Table of Contents

Advertisement

Installation

and

Maintenance

Manual

INVERTER-DRIVEN

MULTI-SPLIT SYSTEM

HEAT PUMP

AIR CONDITIONERS

Type

(H,Y,C)IC4008B21S

(H,Y,C)IC4012B21S

(H,Y,C)IC4015B21S

(H,Y,C)IC4018B21S

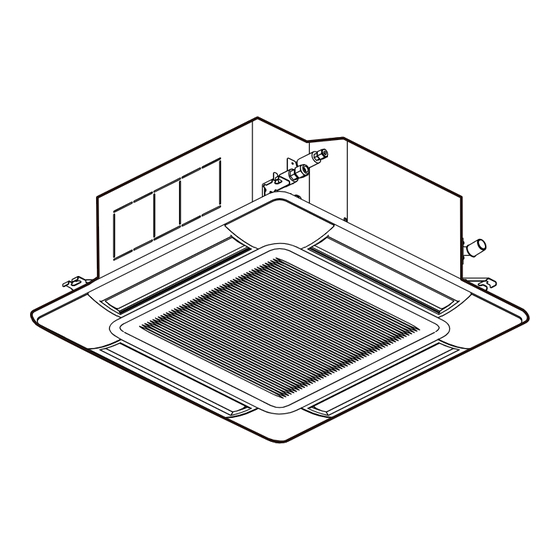

4-Way Cassette

(H,Y,C)IC4024B21S

(H,Y,C)IC4030B21S

(H,Y,C)IC4036B21S

(H,Y,C)IC4048B21S

IMPORTANT:

READ AND UNDERSTAND

THIS MANUAL BEFORE

INSTALLING THIS HEAT

PUMP AIR CONDITIONER.

KEEP THIS MANUAL FOR

FUTURE REFERENCE.

Model

P5417054

Advertisement

Table of Contents

Summary of Contents for York HIC4008B21S

- Page 1 Installation Maintenance Manual INVERTER-DRIVEN MULTI-SPLIT SYSTEM HEAT PUMP AIR CONDITIONERS Type Model (H,Y,C)IC4008B21S (H,Y,C)IC4012B21S (H,Y,C)IC4015B21S (H,Y,C)IC4018B21S 4-Way Cassette (H,Y,C)IC4024B21S (H,Y,C)IC4030B21S (H,Y,C)IC4036B21S (H,Y,C)IC4048B21S IMPORTANT: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLING THIS HEAT PUMP AIR CONDITIONER. KEEP THIS MANUAL FOR FUTURE REFERENCE. P5417054...

- Page 2 ATTENTION Each model number and all matching model numbers within a system must have the same version of software. Follow these steps to verify that your product model numbers have the same version of software. • Access the main printed circuit board in each product. •...

- Page 3 Important Notice ● Johnson Controls Inc. pursues a policy of continuing improvement in design and performance in its products. As such, Johnson Controls Inc. reserves the right to make changes at any time without prior notice. ● Johnson Controls Inc. cannot anticipate every possible circumstance that might involve a potential hazard. ●...

-

Page 4: Table Of Contents

TABLE OF CONTENTS 1. Introduction ................................1 2. Safety Instructions ..............................1 3. Before Installation ..............................7 3.1 Combination of Outdoor Unit and Indoor Unit ....................7 3.2 Transportation and Handling ........................7 3.3 Factory-Supplied Accessories ........................7 4. Installation Location .............................. 8 5. -

Page 5: Introduction

Introduction Read following sections carefully before installing this product. Read over the "Installation and Maintenance Manual" for the outdoor unit as well. Forward this information, and the warranty to all installers and users. Ask end users to maintain copies for future reference. (Refrigerant Piping Work) (Electrical Wiring Work) (Ref. - Page 6 ● Do not touch or adjust any safety devices inside the indoor or outdoor units. All safety features, disengagement, and interlocks must be in place and functioning correctly before the equipment is put into operation. If these devices are improperly adjusted or tampered with in any way, a serious accident can occur.

