Summary of Contents for Generac Power Systems MIH800

- Page 1 MIH800 Indirect Fired Heater Owner’s Manual 010409 For technical assistance contact: www.generacmobileproducts.com Technical Support 1-800-926-9768 SAVE THIS MANUAL FOR FUTURE REFERENCE...

- Page 2 Use this page to record important information about your mobile heater Record the information found on your unit data label on Unit Model No. Unit Serial Number Locations. this page. See Engine and generator serial numbers are located on data Unit Serial No.

-

Page 3: Table Of Contents

Table of Contents Section 1: Introduction and Safety Ducting Guidelines ..........15 Engine and Heater Startup ....... 16 Introduction ............1 Read This Manual Thoroughly ........1 Adjusting Heater Output ........16 Intended Applications .........1 Engine and Heater Shutdown ......17 Safety Rules ............1 Thermostat ............ - Page 4 This page intentionally left blank. Owner’s Manual for Indirect Fired Heater...

-

Page 5: Section 1: Introduction And Safety

• Emergency thawing maintained properly. • Pre-warming of equipment and motors The MIH800 indirect fired heater is designed and built for Offshore drilling rigs • sustained, reliable heat production in industrial operating • Painting and coating locations conditions and environments. -

Page 6: How To Obtain Service

Introduction and Safety WARNING CAUTION Hot Surfaces. When operating machine, do not Indicates a hazardous situation which, if not avoided, touch hot surfaces. Keep machine away from could result in minor or moderate injury. combustibles during use. Hot surfaces could result in severe burns or fire. -

Page 7: Trailer Hazards

Introduction and Safety Battery Hazards WARNING WARNING Fire risk. Fuel and vapors are extremely flammable. Do not operate indoors. Doing so Explosion. Do not dispose of batteries in a fire. could result in death, serious injury, or Batteries are explosive. Electrolyte solution can cause property or equipment damage. -

Page 8: Hitch And Coupling

Introduction and Safety states require that large trailers be registered and Reporting Trailer Safety Defects licensed. Contact your local Department of Transporta- If you believe your trailer has a defect which could cause tion (DOT) office to verify license requirements for your a crash, injury, or death, you should immediately inform particular unit. -

Page 9: Safety And Operating Decals

Introduction and Safety Safety and Operating Decals Figure 1-1. This unit features numerous safety and tions. Replace any missing or hard-to-read decals and operating decals. These decals provide important operat- use care when washing and cleaning the unit. Decal part ing instructions and warn of dangers and hazards. - Page 10 Introduction and Safety This page intentionally left blank. Owner’s Manual for Indirect Fired Heater...

-

Page 11: Section 2: General Information

Section 2: General Information Specifications Description Unit of Measure MIH800 Engine ® Make (Model) — Isuzu (3CE1) EPA Certification tier 4 Final Type — Naturally aspirated Horsepower At Operating Speed hp (kW) 21.1 (15.7) Operating Speed 1,800 Displacement 97.6 (1.6) -

Page 12: Unit Dimensions

General Information Unit Dimensions 010064 Figure 2-1. MIH800 186 in (4.72 m) 72 in (1.83 m) 91.5 in (2.32 m) Unit Serial Number Locations Figure 2-2 for unit ID tag and Vehicle Identification information from these tags so it is available if the tags Number (VIN) tag. -

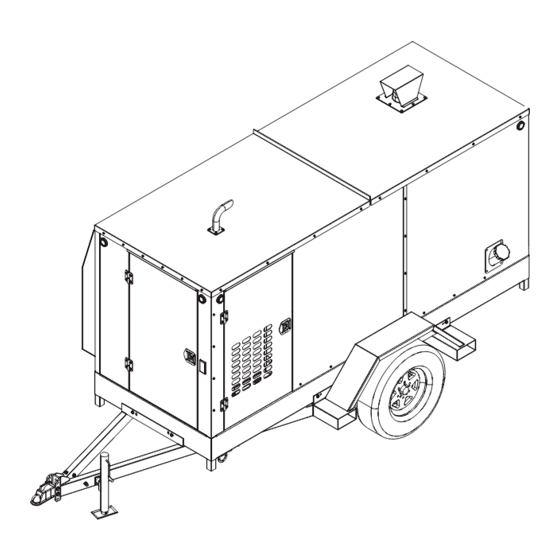

Page 13: Component Locations

General Information Component Locations Exterior 010410 Figure 2-3. Exterior Components Engine exhaust Tie-down (4 locations) Burner exhaust Control panel access door Reflector light (multiple locations) Inlet vent Fuel fill Hot air discharge ducts Forklift pocket (4 locations) Burner and thermostat access door Engine access door Owner’s Manual for Indirect Fired Heater... -

