Table of Contents

Advertisement

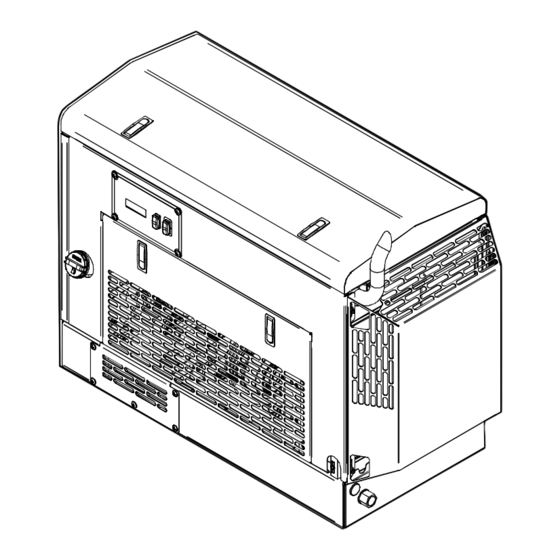

ROTARY SCREW AIR COMPRESSOR

OPERATOR'S MANUAL & PARTS LIST

NOTE

This publication contains the

latest information available at

the time of preparation. Every

effort has been made to ensure

accuracy. However, Vanair

Manufacturing, Inc. takes no

responsibility for errors or

consequential damages

caused by reliance on the

information contained herein.

Vanair Manufacturing, Inc.

reserves the right to make

design change modifications

or improvements without prior

notification.

NOTE

Use only Vanair Vanguard™

Premium Synthetic Oil and

Genuine Vanair Parts. Inspect

and replace damaged

components before operation.

Substituting non-Vanguard™

Oil or non-genuine Vanair filter

components WILL VOID THE

COMPRESSOR WARRANTY!

KEEP THE MANUAL

WITH THE VEHICLE

Vanair Manufacturing, Inc.

10896 West 300 North

Michigan City, IN 46360

Phone: (219) 879-5100

(800) 526-8817

Service Fax: (219) 879-5335

Parts Fax: (219) 879-5340

Sales Fax: (219) 879-5800

www.vanair.com

©2014 Vanair Manufacturing, Inc.

All rights reserved.

Read this manual before

installing, operating or

servicing this equipment.

Failure to comply with the

operation and maintenance

instructions in this manual

WILL VOID THE EQUIPMENT

WARRANTY.

NOTE

Making unauthorized

modifications to the system

components WILL VOID THE

WARRANTY!

Always inform Vanair

Manufacturing, Inc., before

beginning any changes to the

Viper Diesel system.

P/N: 090058-OP_r0

Effective Date:

August-2014

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Vanair Viper Series

- Page 1 Phone: (219) 879-5100 components before operation. beginning any changes to the (800) 526-8817 Substituting non-Vanguard™ Viper Diesel system. Oil or non-genuine Vanair filter Service Fax: (219) 879-5335 components WILL VOID THE COMPRESSOR WARRANTY! Parts Fax: (219) 879-5340 Sales Fax: (219) 879-5800 www.vanair.com...

- Page 2 Vanair's control or due to negligence or other fault of Vanair, its agents, affiliates, employees or representatives.

-

Page 3: Table Of Contents

SECTION 3: INSTALLATION..........7 MACHINE PACKAGE RECEIPT/INSPECTION................7 INSTALLATION INSTRUCTIONS....................7 INSTRUMENT PANEL RELOCATION ..................8 FIGURE 3-1: DIMENSION DIAGRAM - PART 1 OF 2................8 FIGURE 3-1: DIMENSION DIAGRAM - PART 2 OF 2................9 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - I (800) 526-8817 • www.vanair.com... -

Page 4: Table Of Contents

ADJUSTING THE ENGINE SPEED ........................21 SERVICING THE SYSTEM FUSES AND CIRCUIT BREAKER ..........21 STORAGE AND INTERMITTENT USE..................21 5.7.1 INTERMITTENT USE..............................22 5.7.2 LONG TERM STORAGE ............................22 VANAIR MANUFACTURING, INC. PAGE - II 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 5 FUEL TANK ASSEMBLY ......................54 7.11A DECALS (LOCATION) ........................56 7.11B DECALS (IDENTIFICATION)......................57 7.11C DECALS (PART NUMBERS)......................58 7.12 WIRING DIAGRAM ........................59 7.13 SCHEMATIC FLOW DIAGRAM ....................60 7.14 HOSE INSTALLATION GUIDE....................61 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - III (800) 526-8817 • www.vanair.com...