- Page 7 ▫ A room: Properly insulate any refrigerant tubing run inside a room to prevent “sweating” that can cause dripping and water damage to wall and floors. ▫ Damp or uneven areas: Use a raised concrete pad or concrete blocks to provide a solid, level foundation for the unit to prevent water damage and abnormal vibration.

- Page 8 Refrigerant Precautions To reduce the risk of serious injury or death, the following refrigerant precautions must be followed. ● As originally manufactured, this unit contains refrigerant installed by Johnson Controls. Johnson Controls uses only refrigerants that have been approved for use in the unit’s intended home country or market.

- Page 9 ● Clamp electrical wires securely with a cable band after all wiring is connected to the terminal block. In addition, run wires securely through the wiring access channel. ● When installing the power lines, do not apply tension to the cables. Secure the suspended cables at regular intervals, but not too tightly.

- Page 10 ● Proper handling of this unit requires two-people. Safe handling and installing the indoor unit requires the strength of two people. Mounting the unit alone may cause injury due to fall of the unit. Although the unit may be girded with steel banding, do not use it for transportation. Avoid contact with finned surfaces of the heat exchanger as sharp edges can cause severe injury to hands and fingers.

-

Page 11: Before Installation

Before Installation Combination of Outdoor Unit and Indoor Unit The combination capacity of indoor unit against the outdoor unit is selected depending on the outdoor unit capacity. Refer to the "Installation and Maintenance Manual" for the outdoor unit to decide the required combination of indoor and outdoor units, and the combination unit capacity. -

Page 12: Installation Location

NOTICE The decorative panel, controller, and branch piping are optional accessories and are not included with the indoor unit. If necessary, please contact your contractor. 2. Do not insert or leave any foreign objects inside the indoor unit and verify that no foreign objects remain inside in the indoor unit before the installation and Test Run. - Page 13 3. Select the installation location as follows: • Minimum Space • Down slope gradient for condensate piping: 1/25 to 1/100 Unit: inch (mm) It is recommended that the indoor unit be Minimum 3/8 (10) Clearance installed at 7.9 ft (2.4m) from floor level. 008 to 018 Type: 9-3/4 (248) 024 to 048 Type: 11-3/4 (298) NOTE:...

-

Page 14: Installation Work

Installation Work Opening of False Ceiling and Location of Suspension Bolts 1. Determine the final location and installation orientation of the indoor unit with respect to the space allowed for piping, wiring, and maintenance access. 2. Then cut away the false ceiling area for the indoor unit installation and install suspension bolts. 3. -

Page 15: Working Procedure

Working Procedure 1. Size the opening to the correct dimensions to Checking Scale for facilitate easy and repeated installation by using Dimension of Opening the pattern board (template). The template provided for the installation comes with a scale printed on a portion of the outer packaging. - Page 16 3. Mounting Position of the Indoor Unit when optional parts are used (B) When the optional parts are used with the decorative panel, add the additional value (h) to the indoor unit mounting position (A) as shown below. When the calculated value is (-) minus, the unit mounting position is lower than the ceiling surface.

- Page 17 5. Mounting the Indoor Unit • Hoist the indoor unit but do not apply any force against the condensate pan (the air outlet portions and the condensate pan portion). If there is insufficient access for a hoist, the work must be performed manually by two skilled installers.

-

Page 18: Installation Of Decorative Panel

7. Tighten the nuts on the suspension brackets after adjustments are completed. LockTite thread lock compound to the suspension bolts and nuts in order to prevent them from loosening. Adjust the indoor unit into correct position, using the scale of the pattern board (template). NOTE: While adjusting the clearance spacing between the indoor unit and the ceiling surface, keep the indoor unit level. -

Page 19: Refrigerant Piping Work

Refrigerant Piping Work Use the specified non-flammable refrigerant (HFC R410A) for the outdoor unit refrigerant cycle. Do not charge the unit with anything other than HFC R410A, such as hydrocarbon refrigerants (propane and Isobutene), oxygen, and other flammable gases (acetylene, ammonia, and so forth), or any poisonous gases when installing, maintaining and moving the unit. - Page 20 2. Use specific flare nut attached with the unit. 3. Verify that there are no scratches, burrs stuck to internal surfaces, or surface deformations at the flared opening. 4. Before tightening the flare nut, apply the (Field-Supplied) refrigerant oil in a thin layer over the flared part.

