Table of Contents

Advertisement

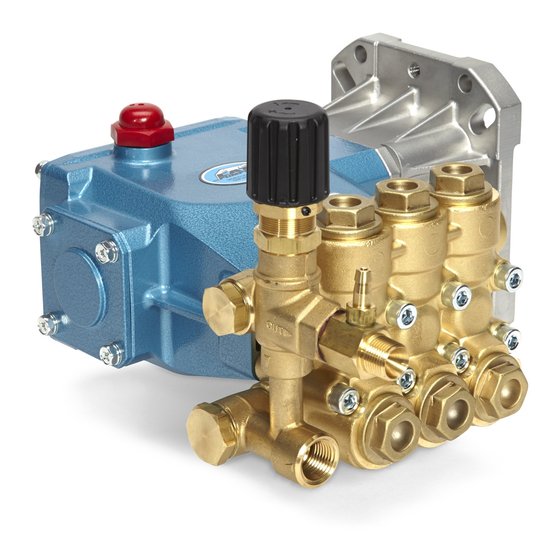

5DX, 6DX, 66DX PLUNGER PUMP SERVICE MANUAL

5DX MODELS:

6DX MODELS:

66DX MODELS:

Optimum performance of the pump is dependent upon the entire liquid system and will be obtained only

with the proper selection, installation of plumbing, and operation of the pump and accessories.

SPECIFICATIONS: Maximum specifications refer to individual attributes.

It is not implied that all maximums can be performed simultaneously.

If more than one maximum is considered, check with your CAT PUMPS

supplier to confirm the proper performance and pump selection. Refer

to individual Data Sheets for complete specifications, parts list and

exploded view.

LUBRICATION: Fill crankcase with special CAT PUMP Hydraulic oil per

pump specifications [5DX-22.65 oz., 6DX-18.6 oz., 66DX-18.0 oz.]. DO

NOT RUN PUMP WITHOUT OIL IN CRANKCASE. Change initial fill after

50 hours running period. Thereafter, change oil every 3 months or 500

hour intervals.

DRIVE SELECTION: The pump shaft size is a 1" gas shaft. The engine

driving the pump must be of adequate horsepower to maintain full

RPM when the pump is under load. Select the horsepower requirement

according to required pump discharge flow and maximum pressure at the

pump! Consult the manufacturer of gas or diesel engine for selection of

the proper engine.

MOUNTING: All DX models are direct-drive and come with a flange adapter

that mounts to a gas engine. Before mounting pump to gas engine, apply

PN 6106 antiseize lubricant to pump shaft. Refer to Technical Bulletin 055

for instructions on removing pump from gas engine. To minimize piping

stress, use appropriate flexible hose to inlet and discharge ports.

LOCATION: If the pump is used in extremely dirty or humid conditions, it is

recommended pump be enclosed. Do not store or operate in excessively

high temperature areas or without proper ventilation. Liquid temperatures

above 130°F are permissible. Add 1/2 PSI inlet pressure per each degree

F over 130°F. Elastomer or RPM changes may be required. See Tech

Bulletin 002 or call CAT PUMPS for recommendations.

INLET CONDITIONS: Refer to complete Inlet Condition Check-List in this

manual before starting system. DO NOT STARVE THE PUMP OR RUN DRY.

DISCHARGE CONDITIONS: OPEN ALL VALVES BEFORE STARTING

SYSTEM to avoid deadhead overpressure condition and severe damage

to the pump or system.

All systems require both a primary pressure regulating device (i.e., regulator, unloader) and a secondary pressure safety relief device (i.e., pop-off valve, safety valve).

Failure to install such relief devices could result in personal injury or damage to the pump or to system components. CAT PUMPS does not assume any liability or responsibility

for the operation of a customer's high pressure system.

Products described hereon are covered by one or more of the following U.S. patents 3558244, 3652188, 3809508, 3920356, 3930756 and 5035580

World Headquarters

CAT PUMPS

1681 - 94th Lane N.E. Minneapolis, MN 55449 - 4324

Phone (763) 780-5440 — FAX (763) 780-2958

e-mail: techsupport@catpumps.com

www.catpumps.com

International Inquiries

FAX (763) 785-4329

e-mail: intlsales@catpumps.com

®

5DX30G1, 5DX35G1, 5DX40G1, 5DX50G1

6DX35G1I, 6DX40G1I

66DX30G1I, 66DX35G1I, 66DX40G1I

INSTALLATION AND START-UP INFORMATION

®

The Pumps with Nine Lives

A reliable Pressure Gauge should be installed near the discharge outlet

of the high pressure manifold. This is extremely important for adjusting

pressure regulating devices and also for proper sizing of the nozzle or

restricting orifice. The pump is rated for a maximum pressure; this is the

pressure which would be read at the discharge manifold of the pump,

NOT AT THE GUN OR NOZZLE.

Use PTFE thread tape or pipe thread sealant (sparingly) to connect acces-

sories or plumbing. Exercise caution not to wrap tape beyond the last

thread to avoid tape from becoming lodged in the pump or accessories.