Page 14: Engine

General Information Engine 004144 Figure 2-4. Engine Components Generator Engine oil filter Battery Radiator Engine air cleaner assembly Coolant sub-tank (not shown) Engine fuel pump Engine oil fill Water separator assembly Breakaway brake system Engine oil dipstick Engine fuel filter Owner’s Manual for Indirect Fired Heater... -

Page 15: Heater

General Information Heater 010412 Figure 2-5. Heater Components Differential pressure meter Burner fuel filter Thermostat Burner reset Electrical junction box Diesel fired burner Fan limit controller Owner’s Manual for Indirect Fired Heater... -

Page 16: Control Panel

General Information Control Panel 008962 Figure 2-6. Control Panel Engine control box and ignition Blower STOP button Fuel gauge Blower ON indicator lamp Burner ON-OFF switch Blower OFF indicator lamp Blower START button Control panel main disconnect switch Owner’s Manual for Indirect Fired Heater... -

Page 17: Emissions

General Information Emissions Fuel System The United States Environmental Protection Agency (US DANGER EPA) (and California Air Resources Board (CARB), for engines/equipment certified to California standards) Explosion and Fire. Fuel and vapors are requires this engine/equipment to comply with exhaust extremely flammable and explosive. -

Page 18: Wheel Chock Guidelines

General Information Wheel Chock Guidelines WARNING WARNING Personal injury. Do not operate unit during transport. Doing so could result in death, serious injury, or Crushing hazard. Verify unit is properly secured and property damage. on level ground. An unsecured unit can suddenly roll (000231a) or move, causing death or serious injury. -

Page 19: Section 3: Operation

Section 3: Operation Before Starting Engine 2. Slowly insert the clean oil dipstick into the oil dip- stick tube. Verify the oil dipstick is fully seated. 3. After 10 seconds, remove the oil dipstick and look Pre-start Checklist at the oil level on both sides. The lower of the two readings will be the correct oil level measurement. -

Page 20: Engine And Heater Startup

Operation • Tightly secure ducting end to the unit. Verify any CAUTION additional ducting is also tightly secured. • Avoid sharp bends or 90° turns in the ducting. Equipment damage. Do not cover unit during Use only the necessary length of ducting required; •... -

Page 21: Engine And Heater Shutdown

Operation Engine and Heater Shutdown Thermostat Control 1. Press the MENU button. The LCD screen displays CAUTION OFF. 2. Scroll through parameter codes by pressing the UP Equipment damage. Shut down the heater before or DOWN arrow button. turning off the generator. Failure to do so could result in equipment damage. - Page 22 Operation This page intentionally left blank. Owner’s Manual for Indirect Fired Heater...

-

Page 23: Section 4: Maintenance

Section 4: Maintenance Maintenance Draining and Refilling the Oil Regular maintenance will improve performance and WARNING extend engine/equipment life. Generac Mobile recom- mends that all maintenance work be performed by a Risk of burns. Allow engine to cool before GMASD. Regular maintenance, replacement, or repair of draining oil or coolant. -

Page 24: Adding Coolant

Maintenance IMPORTANT NOTE: Do not overfill oil pan. Overfilling may result in white exhaust smoke, sudden over engine speed, or engine damage. Adding Coolant DANGER Risk of poisoning. Do not use mouth to siphon coolant. Doing so will result in death or serious injury. -

Page 25: Maintenance Schedule

Maintenance Maintenance Schedule Periodic inspection, service, and maintenance of this unit Follow all applicable safety alerts in this manual or the is critical to ensuring reliable operation. The following is engine service manual before performing any mainte- the manufacturer’s recommended maintenance sched- nance checks or service. - Page 26 Maintenance • Drain water from fuel filters. • Add coolant. Replace air filter element. • Inspect primary air filter element. • As Required • Replace fan belt. • Inspect fuses. • Inspect electrical wiring and connections. Purge fuel system. • During the initial operation of a new or rebuilt engine with Break-In Plus, change the oil and filter between a minimum of 100 hours and a maximum of up to 500 hours.