-

Page 21: Condensate Piping

Condensate Piping Do not run condensate piping into underground areas near sanitary or sewage lines where toxic and corrosive gas can seep into the system. This creates a pathway for the flow of poisonous gas to penetrate inhabited areas. NOTICE ●... - Page 22 c. Attach the factory-supplied hose clamp to the vinyl tape (white) attached to the condensate hose. The hose clamp shall be 13/16 inch (20mm) away from the end face of the condensate hose. Then tighten the hose clamp to make sure that it is approximately 1-1/8 inches (28mm) in length from the screw to the edge of the hose clamp as shown in the figure below.

- Page 23 g. Installing Main Condensate Piping • Install the main condensate pipe on a downward slope to make sure that it is lower than each rising part of the condensate pipe from the indoor unit. • The size for main condensate pipe must be larger than VP30, the nominal diameter size of 1-3/16 inches (30mm) and, outer diameter 1-1/2 inches (38mm) according to the number of the connected indoor units.

- Page 24 NOTICE ● Moisture which has discharged into the condensate pan and check for drainage in the heating season should be drained completely from the condensate pan. ● The heat exchanger is heated since a slight amount of refrigerant circulates inside the indoor unit during periods of stoppage.

-

Page 25: Electrical Wiring

Electrical Wiring ● All electrical work must be done as outlined in this manual and in accordance with this manual. Substandard work can result in fire and damage to the unit. ● Use specified cables between units and choose the cables correctly. If not, an electrical shock or fire may occur. -

Page 26: Details Of Electrical Wiring Connection

8.2.2 Details of Electrical Wiring Connection The electrical wiring capacity of the outdoor unit should be referred according to the "Installation and Maintenance Manual" for the outdoor unit. Adjusting the DIP switches may be required depending on the arrangement with the outdoor unit. Select wiring capacity according to the table 8.1. -

Page 27: Position Of Electrical Wiring Connection

Position of Electrical Wiring Connection ● The electrical wiring connection for the indoor unit is shown in Section 8.2.2. For details relating to the intermediate connections between the indoor unit and the decorative panel, refer to the "Installation and Maintenance Manual" for the 4-Way Cassette Decorative Panel. ●... - Page 28 All electrical work should be performed in strict accordance with electrical schematics in the "Installation and Maintenance Manual". If Power Supply Voltage (208V/230V) is introduced into the Communication Line: If 208V/230V are applied to the communication line at (Terminals 1 and 2 of TB2) by mistake, the fuse on the PCB for the communication line will blow.

- Page 29 NOTICE 1. The DIP switch settings for the outdoor unit should be performed in accordance with the "Installation and Maintenance Manual" for the outdoor unit. 2. Be aware that communication cable for the wired controller is required in these instances: a.

-

Page 30: Wired Controller Cable

Wired Controller Cable 8.4.1 Cautions for Individual Louver Settings 1. Individual louver settings are available up to 16 indoor units by single wired controller. Connections for 17 or more indoor units is not possible. Individual Louver Individual Individual Individual Individual Louver Louver Louver... -

Page 31: Cautions For Decorative Panel With Motion Sensor

8.4.2 Cautions for Decorative Panel with Motion Sensor 1. By means of decorative panels with motion sensors, a single wired controller can connect up to 16 indoor units. A decorative panel equipped with a motion sensor is activated even if it is installed together with a decorative panel without a motion sensor. -

Page 32: Caution For Electrical Wiring

Use Conditions and Precaution Statements The motion sensor operates by detecting minute changes in temperature in the infrared spectrum. Moving objects or human activity with temperature differences can be distinguished from the temperature of the surrounding body. DO NOT install the decorative panel equipped with motion sensor (P-AP160NAE1) in the following places: It can result in poorly identified or defined motion, or degraded performance of the motion sensor. -

Page 33: Wiring Connections

Wiring Connections Wiring connections for the indoor unit are shown below. Cable Band Piping Cover View from Wiring Support Plate Wiring Opening Electrical Box Electrical Box Cover Communication Cable and Wired Controller Cable Screw Power Supply Wiring (for Electrical Box Cover) Power Supply Wiring Ground Screw (M5) (between Indoor Units) -

