Table of Contents

Advertisement

Advertisement

Table of Contents

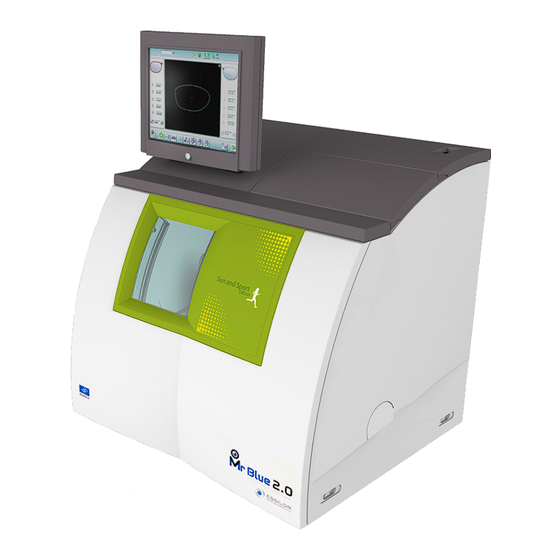

Summary of Contents for Essilor Instruments Mr Blue 2.0 Sun and Sport Edition

- Page 1 User manual...

-

Page 2: Table Of Contents

> C SER MANUAL ONTENTS ONTENTS & S PORT DITION I. P ERFORM A HEMISTRIE 1. Prerequisites 2. Prepare the Chemistrie TM lenses 3. Perform a Chemistrie TM job II. C ARRY OUT A ACKET JOB 1. Outline the step bevel trajectory on a Half Jacket shape a. -

Page 3: Lue Un Port Dition

> M & S SER MANUAL PORT DITION & S PORT DITION Mr Blue Sun & Sport Edition has: • two new features: • an improvement to the edging time on the step bevel with the addition of a “step ++” new tool: Mr Blue 2.0 Sun &... - Page 4 I. P ERFORM A HEMISTRIE...

-

Page 5: Prerequisites

> I. P SER MANUAL ERFORM A HEMISTRIE is a technical solution that, through a magnet system, allows you to superimpose a pair of additional “CLIP” lenses on the “ophthalmic” lenses. 1. P REREQUISITES You must center and block the lens before placing it in the edger. Before calling up the job on the edger, you must select and configure beforehand the clips which you wish to carry out on the tracer. -

Page 6: Prepare The Chemistrie Tm Lenses

> I. P SER MANUAL ERFORM A HEMISTRIE 2. P REPARE THE HEMISTRIE LENSES To assemble the two lenses, position them as indicated and apply light pressure in the opposite direction of the curve of the lenses. Check visually that the lens can accommodate the shape. For more precision, you can verify it using the tracer, by using the centering function. -

Page 7: Perform A Chemistrie Tm Job

> I. P SER MANUAL ERFORM A HEMISTRIE 3. P ERFORM A HEMISTRIE Press to call up the desired shape located on the tracer. > The shape is displayed on the edger work screen with the selected clips: Press on to select the ophthalmic lenses: Configure edging: 1. - Page 8 > I. P SER MANUAL ERFORM A HEMISTRIE You can clamp the lens manually by pressing Make sure you move your hand well away before you start the edging cycle. Press to start the cycle. Proceed to a retouch if necessary, then carry out the edging of the second lens. >...

- Page 9 > I. P SER MANUAL ERFORM A HEMISTRIE You can clamp the lens manually by pressing Make sure you move your hand well away before you start the edging cycle. Check that the Chemistrie lenses are still properly in place during the clamping phase. They must remain clipped together.

-

Page 10: Carry Out A

II. C ARRY OUT A ACKET JOB... -

Page 11: Alf Acket Job

> II. C SER MANUAL ARRY OUT A ACKET JOB We highly recommend that you edge a test lens before carrying out the edging of the final lens. Preferably use a test lens that has a base unit equivalent to the ophthalmic lens. 1. - Page 12 > II. C SER MANUAL ARRY OUT A ACKET JOB Press > The door closes, the lens is clamped and then felt. > The step bevel finishing screen is displayed by default. Press on to create step bevel shelf bevel, Half Jacket specific. Mr Blue 2.0 Sun &...

- Page 13 > II. C SER MANUAL ARRY OUT A ACKET JOB > The following screen will appear: Front surface tracking step bevel screen Work area Image of the shape to be edged: Frame shape at bottom of groove Bevel trajectory on rear surface Bevel trajectory on rear surface if the lens used is too thin to achieve the desired finish.

-

Page 14: Set The Step Bevel Trajectory

> II. C SER MANUAL ARRY OUT A ACKET JOB Window showing the bevel trajectory on the lens section Centre of the flat side of the bevel Front surface/rear surface of lens Number of shelf bevel values Transition from 4 to 8 shelf bevel values. Transition from 8 to 4 shelf bevel values. - Page 15 > II. C SER MANUAL ARRY OUT A ACKET JOB Tool bar : Selection of the shelf bevel area for modification. When the form is selected: ◦ the button changes: ◦ the “non-machinable” zone appears in red ( ) on the screen. : Addition of points to outline the shelf bevel trajectory.

- Page 16 > II. C SER MANUAL ARRY OUT A ACKET JOB Create the step bevel trajectory From the customized screen for the step outline, press to select the shape, then to add points. > The following screen will appear: Press and hold the stylus to set the first point of the step bevel trajectory. >...

