Bentone BG 300-2 Installation And Maintenance Instruction

Hide thumbs

Also See for BG 300-2:

- Installation and maintenance instruction (44 pages) ,

- Installation and maintenance instruction (48 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Bentone BG 300-2

- Page 1 178 001 72-4 2018-03-23 Providing sustainable energy solutions worldwide Installation- and maintenance instruction BG 300-2...

- Page 2 Bentone...

-

Page 3: Table Of Contents

9.2 Wiring diagram LME _________________________________________ 34 9.3 List of components __________________________________________ 35 9.4 Control program at faults; fault mode indicator LME ..___________ 36 10. Troubleshooting _____________________________________________ 38 11. EU Declaration of conformity _________________________________ 41 13. General instructions for gasburners ____________________________ 42 Bentone... -

Page 4: General Information

• Burner pipes, fan wheels and air dampers may contain sharp edges. • The surface temperature of the burner’s components can exceed 60 °C. • Caution: The burner has moving parts, and there is risk of crushing injuries. 172 515 01 2018-01-02 Bentone... - Page 5 Open windows and doors. Close the gas ball valve. Warn residents; do not use doorbells. Evacuate the building. Notify the installer or gas supplier once the building has been evacuated. Bentone...

- Page 6 Delivery check • Make sure everything is delivered and the goods have not been damaged during transit. • If something is wrong with a delivery, report it to the supplier. • Transport damage must be reported to the shipping company. Bentone...

-

Page 7: Technical Data

BG 300 * The above dimensions are max. measurements. Depending on the components used, the measurements may vary. ** Min. recommended distance to loor. ***Dimensions when installing blast tubes from the inside of the boiler 172 515 62 2018-02-02 Bentone... - Page 8 BG, CZ, DE, EE, ES, FR, GR, HU, IS, 2R/3R IT, LU, LV, NO, PT, SI, All countries 20-360mBar AT, CH, CY, DK, FI, LT, RO, SE, 2H3B/P 20-360mBar GB, IE, 2H3P 20-360mBar NL, RO 2L3B/P 20-360mBar 2E3B/P 20-360mBar 2E(R)B 20-360mBar Bentone...

- Page 9 Alt.2 The burner’s noise level can be reduced by connecting the burner’s air intake to the air duct that opens into an appropriate location. Installation must be done so it does not prevent air supply to the burner. Bentone...

-

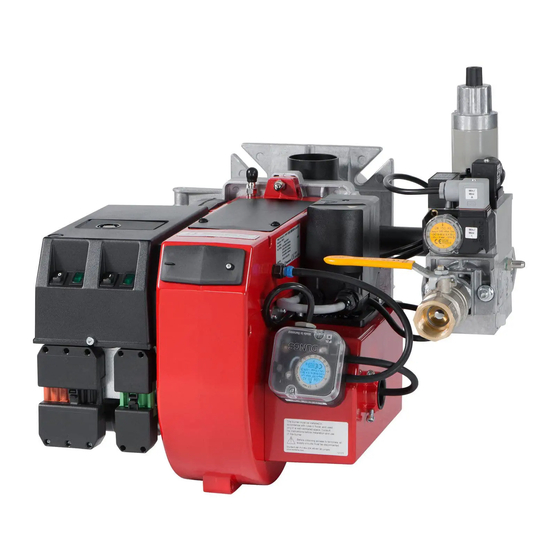

Page 10: Description Bg 300

Cover, inspection glass Air damper Ionization electrode Reset button Air intake Transformer Air pressure switch Ignition electrode Inner assembly Damper motor Electric panel Nozzle Brake plate Inner assembly adjustment Indicating lamp Stage 2 (not town gas) Indicating lamp Stage 1 Bentone... -

Page 11: General Instruktions

Adjust the burner to appr. 20% excess air in accordance with the table. Check the lue gas temperature. Calculate the eficiency. Check also the actual gas volume on the gas meter so that the correct input is achieved. 172 515 03 2018-01-02 Bentone... -

Page 12: Installation

If not, use the connectors included. (Refer to connection under Electric equipment) If an electric connection other than the one recommended by Enertech is used, a risk of damage and injury can arise. 172 515 03 2018-01-02 Bentone... -

