Summary of Contents for CAT Pumps 7CP6110CS

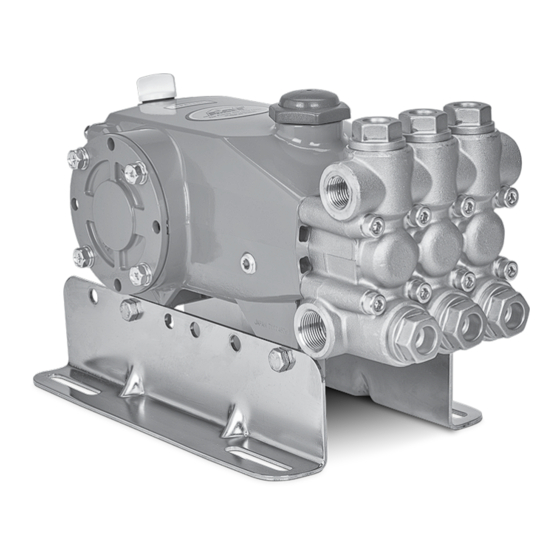

- Page 1 SERVICE MANUAL 7CP BRASS PLUNGER PUMPS PUMP MODELS INCLUDED 7CP6110CS 7CP6110CSG1 7CP6160CS 7CP6160CSG1 7CP6170 7CP6170G1 Product Quality, Reliability and Support You Expect www.catpumps.com...

-

Page 2: Table Of Contents

Table of Contents Safety Symbols IMPORTANT SAFETY INSTRUCTIONS Safety Symbols It is the responsibility of the user to read and understand all General Safety Information instructions, important safeguards and safety precautions before Seal & Valve Kits operating or servicing any pump. Failure to do so may result in Service Intervals property damage, personal injury or death. -

Page 3: General Safety Information

General Safety Information A. FLAMMABLE OR EXPLOSIVE LIQUID HAZARD Do not operate pump with flammable or explosive liquids unless extraordinary safety precautions are observed. Leaks of flammable or explosive liquids, if exposed to elevated temperatures, static electricity, sparks or other hazards, will result in flame or possible explosion, causing serious personal injury, death or property damage. - Page 4 General Safety Information and Symbols F. OVER PRESSURIZATION HAZARD CONTINUED Do not operate high-pressure pumping system unless extraordinary safety precautions are observed. A high-pressure pumping system can deadhead or over pressurize causing serious personal injury and property damage. 1. All high-pressure systems require a primary pressure regulating device (e.g., regulator or unloader) and a secondary pressure safety relief device (e.g., pop-off valve, safety valve, rupture disc) to assure proper pressure setting and overpressure protection.

- Page 5 1. Fill pump crankcase to specific capacity indicated on data sheet or service manual prior to startup. 2. Cat Pumps premium custom-blend oil is available worldwide in 21-ounce bottles, (single and 12-pack cases), 2.5 gallon jugs (single and 2-pack) or 30 gallon drums. Use of other oils may void the warranty.

-

Page 6: Seal & Valve Kits

The seals on our pumps, operating under normal conditions, will perform for a minimum of 1500 hours, with most lasting much longer. The valves typically perform for 3000 hours, with many lasting much longer. Cat Pumps always recommends replacing these items as a kit since components usually wear at about the same rate. -

Page 7: Seal & Valve Kit Pump Diagram

Seal & Valve Kit Pump Diagram SEAL KIT COMPONENTS 7CP6110CS, 7CP6170 : PN 76933 | Qty 1 7CP6160CS : PN 77052 | Qty 1 VALVE KIT COMPONENTS 7CP6110CS, 7CP6170 : PN 34920 | Qty 2 7CP6160CS : PN 77053 | Qty 2... -

Page 8: Servicing The Seals

Servicing the Seals MANIFOLD AND SEAL REMOVAL NOTE: One (1) seal kit is required to repair the pump. 1.01 Use a 6 mm hex wrench to remove the 1.02 Rotate the crankshaft with an 1.03 Insert two (2) large flat tip screwdrivers eight (8) hex socket head (HSH) screws adjustable wrench to create separation on opposite sides to pry the manifold... - Page 9 Servicing the Seals MANIFOLD AND SEAL REMOVAL 1.10 Inspect the seal case O-ring for cuts, 1.11 Inspect the grooved V-packing surface 1.09 Using a pick, remove the seal case nicks or damage. of the seal case for scoring or damage. O-ring.