Page 34: Dip Switch Settings

DIP Switch Settings 1. Turn OFF the power supply to both indoor and outdoor units before adjusting DIP switch settings. Otherwise, the settings will be invalidated and will not take effect. 2. Positions of DIP Switches on the PCB are shown below. DSW5 (Refrigerant Cycle No. - Page 35 Refrigerant Cycle No. Setting (RSW2 & DSW5) Refrigerant Cycle No. Setting DSW5 (Tens Digit) RSW2 (Units Digit) This setting is required. The unit arrives with all Ex.) Set at No.5 Cycle DSW5 settings in the OFF position. Setting Set by inserting Position slotted screwdriver into the groove.

-

Page 36: High Speed Setting

High Speed Setting ● This function is used to set the airflow volume higher than the normal airflow volume. This is used for high ceiling areas on site. Set High Speed setting (1 or 2) from the function selection menu, depending on the ceiling height as shown in the table below. -

Page 37: Control Of Dew Condensation Prevention

Select “Individual Louver Setting” from Individual Louver Individual Louver Setting Setting screen and press “OK”. Individual Louver Setting Cancel INDV Louver SET Sel. Entr Rtrn Back Select the indoor unit to change the louver direction by Individual Louver Setting pressing “ ”... -

Page 38: Function Selection By Wired Controller

8.11 Function Selection by Wired Controller Each function can be selected with the wired controller. Refer to "Installation and Maintenance Manual" for wired controller, and the "Service Manual" for indoor units for details. (1) Press and hold "Menu" and "Back/Help" simultaneously for at least 3 Test Run Menu seconds during the normal mode (when unit is not operated). - Page 39 Function Setting Condition (Underlined Part is Factory Setting) Optional Function Selection Unit Item Less than 8.9-9.8 9.8-11.5 Ceiling Height of 008 to 018 Type 8.9 (2.7) (2.7-3.0) (3.0 - 3.5) High Speed Setting Less than 10.5-11.8 11.8-13.8 Ceiling Height of 024 to 048 Type 10.5 (3.2) (3.2-3.6) (3.6-4.2)

-

Page 40: Setback Operation

8.12 Setback Operation (1) Press and hold “Menu” and “Back/Help”on the wired controller simultaneously for at least three seconds during the normal mode (unit stoppage). The Test Run menu is displayed. (2) Select “Input/Output” from the Test Run menu and press “OK”. Test Run Menu Test Run Function Selection... -

Page 41: Test Run

Test Run Before Test Run Verify that there are no problems with the installation, and do not perform Test Run until all the following conditions have been resolved. Refer to the "Installation and Maintenance Manual" for the outdoor unit for details on Test Run operations from the outdoor unit. - Page 42 ● The total number of connected indoor units is indicated on the LCD (Liquid Crystal Display). In the case of a twin combination (set of two indoor units), the total number of the connected indoor units is displayed as “2 units”, and where there is a triple combination (set of three indoor units), the total number of the connected indoor units is displayed as “3 units”.

- Page 43 Check of the Motion Sensor 1. Perform the motion detection (waving a hand, etc) under the motion sensor of the selected indoor unit for approximately 10 to 15 seconds. (*1) 2. Check the value of “q3” ~ "q6" after 30 seconds from starting the motion detection at Item 1.

- Page 44 ● The RUN indicator on the wired controller for the indoor unit will flash orange (0.5 second ON/ 0.5 second OFF), indicative of a fault or error having been generated with activation of protection devices during the Test Run phase. Alarm code, unit model code, and the number of interconnected indoor units will be displayed on the LCD as shown below.

-

Page 45: Alarm Code

Alarm Code Alarm (Troubleshooting) Code Table Code Category Nature of Problem Likely Cause Activation of a protection device Activation of the float switch; (High water level present in Indoor Unit (Float switch) the condensate pan.) A problem exists in the piping. Activation of protection device;... - Page 46 © 2017 Johnson Controls, Inc. P5417054 Code No. LIT-12012613 Issued November 2017...

Need help?

Do you have a question about the HIC4008B21S and is the answer not in the manual?

Questions and answers