Advertisement

Quick Links

SERVICE MANUAL

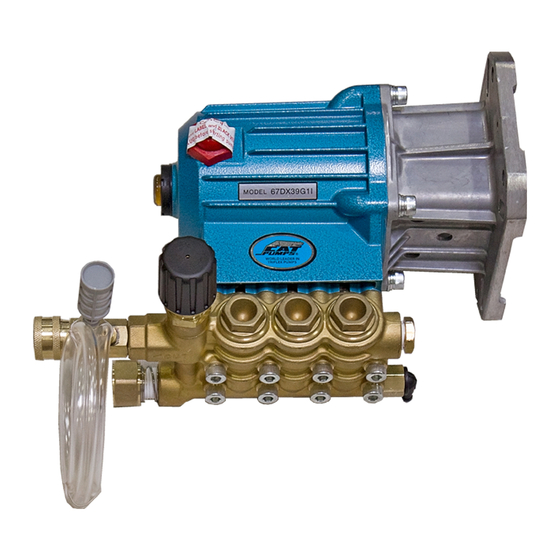

67DX PLUNGER PUMP SERIES

FLOW

PUMP MODEL

GPM (L/M)

67DX39G1I

3.9 (14.8)

IMPORTANT SAFETY INSTRUCTIONS

It is the responsibility of the user to read and understand all instructions, important safeguards, and safety precautions before

operating or servicing any pump. Failure to do so may result in property damage, personal injury or death.

General Safety Information and Symbols

Pay special attention to the following signal words, safety alert symbols and statements:

DANGER

indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

indicates a hazardous situation which, if not avoided, could result in minor or moderate injury or property damage.

NOTICE

indicates a hazardous situation which, if not avoided, could result in property damage.

Indicates a potential personal injury hazard. Obey all safety messages that follow this symbol to avoid possible injury or death.

SERVICING THE 67DX SERIES PLUNGER PUMP

WARNING

Do not service pump or electrical equipment while energized.

Electricity can cause personal injury, death or property damage.

1.

Adhere to "Lock Out" and "Tag Out" procedures for electrical equipment.

2.

Before commencing pump service, turn power supply off.

3.

Keep water away from electrical outlets and electrical devices.

4.

Electrical components must be installed by a qualified

electrician to avoid risk of electrocution.

SERVICING THE VALVES

Disassembly

NOTE:

Pump requires one (1) stacked valve kit to repair pump.

NOTE:

Discharge and inlet valve assemblies may stay together or separate during

removal. Spring retainer may also separate from the seat during removal.

1.

Use a M24 hex tool to remove three (3) valve plugs.

2.

Use reverse pliers to remove stacked valve assemblies from each valve chamber.

3.

If the discharge assembly separates from the inlet valve

assembly, use reverse pliers to remove the inlet valve seat.

Available from Allparts Equipment and Accessories - 1-877-475-5660 - www.allpartsinc.com

PRESSURE

PUMP

MOTOR

PSI (BAR)

RPM

RPM

4000 (275)

3450

TEMPERATURE

SHAFT DIA.

Far. (Cent)

INCH (MM)

—

140º (60º)

OIL CAP

Oz. (l)

1.00 (25.4)

13.5 (0.04)

Advertisement

Summary of Contents for CAT Pumps 67DX39G1I

- Page 1 TEMPERATURE SHAFT DIA. OIL CAP PUMP MODEL GPM (L/M) PSI (BAR) Far. (Cent) INCH (MM) Oz. (l) 67DX39G1I 3.9 (14.8) 4000 (275) 3450 — 140º (60º) 1.00 (25.4) 13.5 (0.04) IMPORTANT SAFETY INSTRUCTIONS It is the responsibility of the user to read and understand all instructions, important safeguards, and safety precautions before operating or servicing any pump.

- Page 2 NOTICE Exercise caution as the reverse pliers may damage the threads in valve chamber or spring retainer. Separate discharge valve assembly from inlet valve assembly. Remove o-ring and backup-ring from discharge seat. Using a small tipped screw driver, place end of screw driver through spring retainer and above the valve and pry upwards to separate spring retainer from valve seat.

- Page 3 NOTICE Exercise caution as the pick may score o-ring sealing surface. Remove V-Packing and male adapter from each seal chamber by using a screw driver. Reassembly Examine the manifold chamber walls for scale buildup or damage and replace as needed. Examine V-Packings for frayed edges or uneven wear and replace as needed.

- Page 4 Lubricate and install backup-ring and o-rings on valve retainer. Contact Cat Pumps or your local distributor if crankcase service is needed. Install washer and valve retainer onto piston stem. Apply Loctite®609 to threads of piston stem and screw SERVICING THE UNLOADER/CHEMICAL INJECTOR valve/ball assembly onto piston stem.

- Page 5 Seal Change Valve Change Accessories * If other than Cat Pumps special custom blend, ISO 68 hydraulic oil is used, change cycle should be every 300 hours. ** Each system’s maintenance cycle will be exclusive. If system performance decreases, check immediately. If no wear at 1000 hours, check again at 1500 hours and each 500 hours until wear is observed.

- Page 6 B. ROTATING PARTS HAZARD Do not service pump while energized. Moving, rotating or reciprocating parts can crush and cut, causing personal injury, death or property damage. 1. Adhere to “Lock Out” and “Tag Out” procedures for electrical equipment. 2. Before commencing pump service, turn power supply off, turn water supply off, squeeze trigger on gun to relieve system pressure. 3.

- Page 7 1. Cat Pumps custom-blend oil is available worldwide in 21 oz. bottles, cases, or 5-gallon twin packs. Use of other oils may void the warranty.

- Page 8 Cat Pumps are very easy pumps to service and require far less frequent service than most pumps. Typically, only common tools are required, making in-field service convenient, however, there are a few custom tools, special to certain models, that do simplify the process. This service manual is designed to assist you with the disassembly and reassembly of your pump.

Need help?

Do you have a question about the 67DX39G1I and is the answer not in the manual?

Questions and answers

How do you remove the crankshaft oil seal?