating *...

- Page 31 User manual Operating instructions Location of controls (YLHD 40 and 70) Fan heat switch (TK1, TK2, Pump TK3) Compressor 1 heat switch Low-pressure switch (A3) (LP) Compressor 2 heat switch Compressor 1 (M1) (A4) Fan ‑1 (M3, M4, M5) Compressor 2 (M2) High-pressure switch Flow switch (FS) (HP)

- Page 32 User manual Operating instructions Parameters relating to probes Parameters relating to probes Display Description Level Unit Max. Min. Value NTC B1 probe (water inlet): 0= Absent (function not available) 1 (R/W) 1= Present NTC B2 probe (water outlet): 0= Absent (function not available) 2 (R/W) 1= Present NTC B3 probe (Outdoor temperature):...

- Page 33 User manual Operating instructions Operating graphics Min. operating time of a compressor Signal Compressor Min. stoppage time of a compressor Signal Compressor Min. time between compressor start-ups Signal Compressor...

- Page 34 User manual Operating instructions Min. time between start-up of two compressors Signal 1 Compressor 1 Signal 2 Compressor 2 Time between stoppage of two compressors Signal 1 Compressor 1 Signal 2 Compressor 2 Compressor / pump stoppage delays Compressor Pump...

- Page 35 User manual Operating instructions Pump / compressor start-up delays Pump Compressor...

- Page 36 User manual Operating instructions Parameters relating to fans Parameters relating to fans Parameters Description Level Unit Max. Min. Value Fan outlet: 0= Absent (function not available) 10 (R/W) 1= Present Operating mode: 0= Always ON 1= In parallel with the compressor (function not available) 48 (R/W) 2= ON/OFF operation (function not availa‐...

- Page 37 User manual Operating instructions Parameters relating to defrost Parameters relating to defrost Parameters Description Level Unit Max. Min. Value Defrost operation: 0= Absent (function not available) 7 (R/W) 1= Present Defrost at time or temperature: 0= Time (function not available) 8 (R/W) 1= Temperature / Pressure Defrost start pressure...

- Page 38 User manual Operating instructions Antifreeze control configuration parameters Antifreeze control configuration parameters Parameters Description Level Unit Max. Min. Value Antifreeze control set point temperature 11 (R/W) °C Antifreeze reset differential 12 (R/W) °K Antifreeze alarm bypass time 22 (R/W) Seconds Antifreeze heater activation temperature 13 (R/W) °C...

- Page 39 User manual Operating instructions Unit configuration parameters Unit configuration parameters Display Description Level Unit Max. Min. Value Unit model: 2= Water cooler 54 (R/W) 3= Air-water heat pump Number of ventilation circuits (do not modify this pa‐ 12 (R/W) rameter) No.

- Page 40 User manual Operating instructions Alarm configuration parameters Alarm configuration parameters Parameters Description Level Unit Max. Min. Value Alarm delay by flow switch at start-up. 63 (R/W) Seconds Alarm delay by flow switch with unit in operation. 64 (R/W) Seconds Alarm delay by low-pressure switch at start-up. 65 (R/W) Seconds Alarm reset...

- Page 41 User manual Operating instructions Controller configuration parameters Controller configuration parameters Display Description Level Unit Max. Min. Value Cool cycle set point temperature 41 (R/W) °C Cool set point temperature differential 42 (R/W) °C Heat cycle set point temperature 43 (R/W) °C Heat cycle set point temperature differential 44 (R/W)

- Page 42 User manual Operating instructions Alarm table Alarm table Display Alarm type Reset Antifreeze alarm Manual High temperature at start-up (if activated, P20=1) Automatic Low temperature at start-up (if activated, P20=1) Automatic d1-2 Defrost operating dF1-2 Problem in defrost Automatic B1 probe Automatic B2 probe Automatic...

- Page 43 User manual Operating instructions Functions Alarm reset Pressing the UP and DOWN keys for 5 seconds cancels alarms present in the memory. At the same time, the alarm message disappears from the display and the alarm relay is deactivated. Forced defrost (heat pumps) Pressing the SEL and UP keys simultaneously for 5 seconds activates forced defrost of the unit.

-

Page 44: Regular Maintenance Activities For Which The User Is Responsible

User manual Regular maintenance activities for which the user is responsible 1.6 Regular maintenance activities for which the user is responsible 1.6.1 Maintenance Schedule The HVAC unit is designed to require as little maintenance as possible. Nevertheless, to ensure the correct operation of the unit with a minimal use of electricity, a long working life and compliance with the regulations of each country, regular maintenance inspections must be made.

Need help?

Do you have a question about the YLCD Series and is the answer not in the manual?

Questions and answers