Page 13: Skeleton Diagrams

Safety valve 1)7. Valve proving system Air pressure switch Gas burner control Pos. 5b, 7: Components not required according to EN 676. Required over 1200 kW according to EN 676.hhh 172 515 05 2018-01-02 Bentone... -

Page 14: Mounting On The Boiler

Connect the gas to the burner by means of the ball valve. Ensure that the union nut, ball valve and tubing make it easy to remove the burner for inspection and service. Check the gas tightness. 172 515 06 2018-01-02 Bentone... -

Page 15: Inspection Of Gas Nozzle Before Commissioning

2 and just before the end of the pre-purging period it goes down to the air setting for stage 1. On some burners under 350kW the pre-purging mainly takes place with the air damper set for stage 1. 172 515 08 2018-01-02 Bentone... -

Page 16: Gas Nozzle

4.8 Gas nozzle Natural gas Propan Biogas (UV detector) 172 515 08 2018-01-02 Bentone... -

Page 17: Setting Air Damper

This function facilitates an exchange of damper motor. Solenoid valve High capacity (black) High capacity (red) Low capacity (orange) Closed damper (blue) Releasing button N.B! The upper position is the standard positiont 172 515 14 2018-01-02 Bentone... -

Page 18: Setting The Burner

Loosen the nuts a. Swing out the burner. Remove the screw b and the knob for adjustment of burner head. Loosen the screw c so much so that the inner assembly can be pulled out. Control of burner head 172 515 10 2018-01-02 Bentone... - Page 19 Howerer, study the sections dealing with adjustments of multi-bloc, combustion air and combustion head. Gas quality max. CO lambda 1,2 Open the ball valve and switch on the main switch. If the Natural gas 10,0 11,9 burner starts the actual adjustment can be made. 11,5 13,9 Bentone...

-

Page 20: Setting The Air Pressure Switch

This is to ensure the reliable function of the burner. If breakdowns or interruptions occur, the air pressure switch is probably set to a too narrow position. Fit the protective cover, screw (Y). Bentone... -

Page 21: Setting The Min. Gas Pressure Switch

The tolerance on the scale for the min. gas pressure switch is approx. ±15%. Open the ball valve. Remove the pressure gauge and close the pressure outlet (X). Check the gas tightness. Fit the protective cover, screw (Y). Bentone... -

Page 22: Multiblock Mb-Zrdle 405-412

2. Knob for adjustment of stage 1 Turn to the left = the start gas l ow is Test nipple, pressure after governor increased. Test nipple for nozzle pressure Filter Fixing l ange Ball valve 172 515 11 2018-01-03 Bentone... - Page 23 Turn to the right = the outlet pressure is increased Turn to the left = the outlet pressure is reduced Adjustment of start gas low Adjustment of governor Multi-bloc MB-ZRDLE 405-420 Flow adjustment 172 515 11 2018-01-03 Bentone...

- Page 24 5.5.1 Pressure taps 1,2,3,4,5 1/8 screwed sealing plug 5.5.2 Electrical connection S 20/S 50 172 515 11 2018-01-03 Bentone...

-

Page 25: Recommended Excess Air When Using Default Setting

Lower heat value Hu at normal state 15°C and 1013.25 mbar EN676 Grade of gas kWh/Nm MJ/Nm kcal/Nm Natural gas 34.02 8126 Natural gas 29.25 6986 Propane 24.6 88.00 21019 Butane 32.5 116.09 27728 172 515 13 2018-01-02 Bentone... - Page 26 Temperature of gas at the gas meter [°C] Barometer reading [mbar] Pressure of gas at the gas meter [mbar] Factor calculated for multiplication with low in Nm /h to arrive at actual low in Nm Actual low · 273+T 1013.25 Bentone...

