Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Prusa Research i3 MK2.5S Multi Material Upgrade 2S

- Page 2 Important notice, tip, hint or information that helps you print with ease. Read carefully! This part of the text has the greatest importance - either for user safety or for p roper p rinter service. Handbook version 1.0 from February 25, 2019 © Prusa Research s.r.o.

-

Page 3: About The Author

About the author rd Josef Prusa (born Feb 23 , 1990) became interested in the 3D printing phenomenon before joining Prague’s University of Economics in 2009. At first, 3D printing was a hobby, a new technology open to changes and improvements. This hobby soon became a passion and Josef grew into one of the leading developers of Adrien Bowyer’s international, open source, RepRap project. -

Page 4: Table Of Contents

Table of contents About the author Table of contents 1 About the product 2 Quick-start instructions 3 Placement and setup 4 Flashing the firmware 4.1 Flashing firmware on Windows 5 Initialization procedure 6 Loading/Unloading/Selecting/Ejecting filament 6.1 Loading all five filaments at once 6.2 Loading one of the filaments using the LCD Menu 6.3 Loading one of the filaments using the MMU control buttons 6.4 Ejecting filament... - Page 5 10 Printing in Single Mode 10.1 Colorprint 10.2 SpoolJoin 11 Handling 11.1 Mounting/Unmounting the MMU2S unit 11.2 Transporting the printer 12 Menu structure 13 Troubleshooting 13.1 MMU load failed - Blinking red LED 13.2 MMU needs user attention - Blinking red LED 13.3 All five LEDs blinking red 13.4 All five LEDs blinking red and green 13.5 Selector not moving...

-

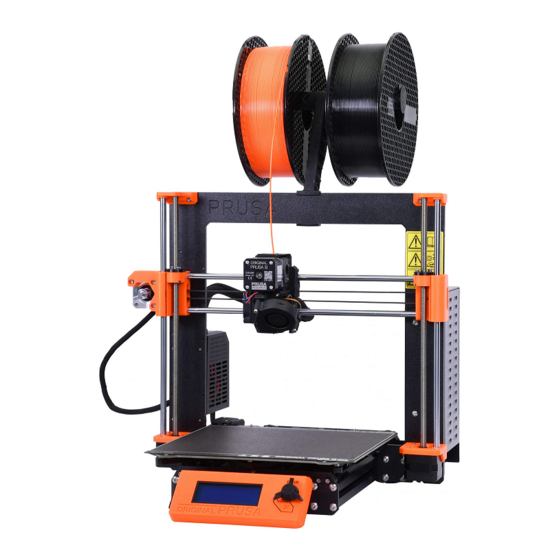

Page 6: About The Product

1 About the product Multi Material Upgrade 2S (MMU2S) is the latest revision of the Multi Material Upgrade 2.0, originally released in 2018. Our unique multi-material printing solution is now compatible with the Original Prusa i3 MK2.5S and MK3S 3D printers. Actually, MMU2 and MMU2S units are almost the same, but the printer extruder is equipped with a new filament sensor mechanism, which improves the reliability of the MMU2S unit. -

Page 7: Quick-Start Instructions

2 Quick-start instructions We get it. You just assembled the MMU2S according to Assembly Guide, connected it to your printer and now you are eager to start printing. :) But give us just a second! There’s a couple of important steps you need to take before you can print your first multi-material G-Code. -

Page 8: Placement And Setup

3 Placement and setup During filament changes, all of the filament is unloaded from the orange/white PTFE tube in the front. Our new solution for dealing with retracted filament is a device called filament buffer. The filament string creates a loop inside in order to prevent tangling. The setup requires a space of at least 70 ×... -

Page 9: Flashing The Firmware

Pict. 4 - Order of PTFE tubes plugged to the buffer Pict. 5 - Loading filament into the buffer The placement described above is ideal as an initial setup and it is designed to save as much space as possible. Alternatively, you can place the filament buffer and spool holders behind the printer in line. -

Page 10: Flashing Firmware On Windows

4.1 Flashing firmware on Windows 1. Go to w ww.prusa3d.com/drivers and download the correct firmware for your printer and/or MMU2S unit. Please note that there is a different firmware for each of our printers and also a different type of firmware for the MMU2S. 2. - Page 11 Pict. 7 - Connection of MMU2S unit 5. Start Slic3r PE and select Configuration -> Flash Printer Firmware. 6. A new window will appear. Your printer should be detected in the ‘Serial Port’ box. 7. Click Browse to select the downloaded firmware file. 8.