- Page 6 TABLE OF CONTENTS DIESEL VIPER BLANK PAGE VANAIR MANUFACTURING, INC. PAGE - IV 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

-

Page 7: Warranty Claims Procedure

1. Locate the machine’s serial number: Authorization) number that will provide The machine package serial number plate is for the return of the item to Vanair for located inside the machine compartment on analysis and a final determination as to the floor near to the engine air filter mounting the item’s warranty status. - Page 8 Serial Number Figure W-1: Machine Serial Number Location Disposition of Goods, Notifications and Vanair will issue credit to the customer. All Additional Notes, will be required. parts eligible for warranty must have the RMA number on the invoice at the time of Customers have 30 days after the RMA purchase.

-

Page 9: Safety

Vanair Manufacturing CAUTIONS AND NOTES Inc., disclaims any and all liabilities for damage or loss due to fatalities, personal These boxes are labeled clearly with the title injuries resulting from the use of a Vanair block listing either Danger, Warning, compressor to supply breathing air. -

Page 10: Cautions

• Ensure that no tools, rags, or other objects are left on compressor drive systems or near intakes. VANAIR MANUFACTURING, INC. PAGE - 2 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 11: Safety Decals

• Immediately clean up any lubricant or spills. 1.3.4 SAFETY DECALS Safety decals are placed onto, or located near, system components that can present a VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 3 (800) 526-8817 • www.vanair.com... - Page 12 SECTION 1: SAFETY VIPER DIESEL BLANK PAGE VANAIR MANUFACTURING, INC. PAGE - 4 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

-

Page 13: Section 2: Specifications

Service Department (refer to Section 5.5.1). Vanair recommends: Diesel Fuel Specification Type and Sulfur Content % (ppm) used must be compliant with all applicable emission regulations for the area in which the engine is operated. Engine manufacturer recommends a fuel sulfur content of less than 0.10% (1000 ppm). For fuels with a high sulfur content 0.50% (5000 ppm) to 1.0% (10000 ppm) a more frequent engine oil and oil filter change schedule is needed... - Page 14 Service Department (refer to Section 5.5.1). Vanair recommends: Diesel Fuel Specification Type and Sulfur Content % (ppm) used must be compliant with all applicable emission regulations for the area in which the engine is operated. Engine manufacturer recommends a fuel sulfur content of less than 0.10% (1000 ppm). For fuels with a high sulfur content 0.50% (5000 ppm) to 1.0% (10000 ppm) a more frequent engine oil and oil filter change schedule is needed...

-

Page 15: Section 3: Installation

In order to prevent accidental damage to due to down time. vehicle components (fuel tanks, lines, brake lines, wiring harnesses), note their location before drilling any holes. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 7 (800) 526-8817 • www.vanair.com... -

Page 16: Instrument Panel Relocation

Additional clearance room may be desired for easier access for control and/or maintenance functions. 050848_r1_1of2 Figure 3-1: Dimension Diagram - Part 1 of 2 VANAIR MANUFACTURING, INC. PAGE - 8 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 17 VIPER DIESEL SECTION 3: INSTALLATION 050848_r1_2of2 Figure 3-1: Dimension Diagram - Part 2 of 2 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 9 (800) 526-8817 • www.vanair.com...

- Page 18 COOLANT RECOVERY TANK SEPARATOR ENGINE EXHAUST MUFFLER RADIATOR DRAIN VALVE There is an oil dipstick indicator located on either side of the engine. Figure 4-1: Main Machine Component Locations VANAIR MANUFACTURING, INC. PAGE - 10 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

-

Page 19: Section 4: Operation

OPERATION 4.2.1 DIGITAL DISPLAY SCREEN 4.1 GENERAL INFORMATION ® The air pressure readout monitors service air Refer to Figure 4-1. The Vanair Viper pressure and incorporates an over-pressure Diesel compressor has a comprehensive shutdown function. array of controls and indicators for optimum machine performance. -

Page 20: Shutdown Procedure

On subsequent starts, follow the procedure control. When used properly, they will reduce explained below: fuel consumption, remind the user when periodic service is due, extend the useful life VANAIR MANUFACTURING, INC. PAGE - 12 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 21: Home Screen

VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 13 (800) 526-8817 • www.vanair.com... -

Page 22: Service Intervals

Hot engine exhaust and cooling air will generate high heat. 4. Be sure to leave sufficient room around the machine for cooling air. See Figure 3-1. VANAIR MANUFACTURING, INC. PAGE - 14 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 23: Section 5: Maintenance