-

Page 27: Calculating The Quantity Of Gas Supplied

= Time for a certain quantity of gas consumed by the burner. M = Quantity of gas consumed. V = Actual gas low Calculation example: t = 1 min 10 s M = 330 dm (litre) 0.33 m 1000 0.0194 h 3600 0,33 ≈ 17 m 0.0194 Bentone... -

Page 28: Service

Check the ionisation electrode (see chapter Gas nozzle). Replace if necessary. Fit the combustion assembly in reverse order. Press the burner together and lock using the nuts (B). Fit the Euro plugs and turn on the main power supply. Check/adjust the combustion. 172 615 08 2018-01-03 Bentone... -

Page 29: Replacement Of Damper Motor, Air

Re-install the damper motor and mounting plate on the air intake. Ensure that the damper shaft and control arm are connected correctly. Connect the damper motor cable. Fit the Euro plugs and turn on the mains power. Check/adjust the combustion. Bentone... -

Page 30: Flame Monitoring And Ionisation Current Check

Min. DC 1.5 µA Required current to ensure Min. DC 3 µA detection Possible detection current Max. DC 20 µA Operational indicator lamp <5 µA DC lashes green Operational indicator lamp >5 µA DC shines green 172 615 02 2018-01-02 Bentone... -

Page 31: Uv-Detector

AGQ3...A27 is mandatory. Correct functioning of aged UV cells can be checked as UV test with a higher supply voltage across the UV cell after controlled shutdown until terminal 3 ON. Connection diagram Measuring circuit for measuring the UV lame current Measurement made at the lame detector QRA… Bentone... -

Page 32: Handing Over Of The Installation

• Is the circulation pump in operation? • Is there a supply of fresh air to the installation? • If integral components are of a different make from what is stated in this manual, see the enclosed loose-leaf. 172 615 04 2018-01-02 Bentone... -

Page 33: Electric Equipment

Signals must be in different harnesses for safety reasons. Safety system as door switches, water level, pressure, temperature and other safety limiters must be installed in safety loop according to process. 172 615 13 2018-01-12 Bentone... -

Page 34: Wiring Diagram Lme

If there is no Plug-in If S6 is missing connect T6 and T8. contact (X4,X6) on the boiler, connect to the contact enclosed. 1N~50/60Hz 230V... -

Page 35: List Of Components

The operation of the burner can now be stopped with the control switch or thermostat If the gas burner control is blocked Red light in the gas burner control is lit. The burner is restarted by pushing the reset button Bentone... -

Page 36: Control Program At Faults; Fault Mode Indicator Lme

(waiting period ≥ 10 s) 9.4.1.2 Limiting of starting repetitions LME 11... has a function with start repetition if the lame is not created at start or disappears during operation.. LME 11... allows max. three repetitions during continuous starting cycle. Bentone... - Page 37 3 s. To go back to the normal position, press and hold the reset button longer than 3 s. If the gas burner control is in the alarm position, it is reset by pressing the reset button 0.5...3 s. Bentone...

-

Page 38: Troubleshooting

Replace solenoid valve terminals, or entire valve No power to solenoid valve Check the connection No electrical connection through air pressure gauge Check the air pressure gauge’s settings and functions Ignition load incorrectly set Increase/decrease gas supply Reduce airlow 172 615 06 2018-01-10 Bentone... - Page 39 Incorrectly set or faulty air sensor Check the settings and reset, or replace Ignition electrode overload Replace Burner control ambient temperature too high Insulate for heat, Max. 60 ° Ignition spark too weak Check the transformer Poor combustion Poor draught conditions Check the chimney Bentone...

- Page 40 Flame at incorrect angle due to combustion head out of position Check the combustion head and readjust Condensation build up in boiler and chimney Flue gas temperature too low or gas volume too low Raise the lue gas temperature by increasing gas volume Insulate the chimney Bentone...

-

Page 41: Eu Declaration Of Conformity

11. EU Declaration of conformity Bentone Gasburners 172 905 04 2018-02-15... -

Page 42: General Instructions For Gasburners

13. General instructions for gasburners 13.3.1 Installation Follow standards and instructions applicable to the Check that the burner is adapted to the gas quality in installation of gas burners question Ensure that the electric installation is made in accordance Check that the input pressure of the gas is correct with existing regulations Check that the dampers of the boiler are open Check that the fresh air intake of the boiler room is... - Page 43 Service- and inspection card Installation Boiler Name: Type: Eficiency kW: Address: Burner Type: Eficiency kW: Installed by: Date: Date gas/h Governor Fluegas Ionisation Pressure Eficiency temp current Fire Chimney room Measu- rement Before After °C µ A mbar mbar Small Flame Large Flame...

- Page 48 Enertech AB. P.O Box 309, SE-341 26 Ljungby. www.bentone.se, www.bentone.com...

Need help?

Do you have a question about the BG 300-2 and is the answer not in the manual?

Questions and answers