-

Page 12: Initialization Procedure

The firmware for our lineup of printers is updated regularly. To ensure the best possible experience when working with the printer and the MMU2S, it is necessary to always use the latest firmware. 5 Initialization procedure MMU2S unit is turned on simultaneously with the printer. After that, the homing procedure of the idler body (extruder stepper) is started. -

Page 13: Loading All Five Filaments At Once

6.1 Loading all five filaments at once 1. Go to L CD Menu - Load filament - Load All. 2. The selector will move to the first position, the first LED will start blinking red. 3. Push the filament to the first PTFE tube until it’s caught by the drive gear. 4. -

Page 14: Ejecting Filament

Pict. 10 - Inside of the MMU2S unit with properly loaded filament If you want to verify proper load of all five filaments before print, select L CD Menu - Load filament - Load all. T he MMU2S unit should quickly try loading and unloading all 5 filaments one after another without any user interaction. -

Page 15: Load To The Nozzle

Pict. 11 - Ejected filament string is ready to be removed Please note that the ends of the filament string must be straight in order to perform the ejecting process correctly. If the next filament slot is empty (filament string is not inside the MMU2S), the printer will ask you to insert filament. -

Page 16: Explained

6.7 F.I.N.D.A explained F.I.N.D.A is an older design P.I.N.D.A probe repurposed as a filament sensor. When the filament is pushed through the selector, it raises a stainless steel ball. Its movement is detected by the F.I.N.D.A. There is a small red LED light on the back of the probe. As soon as the filament is detected, the light turns off. -

Page 17: Calibrate The Z-Axis

5. Move the chimney as far left as possible (red arrow) and make sure, that the IR value is “0”. 6. Tighten the M3 screws on the chimney. 7. Prepare the smaller 1.5 mm Allen key which was included in the kit. I nsert the Allen key instead of the filament... -

Page 18: First Layer Calibration

Pict. 14 - Z calibration Alternatively, you can run a “manual” Z-axis calibration. After you power on the printer, press and hold the knob for 2 seconds. A new menu will be displayed, showing the letter ‘Z’ and a number representing the current height of the Z-axis. Rotate the knob clockwise until b oth ends of the Z-axis hit the top part of the frame... - Page 19 Pict. 15 - How to tune the nozzle height in real time during the test print. Note: -0.640 mm is only for illustration. Y our setting will be different! Observe the line which is being extruded on the print surface. A new menu will automatically show up, with an option to tune the nozzle height in real time by turning the knob.

-

Page 20: Individual Filament Calibration

If your printer was working without any issues before adding the MMU2S unit, these two calibrations should be everything you need to start printing. In case you still have trouble calibrating the first layer height, please refer to the printer’s handbook or our knowledge base at ... -

Page 21: Printing In Multi Material Mode

Do not leave your printer unattended during the first print. Watch the process closely and in case of any kind of trouble, use the Menu - Stop print function to cancel the process immediately. 9 Printing in Multi Material Mode With the MMU2S unit mounted, you can print in two different modes: ... -

Page 22: Setting Up Colors

7. Select all remaining parts of the object and click Open. 8. Check the preview window to see whether the object has been imported successfully and no parts are missing. In the next step, we’ll set up colors for each part of the object. Pict. -

Page 23: Slicing A Multi-Material Object

Pict. 19 - Assigning colors in Slic3r and the corresponding PTFE tubes If your object has a solid-green color in Slic3r, it means it’s selected. Click anywhere in the Slic3r 3D view to deselect the object. 9.3 Slicing a multi-material object You can use the standard procedure to slice a multi-material object. -

Page 24: Purging Volumes

Pict. 20 - Smart wipe tower preview and real size after slicing 9.4.2 Purging volumes In the panel on the right side, you’ll find a P urging volumes button. In the S implified settings you can simply set how much filament will be purged when filament is being unloaded or loaded. - Page 25 Pict. 22 - Simplified settings of purging volumes In the table below you can see suggested values for some of the commonly used colors/filaments. Color Unloaded Loaded Black White Yellow Silver High gloss filaments PVA/BVOH The A dvanced settings let you set the purging values for each combination of filaments in a 3...

-

Page 26: Wipe To Infill

Pict. 23 - Advanced settings, a purging volumes matrix 9.5 Wipe to infill Since the inside of the model isn’t visible, it can be used to wipe the nozzle during the color transition. The wipe tower cannot be eliminated completely, because some models do not have enough infill, but wipe to infill can ... -

Page 27: Wipe Object

Pict. 25 - Wipe to infill settings in Slic3r PE 9.6 Wipe object To further decrease the amount of material used for the smart wipe tower, you can choose to wipe residual filament into an object. The so-called ‘wipe object’ will be used during the color transition to wipe the nozzle. -

Page 28: Supported Materials

9.7 Supported Materials MMU2S supports the most common materials (such as PLA, PETG and ABS) along with soluble materials (BVOH) from the start. In addition, we’re working on expanding the range of supported materials (Flex and PVA+ coming soon). Support for additional materials is delivered through software updates. -

Page 29: Completely Soluble Supports

9.8.2 Completely soluble supports When removing soluble supports, try to break away as much material as possible while the object is still dry. Then continue peeling the material under running warm water. The last bits can be removed by letting the print soak in warm water. Water-soluble filaments must be always ... -

Page 30: Printing In Single Mode

10 Printing in Single Mode Even with the MMU2S unit mounted, you can still use the printer for single-color printing, also known as ‘Single Mode’. The best option is to have 5 of your favorite filaments loaded, so once you start printing, you can choose which filament to use via an on-screen menu. To prepare a Single Mode G-code, follow these steps: 1. -