5.1 GENERAL INFORMATION A strict maintenance program is the key to WARNING long life for the Viper Series Compressor System package. Below is a program that, DO NOT remove caps, plugs and/or other when adhered to, should keep the package components when compressor is running or in top operating condition. - Page 24 Table 7A: Recommended Spare Parts The following schedule is designed so that List. many of the other maintenance tasks are completed when the engine and compressor VANAIR MANUFACTURING, INC. PAGE - 16 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

-

Page 25: A Maintenance Schedule Table - Compressor Intervals

VIPER DIESEL SECTION 5: MAINTENANCE VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 17 (800) 526-8817 • www.vanair.com... -

Page 26: B Maintenance Schedule Table - Engine Intervals

SECTION 5: MAINTENANCE VIPER DIESEL VANAIR MANUFACTURING, INC. PAGE - 18 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 27 VIPER DIESEL SECTION 5: MAINTENANCE VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 19 (800) 526-8817 • www.vanair.com...

- Page 28 SECTION 5: MAINTENANCE VIPER DIESEL VANAIR MANUFACTURING, INC. PAGE - 20 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

-

Page 29: Replacement Parts

Overspeed is hazardous and will void the engine warranty. System was purchased. If, for any reason, parts are not available in this manner, they 5.6 SERVICING THE SYSTEM can be purchased through Vanair directly. FUSES AND CIRCUIT NOTE BREAKER For assistance when ordering new Consult Section 7.9, Electrical System,... -

Page 30: Intermittent Use

5.7.2 LONG TERM STORAGE Disconnect battery cable that connected to the negative (-) side of the battery. VANAIR MANUFACTURING, INC. PAGE - 22 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 31: Section 6: Troubleshooting

NOTE The information contained in this section has been compiled from years’ worth of informa- When contacting the Vanair Service tion gathered from the field. It contains symp- Department, please have machine serial toms and usual causes for the most common number on hand to quickly expedite types of problems that may occur. -

Page 32: Troubleshooting Guide

Speed control actuator stuck Lubricate; replace speed control actuator if Engine does not speed up necessary. Engine speed control lever stuck Free lever and lubricate if necessary. Continued on next page VANAIR MANUFACTURING, INC. PAGE - 24 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 33 Check fuel filters. Refer to the Engine Operator’s Manual for additional information on engine maintenance. Low fuel level Add fuel. Overload Reduce load; check load use, and reduce Continued on next page VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 25 (800) 526-8817 • www.vanair.com...

- Page 34 Inlet valve fails to open Repair/replace inlet valve. Inlet valve frozen shut Leak in air control line Check for leaks and take corrective action. Continued on next page VANAIR MANUFACTURING, INC. PAGE - 26 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

- Page 35 Idle speed is set too low Adjust idle speed; consult factory. Excess amount of oil in air Machine not on level surface Move machine to level surface. discharge Continued on next page VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 27 (800) 526-8817 • www.vanair.com...

-

Page 36: Extreme Condition Operation

Engine Operator’s Manual, or visit the engine manufacturer’s web site given in that manual. VANAIR MANUFACTURING, INC. PAGE - 28 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 37: Cold Weather Operation

• This forces moisture to be ® If the system is badly contaminated, Vanair ingested by the compressor. recommends a lube flush that will help clean out any remaining contamination throughout Any of the above causes will be the system. -

Page 38: High Temperature Operation

The fan, driven by the engine, restrict the air flow around the unit. Consult VANAIR MANUFACTURING, INC. PAGE - 30 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 39: High Dust Content Operation

• For extreme cases of high dust content environ- ments, machine fluids may need to be replaced at more frequent intervals. Adjust maintenance schedule accordingly. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 31 (800) 526-8817 • www.vanair.com... -

Page 40: High Altitude Operation

1,000 feet over 6,000 feet increase in altitude. high altitude overall unit performance will deteriorate, and care will need to be taken not to overload the engine. VANAIR MANUFACTURING, INC. PAGE - 32 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 41: Section 7: Illustrated Parts List

NOTE Machine serial number also displays on instrument panel at start-up, on the hours screen. Figure 7-1: Machine Package Serial Number Plate Location VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 33 (800) 526-8817 • www.vanair.com... - Page 42 This belt replaces the engine alternator belt only. For full engine belt coverage, consult factory. Due to shipping regulations pertaining to lead acid batteries, Vanair recommends procuring a replacement battery from a localized source. Two possible replacement models include: BatteriesPlus® no. SLi96R, and NAPA battery no. BAT 7590.

