Summary of Contents for Generac Power Systems MAC400HC

- Page 1 MAC400FHC Flameless Heat Cart Owner’s Manual 004390 MODEL NUMBER: _________________________ SERIAL NUMBER: _________________________ DATE PURCHASED:________________________ SAVE THIS MANUAL FOR FUTURE REFERENCE...

- Page 2 WARNING CANCER AND REPRODUCTIVE HARM www.P65Warnings.ca.gov. (000393a) Owner’s Manual for Flameless Heat Cart...

-

Page 3: Table Of Contents

Table of Contents Section 1: Introduction and Safety Section 4: Maintenance Introduction ..............1 Maintenance ...............17 Read This Manual Thoroughly ........1 Maintenance Tasks ............17 Safety Rules ..............1 Daily Walk Around Inspection ........17 How to Obtain Service ..........1 Draining and Refilling the Oil ........17 General Hazards ............2 Adding Coolant ............18 Explosion and Fire Hazards ........2... - Page 4 This page intentionally left blank. Owner’s Manual for Flameless Heat Cart...

-

Page 5: Section 1: Introduction And Safety

Introduction and Safety Section 1: Introduction and Safety Introduction Throughout this publication, and on tags and decals affixed to the unit, DANGER, WARNING, CAUTION, and Thank you for purchasing a Generac Mobile Products, NOTE blocks are used to alert personnel to special LLC product. -

Page 6: General Hazards

Introduction and Safety General Hazards CAUTION DANGER Unit damage. Do not stop engine before heating Asphyxiation. Running engines produce unit is cooled. Doing so could result in unit damage. carbon monoxide, a colorless, odorless, poisonous gas. Carbon monoxide, if not (000240a) avoided, will result in death or serious injury. -

Page 7: Towing Hazards

Introduction and Safety WARNING WARNING Risk of burn. Do not open or mutilate batteries. Explosion and fire risk. Do not smoke near unit. Batteries contain electrolyte solution which can Keep fire and spark away. Failure to do so could cause burns and blindness. If electrolyte contacts result in death, serious injury, or property or skin or eyes, flush with water and seek immediate equipment damage. - Page 8 Introduction and Safety This page intentionally left blank. Owner’s Manual for Flameless Heat Cart...

-

Page 9: Section 2: General Information

General Information Section 2: General Information Specifications Heater 400,000 BTU/hour (117.2 kW/hour) maximum Type Flameless Power Isuzu 4LE2X Tier 4 turbo diesel, 66 HP (49.2 kW) Operating Speed 2400 rpm Engine Controls/Display IFM CR0403 / Murphy PV405 Air Velocity 3600 CFM (6116 m /hour) Battery 950CCA wet cell battery... -

Page 10: Internal Component Locations

General Information Internal Component Locations 001920 001918 Figure 2-1. Heater Components Engine radiator Diesel oxidation catalyst Air filter Engine oil dipstick Hydraulic fluid breather/separator Diesel injection system Hydraulic fluid fill Fuel pump Reservoir fluid-level indicator Fuel filters Hydraulic fluid reservoir Engine oil filter Hydraulic fluid filters Engine oil cooler... -

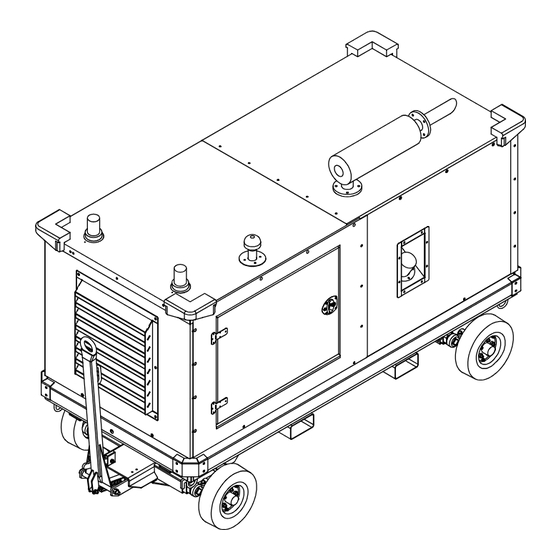

Page 11: External Component Locations

General Information External Component Locations 004395 Figure 2-2. External Components Muffler Ducting storage (rear) Air intake cap Diesel fuel fill Tie-down rings Street side engine access Tow hitch Temperature beacon (amber) Parking brake lever Low fuel level beacon (blue) Curb side engine access Control panel Fork lift pockets Owner’s Manual for Flameless Heat Cart... -