Page 31: Spooljoin

10.2 SpoolJoin When printing in Single mode with filament sensor turned on, the SpoolJoin function can be switched on in L CD Menu - Settings - SpoolJoin [on/off] . This function enables automatic switching of filament spools in case one of the filaments runs out. This is especially useful when you want to get rid of filament scraps that are still on spools without the need to pay close attention to the printer during the printing process. -

Page 32: Transporting The Printer

11.2 Transporting the printer To transport the printer with the MMU2S unit attached, please follow these instructions: 1. Unload all filaments completely - see chapter 6 Loading and Unloading filaments 2. Take all white PTFE tubes and push them through one of the hexagonal openings at the top of the printer. -

Page 33: Menu Structure

12 Menu structure ❏ Info screen ❏ Live adjust Z ( during the p rinting process only) ❏ Tune ( during the p rinting process only) ❏ Speed ❏ Nozzle ❏ Bed ❏ Fan s peed ❏... - Page 34 ❏ Move Y ❏ Move Z ❏ Extruder ❏ Disable steppers ❏ Filament sensor - On / Off ❏ F. autoload - On / Off (only when MMU2S is not connected) ❏ SpoolJoin - On / Off ( only when MMU2S is connected and filament sensor is turned on) ❏...

-

Page 35: Troubleshooting

13 Troubleshooting In case you encounter any problems with the MMU2S unit, first make sure that you have the unit properly assembled and positioned as described in the assembly instructions and this manual. Please pay attention to every step of the assembly manual and this handbook. - Page 36 Pict. 31 - Tighten idler springs 4. Incorrectly placed short PTFE tubes It’s possible that you have inserted the short PTFE tubes incorrectly during the assembly. Doing this will cause a problem with filament jams due to retraction. The thicker end of the filament will always get stuck on the sharp edge of the PTFE tube. Check their correct orientation -...

-

Page 37: Mmu Load Failed - Blinking Red Led

How to check it: 1. Loosen the two screws which hold the extruder-idler (door) and remove them. 2. Try to push the Bondtech gear on the motor shaft by an Allen key. If it moves, continue with the next step. If it doesn’t move, it means that the screw is properly tightened and you can close and secure the extruder-idler again. - Page 38 Pict. 34 - LCD notification: printer is paused because of an unsuccessful filament load Cause Solution Check, that the filament can move freely Filament is blocked somewhere between and can be loaded to the unit. Resume the MMU2S unit and the spool. print*...

-

Page 39: Mmu Needs User Attention - Blinking Red Led

If the repair was successful, the LED will flash red and green. If it wasn’t, you will see the red LED still on and you will have to try to resolve the issue again. Once you’re ready, press the middle button again. Press right MMU2S button to resume print. -

Page 40: All Five Leds Blinking Red

7. Finally, screw the Festo fitting back in and press the right button to continue the print. How to solve a problem related to filament l oad - slow flashing: You need to get access to the tip of the problematic filament. 1. -

Page 41: Loud Clicking And Idler Unable To Move Freely

The selector motor isn’t working - first, try powering the printer off and moving the selector by hand. If that didn’t help or you were unable to move the selector, release the three screws holding the selector motor in place, pull the motor out. Then push the smooth rods out with an Allen key. -

Page 42: Filament Not Extruded During The Print (Missing Layers)

Pict. 36 - Idler opening 12.6 Filament not extruded during the print (missing layers) If the extruder keeps moving across the heatbed (following the instructions from a G-code), but the filament is not extruded at all. Solution 1: T he hotend in the extruder might be jammed, please head to the MK3S 3D Printing Handbook - chapter... -

Page 43: Different Filament Tip Shapes After The Unload

2. Incorrect alignment of the F.I.N.D.A. sensor. The sensor is too low and blocks the filament. How to align the F.I.N.D.A. sensor correctly? Please see the assembly manual at manual.prusa3d.com 13.8 Different filament tip shapes after the unload Filament string ends, depending on the material type or manufacturer, can look different after the unload procedure. -

Page 44: Does Not Detect The Absence Of The Filament

13.9 F.I.N.D.A. does not detect the absence of the filament F.I.N.D.A. sensor is located on the top of the selector. Please check out the picture During the printing process, the filament can be pulled completely out of the MMU2S unit (away from the pulleys), so during the next filament load, the gears are unable to grab the filament string. -

Page 45: Can Not Update The Mmu2S Firmware

13.11 Can not update the MMU2S firmware 1. Make sure, that you have the last version of Slic3r PE. https://www.prusa3d.com/drivers/ 2. Make sure you have a MMU2S board connected to your computer and not a printer board. There are two different boards. For a detailed procedure, see the chapter Flashing the firmware... - Page 46 Print and share! Do not forget to tag your prints with #mmu2s while sharing so we can find, pin and showcase them with our http://www.prusa3d.com/original-prusa-i3-prints/ Happy Printing :)

Need help?

Do you have a question about the i3 MK2.5S Multi Material Upgrade 2S and is the answer not in the manual?

Questions and answers