Summary of Contents for WEG WG20

- Page 1 Motors | Automation | Energy | Transmission & Distribution | Coatings WG20 Geared Motors - Mounting Instruction...

-

Page 2: Table Of Contents

18.5. PTC Thermistor protection (TF) E-35 18.6. Brake E-35 Table of Tightening Torques E-38 Disposal E-38 Declaration of incorporation E-39 EU declaration of conformity ATEX 2014/34/EU E-40 EU declaration of conformity: low voltage directive 2014/35/EU E-41 E-2 | WG20 Geared Motors... -

Page 3: General

All technical documents are protected in the sense of the copyright law. The processing, reproduction and dissemination of it, even in extracts, as well as other utilisation is not allowed, unless it has been expressly conceded in written form. WG20 Geared Motors | E-3... -

Page 4: General Safety

■ prevented from being switched on again. Operation of the drive unit by means of a frequency inverter may only occur if the specifications shown on the motor name- plate have been carried out. E-4 | WG20 Geared Motors... -

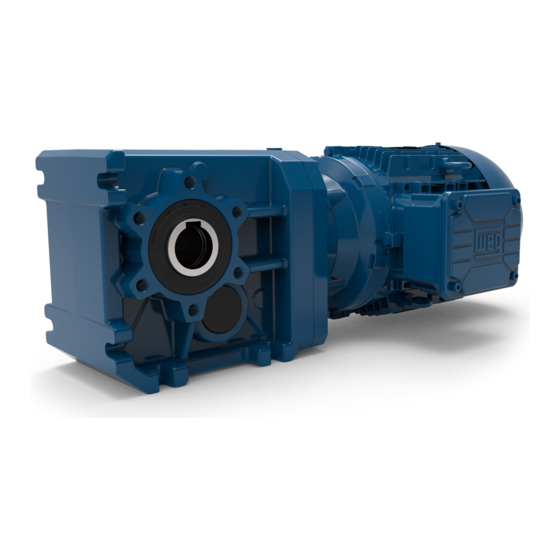

Page 5: Gear Unit / Geared Motor Description

02, 03, 04, 05, 06, 07 02, 03, 04, 05, 06, 07 sizes Possible gear 00, 01: 2 stages 02, 03: 2 stages 02: 2 stages stages 03-08: 2 or 3 stages 04-07: 2 or 3 stages 03-07: 3 stages WG20 Geared Motors | E-5... - Page 6 Brake with manual release and locking device KKM, RSM Back stop U, UW Unventilated Drain Anti condensation heating K1, K2 Climatic protection MIP, MIG Terminal box design Protection cap Hand wheel Metal fan Fly wheel fan ZWM, ZWV Second shaft end E-6 | WG20 Geared Motors...

-

Page 7: Transport

Support hole + eye bolt on 100 - 132 motor (max. angle of 60° between the ropes) 63 - 90 Support hole Support hole + eye bolt on 100 - 160 motor (max. angle of 60° between the ropes) WG20 Geared Motors | E-7... -

Page 8: Storage

If the gear units are stored for longer than 24 months before being put into service, they must be checked for leaks. If there are any visible cracks on the surfaces of sealing elements, such parts must be replaced. E-8 | WG20 Geared Motors... -

Page 9: Gear Unit Construction

Intermediate pinion shaft Shim Bearing 5 Kit Shaft cover Bearing 6 Shaft cover Circlip 1 Gasket Circlip 2 Screws Kit Hollow shaft fixing kit Bearing cover Disc 1st stage gear Circlip Bevel pair Screw Motor Slinger WG20 Geared Motors | E-9... -

Page 10: Basic Design Principles Helical Gear Unit C

6.1. Basic design principles helical gear unit C Gear sizes C00 to C06 E-10 | WG20 Geared Motors... - Page 11 Gear sizes C07 to C08 WG20 Geared Motors | E-11...

-

Page 12: Basic Design Principles Parallel Shaft Gear Unit F

6.2. Basic design principles parallel shaft gear unit F Gear sizes F02 to F05 E-12 | WG20 Geared Motors... - Page 13 Gear sizes F06 to F07 WG20 Geared Motors | E-13...

-

Page 14: Basic Design Principles Helical Bevel Gear Unit K

6.3. Basic design principles helical bevel gear unit K Gear sizes K02 to K05 E-14 | WG20 Geared Motors... - Page 15 Gear sizes K06 to K07 WG20 Geared Motors | E-15...

