Summary of Contents for Graef HA 800

- Page 1 OPERATING MANUAL (original) Semi-Automatic Slicing Machine HA 800 HA 810 Machine No. Year of construction Technical changes reserved. GRAEF (d) February 2010 -CB...

-

Page 2: Table Of Contents

Cutting with the VS Carriage ................25 The Start Program ....................25 Changing the Standard Program (PLU=0000)............27 3.7.1 The “M+PLU” Additional Menu ..............27 3.7.2 The “M” Additional Menu (OPTION HA 800) ..........30 3.7.3 Slicing in the PLU Mode ................34 3.7.4 Programming a PLU ..................35 Cleaning ........................40 Preparing for Cleaning ....................40... - Page 3 4.3.1 Cleaning Procedure ..................48 Assembly.........................49 Maintenance........................51 Sharpening the Blade....................51 5.1.1 Description of the Blade Sharpener...............51 5.1.2 Preparing the Machine..................52 5.1.3 Sharpening the Blade..................52 Changing the Blade....................54 Lubricating ......................55 Faults and Operating Errors ...................56 Service ...........................57...

- Page 4 EC DECLARATION OF CONFORMITY GEBR. GRAEF GMBH + CO. KG, DONNERFELD 6, D- 59757 ARNSBERG We herewith declare that the design of the following machine Slicing Machine Types HA 800, HA 810 In the design supplied by us complies with the provisions of the following EC...

-

Page 5: General Information

1 General Information 1.1 Safety – Notes on the Warranty The semi-automatic models HA 800 and HA 810 are equipped with safety devices. They have been tested for safety. Nevertheless, hazards cannot be entirely excluded if the machine is used improperly or not as intended. - Page 6 General Information Secure the carriage by inserting paper or cardboard between the thumb guard and the stop plate. Set the slicing thickness below “0” by turning the slicing thickness control to the limit position. 1.1.1.1 Set-up site requirements The base must fulfil the following requirements: It must be sufficiently stable, strong, level, flat and non-slip.

-

Page 7: Proper Use

Lay and connect the power supply cord so that no-one can fall or trip over it. The machine is designed for use in sales rooms. 1.1.2 Proper Use The HA 800 / HA 810 semi-automatic slicers are exclusively intended for slicing only the following types of food: sausage / meat / ham / cheese. -

Page 8: Natural Wear

General Information 1.1.3 Natural Wear Natural wear is not covered by our warranty or liability. 1.1.4 Potential Sources of Danger Caution! Danger of injury! Never reach into the area of the moving carriage. Caution! Danger of injury! The blade is sharp and can sever body parts. Your fingers, and especially your thumb, are at risk. -

Page 9: Workplace

General Information Caution! Risk of injury. In the area of the food holder, there is a risk of injury posed by the spikes an the food holder suddenly dropping when inserting the product. Caution! Risk of injury. When mounting parts which can be removed for cleaning. 1.1.5 Workplace Only operate the machine if you are in a standing in a secure position. -

Page 10: Description

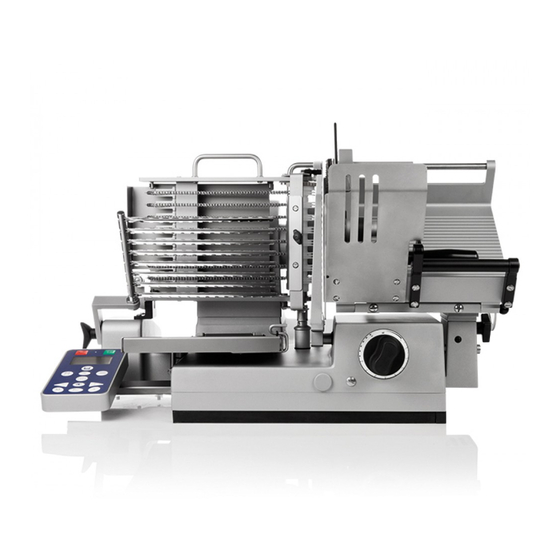

Description 2 Description 2.1 Designation of the Machine Parts Stop plate Blade cover plate Blade Last slice clamp Guide rail Thumb/finger guard Pusher guard Carriage Last slice clamp handle Carriage handle Chain frame handle Chains On button Last slice clamp plate Off button Knurled nut Operating console... -

Page 11: Protective Devices

Description HA 810 Special Features Thumb guard Last slice clamp Hand rail Vario-Slice carriage Last slice clamp handle Bearing block star grip Tilting lever 2.2 Protective Devices Device Function Off button Switches the machine off immediately. Blade guard ring Prevents accidental contact with the blade. Limit stop lock Locks the limit stop when the carriage has been tipped off the machine. -

