Table of Contents

Advertisement

Quick Links

FlowCon SM 15-250 mm (1/2"-10")

1A95106 - 01/2019

Installation and Operation Instruction

The FlowCon SM are available in two different

double union end connected models covering five

different sizes and four different flanged models

covering nine different sizes:

FlowCon SM.1 DN15-25 (1/2"-1")

FlowCon SM.2 DN25-40 (1"-1½")

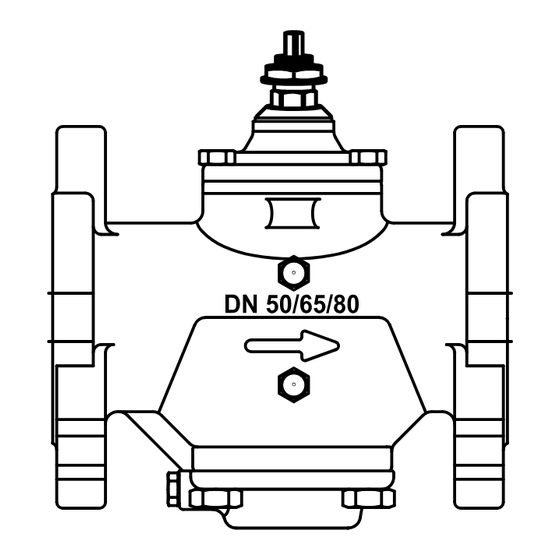

FlowCon SM.3 DN50-80 (2"-3")

FlowCon SM.4 DN80-100 (3"-4")

FlowCon SM.5 DN125-150 (5"-6")

FlowCon SM.6 DN200-250 (8"-10")

DN

25/32/40

O-rings are supplied with the valve body and are

used to seal the connections. It is recommended

to grease the O-rings with silicone grease.

Please make sure these are properly placed

in the O-ring grooves on valve inlet and outlet,

before installing the housing. Please note that

FlowCon SM.6 (DN200-250 / 8"-10") contains two

O-ring grooves. Use the inner groove for DN200 /

8" flanges and outer groove for DN250 / 10" flanges.

O-ring Groove

200 mm (8")

flanges

O-ring Groove

250 mm (10")

flanges

Figure 1

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.flowcon.com

The actuator types FlowCon SM.0.0.0.3,

SM.0.0.0.4, SM.0.0.0.5 and SM.0.0.0.6 are elec-

trical programmable actuators. SM.0.0.0.5 and

.6 are BACnet actuators and have a supplemen-

tary instruction on BACnet connection and pro-

gramming.

Fitting and Re-fitting the actuator

It is recommended to grease the O-ring on the

spindle adaptor with silicone grease before plac-

ing the spindle adaptor on the valve spindle.

Then place the actuator on the spindle adaptor

and place the three actuator "legs" into the three

holes in the mounting bracket (figure 2 and 3).

Make sure that the snap ring is clicked onto the

mounting bracket, so that the snap ring is locked

at the top of the mounting bracket, but still able to

rotate. Then finger-turn the snap ring counter

clockwise (upside view) approximately 1/6 of a

turn until its stop points touch the actuator "legs"

and the mounting is lock with a (small) click. Do

not use additional tools.

Spindle adaptor

Snap ring

Figure 2

The bottom side of the

actuator

"Actuator

legs"

Snap ring:

Stop points

Figure 3

Page 1 of 8

Advertisement

Table of Contents

Summary of Contents for FlowCon SM Series

- Page 1 “Actuator 250 mm (10”) legs” Snap ring: flanges Stop points Figure 2 Figure 3 Figure 1 This paper is a supplement to the FlowCon General Instruction Page 1 of 8 Latest release of any FlowCon material is available on www.flowcon.com...

- Page 2 Figure 5 Figure 4 Do not remove cover from actuator. Opening cover will void warranty. This paper is a supplement to the FlowCon General Instruction Page 2 of 8 Latest release of any FlowCon material is available on www.flowcon.com...

-

Page 3: Start-Up Sequence

At first start-up please enter programming menu tion mode (according to control signal). to set actuator settings. This paper is a supplement to the FlowCon General Instruction Page 3 of 8 Latest release of any FlowCon material is available on www.flowcon.com... -

Page 4: Programming Menu

SELECT CONTROL SIGNAL • 4-20mA for mA • Digital for 2 position or 3 point floating. This paper is a supplement to the FlowCon General Instruction Page 4 of 8 Latest release of any FlowCon material is available on www.flowcon.com... - Page 5 Failsafe direction open means SELECT FAIL SAFE DIRECT opening to max. flow chosen in step 9. This paper is a supplement to the FlowCon General Instruction Page 5 of 8 Latest release of any FlowCon material is available on www.flowcon.com...

- Page 6 If display shows “NA” the valve model has not been chosen in programming menu step 2. This paper is a supplement to the FlowCon General Instruction Page 6 of 8...

-

Page 7: Alarm Menu

Alarm will reset FULL ON when BACnet control signal is refreshed. Only valid for BACnet actuators. This paper is a supplement to the FlowCon General Instruction Page 7 of 8 Latest release of any FlowCon material is available on www.flowcon.com... -

Page 8: Manual Override

13 and show warning code 05 in the actuator display. When voltage is back ⚠ in range will be reset. This paper is a supplement to the FlowCon General Instruction Page 8 of 8 Latest release of any FlowCon material is available on www.flowcon.com... -

Page 9: Warranty

Failure to abide by all recommendations as per this General Instruction will void warranty. For any supplementary warranty obligations, plea- se see the relevant product specific installation and operation instruction. Latest release of any FlowCon material is available on www.flowcon.com Page 1 of 4... - Page 10 P/t plugs without collar. The valve is available for double flanged connec- tions for all model sizes. P/t plugs without collar. Latest release of any FlowCon material is available on www.flowcon.com Page 2 of 4...

- Page 11 300 according to ASME B16.5. depending on WILL DAMAGE THE O-RING). If the capillary product ordered. tube is to be mounted in a FlowCon Partner Ball Flanges are not supplied by FlowCon. or other valve with 1/4” (ISO 7/1) tapping, a 1/4”...

- Page 12 FlowCon General Instruction 1B95011 - 01/2019 Latest release of any FlowCon material is available on www.flowcon.com Page 4 of 4...

Need help?

Do you have a question about the SM Series and is the answer not in the manual?

Questions and answers