Summary of Contents for Wilden HS400S

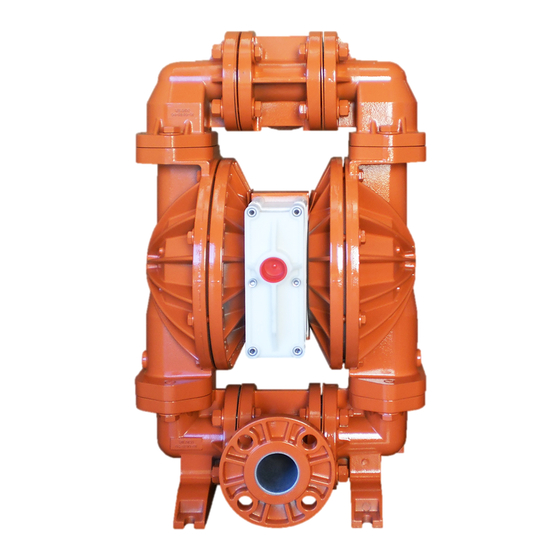

- Page 1 Engineering Operation & Maintenance HS400S Advanced ™ Metal Pump Where Innovation Flows wildenpump.com...

-

Page 2: Table Of Contents

SECTION 2 WILDEN PUMP DESIGNATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 SECTION 3 HOW IT WORKS—PUMP &... -

Page 3: Cautions-Read First

Pump, valves and containers must be grounded to a proper grounding point when handling flammable fluids and whenever discharge of static electricity is a hazard. CAUTION: Do not exceed 8.6 bar (125 psig) air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... -

Page 4: Wilden Pump Designation System

VALVE SEAT O-RINGS ™ AIR CHAMBERS [Santoprene (Two Orange ® TF = PTFE (White) A = ALUMINUM Dots)] SPECIALTY CODES 0320 Single-Point Exhaust 0504 DIN flange NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOT FOR IDENTIFICATION. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... - Page 5 H O W I T W O R K S — P U M P The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show flow pattern through the pump upon its initial stroke. It is assumed the pump has no fluid in it prior to its initial stroke.

-

Page 6: Dimensional Drawing

HS 40 0S AL UM INUM DIMENSIONS ITEM METRIC (mm) STANDARD (inch) 13.5 13.2 20.9 23.8 12.8 12.6 20.9 DIN (mm) ANSI (inch) 150 DIA. 5.0 DIA. 110 DIA. 3.9 DIA. 18 DIA. 0.6 DIA. LW0287 REV. A WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... -

Page 7: Tpe-Fitted

For optimum life and performance, pumps should be specified so that daily operation Caution: Do not exceed 8.6 bar (125 psig) parameters will fall in the center of the pump's performance curve. air supply pressure. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... -

Page 8: Suction-Lift Curve

S U C T I O N — L I F T C U R V E S HS400S ALUMIUM SUCTION-LIFT CAPABILITY Aluminum Wetted Path (HS400S) Suction-lift curves are calibrated for pumps operating number of intake and discharge elbows, viscosity of at 305 m (1,000') above sea level. - Page 9 In addition, pump efficiency can be adversely your pump. Wilden offers the widest variety of elastomer affected if proper attention is not given to site location. options in the industry to satisfy temperature, chemical PIPING: Final determination of the pump site should not be compatibility, abrasion resistance and flex concerns.

- Page 10 A properly functioning valve will stop the air supply to the pump, therefore stopping output. This shut-off valve should be located far enough away from the pumping equipment such that it can be reached safely in an emergency situation. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

- Page 11 Wilden pump. Periodic pump. An air regulator is used to regulate air pressure. inspections have been found to offer the best A needle valve is used to regulate volume.

-

Page 12: Disassembly / Reassembly

This chambers. NOTE: The HS400S pump does not line will assist in proper realignment use valve balls in the amplification during reassembly. chamber. Step 4... - Page 13 Using an adjustable wrench, remove diaphragm assembly from shaft. Inspect all parts for wear and replace with genuine Wilden parts, if necessary. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

- Page 14 This principle is how the HS400S high- pressure pump achieves a 2:1 ratio of inlet air pressure to discharge pressure. When reassembling the HS400S pump, the outer piston...

- Page 15 Using a pair of snap-ring pliers, Using an O-ring pick, remove O-ring Using the appropriate-sized wrench, remove the snap ring from pilot from modulator spool. loosen and remove the fasteners sleeve. that attach the air chamber to center section. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

- Page 16 O-ring by passing it over the ports in the pilot sleeve. NOTE: Seals should not be removed from the assembly. Seals are not sold separately. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

-

Page 17: Air Valve / Center Section Disassembly

Lift away the air valve assembly and four (4) air valve bolts from center remove air valve gasket. Inspect the gasket and replace if necessary. section assembly. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... - Page 18 (04-2638-52). The single-point air valve of the center block. Install 1/4" NPT gasket can be purchased as a spare part or included pipe plug (00-7010-08) into bleed with the purchase of a new Pro-Flo SHIFT pump. ® port. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

-

Page 19: Reassembly Hints & Tips

• With the seal clamped in the pliers, insert the seal into HS400S MAXIMUM TORQUE SPECIFICATIONS the bushing bore and position the bottom of the seal Description Torque into the correct groove. -

Page 20: Exploded View & Parts Listing

E X P L O D E D V I E W & P A R T S L I S T I N G HS400S ALUMINUM E X P L O D E D V I E W LW0288 REV.B ALL CIRCLED PART IDENTIFIERS ARE INCLUDED IN CONVERSION KIT (See Section 9). WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01... - Page 21 LW0289 REV. A *See elastomer chart - Section 9 Air Valve Assembly includes items 2 and 3. Center Block Assembly includes items 11, 12, 14, 15 and 16. All boldface items are primary wear parts. WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

- Page 22 N O T E S WILDEN PUMP & ENGINEERING, LLC WIL-11112-E-01...

- Page 23 Since the use of Wilden pumps and parts is beyond our control, we cannot guarantee the suitability of any pump or part for a particular application and Wilden Pump and Engineering, LLC shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application.

- Page 24 Where Innovation Flows 22069 Van Buren Street, ® reserves the right to modify the information and illustrations contained in this document without prior notice. This is a non-contractual document. 07-2015 Grand Terrace, CA 92313-5607 Authorized PSG Representative: Telephone: (909) 422-1731 Fax: (909) 783-3440 22069 Van Buren St., Grand Terrace, CA 92313-5607 P: +1 (909) 422-1731...

Need help?

Do you have a question about the HS400S and is the answer not in the manual?

Questions and answers