Page 12: Emissions Information

General Information Emissions Information recommended to eliminate the need for repeated drain- ing and refilling. Follow these antifreeze/water guidelines: See the diesel engine manual for more information. • A 50/50 ethylene glycol base antifreeze/water mix, which provides protection to -34 °F (-37 °C), is Engine Oil Recommendations recommended for use in this engine. -

Page 13: Hydraulic Oil

General Information Driving a vehicle with a cart in tow is vastly different than driving the same vehicle without a cart in tow. Consider Applicable Standard Recommendation the following: JIS (Japanese Industrial Standard) No. 2 • It takes longer to get up to speed. DIN (Deutsche Industrie Normen) DIN 51601 •... -

Page 14: Controller

General Information Monitoring, Diagnostic, and Protective Features Mechanical and electrical systems are connected to vari- ous sensors that monitor unit status. The controller will automatically stop the unit and display fault information if conditions occur outside of predetermined manufacturing parameters. The controller can also display a variety of critical alerts, diagnostics, and recommendations. -

Page 15: Section 3: Operation

Operation Section 3: Operation Theory of Operation Engine Oil Level Check The flameless heater generates heat by running pressur- ized fluid through a restrictive orifice, which drops the CAUTION hydraulic pressure and results in heated fluid. A fan then blows air over the heat exchanger to push heated air out Engine damage. -

Page 16: Ducting Guidelines

Operation Ducting Guidelines CAUTION WARNING Equipment or property damage. Do not block air intake or restrict proper air flow. Doing so could Burn hazard. Do not remove ducting until all air result in unsafe operation or damage to unit. pressure has been emptied from hose duct. (000229) Failure to do so could result in severe injury. -

Page 17: Adjusting Heater Output

Operation 9. See Figure 3-5. When the heater is warm, heat begins blowing from ducts, the amber strobe light on top of the unit activates, and the screen displays “Heater On — Press OFF to stop the heater”. 001584 Figure 3-2. Start Engine 6. -

Page 18: Heater And Engine Shutdown

Operation • For maximum fan, press MAX FAN (Figure 3-7, item B). Maximum fan produces a lower tempera- ture at a higher air flow. 001583 Figure 3-9. Cooling Complete 2. Turn ignition key to OFF. 001579 Figure 3-7. MANUAL Mode CAUTION Heater and Engine Shutdown Unit damage. -

Page 19: Testing The Pas

Operation 5. Reset the T-handle. 6. Repeat steps in Engine and Heater Startup start unit. 004471 Figure 3-10. Reset Handle in Ready State 004470 Figure 3-11. Emergency Stop T-Handle Testing the PAS Test the PAS at least once a month to ensure optimal valve performance. -

Page 20: Owner's Manual For Flameless Heat Cart

Operation This page intentionally left blank. Owner’s Manual for Flameless Heat Cart... -

Page 21: Section 4: Maintenance

Maintenance Section 4: Maintenance Maintenance Draining and Refilling the Oil Regular maintenance will improve performance and WARNING extend engine/equipment life. Generac Mobile Products, LLC. recommends that all maintenance work be per- Risk of burns. Allow engine to cool before formed by a Generac Mobile Products Authorized Ser- draining oil or coolant. -

Page 22: Adding Coolant

Maintenance If coolant level is below the filler neck, coolant must be added. (See Coolant Recommendations.) Proceed as follows to add coolant: 1. Verify engine is stopped and cooled. 2. Remove radiator cap. 3. Fill radiator slowly with coolant until it comes up to filler neck. -

Page 23: Engine Maintenance Schedule

Maintenance Engine Maintenance Schedule To protect the warranty status of the engine, engine maintenance and repairs should be performed by a GMP ASD. For more information on the checks and maintenance described below, see the engine manual. • Check engine oil, coolant, hydraulic oil, and engine fuel levels. •... -