Page 12: Technical Data

Description 2.3 Technical data HA 800 HA 810 Dimensions L x W x H 600 x 840 x 450 mm 600 x 840 x 500 Workspace L x W x H 700 x 900 x 640 mm Space occupied L x W... -

Page 13: Basic Machine Equipment

Description 2.4 Basic Machine Equipment Semi-automatic slicing machine models HA 800 and HA 810 differ in terms of size and some characteristics of the carriage. All models share the same basic features: General Smooth, accessible high quality anodized surfaces Stove-enamelled finished lower part... -

Page 14: Options

This means that none of the following equipment is part of models HA 800 or HA 810. Please check your order documentation to see which of these options are part of your machine. -

Page 15: Operation

Operation 3 Operation 3.1 Operating Controls 3.1.1 Operating Console Display (graphical display) Signal lamp Symbol Designation Function Main “OFF” switch Switches off the machine. Main “ON” switch Switches on the machine. The machine is ready for slicing. Signal lamp Shows that the machine is ready for operation. Graphical display (only Indicates number of slices, cutting program, PLU, slice display!) - Page 16 Increases an edited value. Moves down in the selection menu. Increases the carriage strokes during operation. Menu button Calls subprograms. only HA 800) PLU button Switches on PLU mode, the Plus/Minus buttons can then be only VA 800) used to select the PLUs.

-

Page 17: Programs

If stacks are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you can enter the outer dimensions of the portioning units L x W for central placing. (Option only HA 800: the machine then uses the calibre recognition option to calculate the best placing point.) - Page 18 If rows are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you can enter the outer dimensions of the portioning units L x W for central placing. (Option only HA 800: the machine then uses the calibre recognition option to calculate the best placing point.)

- Page 19 If rows are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you can enter the outer dimensions of the portioning units L x W for central placing. (Option only HA 800: The machine then uses the calibre recognition option to calculate the best placing point.)

-

Page 20: Offset Function (Machines Without Calibration Recognition)

Operation 3.2.2 Offset Function (Machines without Calibration Recognition) On machines without calibration recognition, the “Offset function” can be used to slightly adjust the laying position on the tray, for example, a stack can be placed on the left, in the centre or on the right of the tray. Example: The plus “+”... -

Page 21: Using The Paper Clamp

Operation 3.3 Using the Paper Clamp Press down the lever on the right of the tray to the back. Lay the paper (or film) on the tray and push to the stop limits. Pull the lever to the front and the paper (or film) is clamped. - Page 22 Operation Push the guide rail towards the last slice clamp as far as required by the food to be sliced. Place the sausage to the wall of the carriage and hold in position with your left hand. Using the right hand, pull the guide rail until about 4 mm before the food product and tighten the locking screw (mini wing).

-

Page 23: Ha 810 With Vario-Slice Carriage

Operation Use the slicing thickness control to set the slicing thickness. The value shown in the display is the slice thickness in mm. Select the placing program and specify the number of slices with the +/- buttons if necessary. Take hold of the handle of the last slice clamp and swivel it to the “down”... -

Page 24: Tilting The Carriage To The V Position

Operation 3.5.1 Tilting the Carriage to the V Position Press the Off button to switch off the machine. Hold the carriage with your left hand by the black handle. Swievel the rocker arm on the right towards you so that the carriage unlatches. Using your left hand, tilt the carriage to the V position until you hear the carriage latch in. -

Page 25: Cutting With The Vs Carriage

Switch on the machine. Pull the carriage towards yourself if the display has not yet been enabled, i.e. you can only see the GRAEF logo. Select the program. Open the stop with the slicing thickness control (the slice thickness can be read off at the display). - Page 26 Operation Example: START Program Select function Stacking Circular Long fanning fanning Number of slices Number of rows/stacks Press for 2-3 seconds If programming is done in the sequence P1 P2 P3, the following happens after switching on the machine: “Long fanning” function, 3 rows of 8 slices, which is program “P3”. On changing functions, i.e.

-

Page 27: Changing The Standard Program (Plu=0000)

Operation 3.7 Changing the Standard Program (PLU=0000) In addition to simple variants, like changing the Slice count Number of stacks/rows (1-4) Carriage stroke speed (slices per minute, only for fully automatic machines) it is possible to adjust the following parameters Positions on the tray Placing format (option) Calibre mode (option) - Page 28 Operation Standard Stacking ¦ shingling — shingling o shingling General Reset Dist cross Dist slice X start Dist row Standard Dist length Dist slice Dist row Y start X start X start Dia circle X start Y start Y start Slices/row Y start Max.