This condition will cause a malfunction of the pump or system.

PRESSURE REGULATION: All systems require both a primary pressure

regulating device (i.e., regulator, unloader) and a secondary pressure

safety relief device (i.e., pop-off valve, safety valve). The primary pressure

device must be installed on the discharge side of the pump. The function

of the primary pressure regulating device is to protect the pump from over

pressurization, which can be caused by a plugged or closed off discharge

line. Over pressurization can severely damage the pump, other system

components and can cause bodily harm. The secondary safety relief

device must be installed in-line between the primary device and pump or

on the opposite side of the manifold head. This will ensure pressure

relief of the system if the primary regulating device fails. Failure to install

such a safely device will void the warranty on the pump

NOZZLES: A worn nozzle will result in loss of pressure. Do not adjust

pressure regulating device to compensate. Replace nozzle and reset

regulating device to system pressure.

PUMPED LIQUIDS: Some liquids may require a flush between opera-

tions or before storing. For pumping liquids other than water, contact

your CAT PUMPS supplier.

STORING: For extended storing or between use in cold climates, drain

all pumped liquids from pump and flush with antifreeze solution to

prevent freezing and damage to the pump. DO NOT RUN PUMP WITH

FROZEN LIQUID (refer to Tech Bulletin 083).

WARNING

CAT PUMPS (U.K.) LTD.

1 Fleet Business Park, Sandy Lane, Church Crookham, Fleet

Hampshire GU52 8BF, England

Phone Fleet 44 1252-622031 — Fax 44 1252-626655

e-mail: sales@catpumps.co.uk

N.V. CAT PUMPS INTERNATIONAL S. A.

Heiveldekens 6A, 2550 Kontich, Belgium

Phone 32- 3- 450.71.50 — Fax 32-3- 450.71.51

e-mail: cpi@catpumps.be www.catpumps.be

CAT PUMPS DEUTSCHLAND GmbH

Buchwiese 2, D-65510 Idstein, Germany

Phone 49 6126-9303 0 — Fax 49 6126-9303 33

e-mail: catpumps@t-online.de www.catpumps.de

PN 30004 Rev E 5510

Advertisement

Table of Contents

Summary of Contents for CAT Pumps 66DX Series

- Page 1 All systems require both a primary pressure regulating device (i.e., regulator, unloader) and a secondary pressure safety relief device (i.e., pop-off valve, safety valve). Failure to install such relief devices could result in personal injury or damage to the pump or to system components. CAT PUMPS does not assume any liability or responsibility for the operation of a customer’s high pressure system.

- Page 2 Removal of Valve Assemblies Valve Assembly Components Separation of Manifold Head from Crankcase CAUTION: Before commencing with service, shut off drive (electric motor, gas or diesel engine) and turn off water supply to pump. Relieve all discharge line pressure by triggering gun or opening valve in discharge line.

- Page 3 Removal of Seal Case and Lo-Pressure Seal V-Packing and Lo-Pressure Seal Components Reassembly of V-Packings SERVICING THE SEALS Disassembly Reassembly 1. Using an M6 allen wrench, remove the eight Hex 1. Examine the manifold chamber walls for scale buildup Socket Head (HSH) screws from the face of the or damage.

- Page 4 NOTE: Refer to Tech Bulletin 071 (old 4HP Plunger 1. Visually inspect the Crankcase Oil Seals for deteriora- Rod Change) for additional information on Ceramic tion or leaks. Contact CAT PUMPS for assistance with Plungers. replacement. See SERVICING THE CRANKCASE SECTION.

- Page 5 Piston cracking or leaking. Stem and screw Valve/Ball Assembly onto Piston Stem. 6. Contact CAT PUMPS or your local distributor if 6. Lower complete Piston Stem and Valve Assembly into crankcase service is evidenced. unloader chamber with Valve/Ball Assembly facing downward.

- Page 6 Avoid closed loop systems especially with high temperature, ultra-high Accessories pressure or large volumes. Conditions vary with regulating/unloader * If other than CAT PUMPS special multi-viscosity ISO68 oil is used, valve. change cycle should be every 300 hours. Higher temperature liquids tend to vaporize and require positive heads.

- Page 7 Handy Formulas to Help You HOSE FRICTION LOSS PRESSURE DROP IN PSI PER 100 FT OF HOSE WITH TYPICAL WATER FLOW RATES Q. How can I find the RPM needed to get specific GPM Water* Hose Inside Diameters, Inches Flow (Gallons Per Minute) I want? 5/16 1"...

- Page 8 CAT PUMPS are very easy pumps to service and require far less frequent service than most pumps. Typically, only common tools are required, making in-field service convenient, however, there are a few custom tools, special to certain models, that do simplify the process. This service manual is designed to assist you with the disassembly and reassembly of your pump.

Need help?

Do you have a question about the 66DX Series and is the answer not in the manual?

Questions and answers