Page 24: Other Maintenance Checks

Maintenance • Change engine oil and oil filter element. • Inspect engine accessory drive belts. • Inspect fuel supply system. • Clean cooling system circuit. • Inspect and clean the starter and alternator (*). At 1000 Operation Hours • Inspect valve clearance (*). •... -

Page 25: Battery Inspection

Maintenance Battery Inspection Once every six months, a GMP ASD should inspect the battery system. At this time, the battery condition and state of charge should be checked using a load test WARNING battery. The battery should be recharged or replaced as required. -

Page 26: Other Maintenance Checks

Maintenance Other Maintenance Checks The following inspections should be performed by an authorized service technician, or a properly trained authorized operator. These maintenance items require a high level of experience and skill to evaluate and correct. • Inspect exhaust pipe sleeve. Short Term Storage When the unit will not be in use for three or more months, follow the guidelines below to properly store the unit:... -

Page 27: Section 5: Troubleshooting

Troubleshooting Section 5: Troubleshooting General Troubleshooting Guide Problem Cause Solution Verify there is no fuel leakage and No fuel. replenish. Insufficient oil level. Replenish oil to full. PAS is ON. Turn PAS to OFF. See Resetting the PAS. Air in fuel system. Purge air from fuel system. - Page 28 Troubleshooting Problem Cause Solution Insufficient warm-up time. Conduct warm-up operation. Correct oil level. See Draining and Refill- Excessive engine oil. ing the Oil. Engine control system failure. Exhaust smoke is white Injection pump failure. Contact a GMP ASD. Fuel system failure. Excessive idling (more than two hours).

- Page 29 Troubleshooting Problem Cause Solution Access doors are open. Close all access doors. Open the air outlets and verify there are no Air outlets are closed. obstructions or tight bends in the ducting. Overheat/shutdown Front radiator or rear oil cooler are full of Clean the unit.

-

Page 30: Digital Controller Status Messages

Troubleshooting Digital Controller Status Messages Message Cause Engine Warming — Please Wait Engine coolant temperature < 140 °F (38 °C). Engine Preheat Wait approximately 10 seconds after heater powers up. Engine rpm < 500 Engine is not ready — Check rpm, Fuel Level or Wait to Fuel level <... -

Page 31: Section 6: Installation Diagrams

Installation Diagrams Section 6: Installation Diagrams Engine Harness (1 of 3) Owner’s Manual for Flameless Heat Cart... -

Page 32: Engine Harness (2 Of 3)

Installation Diagrams Engine Harness (2 of 3) Owner’s Manual for Flameless Heat Cart... -

Page 33: Engine Harness (3 Of 3)

Installation Diagrams Engine Harness (3 of 3) Owner’s Manual for Flameless Heat Cart... -

Page 34: Hydraulic System Schematic

Installation Diagrams Hydraulic System Schematic 3-Way Valve Pressure Regulating 3-Way Valve Start-up Bypass Large Hydraulic Exchanger Small Hydraulic Exchanger Filters Hydraulic Oil Tank Owner’s Manual for Flameless Heat Cart... -

Page 35: Hydraulic Heat System

Installation Diagrams Hydraulic Heat System LARGE EXHAUST EXCHANGER C60 HYD EXCHANGER ENGINE RADIATOR Owner’s Manual for Flameless Heat Cart... - Page 36 Installation Diagrams This page intentionally left blank. Owner’s Manual for Flameless Heat Cart...

- Page 37 Installation Diagrams This page intentionally left blank. Owner’s Manual for Flameless Heat Cart...

- Page 38 Installation Diagrams This page intentionally left blank. Owner’s Manual for Flameless Heat Cart...

- Page 40 Part No. 10000012492 Rev. B 05/16/2018 ©2018 Generac Mobile Products, LLC All rights reserved. Specifications are subject to change without notice. Generac Mobile Products, LLC No reproduction allowed in any form without prior written 215 Power Drive, Berlin, WI 54923 consent from Generac Mobile Products, LLC.

Need help?

Do you have a question about the MAC400HC and is the answer not in the manual?

Questions and answers