- Page 29 Operation Dist length Lengthways distance: distance Stacking to the next slice in Y Dist slice Slice distance: distance to the Long fanning next slice Dist row Row distance: distance to the Cross fanning next row X start Moves the initial placing point Stacking, long fanning, cross fanning in X-direction Y start...

-

Page 30: The "M" Additional Menu (Option Ha 800)

Operation 3.7.2 The “M” Additional Menu (OPTION HA 800) You can access the placing format/ calibre mode/counting mode menu items by pressing button. If the continuous mode function is activated in the counting mode, the “Idle time” menu item appears additionally. - Page 31 Operation 3.7.2.1 Placing Format (Option HA 800) The machine can determine the calibre of the food placed on it. It bases all its calculations on a round calibre. You can therefore specify the placing format, i.e. the area in which the sliced food is to be placed, through the parameters “Length (L)” and “Width (W)”.

- Page 32 Operation Activation of calibre recognition “Auto” In this mode, the placing pattern is calculated automatically using the parameters, product width (B) and preset tray dimensions. The fanning distance, the distance between rows and the initial placing position on the tray are calculated by the software. b) “Semi”...

- Page 33 Operation 3.7.2.3 Counting mode The counting mode specifies whether a placing pattern based on the specified basic functions is to be placed once (normal mode) or is to be repeated (continuous mode). Example for normal mode: Basic function settings Stacking – 10 slices – 4 stacks (= pressed “X button” 3 times) When it is started, the machine slices 4 stacks of 10 slices and places them on the table.

-

Page 34: Slicing In The Plu Mode

Operation 3.7.3 Slicing in the PLU Mode Customer-specific placing patterns can be stored in the PLU programs. Specify “Slicing in Standard Mode” when you are preparing the machine and when you feed in the food to be sliced. From the program selection onwards, proceed as follows: Press the PLU button. -

Page 35: Programming A Plu

Operation 3.7.4 Programming a PLU Access the program menu by pressing buttons M+PLU. IMPORTANT! Always press and hold the “M” button and then press the “PLU” button in addition. Use the -/+ button to select “PLU”. Press the M button to confirm. The following menu appears: PLU MENU change... - Page 36 Operation PLU 1 Mode Stacking X number Slices Pattern Lengthwise Portions X start Y start Dist cross Dist length Strokes / min Thickness Idle time Use the +/- buttons to select the individual parameters (mode, X number, slices, arrangement, ... ). Pressing the M button then takes you to the editor where you can determine the value using the +/- buttons.

- Page 37 Operation Overview of PLU Parameters (Designation in brackets = old designation before March 2007) Parameter Description Possible settings / Remarks Mode Selection of basic placing Stacking program Long fanning Cross fanning Circular fanning X number Number of rows/ stacks 1 to 4 (Multi) Circular fanning: no parameter available Slices...

- Page 38 Operation Strokes / min Carriage speed in strokes Only for fully automatic machines (Speed) /min Thickness Indication of desired To enable the entry with the +/- buttons without needing thickness. It is indicated on decimals, the value to be entered is factored by 10. the display next to the S.

- Page 39 Operation Example: Programming PLU “10” Long fanning, 2 rows of 9 slices, with fanning distance 20, row distance 100, 1 portion, slice thickness 1.8 mm, slices per minute 50 (=strokes/min) Tray DELTA Y PLU 10 Mode Long fanning X number Slices Portion DELTA X...

-

Page 40: Cleaning

Cleaning 4 Cleaning The cleaning schedule is the basis for all cleaning procedures. WARNING! Rotating blade can cause serious injuries. Do not reach into the blade. To clean, switch off the machine and pull out the mains plug beforehand. When cleaning the blade, always wear protective gloves with wrist guards. CAUTION! The carriage is a moving part. -

Page 41: Disassembly Of The Removable Parts

Cleaning IMPORTANT! Do not lay removed parts on top of each other as this may damage parts. Only clean the beater and the chain frame with the brush provided. Do not press too hard. 4.1.1 Disassembly of the Removable Parts Tray: Lift the tray as shown in the picture. - Page 42 Cleaning Guide rail: Swivel up the last slice clamp as preparation. Pull the guide rail to the carriage wall with your right hand. Hold the guide rail as illustrated in the picture and lift it until the guide piece jumps out of the guide. Remove the guide rail from the carriage.

