Advertisement

Quick Links

INSTRUCTIONS-PARTS LIST

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

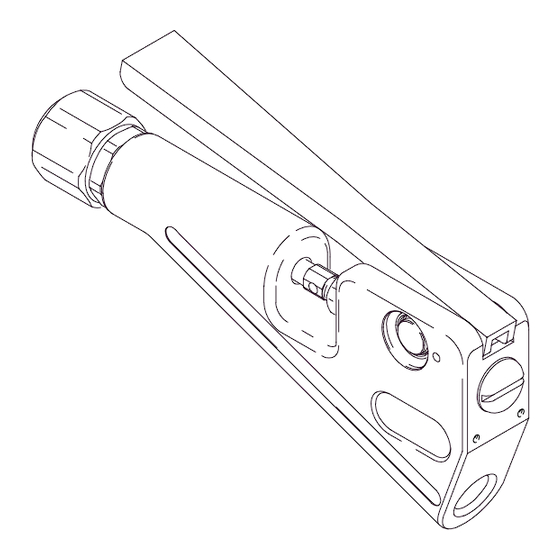

Ultra-Litet In-Line Flow Gun

3400 psi (23.4 MPa, 234 bar) Maximum Working Pressure

Model 240–199

With Ball End Needle

Model 240–200

With Tapered Needle

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Graco Inc. is registered to I.S. EN ISO 9001

308–807

Supersedes A

First choice when

quality counts.t

Rev. B

7903A

Advertisement

Need help?

Do you have a question about the Ultra-Lite 240-200 and is the answer not in the manual?

Questions and answers