-

Page 16: Mechanical Installation

It must be ensured that the terminal box, terminal board and cable connections etc. inside the terminal box are not dam- aged! WARNING! The terminal box must be sealed so that dust and water cannot enter! E-16 | WG20 Geared Motors... - Page 17 The grounding has to be connected in the terminal box at the place intended for this purpose and marked accordingly. The cross-section of the ground conductor of the machine must comply with the regulations for electrical installations, e.g. DIN EN IEC 60204-1. WG20 Geared Motors | E-17...

-

Page 18: Setting Up The Gear Unit / Geared Motor

The vent valve is to be activated before the unit is put into operation by completely demounting the transport protection (rubber clip) as described below. Figure 1: Information label (red) on the gear unit Remove the rubber clip completely before start-up! E-18 | WG20 Geared Motors... - Page 19 The hollow-shaft gear units must always be installed in such a way that no axial forces are applied to the output shaft bearing system. 1. Check the machine shaft (3) on possible damages like e.g. notches or upsettings. 2. Clean the customer’s machine shaft (3) thoroughly before the mounting. WG20 Geared Motors | E-19...

- Page 20 3. Screw in the fixing bolt (9). Through tightening of the screw you are pressing the gear off the machine shaft (3). Figure 4: Demounting the customer shaft with or without contact shoulder Customer's shaft with tapped centre hole as per DIN332, sh.1 Circlip DIN 472 Hollow shaft (9) Retaining screw DIN 933 (to customer specification, length according to machine shaft length) (10) Jack nut (11) Thrust washer E-20 | WG20 Geared Motors...

- Page 21 2. Press the inner ring (4) off using the jack nut (7). Remove any rust beforehand that may have formed on the machine shaft in front of the hollow shaft. 3. Remove the shrink disc from the hollow shaft (2) . 4. Step 2 only required for two-part shrink disk execution! WG20 Geared Motors | E-21...

- Page 22 Counterclockwise Possible positions of the torque arm: K02: 90 °, 135 °, 180 °, 225 °, 270 ° K03 - K05: 90 °, 120 °, 150 °, 180 °, 210 °, 240 °, 270 ° E-22 | WG20 Geared Motors...

- Page 23 Fit the motor onto the adapter. The gearing of the half coupling must fit into the gearing of the coupling bush. ■ Fasten the motor onto the adapter using appropriate fastening screws (not included). Tightening torque see page E-38. Minimum property class 8.8. Mounting an IEC motor on the coupling adapter WG20 Geared Motors | E-23...

-

Page 24: Check List - Gear Unit

The wiring diagram for the motor series 11 and 22 is available in this manual on page E-33. Connections must be made in such a way as to ensure that a permanently safe electrical connection is maintained (no protruding wire ends); use the corresponding cable end pieces. E-24 | WG20 Geared Motors... -

Page 25: Direction Of Rotation

The surface temperature shall be measured with standard commercially available temperature-measuring instruments. ATTENTION! The drive must be shut down if any abnormalities relative to the items listed above have been noted upon inspection. Contact the producer. WG20 Geared Motors | E-25... -

Page 26: Malfunction

Breakage in the gear unit or shaft hub Consult the producer. The gear unit output shaft does not connection disrupted. turn though the motor runs or the drive shaft is being turned. Shrink disc connection slips through. Check the shrink disc connection. E-26 | WG20 Geared Motors... -

Page 27: Inspection And Maintenance

Check the rubber buffer set: The rubber buffer set must be checked for visible damage, such as cracks on the surface, and they must be replaced in some cases. WG20 Geared Motors | E-27... -

Page 28: Lubricants

The following lubricant table shows the lubricants that are approved for WG20 gear units. For helical, parallel shaft and helical bevel gear units at ambient temperatures -10 °C to +60 °C (14 °F to 140 °F) ALPHA SP 220 Klüberoil GEM 1-220 N... -

Page 29: Mounting Positions And Lubricant Capacity

0.8 l 1.7 l 1.8 l 2.1 l 1.2 l 1.3 l 1.5 l 3.6 l 3.5 l 4.4 l 2.6 l 2.4 l 3.3 l 6.9 l 6.6 l 8.8 l 4.8 l 5.1 l WG20 Geared Motors | E-29... -

Page 30: Parallel Shaft Gear Units F

2.3 l 2.2 l 1.4 l 2.5 l 1.6 l 1.5 l 2.7 l 3.5 l 2.3 l 3.8 l 2.4 l 2.3 l 5.8 l 6.2 l 3.9 l 7.7 l 4.4 l 4.5 l E-30 | WG20 Geared Motors... -