-

Page 43: Cleaning The Different Parts Of The Machine

Cleaning Blade cover plate: Secure the blade clover plate from falling with your right hand. Loosen the thumb wheel and pull it slightly out of the guide. Carefully lift the blade cover plate away from the blade with both hands and put it to one side. 4.2 Cleaning the Different Parts of the Machine 4.2.1 Blade and Blade Ring WARNING! -

Page 44: Carriage

Cleaning Press a damp cloth against the blade surface and wipe off the blade slowly from the centre to the edges. Clean the rear side of the blade in the same way. Rub the blade dry with a clean cloth in a similar fashion. -

Page 45: Chain Frame

Cleaning 4.2.3 Chain Frame Place the chain frame on its back on the table. Remove the wing bolt. Gently swing the guide comb out and place it on the side. Swing the pressing roller to the side as shown on the picture. - Page 46 Cleaning Gently jerk the protective cover out of its holding clips and swivel it away from the chains. Clean the cover with a cleaning cloth on all sides. CAUTION! The chain tips can cause injuries! Hold the chain frame by its handle. Use a brush to clean the chains.

-

Page 47: Cleaning Schedule

Cleaning 4.3 Cleaning Schedule Work Steps Cleansers Procedures Cleaning Equipment Note 1 Preparatory Close the slicing measures thickness control. Pull out the mains plug. 2 Disassembly of See operating removable parts instructions. 3 Rough manual Remove remaining food Plastic spatula; also Start directly. -

Page 48: Cleaning Procedure

You must also observe the safety and product data sheets that were included with the cleansers and disinfecting agents. If you do not observe them you may damage the machine. We will not accept any warranty claims if cleaning agents not approved by Graef are used. Never clean detachable parts in a dishwasher. -

Page 49: Assembly

Cleaning 4.4 Assembly Please observe the following during assembly! When you mount the chain frame, make sure That is carefully attached at all three holding points. If necessary, turn the clutch hub (2) manually until the coupling engages. When placing on the pressing roller swing it away from the stop limit. - Page 50 Cleaning Correct position 3 Carriage: Insert the carriage bold in the bearing block and push the carriage carefully to the working position. CAUTION! Press the carriage on the bearing block by hand and make absolutely sure you tighten the star grip. A loose carriage can cause injuries to the operator, damage the machine and result in poor slicing performance.

-

Page 51: Maintenance

Maintenance 5 Maintenance 5.1 Sharpening the Blade WARNING! Rotating blade can sever fingers! Only sharpen the blade with the sharpener provided. The sharpener has been adjusted for this machine and must be used for this machine only. The machine number and the number on the sharpening device must be identical. -

Page 52: Preparing The Machine

Maintenance 5.1.2 Preparing the Machine Thoroughly clean the machine and the blade. Remove the last slice clamp, the guide rail, the feed carriage (VA 802 only), the blade cover plate, the beater and the chain frame. Put the last slice clamp down on the carriage and move this to right, as far away as possible from the blade. - Page 53 Maintenance Grind until a slight cutting ridge is formed. Switch off the machine with the red Off button. Slide a sharpened pencil slowly to the cutting edge as illustrated. Do you feel any resistance at the blade cutting edge? That is the cutting ridge produced from sharpening. If no edge has been formed, repeat the steps described above.

-

Page 54: Changing The Blade

5.2 Changing the Blade WARNING ! The blade is sharp! It can cause serious injury even when it is not moving. The blade may only be replaced by authorised GRAEF service personnel. CAUTION! The blade must be replaced: when the distance between the blade guard ring and the blade is larger than 6 mm. -

Page 55: Lubricating

Maintenance 5.3 Lubricating Use only the GRAEF special lubricating oil with H1 certification that is included in delivery. Chain frame: 2-3 drops in each of the 8 tensioning roller bearings. Linear guide rod: Lubricating interval: As required, whenever the last slice clamp is difficult to move. -

Page 56: Faults And Operating Errors

Faults an Operating Errors 6 Faults and Operating Errors CAUTION! Switch off the machine immediately if it emits unusual noises, malfunctions or if you suspect it could cause injuries. Call customer service if you cannot solve the problem yourself. Fault Cause Measure Carriage stops during operation... -

Page 57: Service

7 Service IMPORTANT! Only use genuine GRAEF spare parts. The use of other parts will invalidate the warranty (see also the declaration of conformity) Contact your GRAEF customer service If you require service or spare parts.

Need help?

Do you have a question about the HA 800 and is the answer not in the manual?

Questions and answers