- Page 17 > II. C SER MANUAL ARRY OUT A ACKET JOB Press and hold the stylus to set the second point of the step bevel trajectory. > A green segment ( ) is created between the points. > An audible signal informs you that the second point is registered. >...

- Page 18 > II. C SER MANUAL ARRY OUT A ACKET JOB With each audible signal, raise the stylus a few seconds before setting a new point by pressing and holding It is preferable to create a greater number of points at the angles to gain precision, if you wish to adjust more precisely the bevel trajectory using the zoom.

- Page 19 > II. C SER MANUAL ARRY OUT A ACKET JOB Go into zoom mode You can zoom in on a specific point or outline an area. Increase a particular point Press to switch into Zoom mode. Press and hold the stylus on the point of the shape that you want to see more precisely. Press on the Frame shape at bottom of groove in white ( >...

- Page 20 > II. C SER MANUAL ARRY OUT A ACKET JOB Press again to enlarge the area. When the enlargement is at a maximum, the icon is grayed Press again to shrink the area. Enlarge a defined area Press to switch into Zoom mode. Using the stylus press on a point of the shape.

- Page 21 > II. C SER MANUAL ARRY OUT A ACKET JOB Adjust the step bevel trajectory Press to select the shape: > The points of reference appear, the shape can be modified. Using the stylus press on a point of the shape. Move the stylus over the shape.

- Page 22 > II. C SER MANUAL ARRY OUT A ACKET JOB Press and hold the stylus to set the end of the segment. > An audible signal sounds 3 times. The segment appears in green. Move the segment using the stylus. When the trajectory passes by the closed area: •...

- Page 23 > II. C SER MANUAL ARRY OUT A ACKET JOB Raise the stylus to validate the modification. > An audible signal sounds 3 times. > The segment becomes blue (only the points of reference set by you will appear), the machine recalculates the trajectory of the curve =>...

- Page 24 > II. C SER MANUAL ARRY OUT A ACKET JOB 2. F “ ” INALIZE THE STEP BEVEL SETTINGS IN FRONT SURFACE FOLLOW MODE Configure the flat side of the bevel and the front shelf bevel of the bevel step. Press the buttons on the right of your screen to modify the width of the flat side of the bevel.

- Page 25 > II. C SER MANUAL ARRY OUT A ACKET JOB > The result can be viewed in the zoom window and the display window of the bevel trajectory on the lens section. Press systematically to perform a back chamfer of the assembly aid. >...

-

Page 26: Modify The Shape On Essibox

> II. C SER MANUAL ARRY OUT A ACKET JOB 3. M ODIFY THE SHAPE ON SSIBOX If the test lens cannot be mounted, we advise you to modify the shape on Essibox. Contact your customer support if the job is not available in the job manager on Essibox. In the job manager screen on Essibox, press the “ID number”... - Page 27 > II. C SER MANUAL ARRY OUT A ACKET JOB Press to return to the “M’Eye Touch” creative modification screen. > The following screen is displayed: Press to select the point from which you wish to modify the shape Press to select the “angle”...

- Page 28 > II. C SER MANUAL ARRY OUT A ACKET JOB Press to check the shape’s feasibility. The button becomes red > The following screen will appear: The shape is valid. Press to confirm the new shape. Recall the shape on the edger to make a new test lens. Mr Blue 2.0 Sun &...

-

Page 29: Carry Out A Step Bevel => " N Ew Step

III. C => " N ARRY OUT A STEP BEVEL EW STEP ” TOOL... - Page 30 > III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL The step bevel finishing is active and available only if the tool is installed on the “small tools” module. Prerequisite: Torque wrench Tool for “wheel” removal Allen key Blocking key “Step ++”...

-

Page 31: Install The Step Bevel Tool

> III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL Cross-section of a step bevel 1: Value of shelf bevel of rear surface 2: Width of the flat side of the bevel 3. Front surface tracking value 1. - Page 32 > III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL Press to select the "step ++" wheel: CX3834. Press to confirm the tool. > The GMD module moves to facilitate the operation. > The following message appears: Position the blocking key on the axle behind the high-base wheel, then position the dismantling accessory on the high-curve wheel and the chamfering wheel.

- Page 33 > III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL Insert the Allen wrench in the screw at the center of the chamfering wheel, and unscrew it (downwards). Remove the dismantling tool. > the high-base wheel and the chamfering wheel is disassembled. Position the “step ++”...

- Page 34 > III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL Tighten (towards yourself) the “step ++” wheel using the torque wrench. Ensure that the tool is correctly fixed onto the axle using the keys. >...

- Page 35 > III. C => " N ” SER MANUAL ARRY OUT A STEP BEVEL EW STEP TOOL 2. S “ ++” TEP BEVEL SPECIFICITIES WITH THE NEW STEP TOOL Tools/Materials/limits The edging cycle with the new “Step++” tool allows for a cycle that’s twice as fast. Mr Blue 2.0 Sun &...

- Page 36 Essilor Instruments USA 8600 W. Catalpa Avenue, Suite 703 Chicago, IL 60656 Phone: 855.393.4647 Email: info@essilorinstrumentsusa.com www.essilorinstrumentsusa.com...

Need help?

Do you have a question about the Mr Blue 2.0 Sun and Sport Edition and is the answer not in the manual?

Questions and answers