-

Page 10: Plunger Removal

Servicing the Seals PLUNGER REMOVAL FOR MODELS 7CP6110CS/7CP6170 1.16 Remove seal retainer from crankcase 1.17 Using an 11 mm combination wrench, 1.18 Before completely removing the housing. loosen the plunger retainer. plunger retainer, stop and push the plunger towards the drive end to break loose from the retainer. -

Page 11: Plunger Reassembly

Inspect for damage. PLUNGER REASSEMBLY FOR MODELS 7CP6110CS/7CP6170 1.27 Install barrier slinger with dish side 1.28 Install new plunger retainer O-ring 1.29 Apply a lubricant to outside surface of facing away from crankcase. - Page 12 Servicing the Seals PLUNGER REASSEMBLY FOR MODEL 7CP6160CS 1.35 Look for stepped side of plunger. This 1.33 Replace seal washer with new one 1.34 Apply a lubricant to outside surface of side goes towards the pump crankcase. from seal kit. the seal washer.

-

Page 13: Seal Installation

Servicing the Seals SEAL INSTALLATION NOTICE: Examine manifold for grooves, pitting or wear and replace as needed. 1.42 Install the second V-packing with the 1.41 One side of the V-packing has a groove. 1.40 Install the male adapter with the flat groove side also facing down. -

Page 14: Manifold Installation

Servicing the Seals MANIFOLD INSTALLATION 1.47 Install manifold by hand, ensuring even 1.48 Use a rubber mallet to tap manifold on 1.46 Rotate crankshaft so outside two alignment. the rest of the way. plungers are even at furthest distance from crankcase. 1.49 Install eight (8) HSH screws by hand. -

Page 15: Servicing The Valves

Servicing the Valves VALVE REMOVAL NOTES: Two (2) valve kits are required to repair the pump. Discharge and inlet valve assemblies are identical (use procedure below for disassembly and reassembly of discharge and inlet valves). 2.02 Using a pick, remove O-ring from valve 2.03 Inspect valve plug O-ring for cuts, nicks 2.01 Use a 27 mm socket with ratchet to plug. -

Page 16: Valve Reassembly

Servicing the Valves VALVE DISASSEMBLY 2.08 Inspect spring for proper tension or any 2.09 Inspect tapered surface of the valve for 2.10 Inspect tapered surface of valve seat for damage. wear, pitting or damage. wear, pitting or damage. NOTICE: Pitting on the valve seat or valve is an indication of cavitation. -

Page 17: Valve Installation

Servicing the Valves VALVE REASSEMBLY 2.16 Place spring retainer onto valve seat. 2.17 Using a rubber mallet, lightly tap spring 2.18 Replace valve seat O-ring into the top retainer into place. of the groove, then backup ring at the bottom. 2.19 Apply a lubricant to outside surface of the valve seat O-ring. - Page 18 Servicing the Valves VALVE INSTALLATION 2.24 Using a 27 mm hex socket with ratchet, 2.23 Install valve plug into manifold and tighten valve plugs. Torque to 870 in- thread by hand. lbs, 72.5 ft-lbs, or 98 Nm. SERVICE MANUAL | 7CP Brass Series Plunger Pumps (763) 780-5440 | techsupport@catpumps.com | www.catpumps.com...

-

Page 19: Reference Information

If contamination is suspected, inspect and replace the seals in the pump manifold, then clean out the inside of the crankcase and change the oil. Spot-check the following areas for signs of leaks and contact Cat Pumps or a local distributor for servicing crankcase if needed. Drain Plug... -

Page 20: Preventive Maintenance Schedule

Cat Pumps recommends using our custom-blend premium grade hydraulic oil formulated to meet Cat Pumps specifications. For best results, perform an initial oil change after the first 50 hours of operation and every 500 hours thereafter. -

Page 21: Torque Chart

THREAD TOOL SIZE TOOL PART NUMBER TORQUE IN-LBS FT-LBS Plunger Retainers 11 mm Combination Wrench — 7CP6110CS, 7CP6170 Plunger Retainers 7CP6160CS 10 mm Combination Wrench — Manifold Screws 6 mm Hex Wrench — 9.58 Valve Plugs 27 mm Hex Socket with Ratchet —... -

Page 22: Diagnosis And Maintenance

For International Inquiries go to www.catpumps.com and navigate to the “Contact” link. ©2022 Cat Pumps. All written and visual data contained in this document reflects the latest product information available at the time of publication. Cat Pumps reserves the right to make changes at any time without notice.

Need help?

Do you have a question about the 7CP6110CS and is the answer not in the manual?

Questions and answers