- Page 43 VIPER DIESEL SECTION 7: ILLUSTRATED PARTS LIST TABLE 7C: MAINTENANCE TRACKING LOG DATE DESCRIPTION OF MAINTENANCE PART(S) REPLACED VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 35 (800) 526-8817 • www.vanair.com...

-

Page 44: Compressor Replacement Parts

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.2 COMPRESSOR REPLACEMENT PARTS 6010148ID_r3 VANAIR MANUFACTURING, INC. PAGE - 36 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 45 PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. COMMONLY REPLACED PARTS ITEM DESCRIPTION PART NUMBER ELEMENT, COALESCING 273080 (SEPARATOR) ELEMENT, OIL FILTER 266801 ELEMENT, AIR FILTER 273673 VANGUARD OIL 264626-1GAL VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 37 (800) 526-8817 • www.vanair.com...

-

Page 46: Airend And Att

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.3 AIREND AND ATT 30 31 32 6180000ID_r4 VANAIR MANUFACTURING, INC. PAGE - 38 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 47 CONNECTOR, OIL FILTER 270037 WASHER, LOCK 5/16 838505-078 VANIR ENCAPS ORIFICE, STRAINER 0.030 #6 271054 MSAE x #4 MJIC PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 39 (800) 526-8817 • www.vanair.com...

-

Page 48: Engine And Drive Parts (1 Of 2)

RETRACT ACTUATOR. 7. SEE CLOSE UP VIEW FOR ACTUATOR MOUNTING TO THROTTLE LINKAGE. 45 52 54 43 52 16 12 52 41 24 47 20 40 32 6100108ID_r1_1of2 VANAIR MANUFACTURING, INC. PAGE - 40 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 49 PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. COMMON REPLACEMENT PARTS ITEM DESCRIPTION PART NUMBER ELEMENT, AIR FILTER 270764 ELEMENT, FUEL FILTER RC77662 ELEMENT, OIL FILTER 269136 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 41 (800) 526-8817 • www.vanair.com...

-

Page 50: Engine And Drive Parts (2 Of 2)

RETRACT ACTUATOR 7. SEE CLOSE UP VIEW FOR ACTUATOR MOUNTING TO THROTTLE LINKAGE. 12. CONCAVE SIDE OF FAN BLADE FACES AWAY FROM ENGINE. 17. TORQUE: 221 IN-LBS. 6100108ID_r1_2of2 VANAIR MANUFACTURING, INC. PAGE - 42 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 51 PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. COMMON REPLACEMENT PARTS ITEM DESCRIPTION PART NUMBER ELEMENT, AIR FILTER 270764 ELEMENT, FUEL FILTER RC77662 ELEMENT, OIL FILTER 269136 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 43 (800) 526-8817 • www.vanair.com...

-

Page 52: Cooling System (Part 1 Of 2)

3. WIRE GUARD IS INSTALLED ON ENGINE ASSEMBLY AND MOUNTS TO COOLER SHROUD WHEN BOTH COMPONENTS ARE SET IN PLACE. 4. HOSE SUPPLIED WITH COOLANT RECOVERY TANK. 6020127ID_r0_1of2 VANAIR MANUFACTURING, INC. PAGE - 44 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 53 SWITCH, HOOD SAFETY NO/NC 15A-125V. AC CO81774 CLAMP, HOSE, #20, 1.75DIA. FA47720 GASKET, SEAL AND TRIM PR35734 5.063 ft ** Made from EN271127. PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 45 (800) 526-8817 • www.vanair.com...

-

Page 54: Cooling System (Part 2 Of 2)

3. WIRE GUARD IS INSTALLED ON ENGINE ASSEMBLY AND MOUNTS TO COOLER SHROUD WHEN BOTH COMPONENTS ARE SET IN PLACE. 4. HOSE SUPPLIED WITH COOLANT RECOVERY TANK. 6020127ID_r0_2of2 VANAIR MANUFACTURING, INC. PAGE - 46 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 55 SWITCH, HOOD SAFETY NO/NC 15A-125V. AC CO81774 CLAMP, HOSE, #20, 1.75DIA. FA47720 GASKET, SEAL AND TRIM PR35734 5.063 ft ** Made from EN271127. PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 47 (800) 526-8817 • www.vanair.com...