-

Page 27: Battery Inspection

Maintenance Battery Inspection A GMASD should inspect the battery system once every six months. At this time, the battery condition and state of charge should be checked using a load test battery. DANGER Recharge or replace the battery as required. Electrocution. -

Page 28: Other Maintenance Checks

Maintenance Other Maintenance Checks Return to Service The following inspections should be performed by an Follow the guidelines below for engines and machines authorized service technician, or a properly trained auth- that have not been operated for three to six months: orized operator. -

Page 29: Section 5: Troubleshooting

Section 5: Troubleshooting General Troubleshooting Guide Problem Cause Solution Bat- Low battery output voltage or discharged Charge or replace batteries. See tery Inspection. battery. Loose or corroded connections. Clean and tighten connections. Faulty start circuit relay. Contact a GMASD. Engine will not crank Blown fuse. - Page 30 Troubleshooting Problem Cause Solution Poor fuel quality; incorrect fuel/dirty fuel. Test fuel, drain water from fuel bowl. Restricted fuel filter. Replace fuel filter element. Water, dirt, or air in fuel system. Drain, flush, fill, and purge fuel system. Engine misfiring or runs Low coolant temperature.

- Page 31 Troubleshooting Problem Cause Solution Restricted fuel return line. Check and fix fuel return lines. Fuel in oil Engine load too light. Increase engine load. Leaking fuel injectors. Contact a GMASD. Restricted fuel filter. Replace fuel filter. Restricted fuel line. Locate restriction, repair as required. Low-pressure fuel system Faulty transfer pump.

- Page 32 Troubleshooting Problem Cause Solution Replace air cleaner element as Restricted or dirty air cleaner. required. Drain fuel and replace with proper Incorrect type of fuel. grade, type, and quality of fuel for oper- ating condition. Engine emits black, gray, or Engine burning oil.

- Page 33 Troubleshooting Problem Cause Solution Drain crankcase and refill with correct Draining and Refill- Insufficient crankcase oil viscosity. viscosity oil. See ing the Oil. Drain oil until oil level is correct. See Excessive crankcase oil. Draining and Refilling the Oil. Determine source of oil leak(s) and External oil leak(s).

- Page 34 Troubleshooting This page intentionally left blank. Owner’s Manual for Indirect Fired Heater...

-

Page 35: Section 6: Wiring Diagrams

Section 6: Wiring Diagrams Cabin Harness Wiring GROUP G WIRE COLOR WIRNG - DIAGRAM REVISION: -A- WD SD-MIH800 CABIN DRAWING #: A0000261121 DATE: 7/11/19 PAGE 1 OF 6 Owner’s Manual for Indirect Fired Heater... -

Page 36: Control Box Components

Wiring Diagrams Control Box Components GROUP G COMPONENTS LOCATED IN CONTROL BOX MLCB CB1 CB2 GNDR GNDB WIRNG - DIAGRAM REVISION: -A- WD SD-MIH800 CABIN DRAWING #: A0000261121 DATE: 7/11/19 PAGE 2 OF 6 Owner’s Manual for Indirect Fired Heater... -

Page 37: Cabin Harness Schematic

Wiring Diagrams Cabin Harness Schematic GROUP G MLCB GNDB GNDL SCHEMATIC - DIAGRAM REVISION: -A- WD SD-MIH800 CABIN DRAWING #: A0000261121 DATE: 7/11/19 PAGE 3 OF 6 Owner’s Manual for Indirect Fired Heater... -

Page 38: Trailer Wiring

Wiring Diagrams Trailer Wiring 3020688_B_10.16.19 Owner’s Manual for Indirect Fired Heater... - Page 40 Part No. A0000244048 Rev. A 11/25/2019 ©2019 Generac Mobile Products, LLC All rights reserved. Generac Mobile Products, LLC Specifications are subject to change without notice. 215 Power Drive, Berlin, WI 54923 GeneracMobileProducts.com │800-926-9768 │920-361-4442 No reproduction allowed in any form without prior written consent from Generac Mobile Products, LLC.

Need help?

Do you have a question about the MIH800 and is the answer not in the manual?

Questions and answers