Page 31: Helical Bevel Gear Units K

0.8 l 2.1 l 2.6 l 3.1 l 2.1 l 2.2 l 0.8 l 2.0 l 2.7 l 3.0 l 2.2 l 2.4 l 1.5 l 3.5 l 4.3 l 5.3 l 3.7 l 4.1 l WG20 Geared Motors | E-31... -

Page 32: Position Of Terminal Box And Cable Entry

(760) - (796) V at 60 Hz 460 V, 120 Hz 330 - 346 - 365 V at 50 Hz Star - Star 330 - 400 - 415 V at 60 Hz 380 - 400 - 415 V at 60 Hz E-32 | WG20 Geared Motors... - Page 33 Bimetal switch (2TB1/2TB2) only available for motor series 11 Table 3: Tightening torque for terminal box Thread Tightening torque M [Nm] 0.7 - 1.0 1.6 - 2.2 2.2 - 3.5 6 - 8 10 - 14 WG20 Geared Motors | E-33...

-

Page 34: Optional Motor Devices

50 Hz 60 Hz 3~ / Star 346 - 525 380 - 575 63 - 180 3~ / Delta 200 - 303 220 - 332 1~ / Delta Steinmetz 230 - 277 230 - 277 E-34 | WG20 Geared Motors... -

Page 35: Temperature Controller Bimetal Switch „Nc Contact" (Th

4. Turn the three hollow screws (9) again clockwise out of the magnetic case (10) and retighten the fixing bolts (11). Con- trol the air gap “a” with a feeler gauge on evenness and make a correction if necessary. WG20 Geared Motors | E-35... - Page 36 Brake motors will be delivered as standard with connected rectifier for AC-side switching. For DC-side switching the bridge between terminals 5 and 6 must be removed and a switching contact must be connected. ATTENTION! Start-up of motor only with connected brake. (Check!) E-36 | WG20 Geared Motors...

- Page 37 Never use the assembled encoder to lift the drive-unit. ■ Never step onto the encoder. Technical Data Standard Encoder: Type Voltage Pulses Output signal Kübler 5020 10 - 30 V 1024 Kübler A02H (Heavy Duty) 10 - 30 V 1024 WG20 Geared Motors | E-37...

-

Page 38: Table Of Tightening Torques

Gear housing, housing parts (input cover, adapters, Aluminium, Grey cast iron flanges etc.) Gear inner parts (tooth wheels, keys, shafts) Steel Shaft sealing rings Elastomer with steel Flat seals Asbestos-free Gear oil Additivated mineral oil E-38 | WG20 Geared Motors... -

Page 39: Declaration Of Incorporation

EC Machinery Directive 2006/42/EC, Annex II B Product: Classification: Helical geared motors WG20 Parallel shaft geared motors WG20 Helical bevel geared motors WG20 Producer: WATT DRIVE Antriebstechnik GmbH Wöllersdorfer Straße 68 2753 Markt Piesting - Austria Authorized person for the compilation of the technical documents: Norbert Reisner - Wöllersdorfer Straße 68 - 2753 Markt Piesting... -

Page 40: Eu Declaration Of Conformity Atex 2014/34/Eu

22. EU declaration of conformity ATEX 2014/34/EU EU - Declaration of Conformity in terms of the EU Directive on Explosion Protection 2014/34/EU Products of the geared motor series WG20/MAS: Classification: Helical geared motors C./H. Shaft mounted geared motors - /A. -

Page 41: Eu Declaration Of Conformity: Low Voltage Directive 2014/35/Eu

Ort und Datum der Ausstellung Klaus Sirrenberg - Managing Director WG20 Geared Motors | E-41 Watt Drive Antriebstechnik GmbH Wöllersdorfer Str. 68 · A-2753 Markt Piesting · Phone: +43 (0) 2633 404-0 · Fax: +43 (0) 2633 404-220 · watt@wattdrive.com · www.wattdrive.com... - Page 42 E-42 | WG20 Geared Motors...

- Page 43 WG20 Geared Motors | E-43...

- Page 44 Watt Drive Antriebstechnik GmbH – WEG Group Wöllersdorfer Straße 68, 2753 Markt Piesting, Austria Phone: +43 (0)2633 / 404-0, Fax: +43 (0)2633 / 404-220 E-Mail: watt@wattdrive.com Web: www.wattdrive.com Code: 50069628 | Rev.: 02 | Date (M/J): 09/2018 Language: English, Original document: German...

Need help?

Do you have a question about the WG20 and is the answer not in the manual?

Questions and answers