-

Page 56: Canopy And Frame Parts

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.6 CANOPY AND FRAME PARTS 6030086ID_r4 VANAIR MANUFACTURING, INC. PAGE - 48 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 57 DOOR, FRONT ACCESS 272257 INSULATION, ACOUSTICAL FOAM, HOOD 272713-001 INSULATION, ACOUSTICAL FOAM, BAFFLE 272713-002 INSULATION, HEAT SHIELD 272713-006 PANEL, REMOVABLE BATTERY ACCESS DIESEL VIPER VANAIR 273468 PLATFORM, VIPER DIESEL VANAIR 273469 BAFFLE, SHROUD 273709 HOSE, AIR OUT LOWER 273968-008 PANEL, REAR SIDE...

-

Page 58: Compressor Thermal Control

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.7 COMPRESSOR THERMAL CONTROL 6120191ID_r1 7.8 INSTRUMENT PANEL OPTIONAL LOCATION 6040049ID_r1 VANAIR MANUFACTURING, INC. PAGE - 50 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 59 SCREW, TRUSS HD 5/16-18 x 3/4 SS 262945 MODULE, CONTROL AUTO SPD CTRL 272527 PLATE, COVER INST. OPENING 272535 PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 51 (800) 526-8817 • www.vanair.com...

-

Page 60: Electrical System

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.9 ELECTRICAL SYSTEM 6060080ID_r9 VANAIR MANUFACTURING, INC. PAGE - 52 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 61 838502-047 GASKET, SEAL AND TRIM PR35734 2.740 ft PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. * NOTE See page 34 (Key No. 18) for battery recommendations. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 53 (800) 526-8817 • www.vanair.com...

-

Page 62: Fuel Tank Assembly

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.10 FUEL TANK ASSEMBLY 6140011ID_r6 VANAIR MANUFACTURING, INC. PAGE - 54 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... - Page 63 HOSE, 1-1/2 DIA. FUEL x 12-1/2” LONG TU269928 1.04 FT HOSE, 3/16 DIA. HT, FUEL x 30 LG. TU28641 2.5 FT PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 55 (800) 526-8817 • www.vanair.com...

-

Page 64: A Decals (Location)

VIPER DIESEL 7.11A DECALS (LOCATION) 14 22 16 17 12 WARNING DO NOT REMOVE OR COVER ANY SAFETY DECAL. Replace any safety decal that becomes damaged or illegible. 6110029ID_r1 VANAIR MANUFACTURING, INC. PAGE - 56 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 65: B Decals (Identification)

MAXIMUM PRE SSURE COMPRE SSOR INPUT RPM 260940 19 & 20 WARNING DO NOT REMOVE OR COVER ANY SAFETY DECAL. Replace any safety 6110029ID_r1 decal that becomes damaged or illegible. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 57 (800) 526-8817 • www.vanair.com... -

Page 66: C Decals (Part Numbers)

DECAL, VIPER DIESEL LARGE 272850-001 DECAL, VIPER DIESEL SMALL 272850-002 DECAL, QUICK START GUIDE 273312 DECAL, MAINTENANCE VANAIR DIESEL VIPER 274130 PLEASE NOTE: WHEN ORDERING PARTS, INDICATE MACHINE SERIAL NUMBER. VANAIR MANUFACTURING, INC. PAGE - 58 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 67: Wiring Diagram

VIPER DIESEL SECTION 7: ILLUSTRATED PARTS LIST 7.12 WIRING DIAGRAM 272618_r8 VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 59 (800) 526-8817 • www.vanair.com... -

Page 68: Schematic Flow Diagram

SECTION 7: ILLUSTRATED PARTS LIST VIPER DIESEL 7.13 SCHEMATIC FLOW DIAGRAM 273387_r2 VANAIR MANUFACTURING, INC. PAGE - 60 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com... -

Page 69: Hose Installation Guide

6. When properly routing, use clamps to secure application, remember that metal hose fittings the hose in its proper position. are not part of the flexible portion. Allow ample free length for flexing. VANAIR MANUFACTURING, INC. 090058-OP_r0 (AUGUST-2014) PAGE - 61 (800) 526-8817 • www.vanair.com... - Page 70 SECTION 8: ILLUSTRATED PARTS LIST VIPER DIESEL BLANK PAGE VANAIR MANUFACTURING, INC. PAGE - 62 090058-OP_r0 (AUGUST-2014) (800) 526-8817 • www.vanair.com...

- Page 71 Vanair Manufacturing, Inc. 10896 West 300 North Michigan City, IN 46360 Phone: (219) 879-5100 (800) 526-8817 Service Fax: (219) 879-5335 Parts Fax: (219) 879-5340 Sales Fax: (219) 879-5800 www.vanair.com Printed in the U.S.A. Specifications Subject to Change Without Prior Notice...

Need help?

Do you have a question about the Viper Series and is the answer not in the manual?

Questions and answers